Patents

Literature

59 results about "Slow freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slow freezing. “Slow freezing”, probably the most commonly used freezing process worldwide, involves the addition of a cryoprotective agent to prevent the formation of ice crystals in the cells, after which the cells are cooled in steps under computer control to -196 degrees Celsius.

Cryopreservation tools and methods

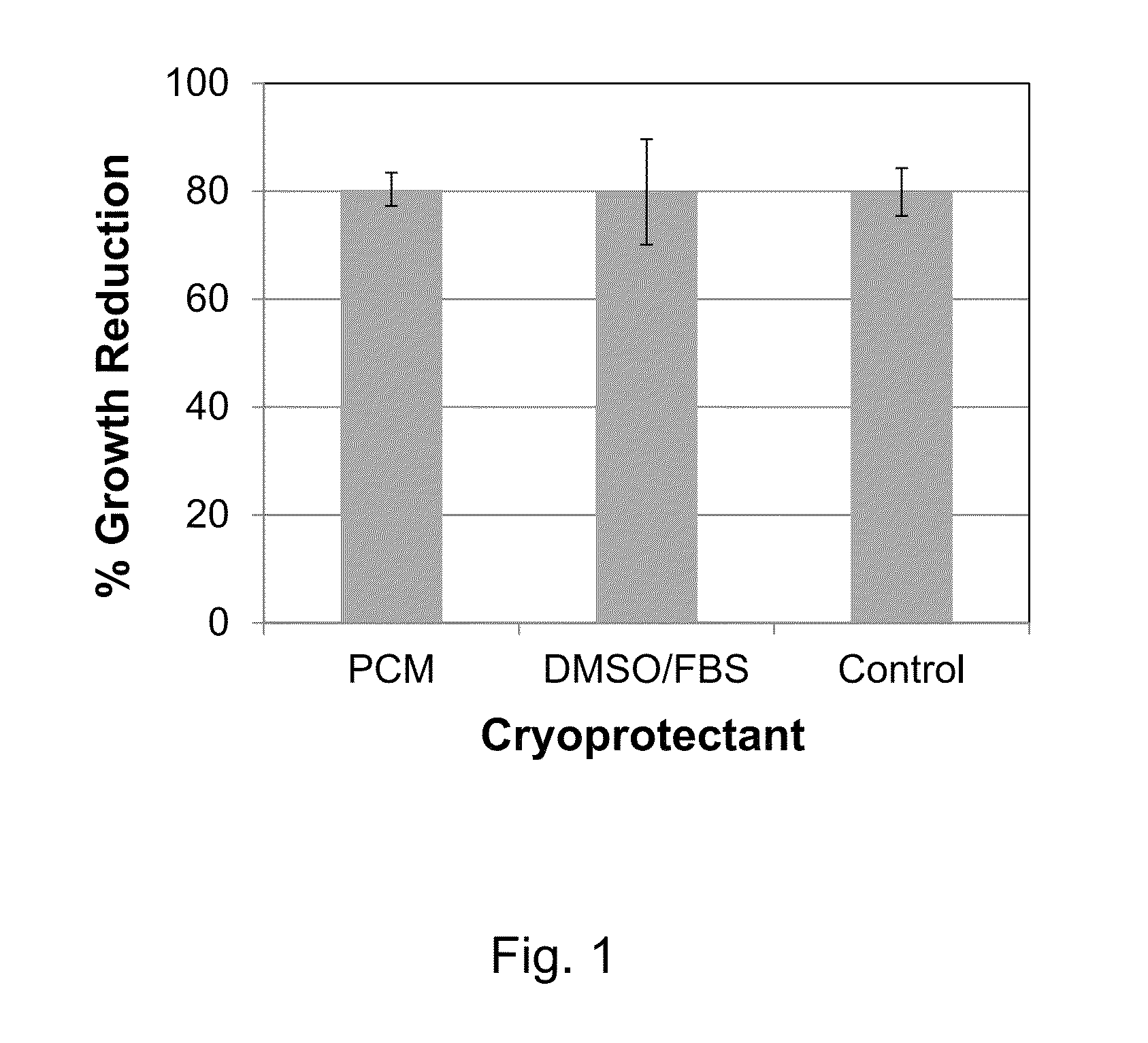

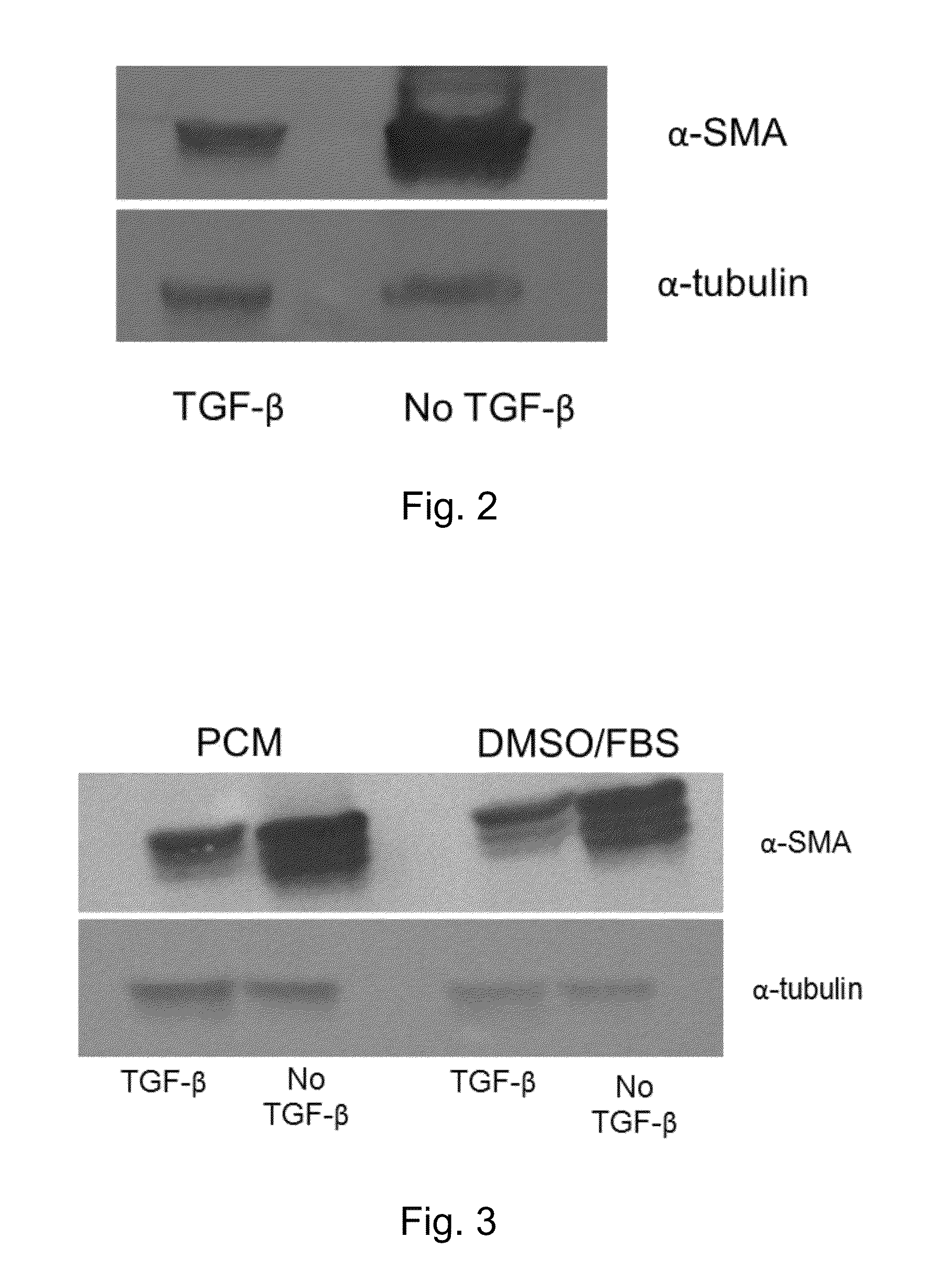

ActiveUS20150175955A1Low toxicityImprove survivabilityCulture processCell culture mediaProgenitorSlow freezing

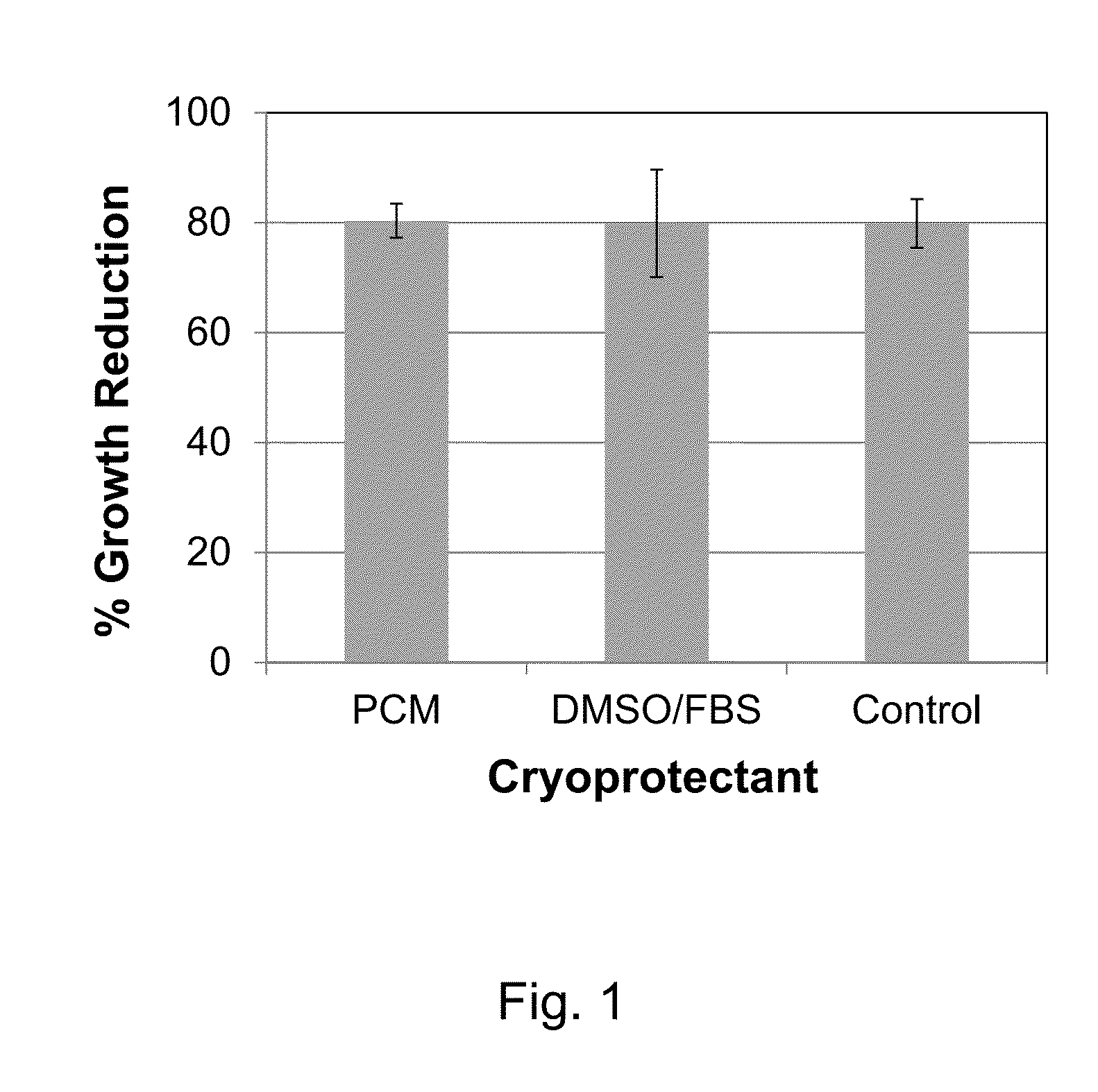

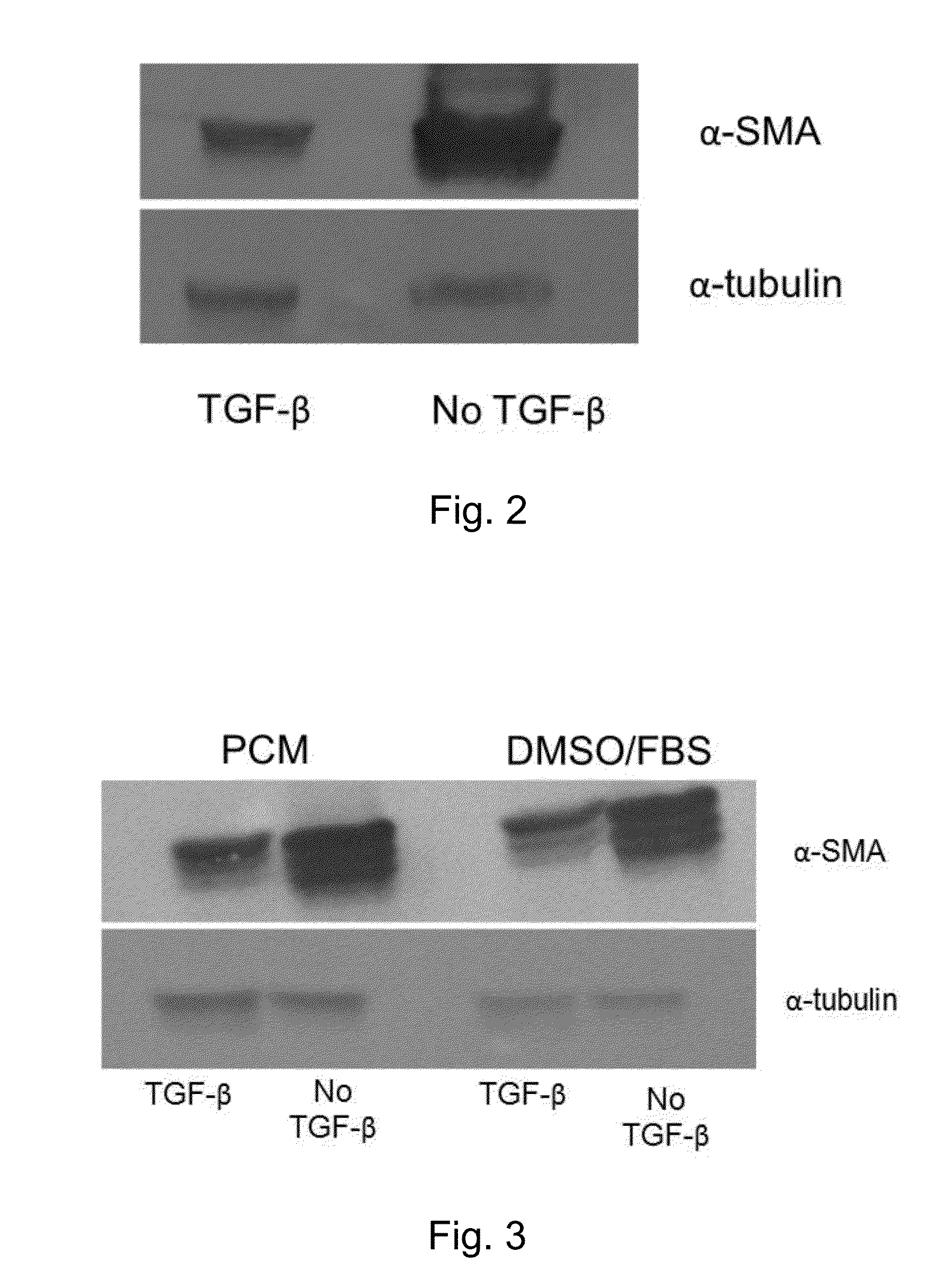

Provided herein are methods for the cryopreservation of stem cells and / or progenitor cells, comprising the steps of (a) contacting stem cells and / or progenitor cells with a cryopreservation medium, said cryopreservation medium comprising between 4 v / v % and 25 v / v % of propylene glycol and between 1.0 w % and 10 w % of a sugar; and (b) slow-freezing said cells, thereby obtaining a frozen composition comprising said cells and said cryopreservation medium.

