Patents

Literature

158results about How to "Avoid whitening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

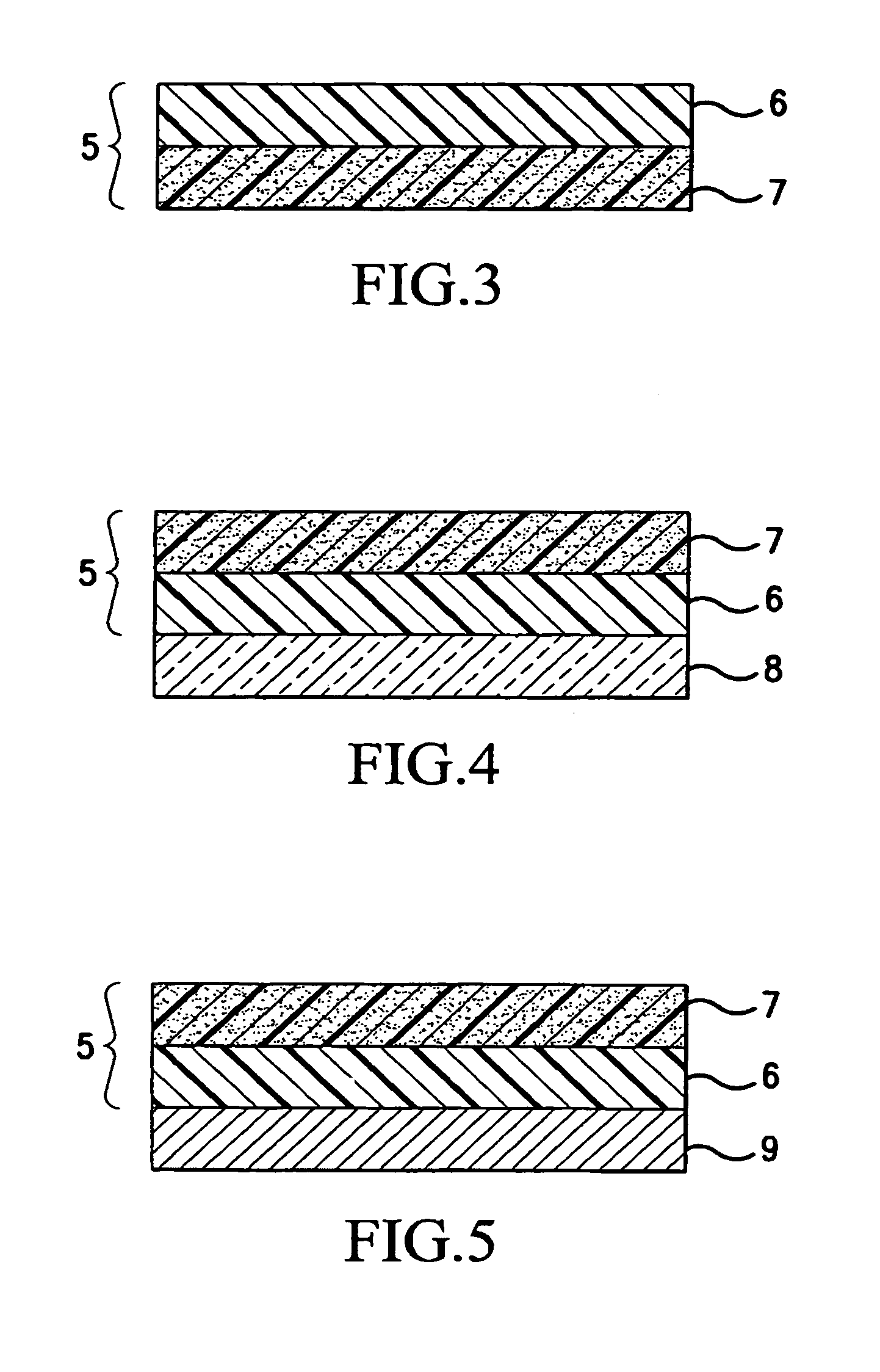

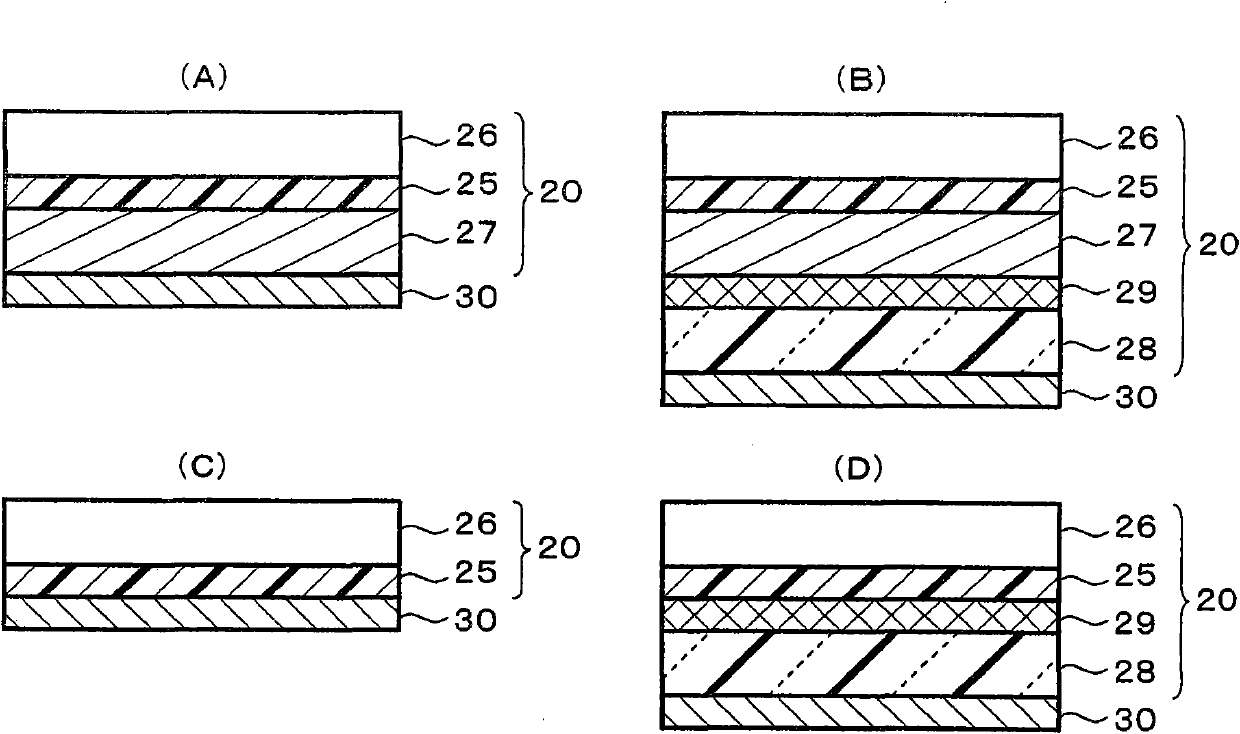

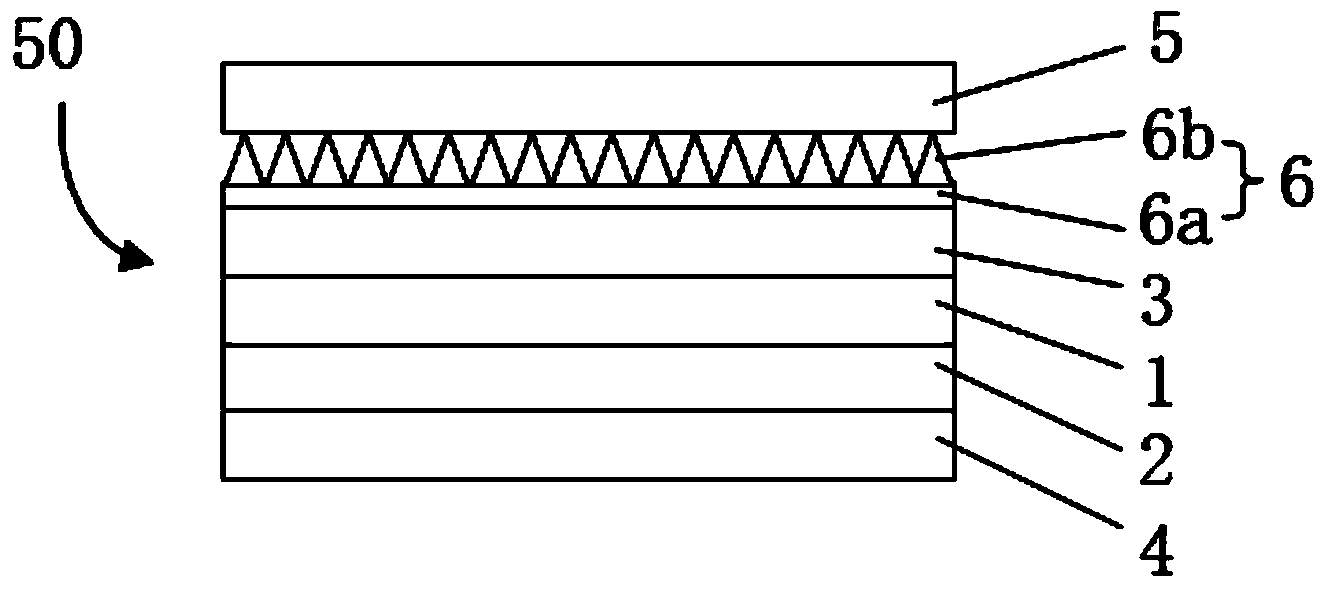

Antireflection film containing ultrafine particles, polarizing plate and liquid crystal display device

InactiveUS6033743AGood dispersionAvoid whiteningLiquid crystal compositionsTelevision system detailsMeth-Liquid-crystal display

An antireflection film, containing ultrafine particles, formed of a resin composition having excellent dispersibility of ultrafine particles in a binder resin and capable of preventing whitening, a polarizing plate, and a liquid crystal display device are provided. At least one resin layer is provided on a transparent substrate film directly or through other layer(s), and at least one of the resin layer has a controlled refractive index and is formed of a resin composition containing ultrafine particles. The outermost layer has a lower refractive index than an underlying layer in direct contact therewith. The resin composition contains a carboxyl-containing (meth)acrylate as part or the whole of a binder resin component. A polyfunctional acrylate having in its molecule three or more acryloyl groups may be added to the binder resin component in order to further enhance the properties of the hard coating.

