Crawfish crispy crawfish ball product and manufacturing technology thereof

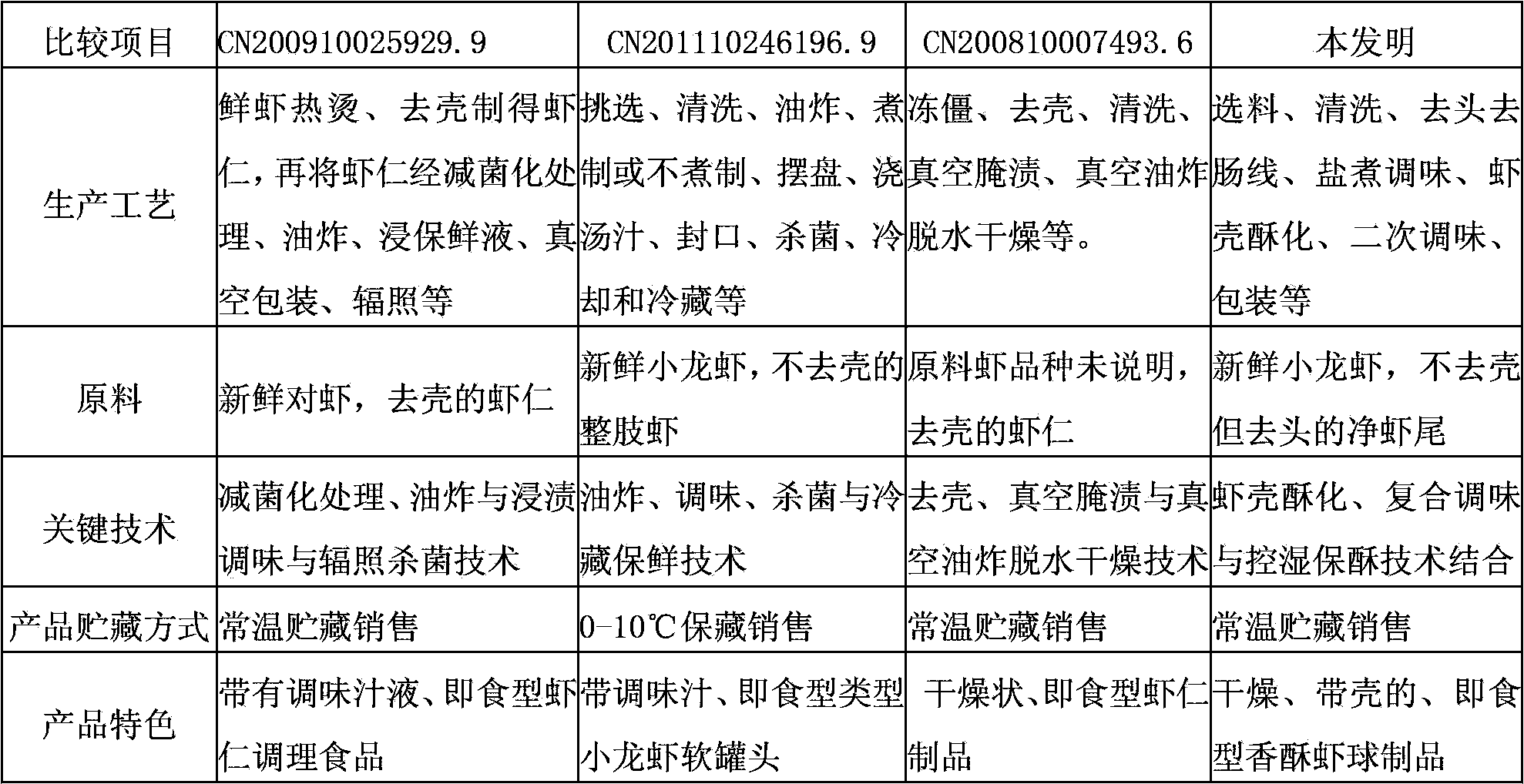

A lobster and shrimp ball technology, which is applied in the field of crayfish crispy shrimp ball products and the production process thereof, can solve the problems of unstable product quality and low price, achieve rich taste and taste, low cost, and reduce manpower input. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