Owner:FERTIPRO

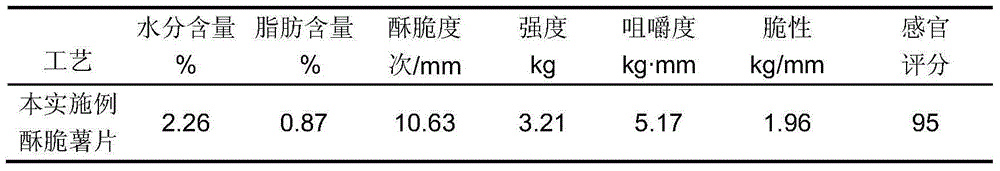

Preparation method of seasoning burdock crisp chips through microwave-assisted efficient vacuum frying

The invention discloses a preparation method of seasoning burdock crisp chips through microwave-assisted efficient vacuum frying, belonging to the technical field of fruit and vegetable crisp chip processing. The preparation method comprises the steps of: by taking fresh burdock as a raw material, cleaning the burdock, peeling and slicing the burdock in water, soaking the burdock in a color-protecting solution, blanching, dipping, slowly freezing, carrying out microwave-assisted vacuum frying, carrying out vacuum deoiling, seasoning, baking, cooling, packaging, sterilizing a finished product and preserving. The color-protecting agent is used for treating to keep the color and luster of the product; the efficient heating is carried out by using microwave and the puffing under the condition of low temperature is realized; and the brittleness of the product is improved by slow freezing, and a low-temperature vacuum frying technology has the characteristics that the color and luster, unique flavor substances and nutritional ingredients of burdock crisp chips can be maintained, oil content is low, fried grease can not be oxidized easily, the shelf life of the product is long, and the like. The seasoning burdock crisp chips are high in cellulose content, crisp and delicious, not greasy, convenient and hygienic, thus being a leisure food appropriate for both the old and the young. The preparation method adopts the combination of vacuum frying and microwave for dehydration, so that the vacuum frying efficiency is improved by 20%-30%, the types of the burdock processing products are enriched, and great economic benefits are expected to be produced.

Owner:宁波素子园八味食品有限公司 +1

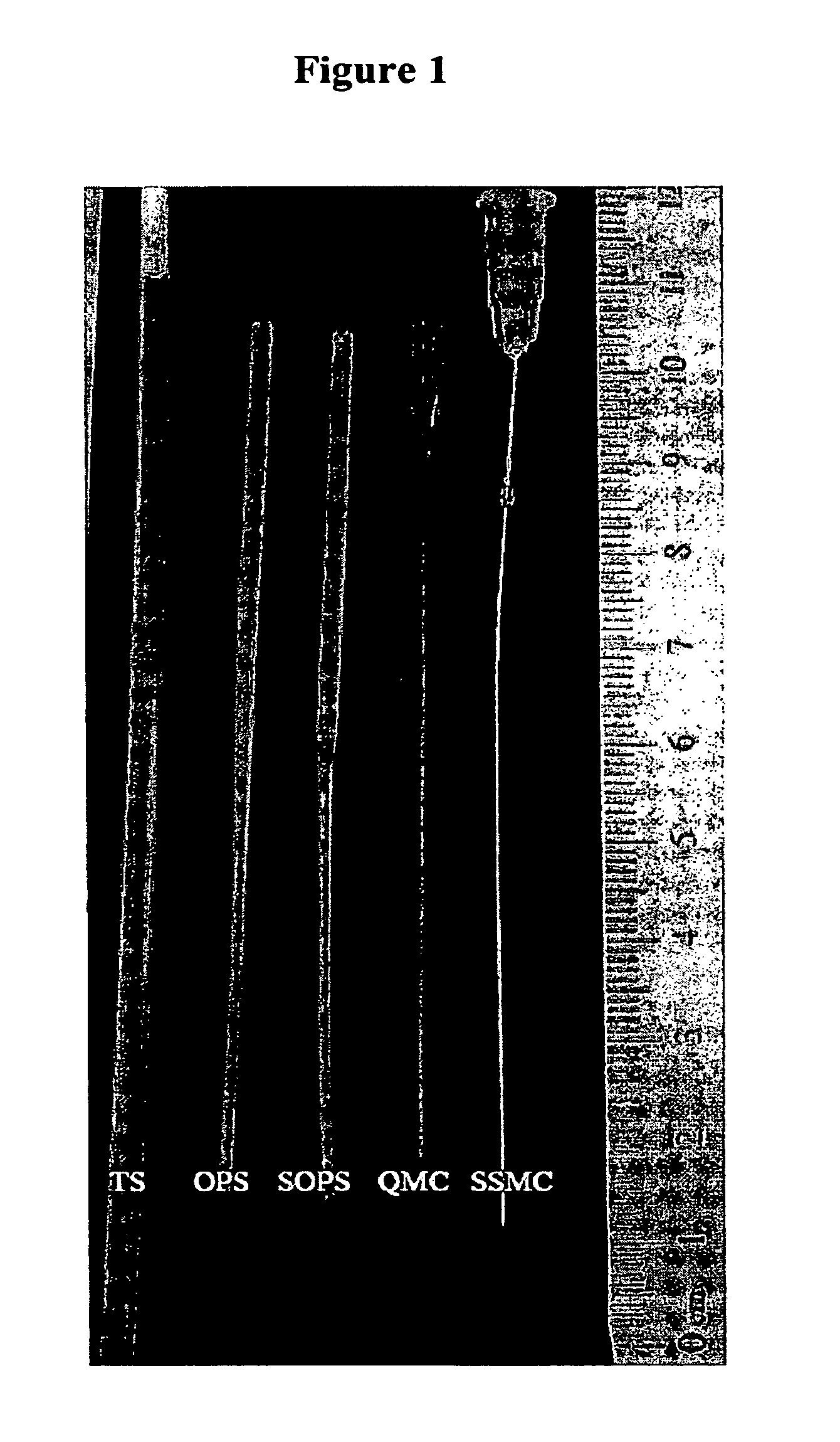

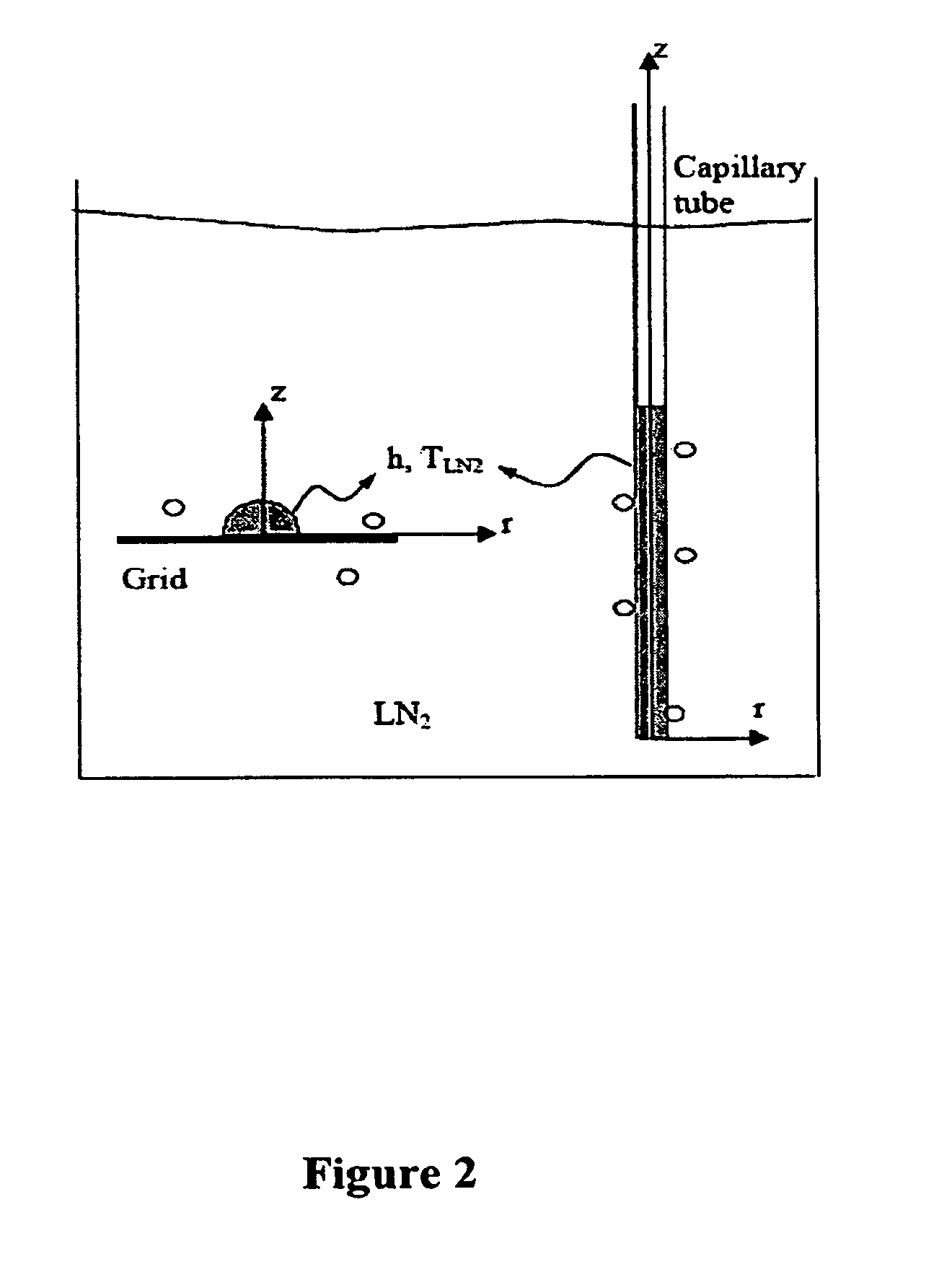

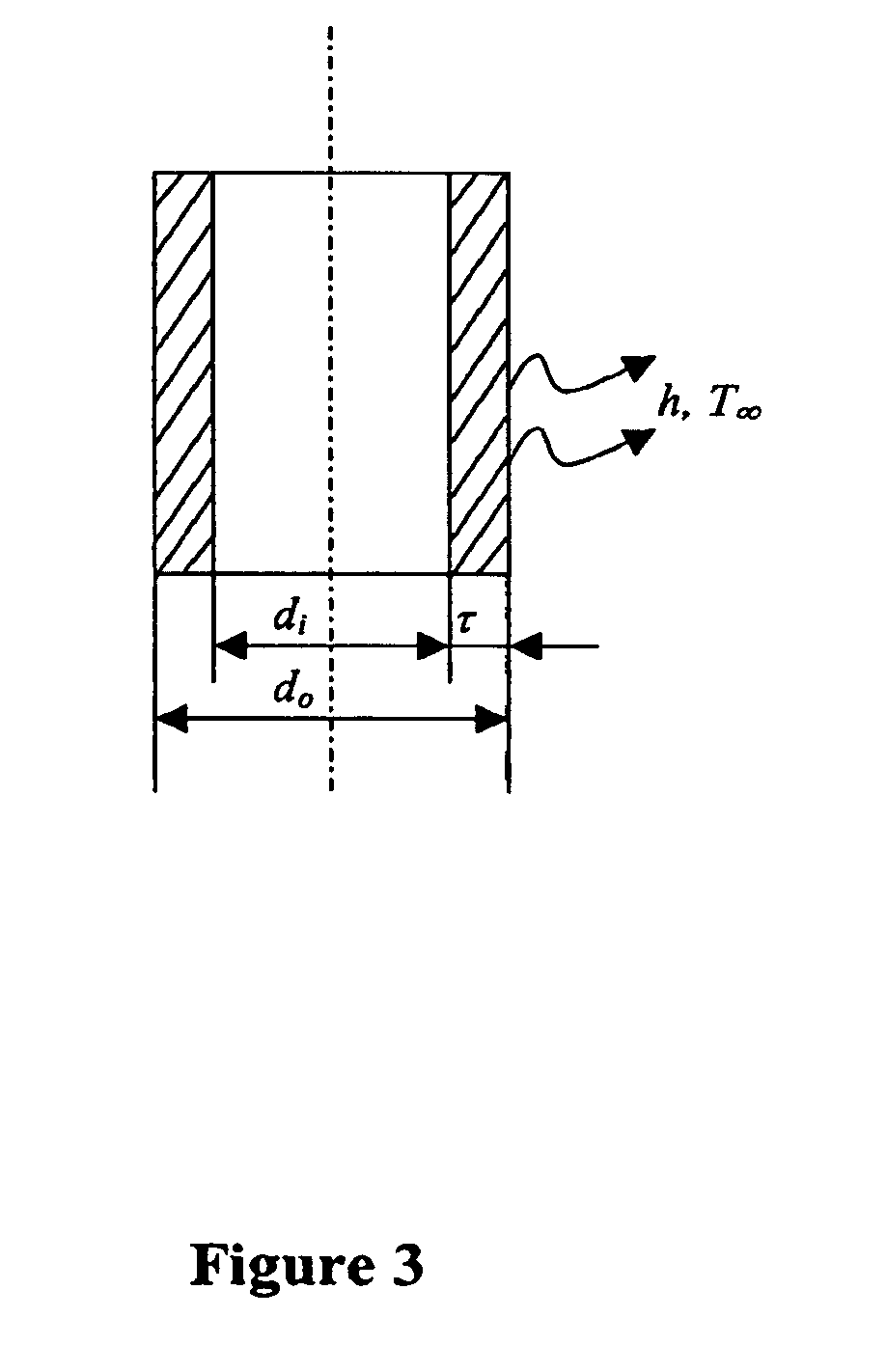

Methods for the Cryopreservation of Mammalian Cells

ActiveUS20090305224A1Lower Level RequirementsImprove survivabilityDead animal preservationTissue cultureMammalSlow freezing