Owner:DAI NIPPON PRINTING CO LTD

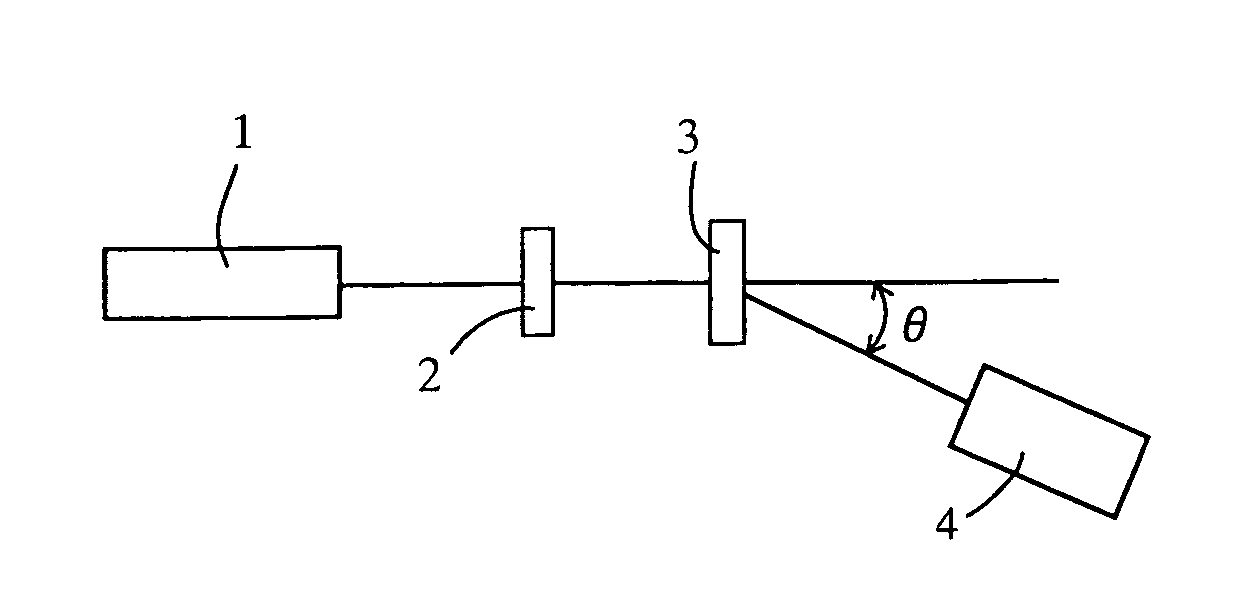

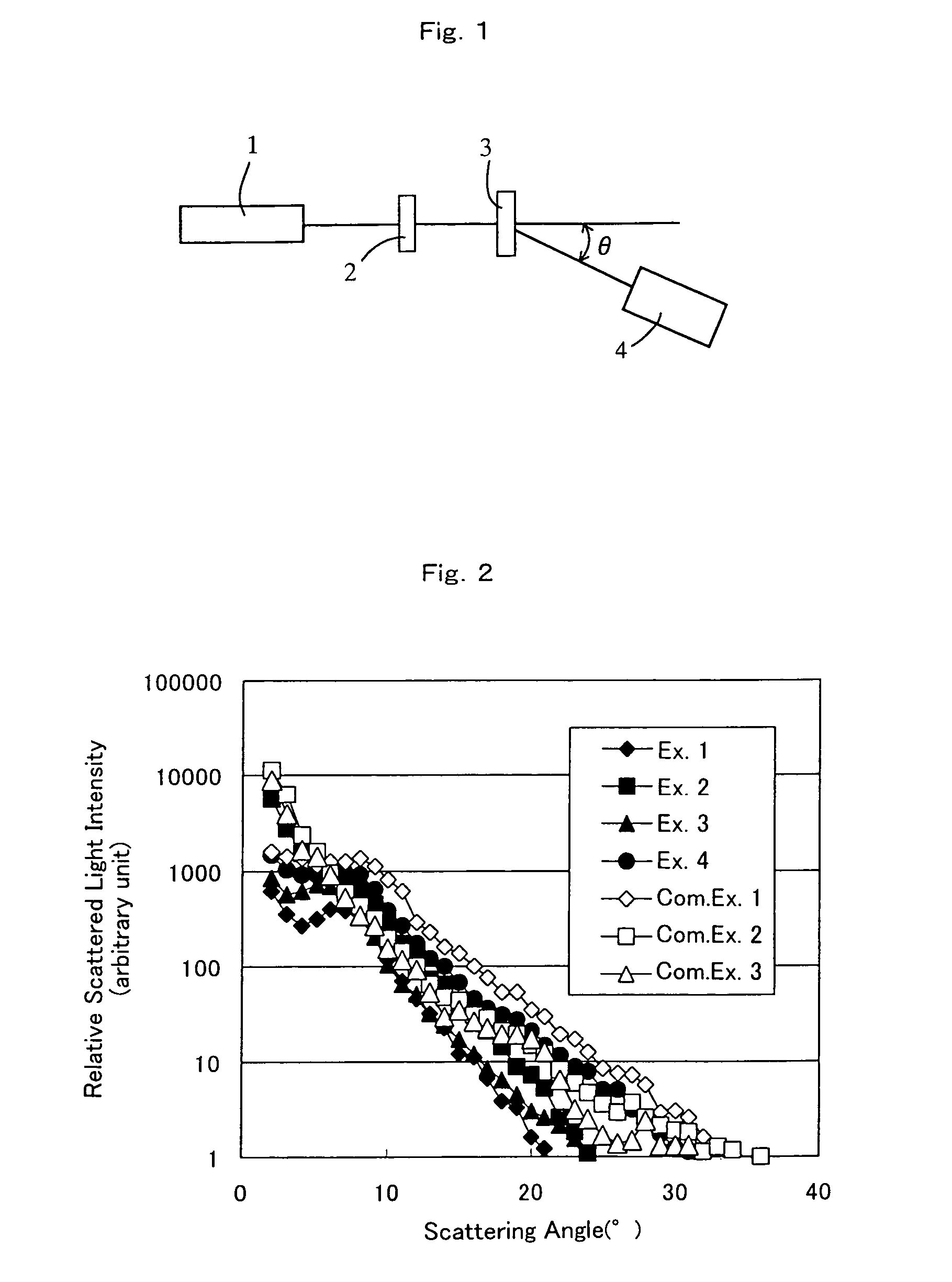

Anti-glare film

InactiveUS7128428B2High anti-glareAvoid reflectionsLiquid crystal compositionsDiffusing elementsDisplay deviceRefractive index

An anti-glare film is obtained by forming a resin layer having a low refraction index on an anti-glare layer is obtained by coating a transparent plastic film with a liquid composition containing a polymer, a curable resin precursor, and a solvent, evaporating the solvent, forming a phase separation structure by spinodal decomposition, and curing the precursor with light irradiation. The anti-glare film has an uneven surface structure in the anti-glare layer, isotropically transmits and scatters an incident light to show the maximum value of the scattered light intensity at a scattering angle of 0.–10°, and has a total light transmittance of 70–100%. The film prevents dazzle or blur of images on a display surface, and reflection of a surrounding scenery, and improves contrast with reducing whitening of the display, even in a high definition display apparatus.

