One-step fermentation preparation method of passion fruit vinegar

A technology of passion fruit and passion fruit juice, which is applied in the food field, can solve the problems of passion fruit vinegar, which is astringent but not alcoholic, lack of whole fruit fermentation production, and lack of deep-processing products, etc., to achieve unique fragrance, rich nutrition and flavor substances, and sour taste soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

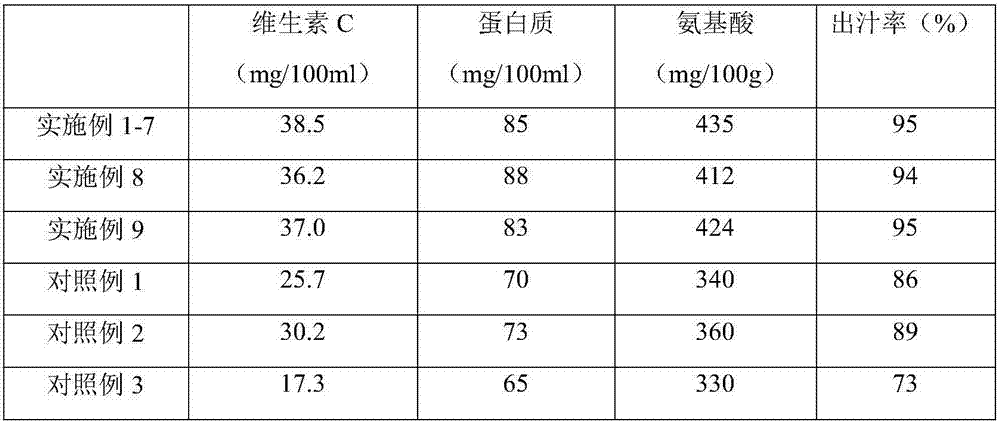

Examples

Embodiment 1

[0034] Proceed as follows:

[0035] (1) Preparation of passion fruit juice:

[0036] (a) Wash the whole passion fruit, the ratio of fruit to water is 1:3, beat and crush,

[0037] (b) Enzymolysis: adjust the pH value to 5.0, add cellulase, pectinase, amylase, glucoamylase, protease, and the amount of cellulase is 30000U / kg (relative to the passion fruit raw material, the same below) , the amount of pectinase added is 30000U / kg, the amount of amylase added is 5000U / kg, the amount of protease added is 15000U / kg, the enzymolysis temperature is 45°C, and the enzymolysis time is 2h; the total juice yield of passion fruit is 95% (juice Rate=gross weight of extracted juice / processed weight of obtained juice*100%);

[0038] (c) After enzymolysis, boil to kill the enzyme, cool to obtain turbid juice, or add an adsorbent with an enzymolysis solution weight percentage of 0.5%-1.5% for adsorption, filter to make clear juice.

[0039] (2) Production of passion fruit vinegar by one-step ...

Embodiment 2

[0047] Proceed as follows:

[0048] (1) prepare passion fruit juice: step is with embodiment 1;

[0049] (2) Production of passion fruit vinegar by one-step fermentation

[0050] Passion fruit juice obtained after enzymatic hydrolysis was used as raw material, and kombucha fungus was added to carry out alcoholic acetic fermentation, wherein the inoculum size was 10% (v / v), the initial sugar content was 20%, the initial pH was 4.0, the fermentation temperature was 25°C, and the fermentation time was 10 One day, passion fruit vinegar was obtained, and the fermented acid value of passion fruit vinegar was 6.8g / 100ml.

[0051] (3) Filter:

[0052] After the passion fruit vinegar liquid after step (3) fermentation finishes is filtered, obtain the passion fruit vinegar solution of clarification;

[0053] (4) Deployment, sterilization, filling:

[0054] Add water, sucrose, and salt to the passion fruit vinegar solution to prepare raw vinegar, and then sterilize at 115°C for 5 sec...

Embodiment 3

[0056] Proceed as follows:

[0057] (1) prepare passion fruit juice: step is with embodiment 1;

[0058] (2) Production of passion fruit vinegar by one-step fermentation

[0059] Passion fruit juice obtained after enzymatic hydrolysis was used as raw material, and kombucha fungus was added to carry out alcoholic acetic acid fermentation, wherein the inoculum size was 20% (v / v), the initial sugar content was 20%, the initial pH was 4.0, the fermentation temperature was 25°C, and the fermentation time was 10 One day, passion fruit vinegar was obtained, and the fermented acid value of passion fruit vinegar was 7.2g / 100ml.

[0060] (3) Filter:

[0061] After the passion fruit vinegar liquid after step (3) fermentation finishes is filtered, obtain the passion fruit vinegar solution of clarification;

[0062] (4) Deployment, sterilization, filling:

[0063] Add water, sucrose, and salt to the passion fruit vinegar solution to prepare raw vinegar, and then sterilize at 115°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com