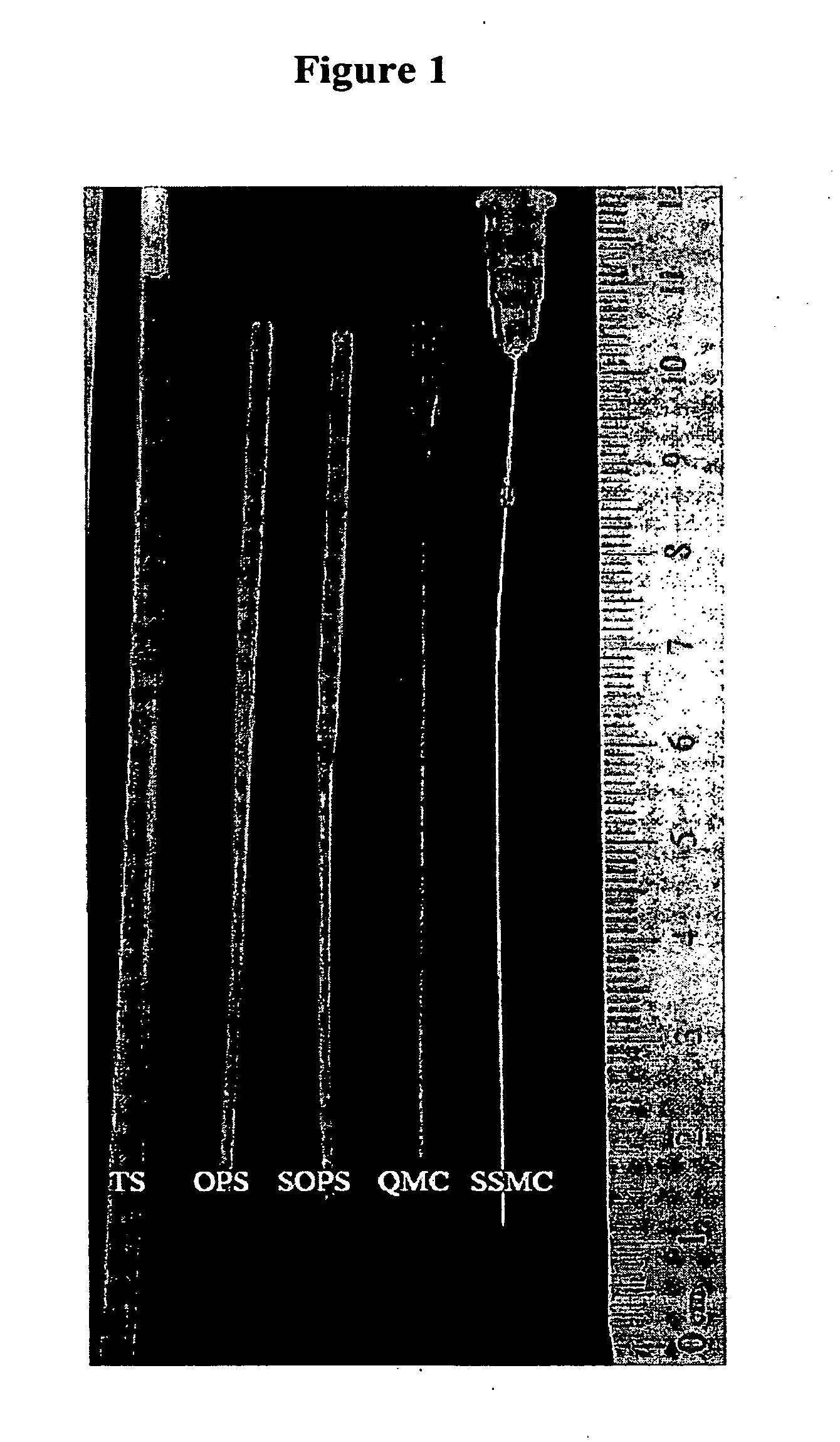

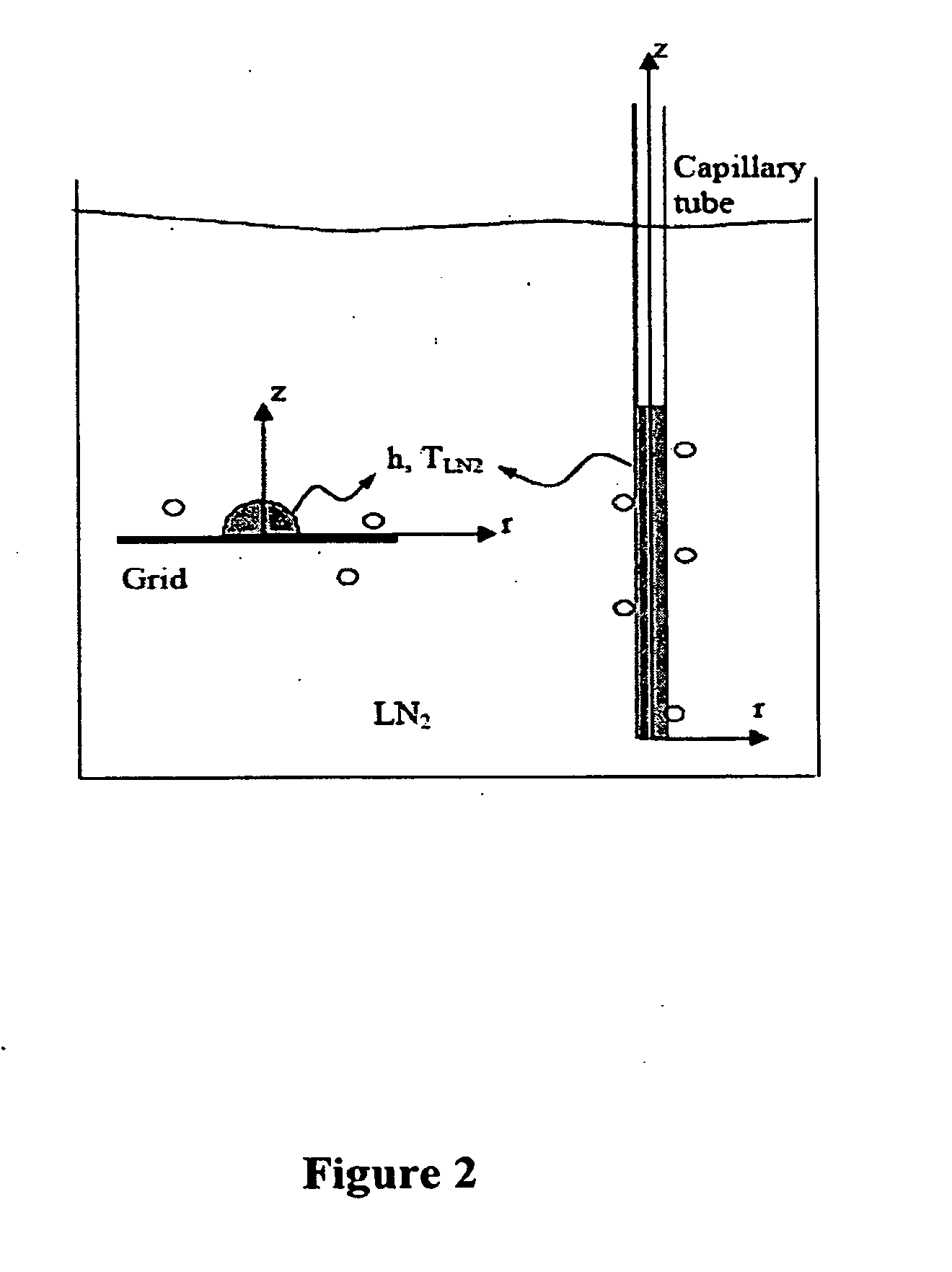

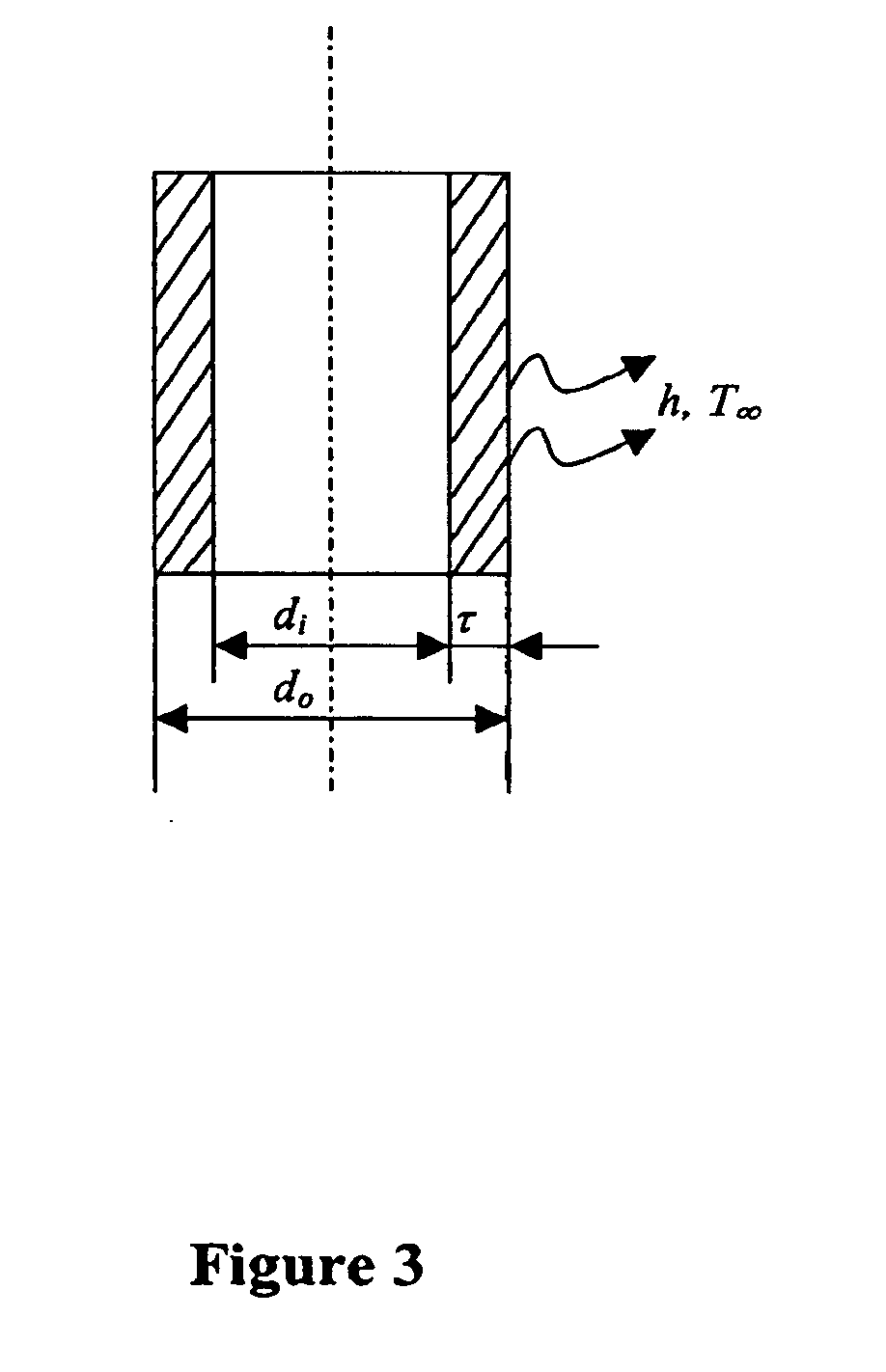

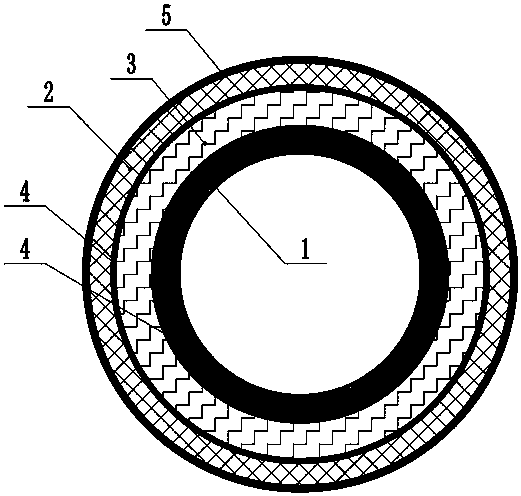

The present invention features novel methods for the cryopreservation of mammalian cell that combine the advantages of the slow-freezing and vitrification approaches while avoiding their shortcomings. Generally, the methods include the use of a capillary tube made of a thermally conductive wall material and a thin wall such that the ratio of the thermal conductivity of the wall material to the wall thickness is at least 1,000-500,000. The solution is then exposed to temperatures equal to or less than −80° C. and the vitrification solution containing the mammalian cells is cooled at a rate equal to or greater than 30,000-100,000,000° C. / minute. The exposure of the capillary tube with a thermally conductive and thin wall allows for vitrification of the solution in the absence of ice formation. Cryoprotectants can also be added to the vitrification solution to further prevent ice formation.