Owner:DAICEL CHEM IND LTD

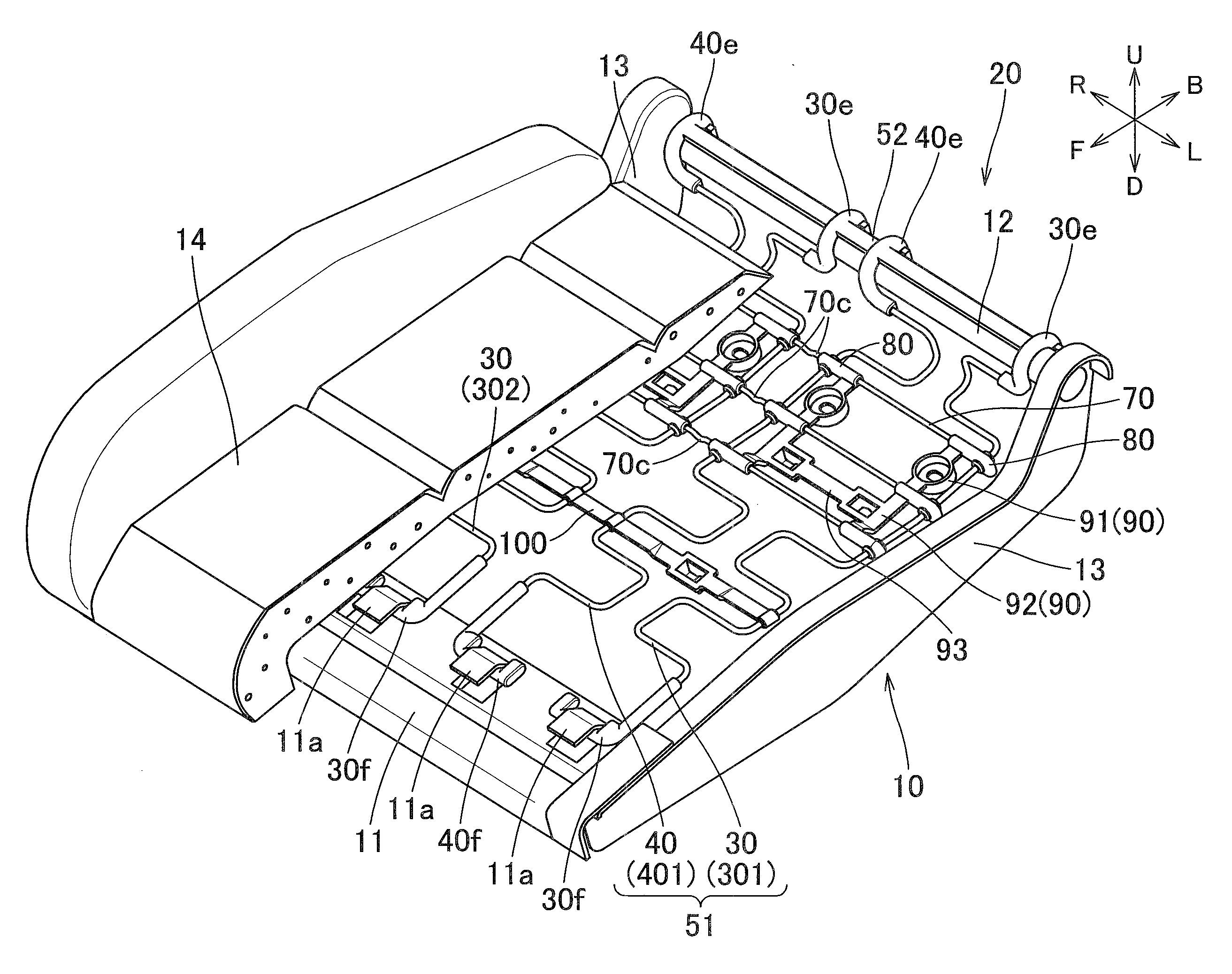

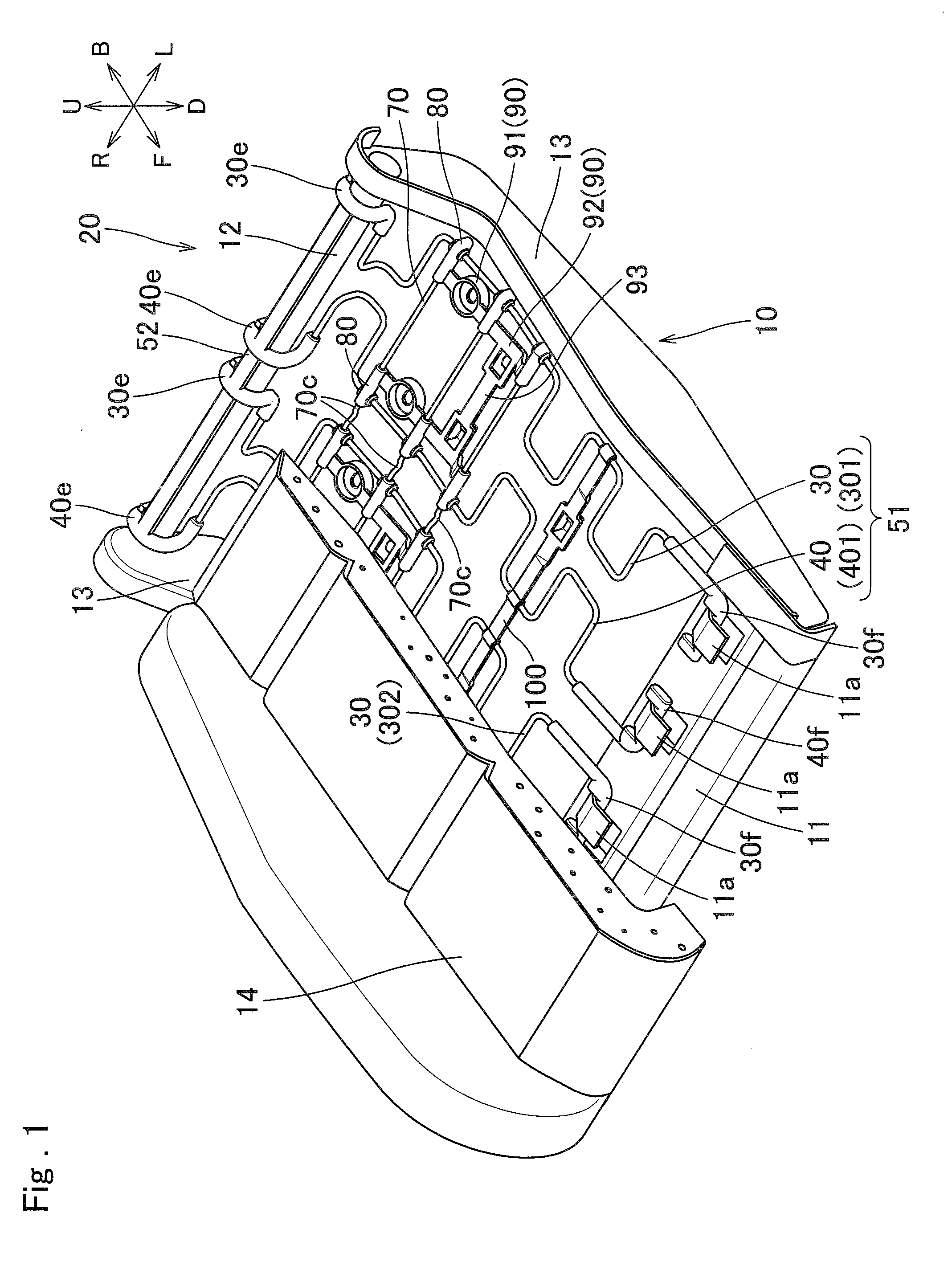

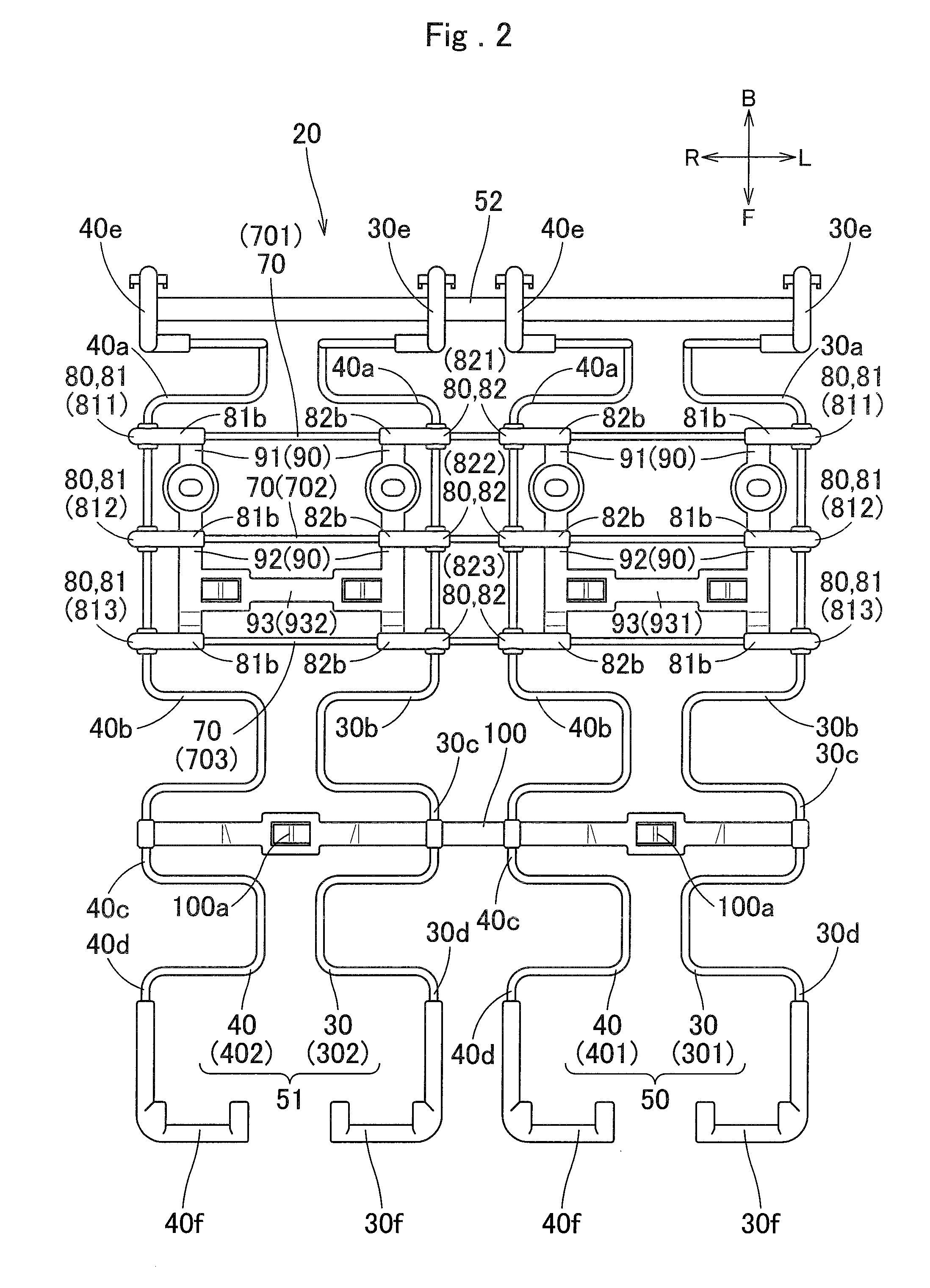

Cushion body for vehicle seat

A cushion body for a vehicle seat is configured including spring members each having a plurality of bent portions, a stretching-across member disposed in a manner stretching across between the spring members, and a coupling member coupling the stretching-across member and the spring member. The stretching-across member is stretched across between the spring members in a manner arranged at a position different from that of a bent portion of the spring member, and the coupling member is formed in a manner not including the bent portion of the spring member.