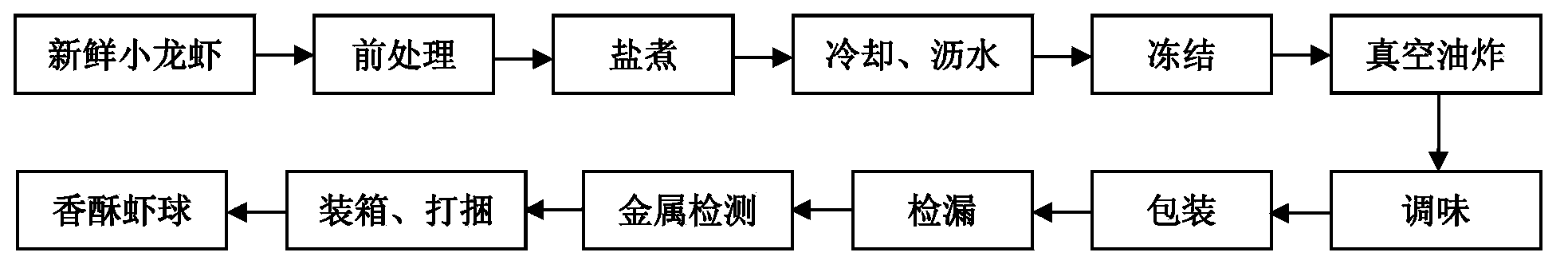

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Preparation Example 1 of Crispy Shrimp Ball Products

[0052] A ready-to-eat crayfish crispy shrimp ball product, which uses crayfish whole limbs or graded shrimp as raw materials. Seasoning and packaging processes are processed into ready-to-eat crispy shrimp ball products, and the proportioning according to the actual amount is as follows:

[0053] Crayfish net tail: 100kg

[0054] Chives: 2kg

[0055] Ginger: 2kg

[0056] Salt: 3kg

[0057] Cooking wine: 3kg

[0058] Maltodextrin: 10kg

[0059] Tap water: 200kg

[0060] Seasoning: 3kg, the seasoning is one of the spicy, cumin, five-flavored and curry seasonings; the seasoning is in the form of powder or oily seasoning; wherein: the powdery seasoning The material is 1kg of pepper powder, 2kg of pepper powder, 1kg of sugar powder, 0.1kg of monosodium glutamate, 5kg of salt or 8kg of one of cumin powder, five-spice powder or curry powder; the oily seasoning material is 1kg of pepper powder, 1kg of pepp...

Embodiment 2

[0068] Embodiment 2: Preparation embodiment 2 of crispy shrimp ball product

[0069] According to the processing step of embodiment 1, the proportioning of each composition in the present embodiment is as follows according to physical quantity:

[0070] Crayfish net tail: 100kg

[0071] Chives: 1kg

[0072] Ginger: 1kg

[0073] Salt: 2kg

[0074] Cooking wine: 4kg

[0075] Maltodextrin: 5kg

[0076] Tap water: 200kg

[0077] Seasoning: 2kg,

[0078] The seasoning is one of spicy, cumin, five-flavored and curry seasoning; the seasoning is in powder or oily seasoning; wherein: the powdery seasoning material is pepper powder 1kg, chili powder 2kg, sugar powder 0.5kg, monosodium glutamate 0.1kg, salt 3kg or one of cumin powder, allspice powder or curry powder 5kg; the oily seasoning material is pepper powder 1kg, chili powder 1kg, sugar powder 0.5kg, monosodium glutamate 0.1kg, salt 3kg, edible oil 2kg or cumin powder, allspice powder or curry powder 5kg, mixed with 2kg ed...

Embodiment 3

[0080] Example 3 Preparation Example 3 of Crispy Shrimp Products

[0081] According to the processing step of embodiment 1, the proportioning of each composition in the present embodiment is as follows according to physical quantity:

[0082] Crayfish net tail: 100kg

[0083] Chives: 3kg

[0084] Ginger: 3kg

[0085] Salt: 4kg

[0086] Cooking wine: 4kg

[0087] Maltodextrin: 10kg

[0088] Tap water: 200kg

[0089] Seasoning: 5kg, the seasoning is one of spicy, cumin, five-flavored and curry seasoning; the state of the seasoning is one of powder or oily seasoning; wherein: the powdery seasoning The material is 1kg of pepper powder, 2 parts of chili powder, 1kg of powdered sugar, 0.2kg of monosodium glutamate, 5kg of salt or 10kg of one of cumin powder, allspice powder or curry powder; the oily seasoning material is 1kg of pepper powder, 1kg of pepper powder, Powder 2kg, powdered sugar 1kg, monosodium glutamate 0.2kg, salt 5kg, edible oil 5kg or one of cumin powder, five...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com