Owner:THE GENERAL HOSPITAL CORP

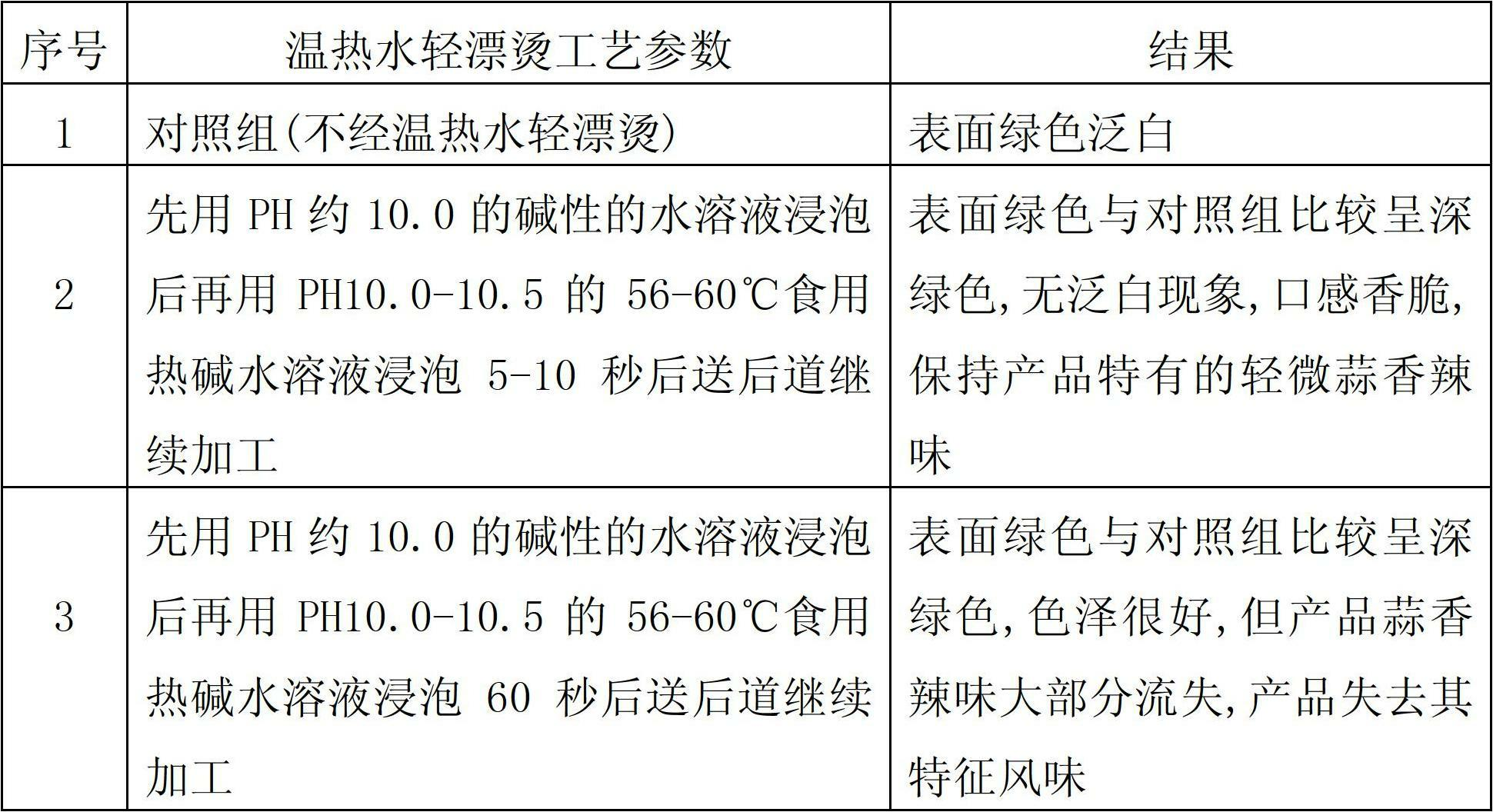

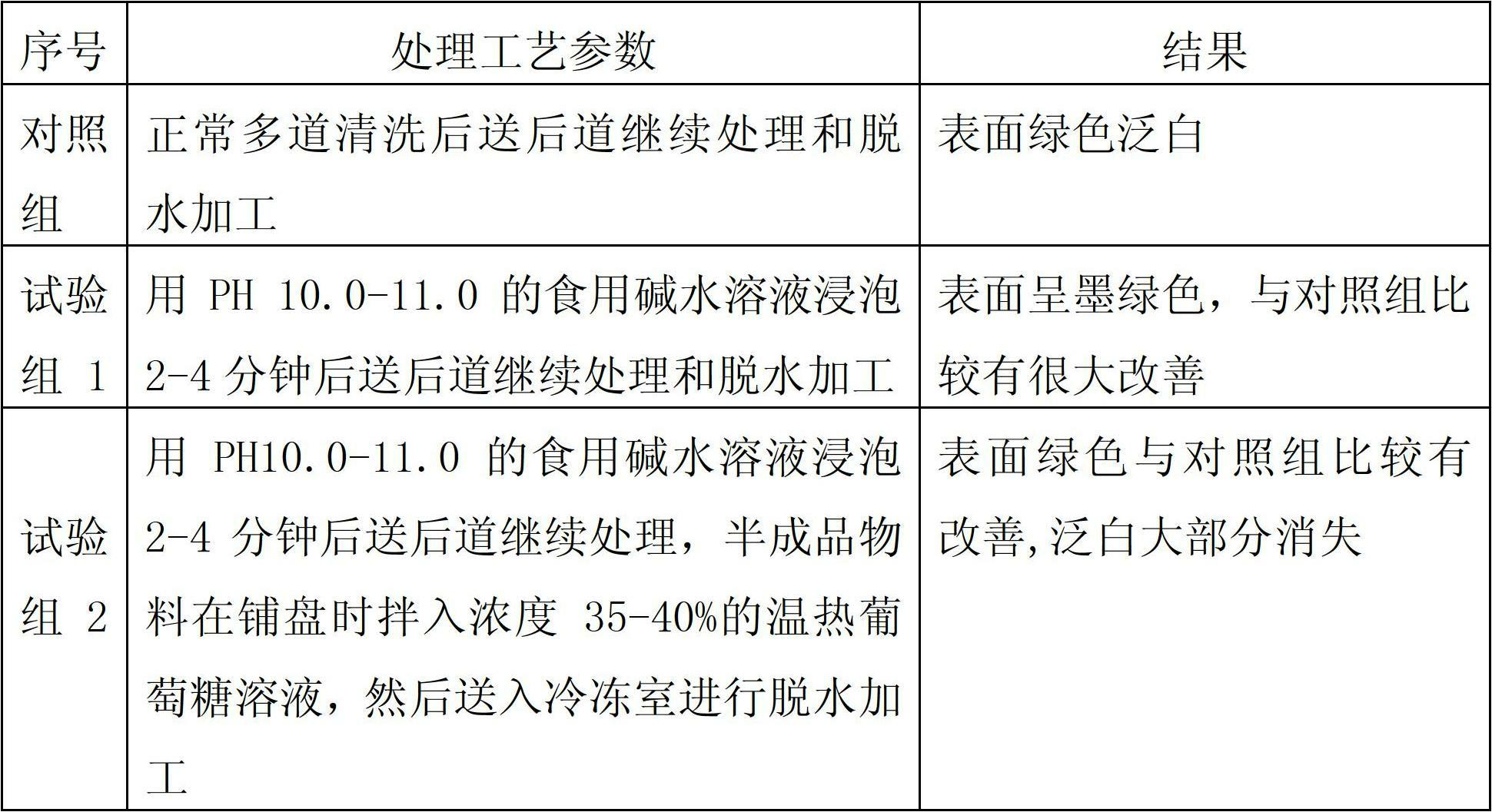

Color-protecting processing method of freeze drying onion

ActiveCN102640916AGreen stableDefects against green fadingFood preparationResidual volAlkaline water

The invention discloses a color-protecting processing method of freeze drying onion, wherein the method comprises the following steps of: immersing onion materials in an alkaline water solution firstly; then bleaching slightly in an alkaline warm water, cleaning, soaking by using a natural reducing sugar solution and draining; then freezing the onion materials by adopting a slow freezing mode; finally, freezing, drying, dehydrating and processing the frozen onion materials, wherein the slow freezing mode is that the total freezing time is not less than 5 hours, and the central temperature of the onion materials after freezing is less than and equal to minus 22 DEG C. After the scheme is adopted, according to the invention, the acid degree is regulated through the alkaline water solution firstly, and chlorophyll is prevented from being subjected to de-magging to lead to the defect of green fading of the materials, thus the green of the onion materials is kept to be stable, and the problem that the metal content of the materials in the prior art exceeds the standard is overcome. Moreover, according to the invention, a non-toxic natural reducing sugar solution is utilized as a processing auxiliary material for protecting the color, the problem that the sulfite residual quantity of the product after color-protection of the freeze drying onion exceeds the standard is overcome, and the product safety is ensured.