Owner:SINDAI KARIYA AICHI JP

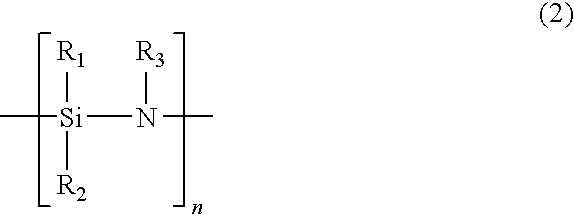

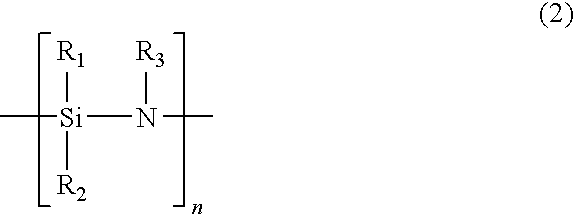

Method for producing water-repellent treated aluminum pigment dispersion, water-repellent treated aluminum pigment, and aqueous ink composition containing the same

ActiveUS20100256283A1Excellent in water dispersibility and metallic glossAvoid whiteningDuplicating/marking methodsInksOrganic solventPolysilazane

A method for producing water-repellent treated aluminum pigment dispersion includes (a) adding a polysilazane solution in which a polysilazane is dissolved in a second organic solvent to an aluminum pigment dispersion in which an aluminum pigment is dispersed in a first organic solvent for reacting a hydroxyl group present on the surface of the aluminum pigment with the polysilazane to form a covering film on the surface of the aluminum pigment. The amount of the polysilazane in the reaction system for forming the covering film is 0.4 parts by mass or less based on 1 part by mass of the aluminum pigment, and the total addition amount of the polysilazane is from 0.2 to 0.6 parts by mass based on 1 part by mass of the aluminum pigment.

Owner:SEIKO EPSON CORP

Covering material for treating asphalt macadam seal coat stone material and method for treating stone material

The invention belongs to the field of asphalt pavement and relates to a coating material for treating stone materials as asphalt macadam seal coat and a method for treating stone materials. The inventive coating material comprises 27-52 wt% of petroleum asphalt, 0.6-4 wt% of cationic asphalt emulsifier, 1-5 wt% of tackifier, 0-8 wt% of diluting agent and water. The production method thereof comprises: the petroleum asphalt is diluted with the diluting agent and then heated or is directly heated, and is emulsified to obtain a concentrated asphalt emulsion; and the concentrated asphalt emulsion is mixed with an aqueous solution of the tackifier, to obtain the coating material. The method for treating stone materials as asphalt macadam seal coat comprises: the stone materials are sorted, washed and sieved, and then the coating material is sprayed onto the surface of the stone materials at room temperature. After the stone materials are treated with the coating material, the bonding performance of the stone material to the asphalt binder is improved, thereby avoiding the looseness and stripping of stone materials in the road surface and improving the driving safety.