Owner:福建省新闽商业运营管理有限公司

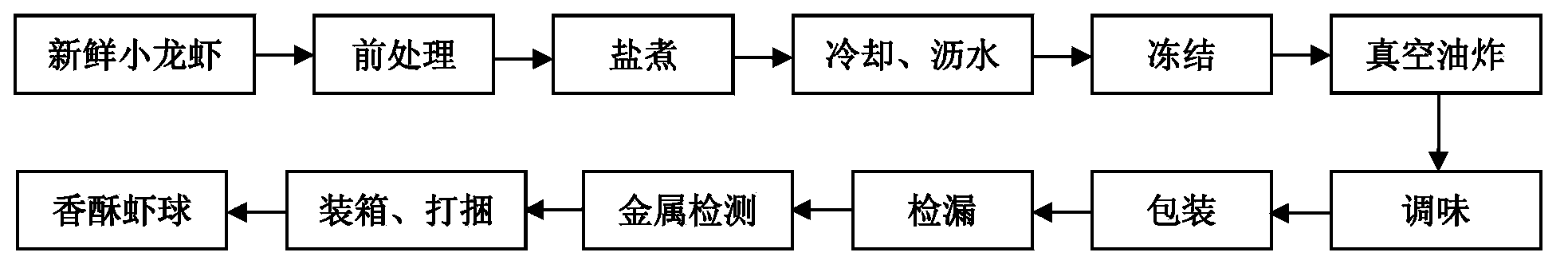

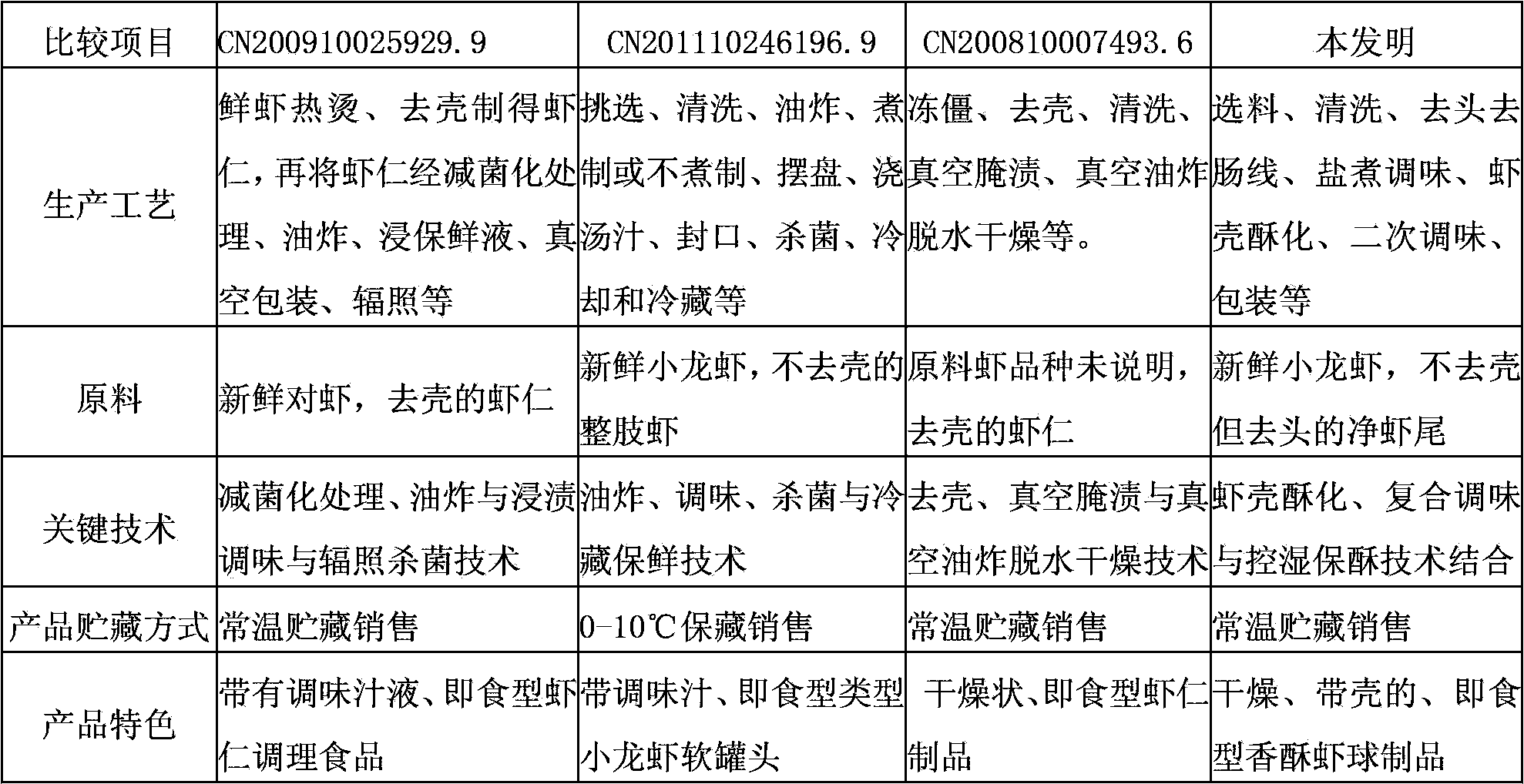

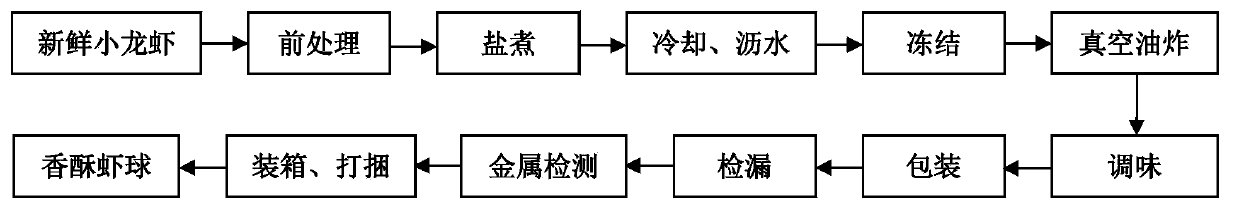

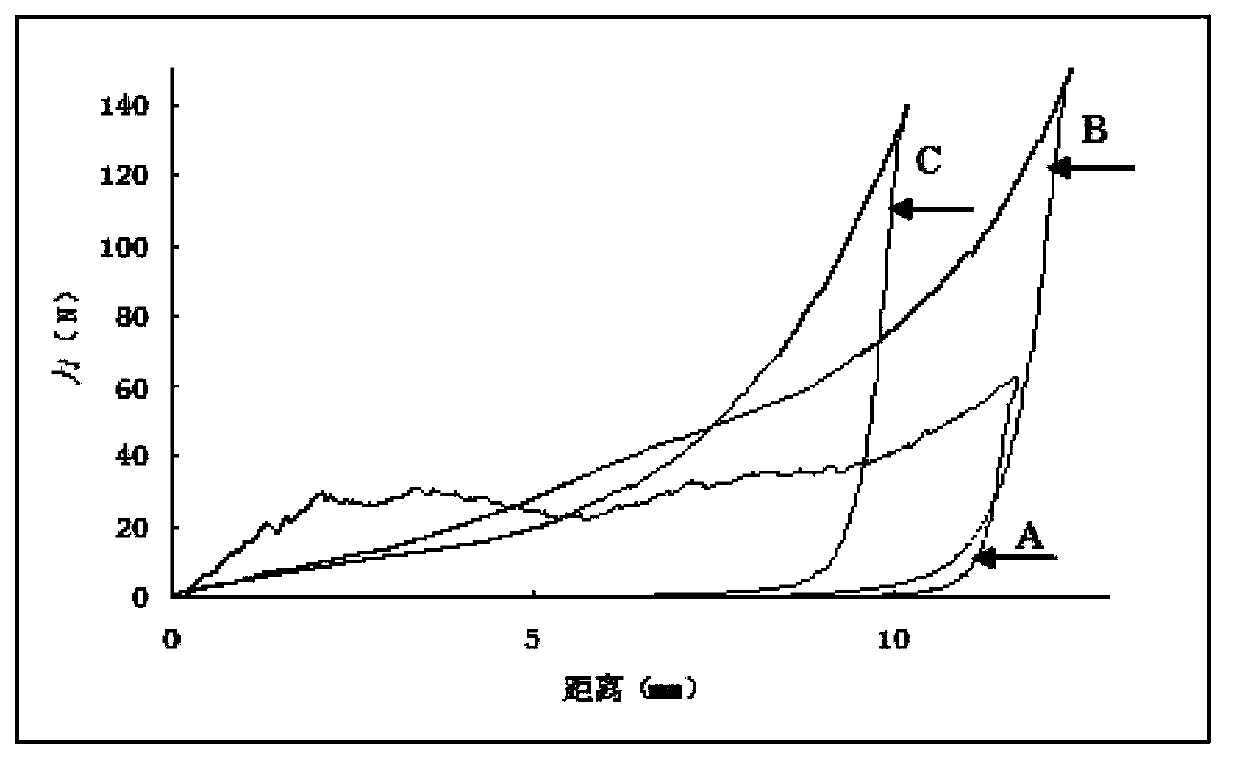

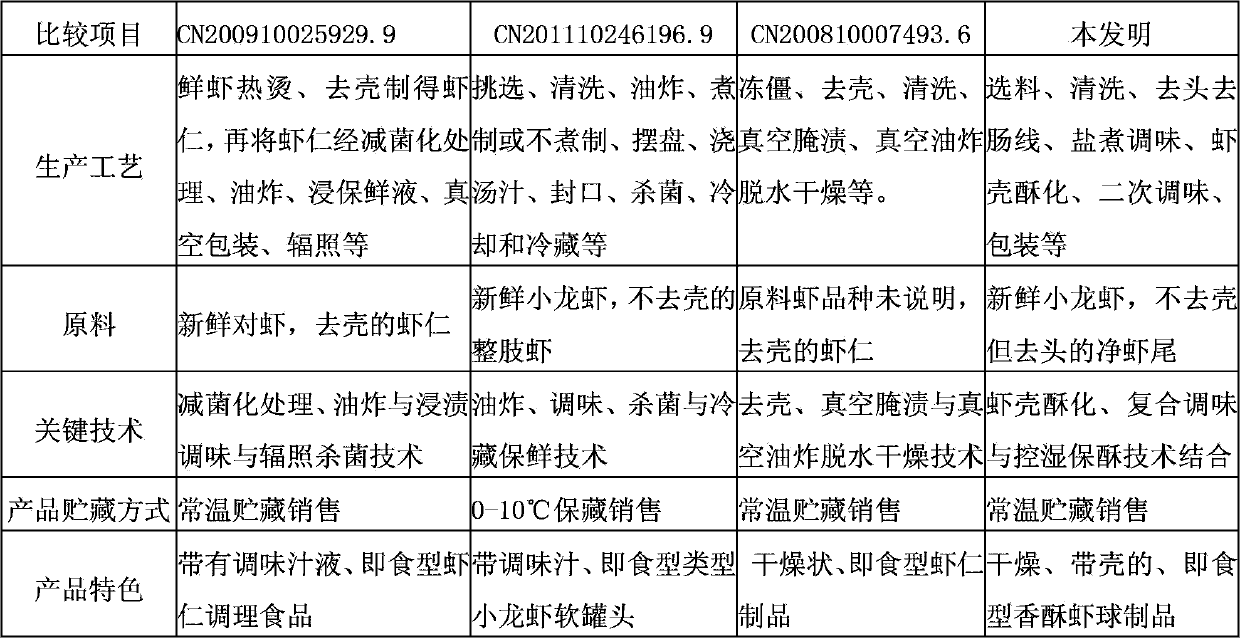

Crawfish crispy crawfish ball product and manufacturing technology thereof

ActiveCN103416788ALow costImprove product added valueFood preparationManufacturing technologySlow freezing

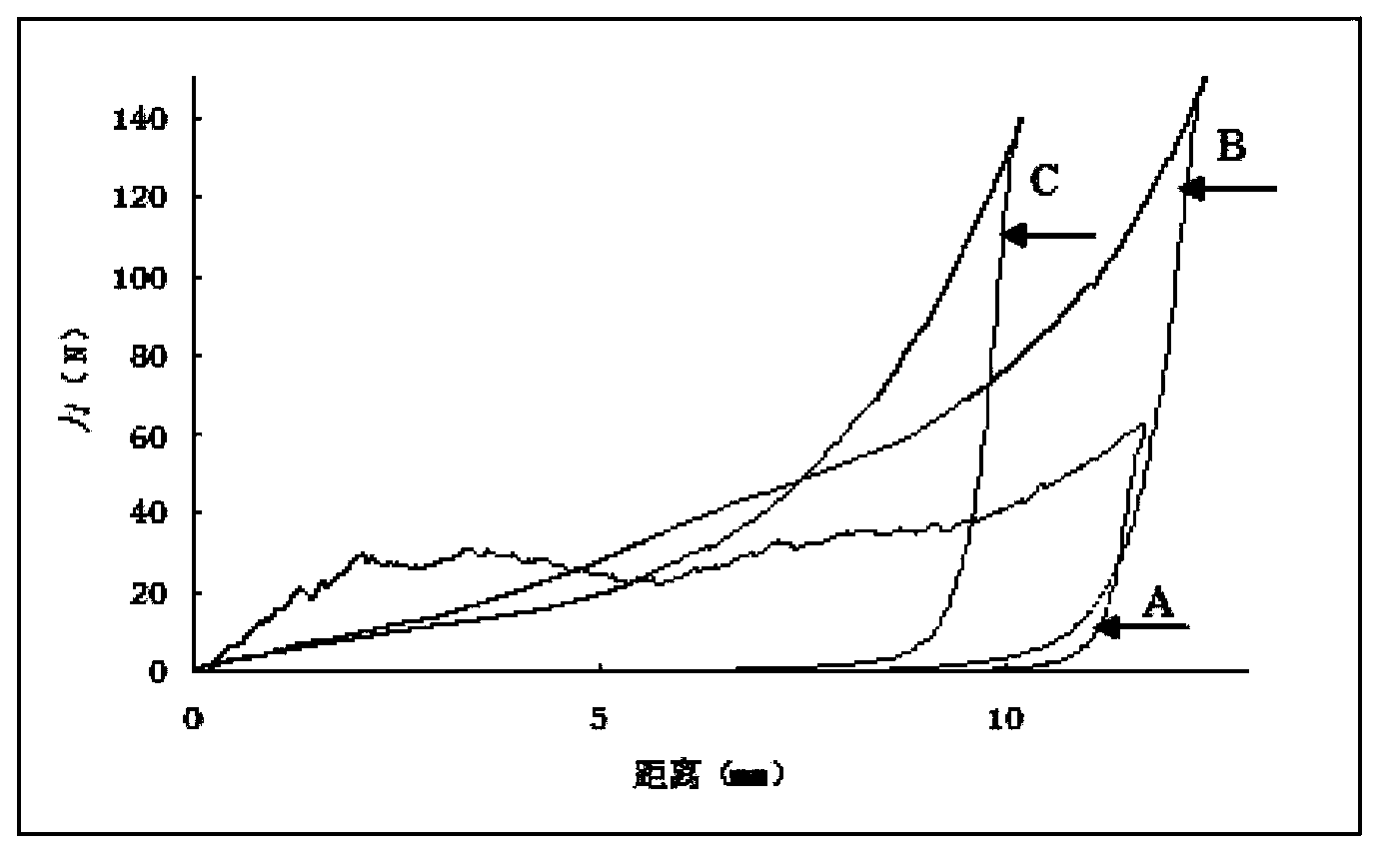

The invention belongs to the field of aquatic product processing, particularly relates to a crawfish crispy crawfish ball product and a manufacturing technology thereof, and belongs to an instant food. The manufacturing technology comprises the step of using an entire crawfish, a shrimp with the body length of 5-10 cm and the body weight less than 25 g obtained by the grading of crawfish meat, or an imperfect crawfish as a raw material to obtain a net crawfish shell being subjected to processes of sorting, cleaning, head and intestine removing, boiling with salts for flavoring, crisping of the crawfish shell, secondary flavoring, packaging, and the like to manufacture the crispy crawfish ball product. The crispy crawfish ball product has the characteristics of crispness and tasty, primary color and taste, low fat content, low water activity, long shelf life, and the like. Compared with the prior art, the crispy crawfish ball product adopts the technologies of the crisping of crawfish shell with the combination of slow freezing and vacuum frying, and compound flavoring and humidity control crisp protection with the combination of pre-cook and secondary flavoring, so that not only is the color of the crispy crawfish ball obviously improved, are the fat content and the water activity of the product lowered, is the crisp of the crawfish shell promoted, and is the crisp maintained, but also the oxidation rate of frying oil is obviously slowed down, the usage count of the oil is increased, the manufacturing cost is lowered, and the shelf life of the product is prolonged.

Owner:HUAZHONG AGRI UNIV

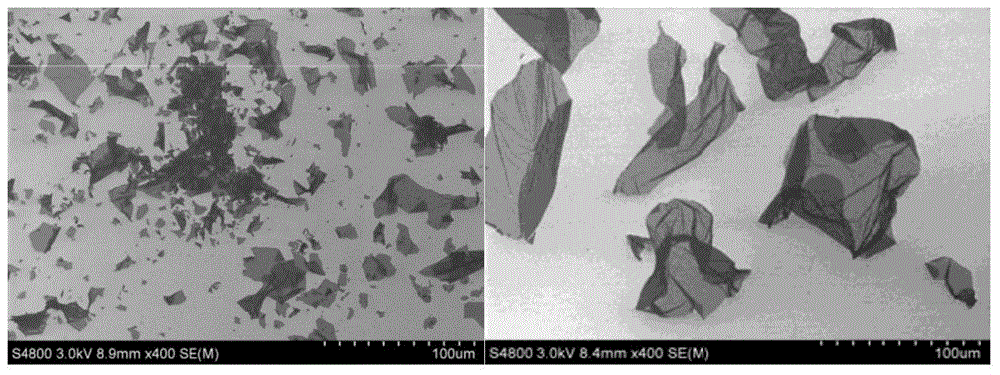

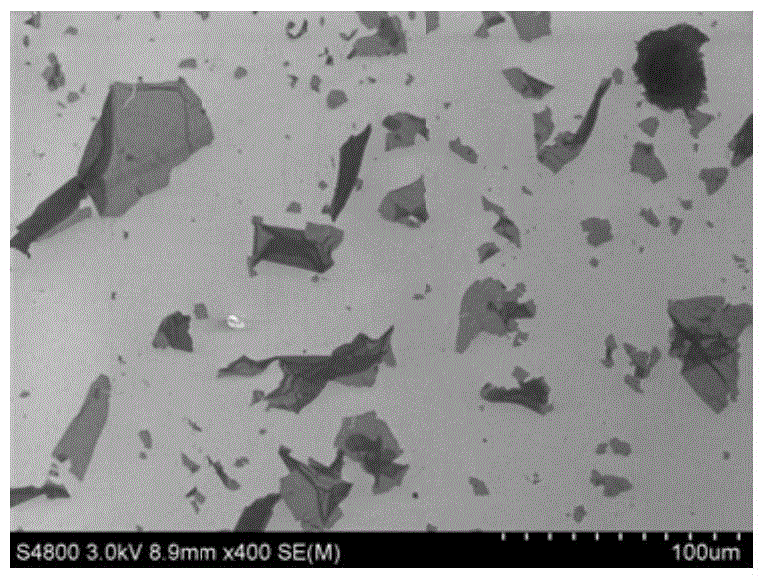

Continuous super-light regularly-oriented pure graphene aerogel film and preparation method thereof

ActiveCN105731436AReduce edge defectsEnhanced thermoelectricityGrapheneSupercritical dryingFreeze-drying

The invention relates to a continuous super-light regularly-oriented pure grapheme aerogel film and a preparation method thereof. The preparation method comprises: after oversized fragment-free graphene oxide with a certain concentration is extruded out by virtue of a linear die orifice, solidifying the graphene oxide into a graphene oxide gel film, and putting the graphene oxide gel film into a refrigerator for slow freezing or into liquid nitrogen for quick freezing; and performing freeze-drying or supercritical drying to obtain a graphene oxide aerogel film, and performing high-temperature heat treatment on the graphene oxide aerogel film in a high-temperature furnace to obtain a high-thermal-conductivity and high-electric-conductivity super-light oriented graphene aerogel film. The electric conductivity of the graphene aerogel film is 100-10000S / m, the thermal conductivity of the graphene aerogel film is 50-800W / mK, and the shielding effectiveness of the graphene aerogel film at 500MHz-40GHz reaches 100-150dB. The preparation method provided by the invention is simple in process, low in energy consumption, green and environment-friendly, capable of realizing continuous operation, capable of being applied to efficient electromagnetic shielding, flexible thermal conduction and electric conductive materials and the like.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

Method for jointly producing low-oil-content chips by microwave vacuum pre-frying and then subsequent negative microwave spouting drying

InactiveCN104489566ARetain flavor substancesMaintain nutrientsFood preparationAdditive ingredientSlow freezing

The invention discloses a method for jointly producing low-oil-content chips by microwave vacuum pre-frying and then subsequent negative microwave spouting drying, belonging to the field of fruit and vegetable food processing. The method comprises the following steps: with fresh potatoes as a raw material, alternative freezing by adopting ultralow temperature and slow freezing, microwave vacuum frying, vacuum deoiling, negative pressure microwave spouting drying, seasoning, packaging and preserving of a finished product. Enzymatic browning is prevented by using high-temperature short-time blanching to keep color of the product, alterative freezing is performed by using slow freezing and ultralow temperature to keep the product shape and control the oil content. The 2450MHz high-frequency microwave is utilized while 95-DEG C vacuum pre-frying is performed, wherein the high-frequency microwave is used for improving the frying efficiency, the microwave vacuum frying can be used for keeping the color and special flavor substances and nutritional ingredients of the chips, so that the low-oil-content chips are low in oil content; meanwhile, the frying oil is not easily oxidized; remained water of the pre-fried chips and partial surface fat are removed by adopting the negative pressure 915MHz low-frequency microwave spouting drying, the crispness of the chips is kept, and the non-uniformity of microwave heating is improved. According to the method, the oil content of the chips is reduced to 23-25 percent from 41 percent.