Owner:陕西长大博源公路养护科技有限公司

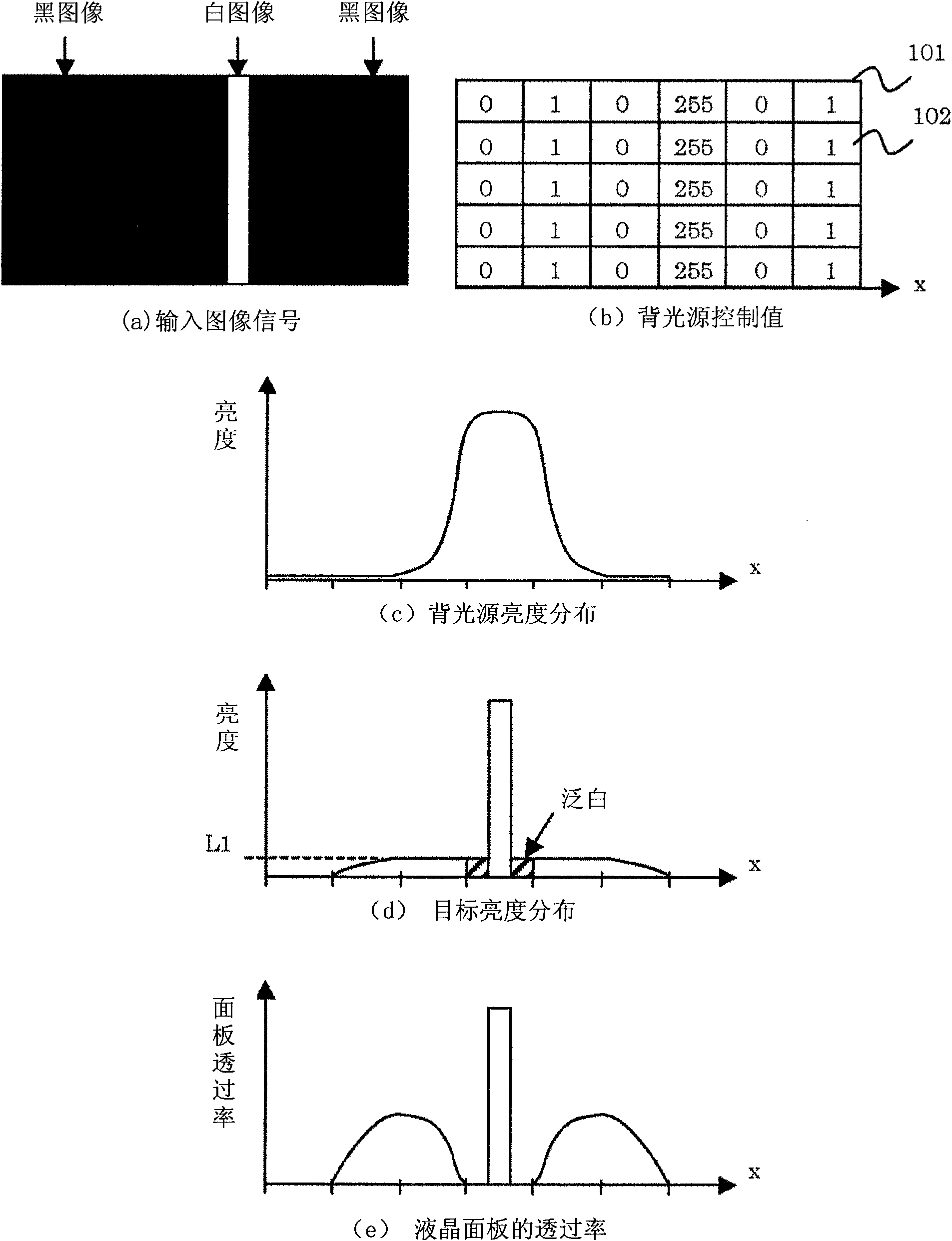

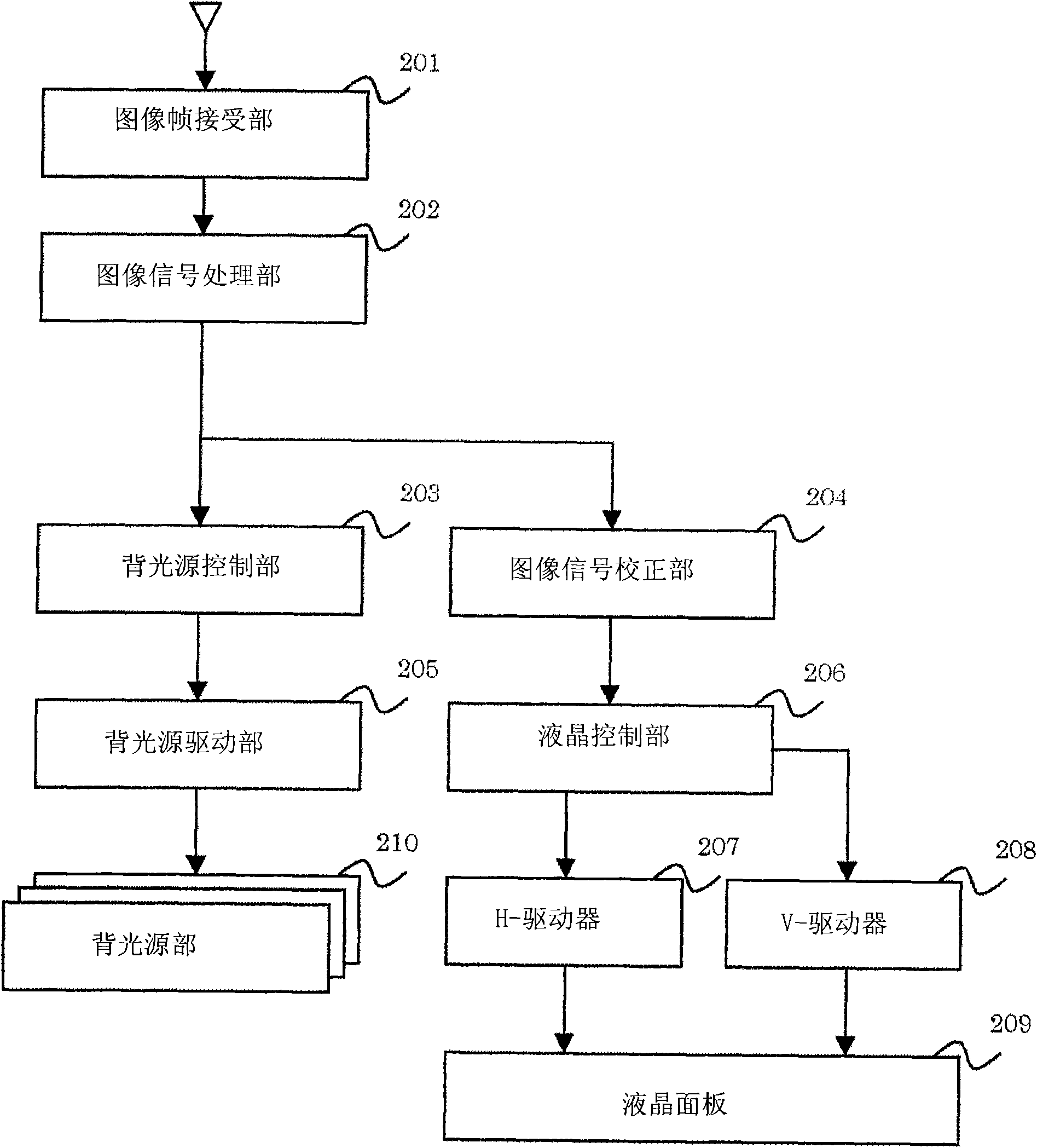

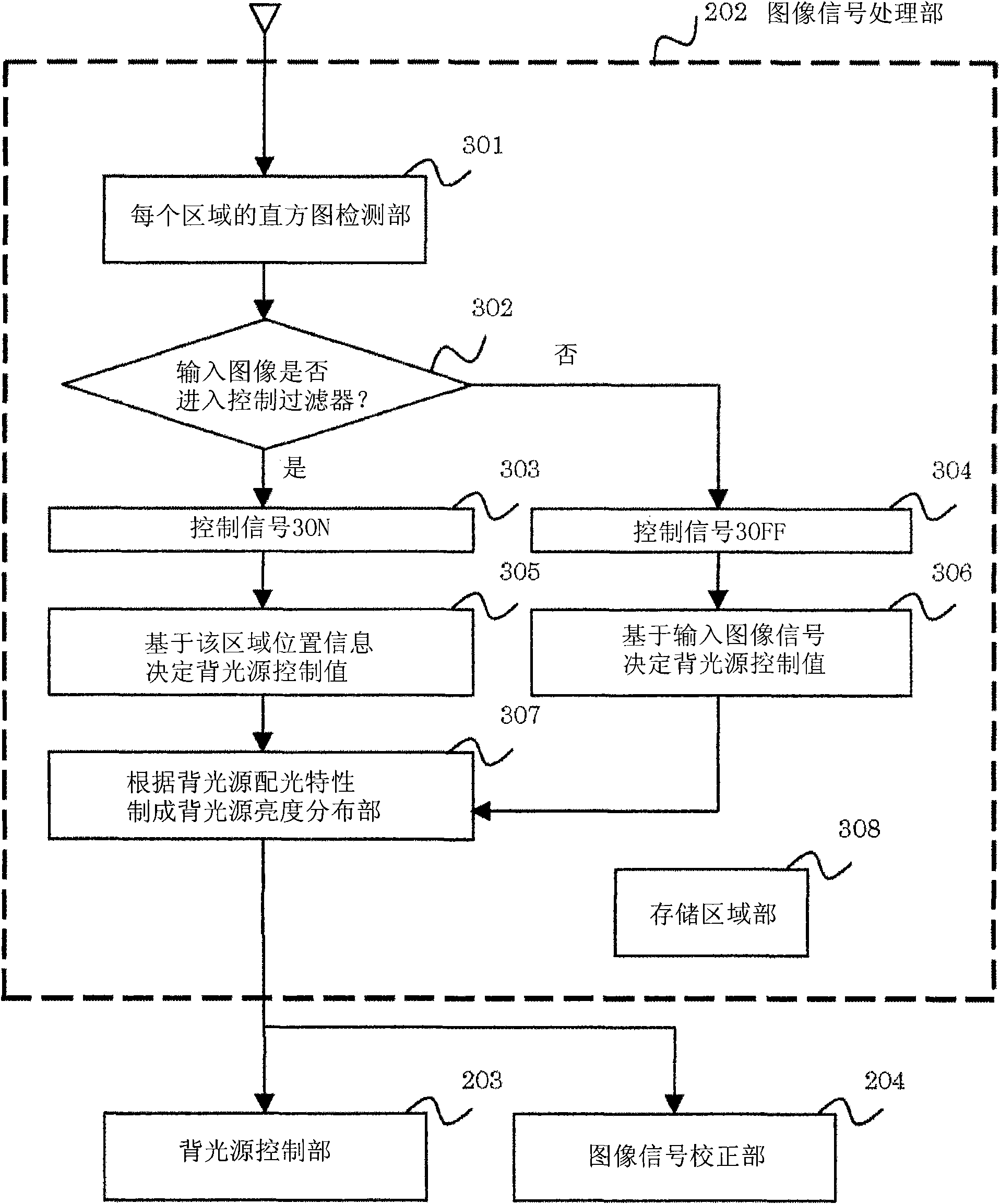

Video display apparatus

InactiveCN101794542AGreat power effectAvoid whiteningImage enhancementImage analysisComputer scienceElectric power

For the purpose of obtaining a video signal by suppressing a black float while not consuming an excess electric power therein, not contributing to display of a backlight, a video display apparatus having a plural number of backlights for irradiating lights upon a display panel, comprises a histogram detector for conducting a histogram detection for each display region corresponding to that backlight from an input video signal of one (1) frame, a means for determining a control value of that plural number of backlights depending on a specific picture or video, which is detected by the histogram detector, and a video signal processor for controlling an amount of a controlled light the display panel of a display region, i.e., a put-out region, depending on the backlight control value, which is determined by the means for determining the control value of the backlight.

Owner:HITACHI CONSUMER ELECTRONICS CORP

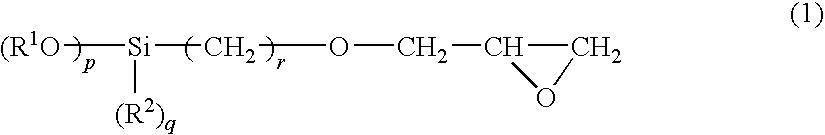

Water-resistant aluminum pigment, water-resistant aluminum pigment dispersion, aqueous ink composition containing the aforementioned, and method for producing water-resistant aluminum pigment dispersion

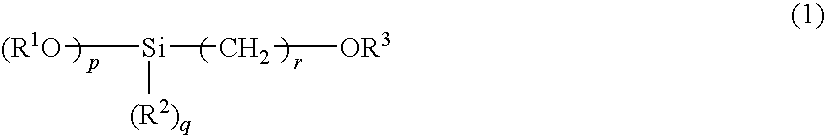

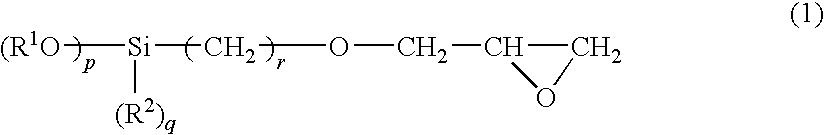

InactiveUS20100251929A1Good water dispersibilityAvoid whiteningMaterial nanotechnologyDuplicating/marking methodsOrganic solventPhosphate

A method for producing a water-resistant aluminum pigment dispersion includes (a) adding a treatment agent containing a compound of general formula (1) described below to an aluminum pigment dispersion containing aluminum pigment particles dispersed in an organic solvent and reacting a hydroxy group present on a surface of each of the aluminum pigment particles with the compound of general formula (1) described below to form a film on the surface of each aluminum pigment particle, (b) removing at least a portion of the organic solvent, and (c) adding an aqueous solution containing at least one selected from polyoxyethylene alkyl ether phosphate and salts thereof,(wherein p represents an integer of 1 to 3, q represents an integer that satisfies the equation p+q=3, r represents an integer of 2 to 10, R1 and R2 each independently represent an alkyl group having 1 to 4 carbon atoms, and R3 represents an acrylic group, an acryloyl group, or a methacryloyl group).

Owner:SEIKO EPSON CORP

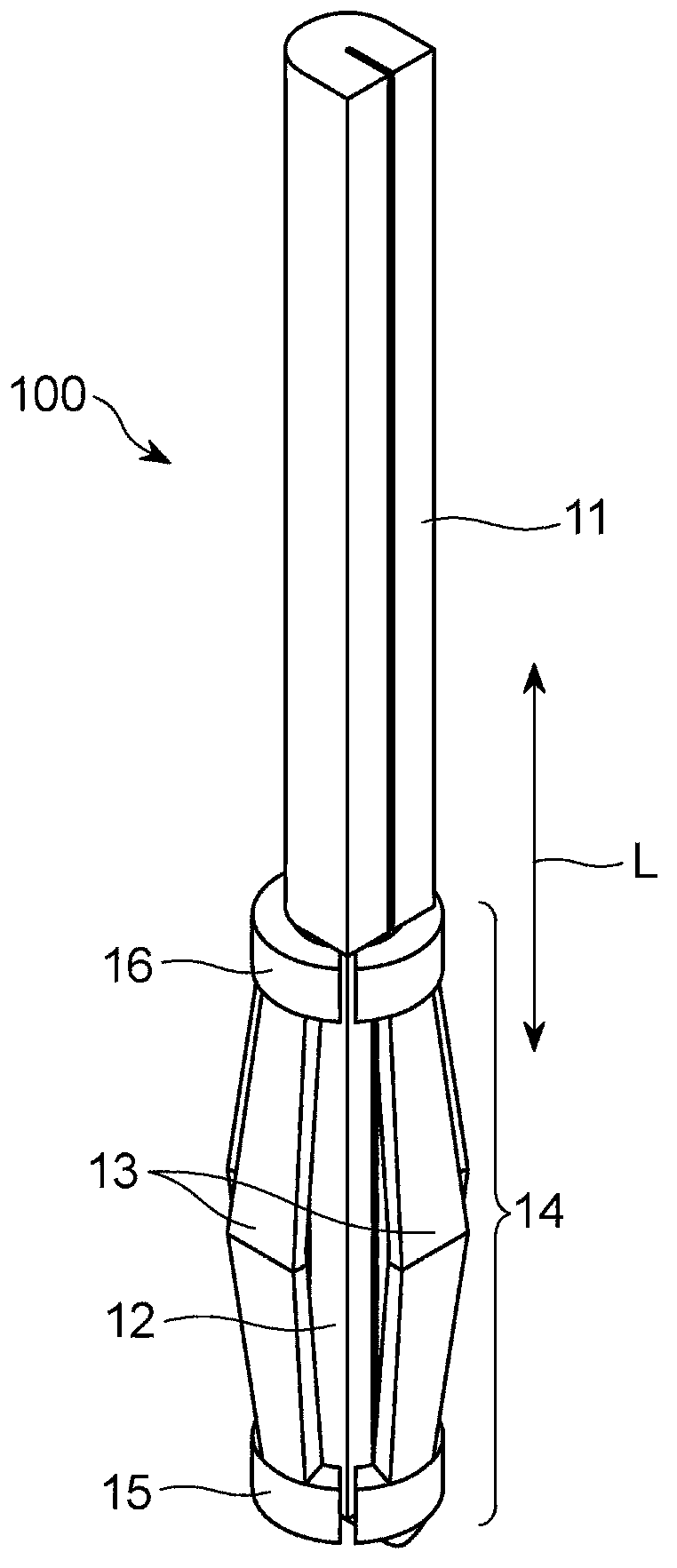

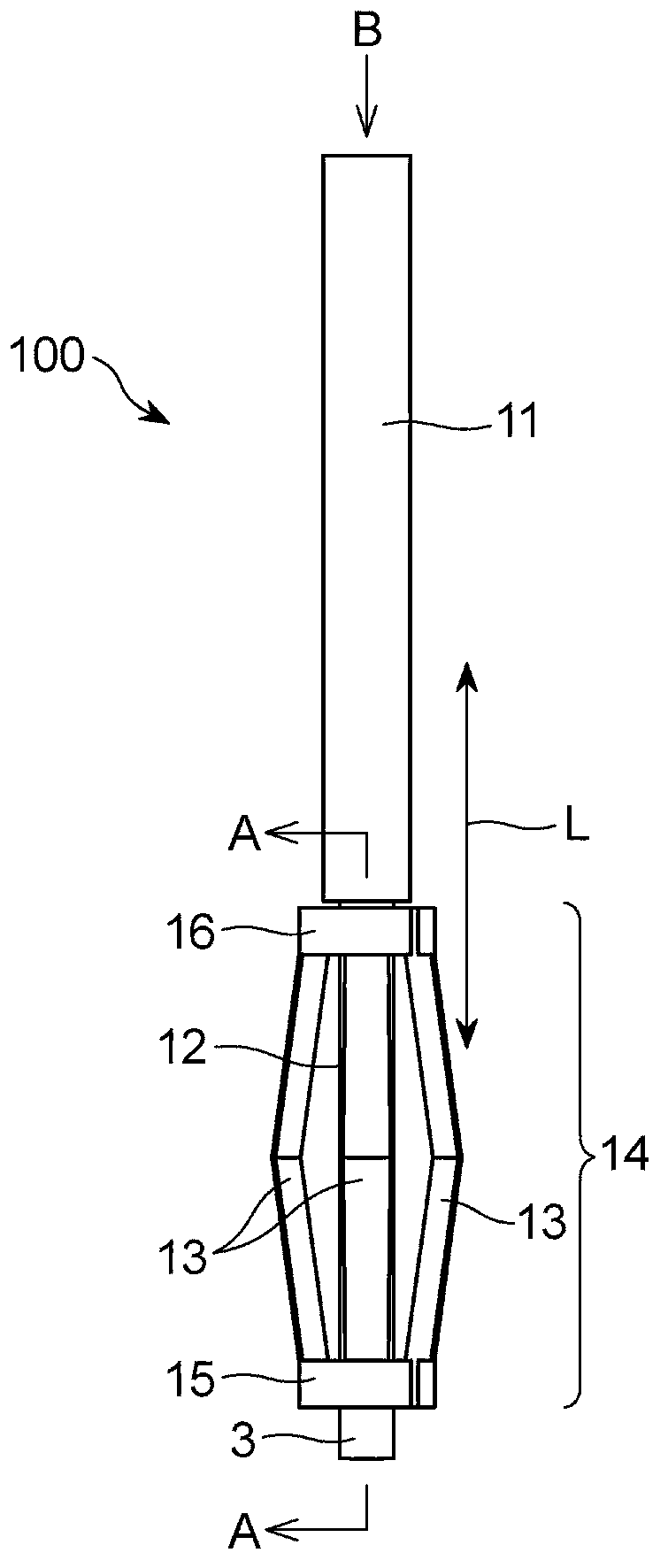

Press-fit type connector terminal

ActiveCN103311708AHigh yield strengthGood repeatabilityContact member manufacturingCoupling contact membersMechanical engineering

The press-fit type connector terminal includes a pin section having a U-shaped or quadrangular cross-section, and a contact section situated at a front end of the pin section. The contact section includes a contact piece surrounding an imaginary center line parallel to a longitudinal axis of the pin section, and a slit formed at a part of the contact piece and extending substantially parallel to the imaginary center line. The connector terminal is comprised of a single bent metal plate having elasticity.

Owner:DAIICHI SEIKO CO LTD

Pressure-sensitive adhesive composition

ActiveUS20130224436A1Reduce adhesionLow weight ratioLiquid surface applicatorsDecorative surface effectsDisplay devicePressure sensitive