Owner:JIANGNAN UNIV +1

Preparation method of vacuum freeze-dried instant tomato-egg soup

The invention discloses a preparation method of vacuum freeze-dried instant tomato-egg soup. The vacuum freeze-dried instant tomato-egg soup comprises tomatoes, eggs and other auxiliary soap materials. The preparation method comprises the following steps of blending tomatoes, eggs and other auxiliary soap materials according to a certain ratio, pouring the mixed materials into a tray with square grooves, and carrying out vacuum freeze-drying dehydration to obtain cooked square solids. The preparation method has the advantages that raw materials are pre-frozen by a slow-freezing technology for a long time (great than or equal to 12-14 hours) and are subjected to sublimation drying under low working pressure (less than or equal to 30Pa) at a low sublimation temperature (less than or equal to 40 DEG C) and because the raw materials are dried under freezing conditions, ice crystals sublimate fast so that sublimation drying time is shortened; and a high desorption temperature (great than or equal to 70 DEG C) is adopted so that desorption drying time and water content are reduced and product rehydration is improved and nutrients of tomato-egg soup are furthest retained. Therefore, the preparation method is suitable for large-scale application.

Owner:福建立兴食品股份有限公司

Prepn process of instant green tea powder

The present invention discloses preparation process of instant green tea powder. Through low temperature slow freezing to form largest ice crystal destroying the cell tissue of fresh tea leaf, the present invention reaches the aim of raising leaching efficiency; and through enriching process, the present invention extracts the chlorophyll and effective components from fresh tea leaf. The present invention has simple operation and low cost, and the prepared instant green tea powder is emerald green, scent and high in tea polyphenol content.

Owner:ZHEJIANG FORESTRY UNIVERSITY

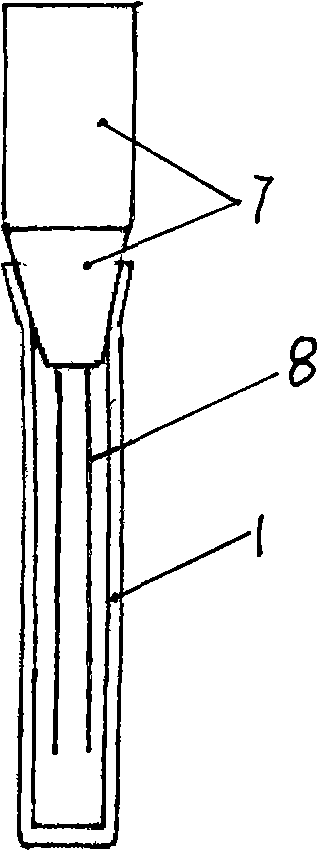

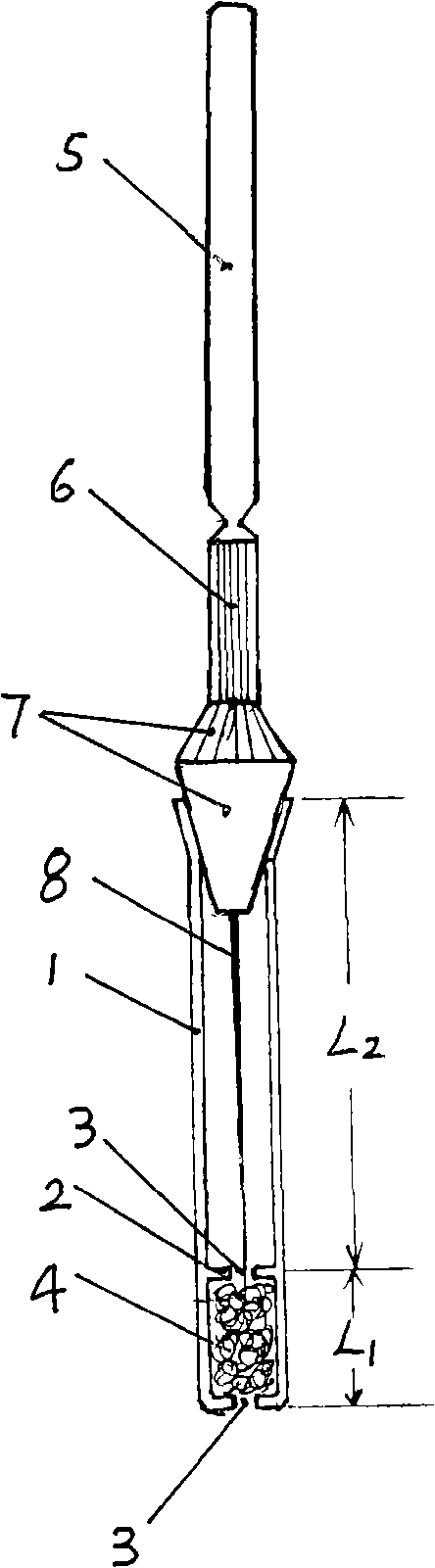

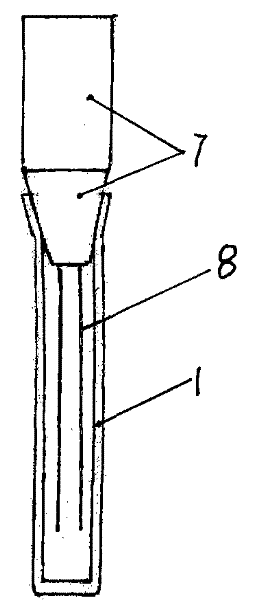

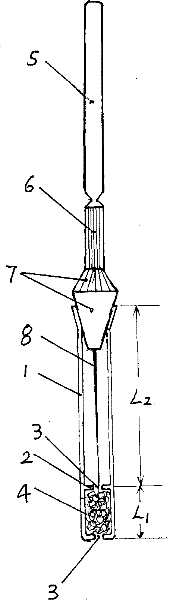

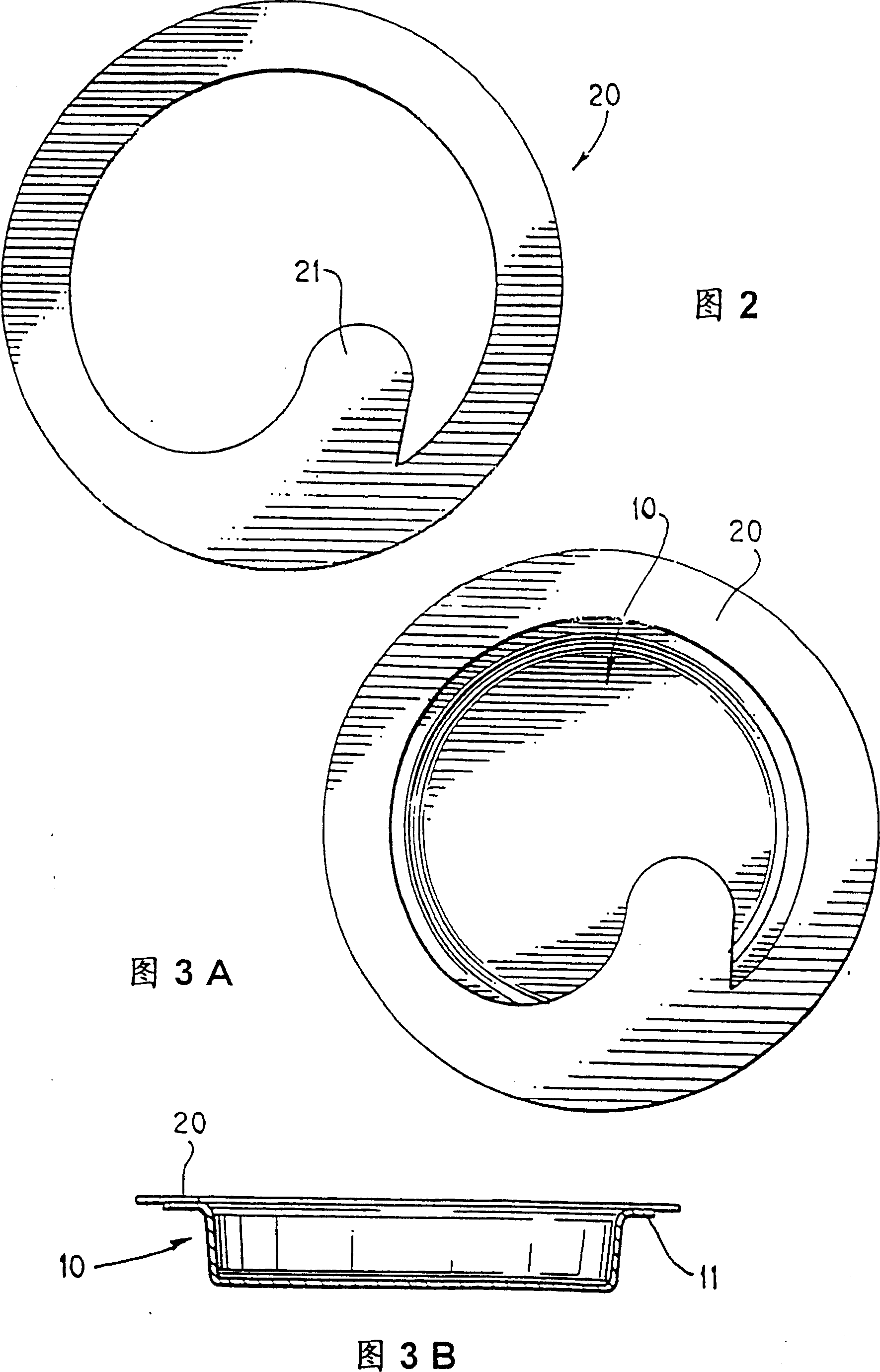

Aculeus type tissue slice glassivation refrigeration carrier and refrigeration method for ovary tissue

ActiveCN101314757AEasy to operatePrevent unstable freezing effectBioreactor/fermenter combinationsBiological substance pretreatmentsNeedle penetrationCell-Extracellular Matrix

An acupuncture-type tissue slice vitrification freezing carrier is composed of a freezing tube with one end being closed and the other end being open, and an acupuncture device. The acupuncture device comprises a needle head and a needle disposed on the needle head and used for threading tissue slices. A section matching with the internal shape and size of the open end of the freezing tube is disposed on the needle head. After the acupuncture device and the freezing tube are combined, the needle is positioned in the freezing tube, and the needle head is adopted as a tube plug of the freezing tube to seal the open end of the freezing tube. A plurality of tissue slices (such as ovary tissue slices and liver tissue slices) can be threaded in a row on the needle at intervals by the carrier so as to be subjected to each operation of the vitrification freezing and storage, and a plurality of sample tissues can be subjected to the vitrification freezing and storage simultaneously, with simple operation and high efficiency, so that the sample tissues can be dehydrated and refrigerated under the same conditions. The storage of the ovary multicellular ingredients (such as the storage of interstitial cells and extracellular matrix ingredients) is superior to the programmed slow freezing and the carrier-free vitrification freezing method.

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

Crisp potato chips and production method thereof

ActiveCN105166783AIncrease crispinessPlay a seasoning roleFood freezingFood dryingChipped potatoesSlow freezing

The present invention provides crisp potato chips which have characteristics of low fat content and crisp mouth feel. In addition, the present invention also discloses a production method of the crisp potato chips. According to the production method, clean potato chips are subjected to high-pressure processing and low-pressure impregnation, so that the solutes of the impregnation solution rapidly permeate into the materials, uniformly distribute, and the product has delicate and uniform mouth feel. Added salt, lemon acid and other substances not only serve as flavorings, but also can induce much more ice crystals as crystal nucleus so as to promote the formation of crisp mouth feel of the product. After the initial cooling refrigeration, slow-freezing is used to facilitate the growth of ice crystals, ice crystals with increased sizes can produce bigger holes which make the product crisp and improve the friability. Freeze sublimation dehydration but not frying is used in the invention, so that the product is crisp and soft, and the nutrition loss is small.

Owner:HUAZHONG AGRI UNIV

Extraction method of cinnamon oil

InactiveCN105296164APromote exudationImprove permeabilityEssential-oils/perfumesSlow freezingCinnamon Oil

The invention discloses an extraction method of cinnamon oil. The method comprises the following steps: firstly, mixing and tempering powdered cinnamon and a water solution of a sodium salt to obtain tempered powdered cinnamon; secondly, freezing the tempered powdered cinnamon obtained in the previous step, and quickly unfreezing the powdered cinnamon to obtain the unfrozen powdered cinnamon; and finally, mixing the unfrozen powdered cinnamon with a gaseous solvent, carrying out pressurized liquid extraction and separating to obtain the cinnamon oil. According to the method for extracting the cinnamon oil from cinnamon at a low temperature, the water solution of the sodium salt is added to temper the powdered cinnamon; slow freezing and quick unfreezing processes are adopted; the gaseous solvent which is easy to liquefy through pressurization is adopted; the gaseous solvent can be liquefied to be separated from an extract without heating; the gaseous solvent does not contact air in the extraction process; the extract is not easy to oxidize; and a heat-sensitive component is not damaged. The extraction method disclosed by the invention has the advantages of low extraction temperature, short time, high yield, simplicity in technology and mild reaction conditions, and is free of a solvent residue basically; and industrialization is easy to achieve.

Owner:INFINITUS (CHINA) CO LTD

Method for fresh keeping of fresh walnuts by slow-freezing and slow-unfreezing freshelizing technology

PendingCN107549308AExtended shelf lifeAchieving annual supplySeed preservation by freezing/coolingFrozen storageSlow freezing

The invention relates to a fresh-keeping method for fresh walnuts, in particular to a method for fresh-keeping walnuts by slow freezing-slow thawing and refreshment process. The technical scheme of the invention includes peeling, grading, slow freezing, frozen storage, slow thawing and freshening. The technology of the invention extends the preservation period of fresh walnuts from 2 to 4 months to more than 10 to 12 months, and realizes the annual supply of fresh walnuts.