Owner:LG CHEM LTD

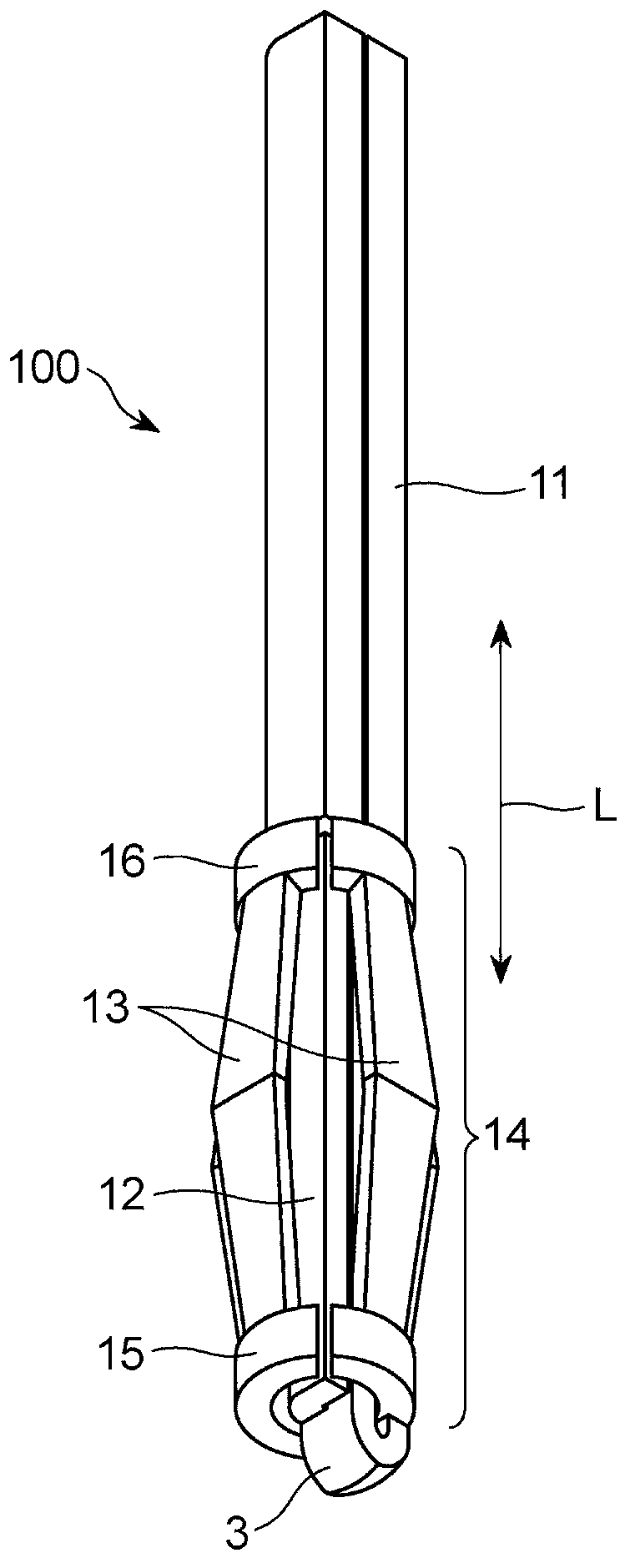

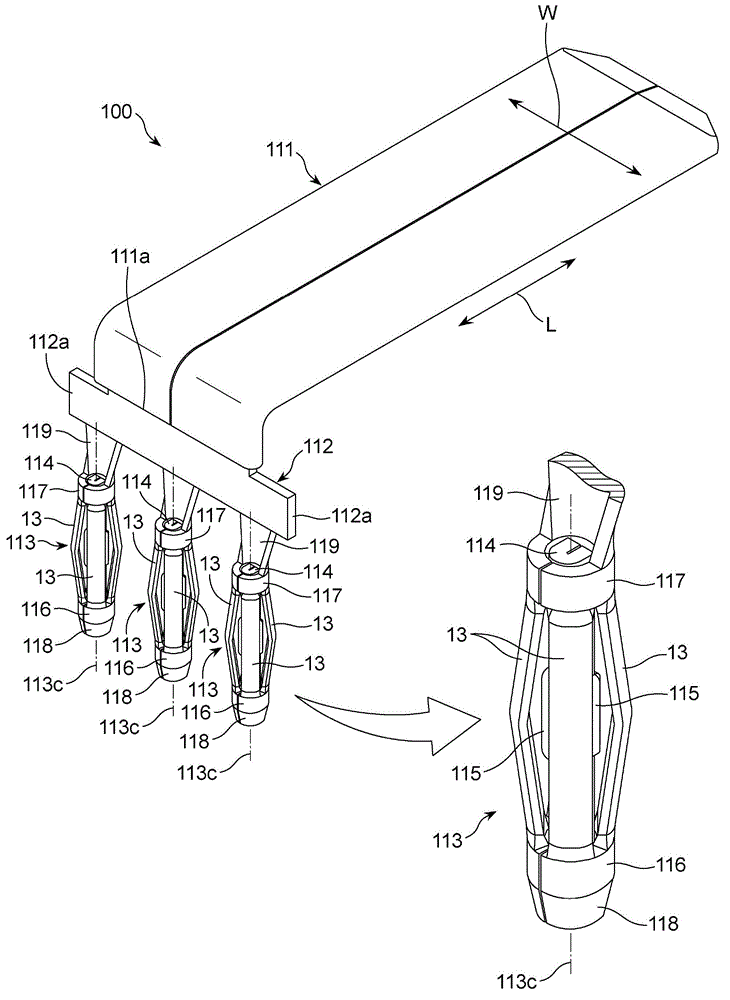

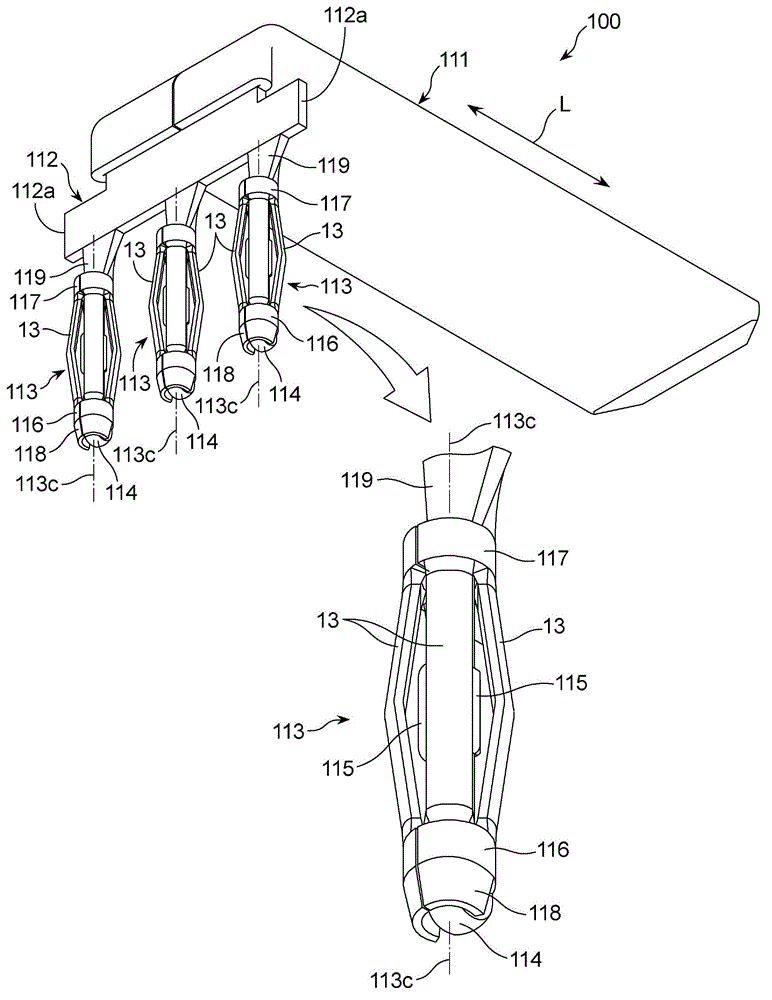

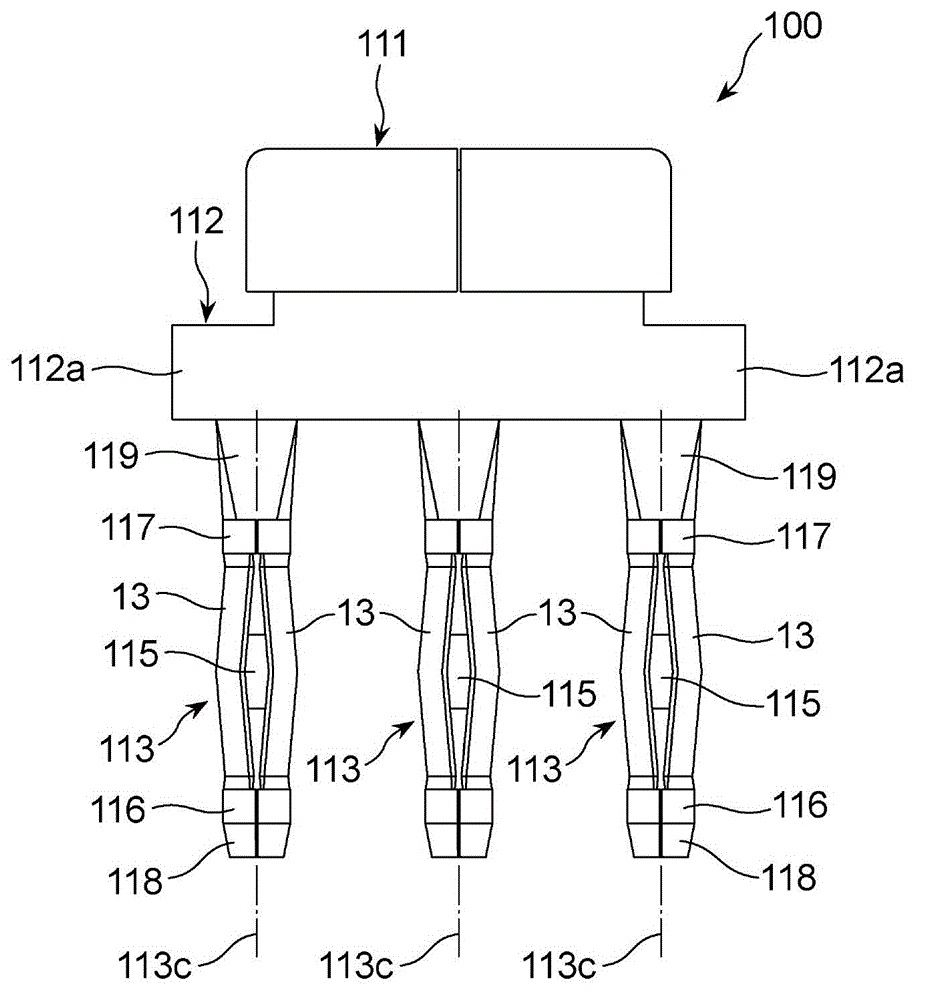

Press-fit type connector terminal

InactiveCN103337728AAvoid whiteningAvoid plastic deformationCoupling contact membersFixed connectionsEngineeringMechanical engineering

The press-fit type connector terminal includes a pin section in the form of a flat plate, and a plurality of contact sections situated continuous to a front end of the pin section, each of the contact sections including a contact piece being in the form of a barrel or a spindle surrounding an imaginary center line, the contact piece being formed with a slit extending substantially parallel to the imaginary center line, the connector terminal being comprised of a single bent metal plate having elasticity.