Owner:甘肃省农业科学院农产品贮藏加工研究所

A kind of preparation method of small molecule cluster structure functional water

InactiveCN102295316AMolecular cluster structure is smallPromote absorptionWater/sewage treatment with mechanical oscillationsWater/sewage treatment by freezingPhysical healthMolecular cluster

The invention discloses a method for preparing water with structure and function of small molecular cluster characteristics. The preparation method is based on the correlation between the structure of ice and water molecular clusters and the structural memory characteristics of water. It consists of the following steps: Put the water in the freezer at -20~-30℃ for slow thawing, and the cooling rate is controlled at 2~5℃·h-1; during the slow freezing process, ultrasonic resonance is carried out at the same time, and the resonance frequency is controlled at 2000~2200MHz; After fully freezing, thawing is carried out at a temperature of 4-10°C, and the heating rate is controlled at 2-3°C·h-1. The functional water molecule clusters prepared by the invention have a small structure, are easier to absorb, and have good physiological and health effects on the human body; the preparation method is relatively simple, the operation is convenient, easy to realize, and is suitable for popularization and use.

Owner:TIANJIN UNIV +1

Methods for the cryopreservation of cells

ActiveUS9538745B2Rapid coolingAvoid disadvantagesDead animal preservationTissue cultureSlow freezingIce formation

Owner:THE GENERAL HOSPITAL CORP

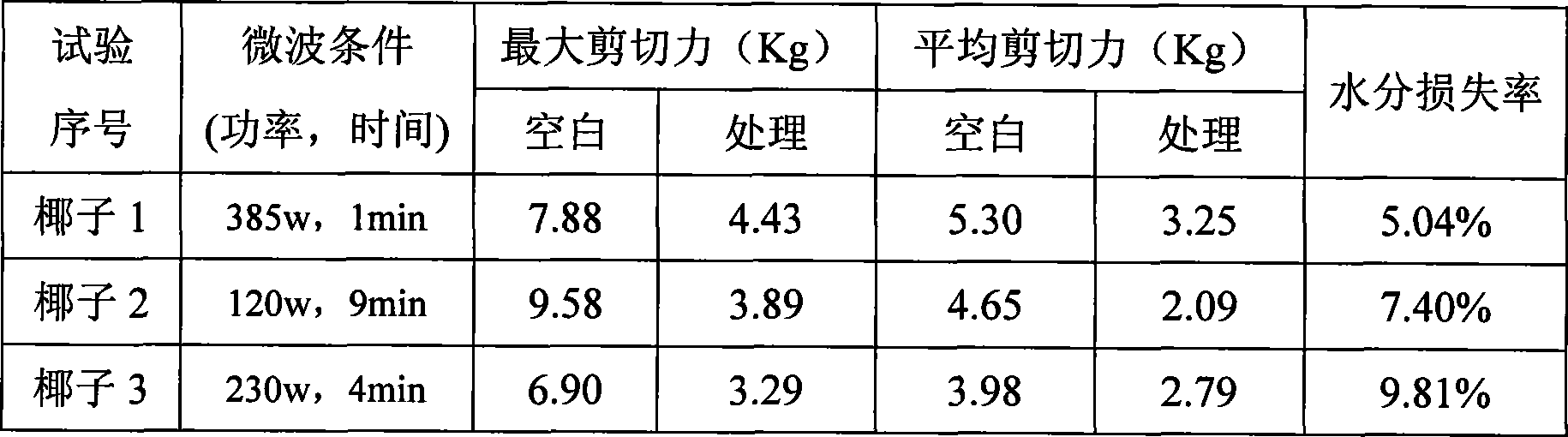

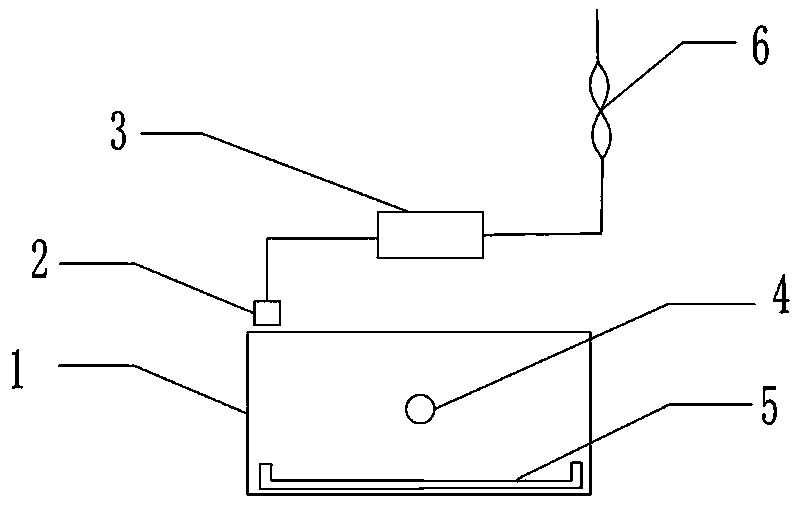

Coconut flesh softening method

The present invention discloses a softening method of copra, which pertains to the field of agricultural products post-processing technology. The method mainly solves the problems that the copra in the mature coconut fruit is hard, and has bad taste so that it is difficult to process follow-up processing. The method includes: preprocessing the copra, processing slow freezing after cutting into blocks; after the copra is completely freezed, putting into warm water for quick-speed ice-out; and then adding in a microwave generator batch by batch fro processing microwave treatment; and then taking out the copra to get the softened copra. The present invention is simple and practical; has low cost, easy application, small destruction to the nutritional content and flavor characteristics of the copra, greatly improved copra processing performance and taste characteristics, and further enlarged use of copra after softening treatment; and can be used in the production of preserved fruits, suspended drinks, jelly, bread, cakes and the like.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

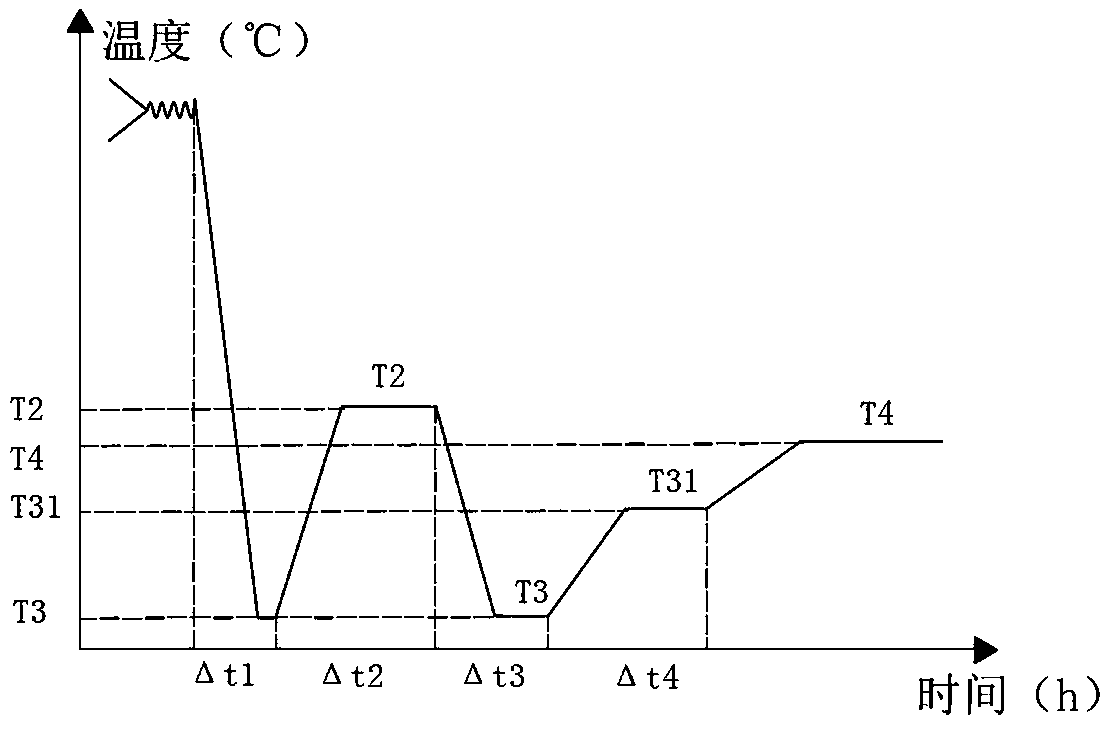

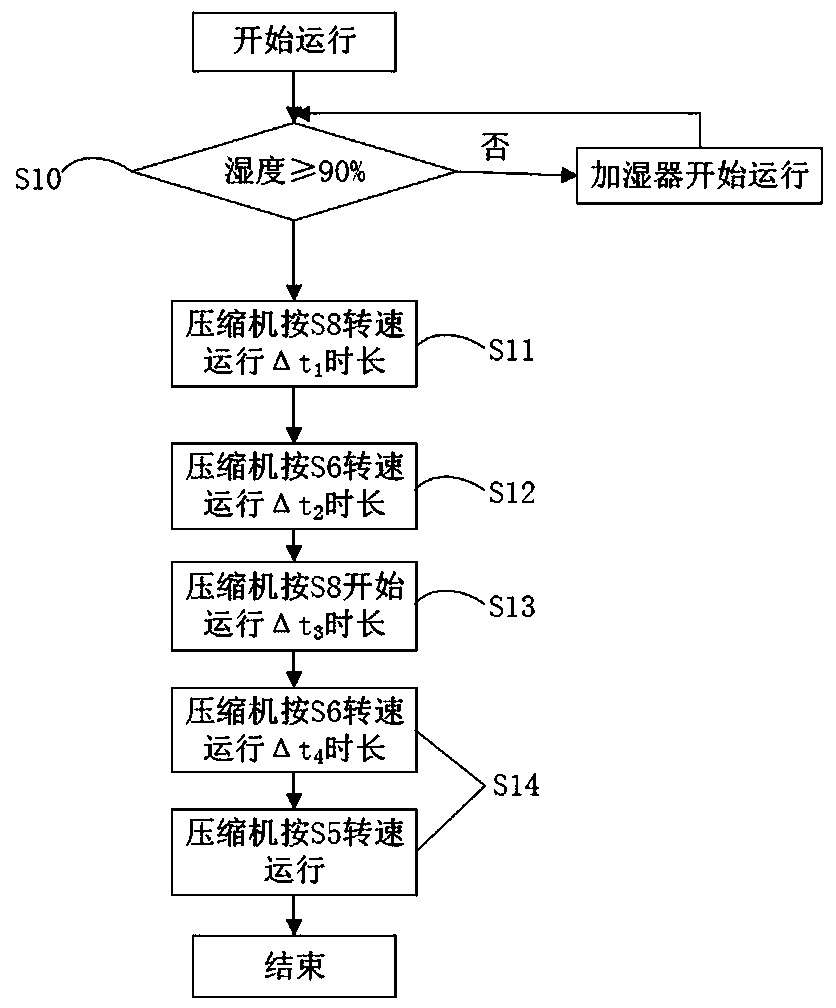

Freezing method of refrigerator compartment and refrigerator using freezing method

ActiveCN111156754AReduce the degree of crackingImprove qualityDomestic refrigeratorsRefrigeration safety arrangementIceboxSlow freezing

The invention discloses a freezing method of a refrigerator compartment and a refrigerator using the freezing method. The freezing method controls the temperature of the compartment in stages, so thatfood reaches the set freezing temperature by means of quick freezing, slow freezing and quick freezing and slow freezing, and is frozen and stored. According to the freezing method, the technical problems of high energy consumption of deep freezing and high equipment cost existing in the prior art under the condition of ensuring the food quality.

Owner:GREE ELECTRIC APPLIANCES INC

Electric heating type anti-freezing water pipe

InactiveCN107816086AFast defrostingShorten freeze timeService pipe systemsOhmic-resistance heatingElectrical resistance and conductanceElectricity

The invention relates to the field of water pipe antifreeze technology, and discloses an electrically heated antifreeze water pipe, which includes a metal pipe body, a layer of heat insulation layer wrapped on the outside of the metal pipe body, and an electric heating pipe is installed between the heat insulation layer and the body. A heating layer, the electric heating layer is composed of a heating resistance wire and an insulating isolation layer; the outer side of the heat insulating layer is wrapped with an aluminum skin protection layer. The outer side of the water pipe of the present invention is provided with an electric heating layer, and the water pipe can be turned on for heating when it freezes, so as to ensure the normal progress of production and life; the outer side of the heating layer is provided with an insulating layer, which not only prevents heat from being lost, but also slows down the freezing of the water pipe Over time, the aluminum skin protection layer can also reflect the heat emitted by the electric heating layer, so that the water pipes can defrost faster and improve efficiency.

Owner:济宁市友领机械设备制造有限公司

Frozen fresh keeping process for litchis

InactiveCN102578216AKeep freshKeep the flavorFruits/vegetable preservation by heatingFlavorSlow freezing

The invention relates to a fruit frozen fresh keeping process, in particular to a frozen fresh keeping process for litchis. The frozen fresh keeping process comprises the steps of: branch removal, selection, cleaning, boiling and blanching, cooling, color protection, individual quick freezing (IQF), slow freezing in a refrigeration house, bag charging, detection by a metal detection instrument, weighing, box loading and finished product warehouse entering. After the litchis are subjected to the boiling and blanching treatment, the activity of enzymes on the surfaces of litchi shells is damaged, the color change of the litchi shells can be prevented, but the tissue structure of litchi flesh cannot be influenced, so the freshness and the flavor of the litchis can be maintained. After the litchis are subjected to soaking and color protection by a color protection liquid, the appearance of the litchis is more fresh and red, meanwhile, the acidity and the salinity are proper, so the litchis are fresher and more delicious and can be stored for a long time. The quick freezing is firstly adopted, and the slow freezing in a refrigeration house is adopted, so the tissue structures of the litchis cannot be influenced because of the slow freezing, cracks caused by fast expansion of the litchis because of fast freezing cannot be caused, the shelf life of the litchis in the freezing state after the treatment can reach two years, and customers can eat the fresh litchis in four seasons in a year.

Owner:RUYIQING GROUP

Treatment method for preventing pine wood deformation cracking

InactiveCN107415004APrevent deformation and crackingDeformation Cracking InhibitionWood treatment detailsWood heatingSlow freezingDissolution

The invention mainly relates to the technical field of wood product machining, and discloses a treatment method for preventing pine wood deformation cracking. The treatment method includes the steps of cutting, primary freezing, secondary freezing, stabilization and drying; the method is simple, operation is facilitated, the pine wood strength and stability are obviously increased, pine wood deformation cracking is prevented, the using value of pine wood is improved, and the economic income is increased by 14.8%; pine wood sections are cut after peel is removed, and therefore even treatment in the later period is facilitated, and the treatment efficiency is improved; battens obtained after cutting are soaked into a sodium selenite solution, the sodium selenite solution is promoted to permeate into the battens, the combining capacity of lignin and hemicelluloses in the pine wood to celluloses is improved, and pine wood deformation is restrained; slow freezing and quick dissolution are sequentially carried out after soaking, and quick freezing and slow dissolution are sequentially carried out after the sodium selenite solution is sprayed, sodium selenite is sufficiently combined with the pine wood, the pine wood hardness is improved, the moisture absorption capacity of the pine wood is reduced, and the pine wood stability is improved.

Owner:阜南佳利工艺品股份有限公司

Methods for cryopreservation of stem cells via slow-freezing

ActiveUS9458424B2Low toxicityImprove survivabilityCulture processCell culture mediaHigh cellProgenitor

Cryopreserved stem cells with high cell viability after thawing were obtained by slow freezing using a DMSO-free cryopreservation medium. Stem cells and / or progenitor cells thereof are contacted with a DMSO-free cryopreservation medium, comprising between 4 v / v % and 25 v / v % of propylene glycol and between 1.0 w % and 10 w % of a sugar; and are subsequently subject to a slow-freezing process. Optionally, the cryopreservation medium may comprise serum albumin and / or hyaluronic acid.

Owner:FERTIPRO

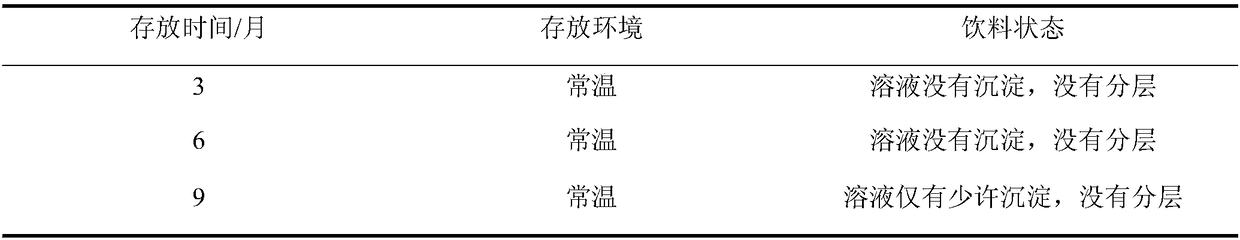

Processing method of mulberry fruit juice beverage

The invention discloses a processing method of a mulberry fruit juice beverage. The processing method comprises the following steps: 1) inspection and acceptance; 2) selection; 3) cleaning; 4) slow freezing; 5) cold-press juicing; 6) color protection and blanching; 7) pulping, enzyme deactivation and clarification; 8) filtration; 9) centrifugation; 10) blending; 11) filling and sealing; and 12) sterilization. The mulberry fruit juice beverage prepared by the method has good mouthfeel, and tested by a WAY abbe refractometer, the solid content of a finished product is 11.2%, which is greater than 10% and meets a criterion. The mulberry fruit juice beverage prepared by the method has clarity of solution, integral uniformity, no impurities, specific fragrance of mulberry fruits, a sour, sweetand delicious taste, no peculiar smell, and popularity in consumers on the market. In the prepared mulberry fruit juice beverage, the microbiological indicator total number of bacteria is 100 CFU / mL,no coliform groups are detected, and no pathogenic bacteria are detected. The mulberry fruit juice beverage meets the national quality standard, reaches commercial sterility and can be drunk safely.

Owner:XUZHOU UNIV OF TECH

Pseudosciaena crocea rapid-freezing preservation process

InactiveCN103125582AGuaranteed qualityAvoid whiteningMeat/fish preservation by freezing/coolingAlcoholSlow freezing

The invention discloses a pseudosciaena crocea rapid-freezing preservation process in which liquid alcohol is used as a refrigerant. A complete set of pseudosciaena crocea rapid-freezing preservation process is formed through the following steps of: washing, sterilizing, rinsing, leachating, packaging, locating, rapid freezing, rinsing, leachating, slow freezing and the like. The rapid-freezing preservation process is small in ice crystal formed on pseudosciaena crocea and capable of well keeping the quality of the pseudosciaena crocea, effectively preventing the eyes of the pseudosciaena crocea from whitening and keeping favorable appearance quality of the pseudosciaena crocea.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Freeze-dried and sugar-soaked strawberry preparation method

The present invention provides a freeze-dried and sugar-soaked strawberry preparation method. The prepared freeze-dried and sugar-soaked strawberry slices or dices preserve various vitamins of strawberries themselves and unique nutrients of fruits and the preparation method retains original color, smell and taste of the strawberries. The sugar-soaked strawberry technology improves a special strong acid taste of the freeze-dried pure strawberries, which is mainly realized through the following steps: primary quick-freezing and preserving, beating, blending, stirring and putting still, plate laying, quick-freezing, slow-freezing, shape cutting, plate laying, quick-freezing, freeze-drying, semi-finished product inspecting, and finished product packaging. The finished products obtained by the process technology are rich in nutrients. Each 100 grams of the freeze-dried and sugar-soaked strawberries contain 1488 KJ of energy, 5.2 g of proteins, 1.3 g of fats, 77.3 g of carbohydrates, 4.7 g of dietary fibers, less than 5 mg of sodium and 520 mg of vitamin C. The freeze-dried and sugar-soaked strawberry preparation method is easy to operate and remarkable in energy saving effect. The obtained sugar-soaked strawberries are very convenient in consumption, transportation, storage, etc. and easy to promote.

Owner:福建欧瑞园食品有限公司

Crawfish crispy crawfish ball product and manufacturing technology thereof

ActiveCN103416788BLow costImprove product added valueFood preparationManufacturing technologySlow freezing

The invention belongs to the field of aquatic product processing, particularly relates to a crawfish crispy crawfish ball product and a manufacturing technology thereof, and belongs to an instant food. The manufacturing technology comprises the step of using an entire crawfish, a shrimp with the body length of 5-10 cm and the body weight less than 25 g obtained by the grading of crawfish meat, or an imperfect crawfish as a raw material to obtain a net crawfish shell being subjected to processes of sorting, cleaning, head and intestine removing, boiling with salts for flavoring, crisping of the crawfish shell, secondary flavoring, packaging, and the like to manufacture the crispy crawfish ball product. The crispy crawfish ball product has the characteristics of crispness and tasty, primary color and taste, low fat content, low water activity, long shelf life, and the like. Compared with the prior art, the crispy crawfish ball product adopts the technologies of the crisping of crawfish shell with the combination of slow freezing and vacuum frying, and compound flavoring and humidity control crisp protection with the combination of pre-cook and secondary flavoring, so that not only is the color of the crispy crawfish ball obviously improved, are the fat content and the water activity of the product lowered, is the crisp of the crawfish shell promoted, and is the crisp maintained, but also the oxidation rate of frying oil is obviously slowed down, the usage count of the oil is increased, the manufacturing cost is lowered, and the shelf life of the product is prolonged.

Owner:HUAZHONG AGRI UNIV

Yeast glucan, novel extruded gluten and production methods of yeast glucan and novel extruded gluten

The invention discloses yeast glucan, novel extruded gluten and production methods of the yeast glucan and the novel extruded gluten. The production method of the yeast glucan includes the steps of firstly, evenly mixing yeast residues with water to obtain a mixture; secondly, subjecting the mixture to slow freezing, natural thawing and microwave assisted processing; thirdly, using helicase to perform enzymolysis on the mixture after the microwave assisted processing, and removing impurities to obtain primary yeast glucan; fourthly, centrifuging the primary yeast glucan, and collecting precipitates; fifthly, subjecting the precipitates to freeze drying and ultrafine grinding to obtain the yeast glucan. The novel extruded gluten is good in puffing degree, high in satiety after eating and long in shelf life.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Aculeus type tissue slice glassivation refrigeration carrier and refrigeration method for ovary tissue

ActiveCN101314757BEasy to operatePrevent unstable freezing effectBioreactor/fermenter combinationsBiological substance pretreatmentsNeedle penetrationCell-Extracellular Matrix

Owner:THE WEST CHINA SECOND UNIV HOSPITAL OF SICHUAN

Method for extracting active ingredient by combination of ultrasonic slow freezing and microwave thawing in near-solid state

InactiveCN107512839AReduce usageReduce processSolvent extractionNatural extract food ingredientsMicrowaveWave slowing

The invention discloses a method for extracting an active ingredient by combination of ultrasonic slow freezing and microwave thawing in a near-solid state, which comprises the steps of grinding raw materials, centrifugally filtering, concentrating and drying. The method is characterized in that ultrasonic wave slow freezing and microwave thawing near-solid extraction sequentially performed between raw material grinding and centrifugal grinding steps. The method is carried out at a low-temperature environment, can achieve the effect of releasing active ingredients in a cell tissue without adding massive extraction solvent, and has remarkable advantage by judging from the extraction yield and protection perspective for active ingredients.

Owner:吴海军

Nutrient-rich and diverse-function miscellaneous grain porridge and processing method thereof

InactiveCN109349508AImprove water absorptionLow in fatFood ingredient functionsMicrowaveFreeze-drying

The invention discloses nutrient-rich and diverse-function miscellaneous grain porridge and a processing method thereof. The porridge is includes, by weight, 20-25 parts of millet, 20-25 parts of wheat, 10-15 parts of corn, 10-15 parts of mung beans, 5-10 parts of soybeans, 5-10 parts of apricot kernels, 5-10 parts of pine nuts, 4-8 parts of lotus seeds and 5-10 parts of red dates. The processingmethod of the grain porridge includes the following steps of 1, miscellaneous grain cleaning and drying, 2, sterilization, 3, freezing of miscellaneous grains, 4, crushing, 5, cooking, 6, drying, 7, freeze-drying, and 8, packaging. Slow freezing in the processing method in the scheme can destroy the tissue structure of the mixed beans, through microwave drying at the normal temperature, a small number of voids and holes can be left through water evaporation, and the water absorption property of the mixed beans can be obviously increased. The porridge is rich in nutrition, the defect that traditional grain porridge is monotonous in nutrition is solved, nutrition is easier to absorb, and the porridge has the functions of preventing and treating common diseases of the elderly.

Owner:ANHUI QIUGUO FOOD

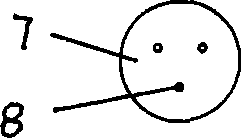

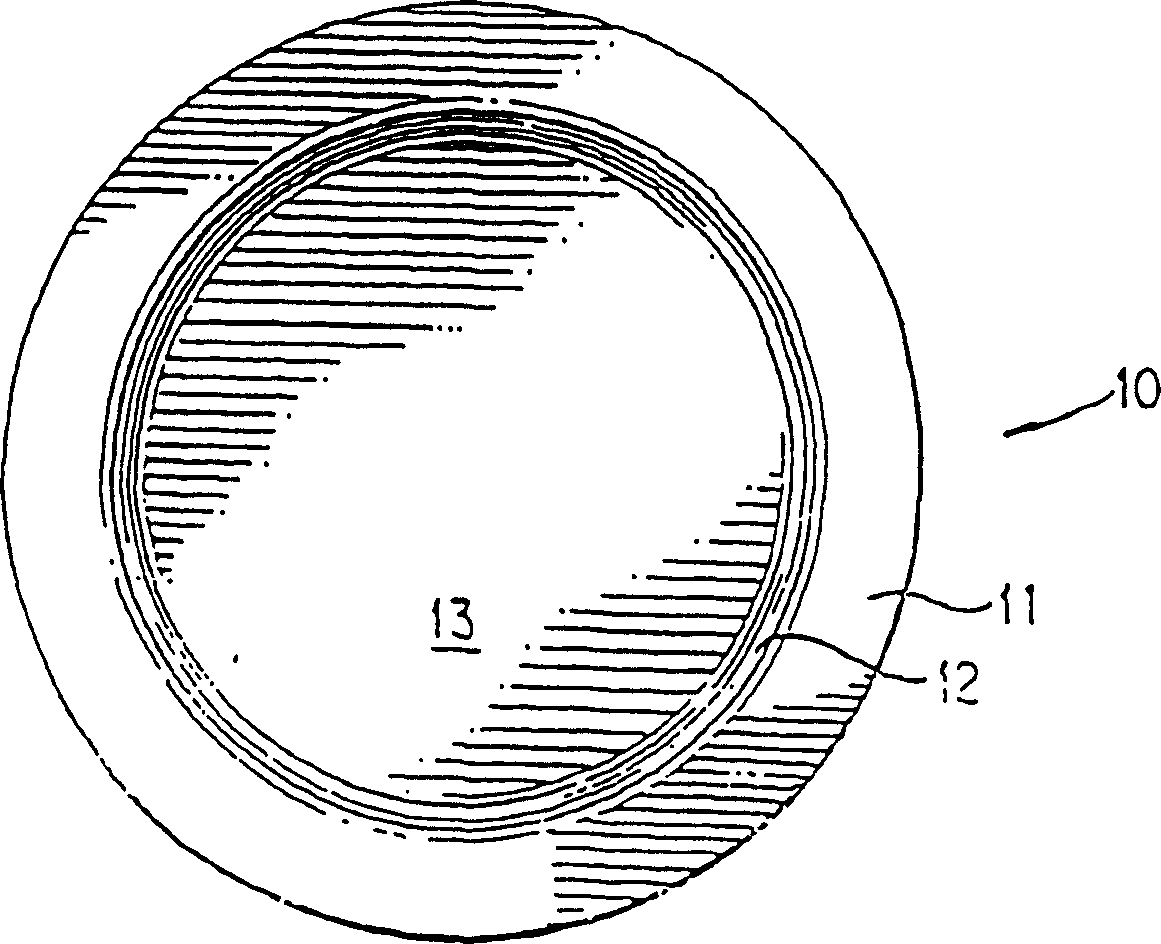

Method and package design for cryopreservation and storage of cultured tissue equivalents

This invention is directed to an efficient cryopreservation package design of harvested mammalian tissues and living cultured tissue equivalents made by in vitro technology. The invention involves immersing a mammalian tissue or cultured tissue equivalent in a cryoprotectant solution, agitating the cryoprotectant solution and the immersed tissue to achieve effective penetration of the cryoprotectant solution into the tissue, and then freezing the tissue at a very slow freezing rate. In the freezing step, extracellular ice formation is initiated by seeding. The cryopreserved tissue may be stored for indefinite periods of time prior to use. The cultured tissue equivalent is an in vitro model of the equivalent human tissue, such as skin or cornea, which, when retrieved from storage can be used for transplantation or implantation in vivo or for screening compounds in vitro.

Owner:ORGANOGENESIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com