Owner:I PEX CO LTD

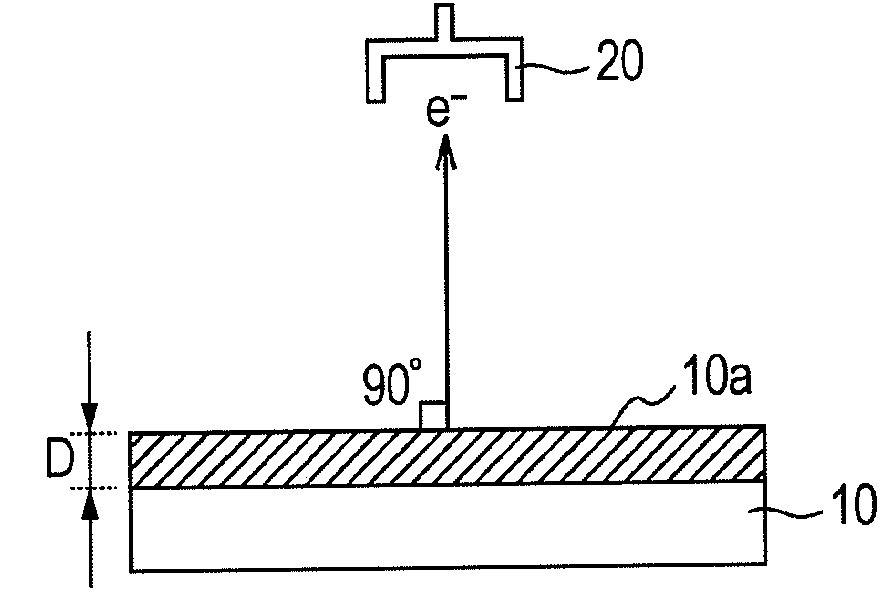

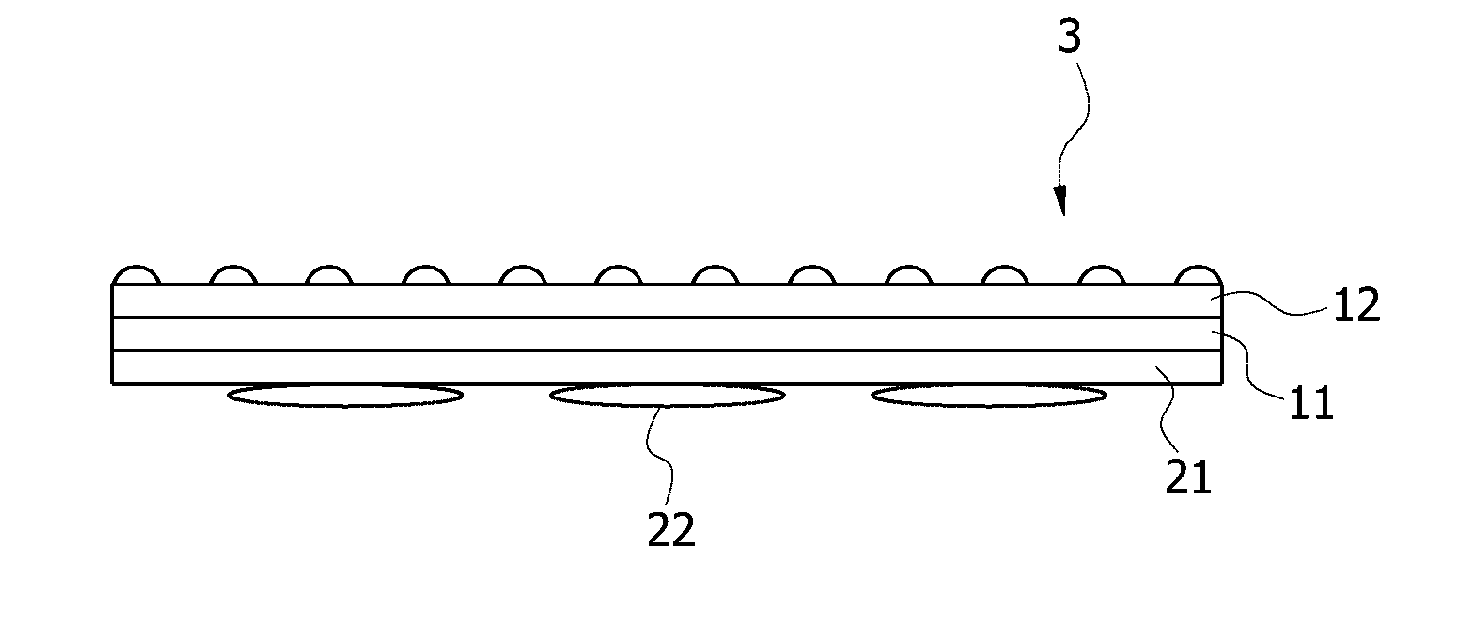

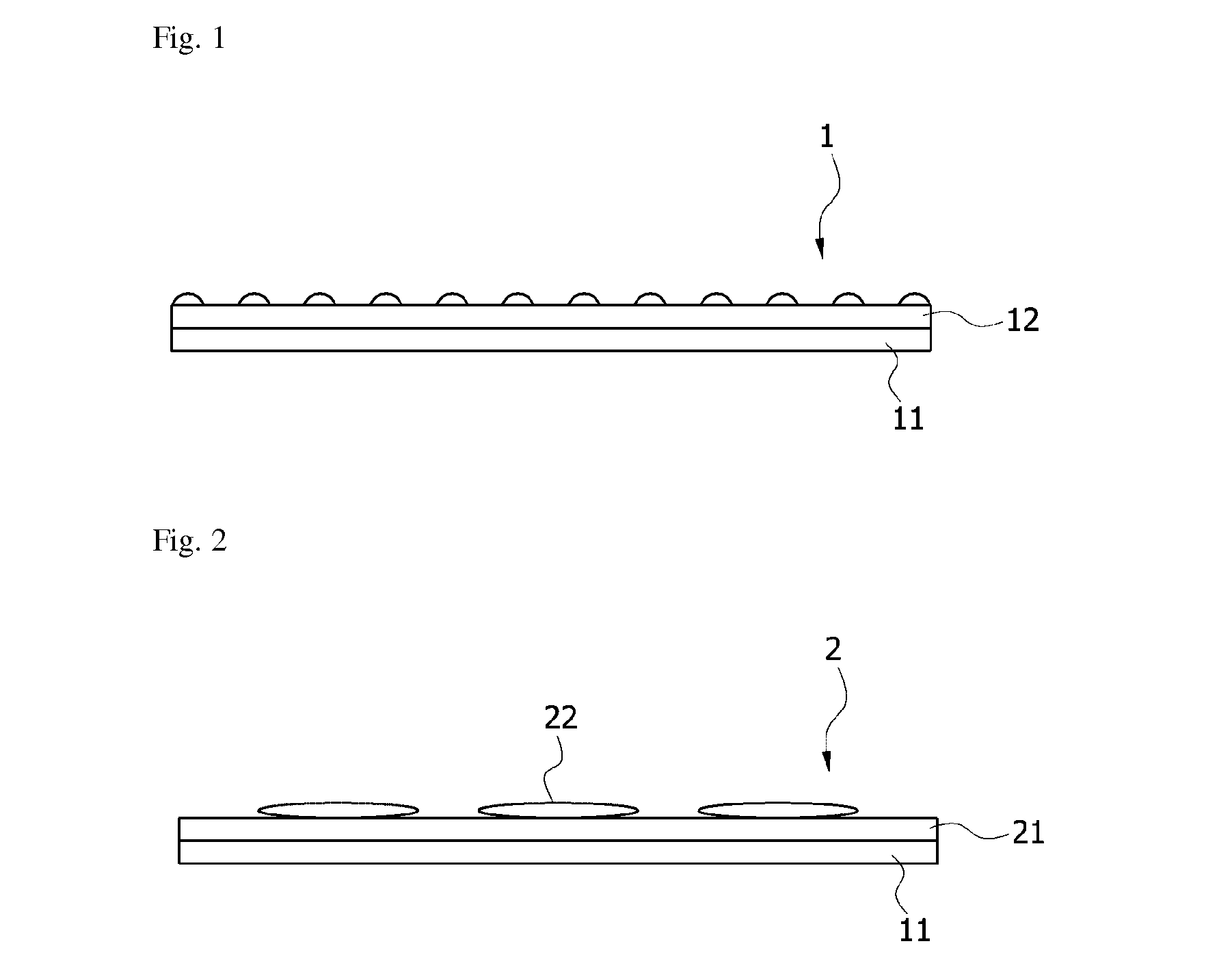

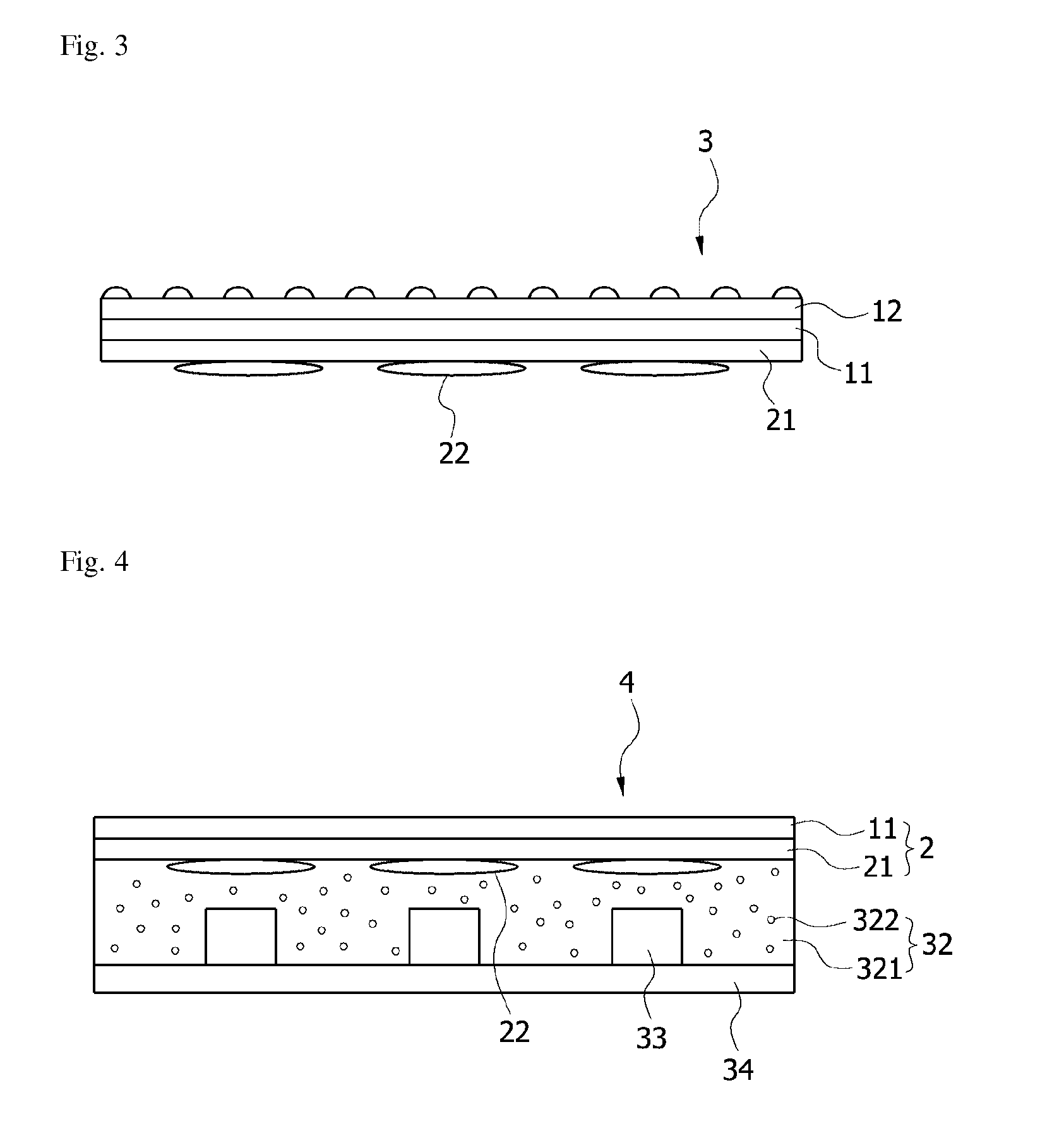

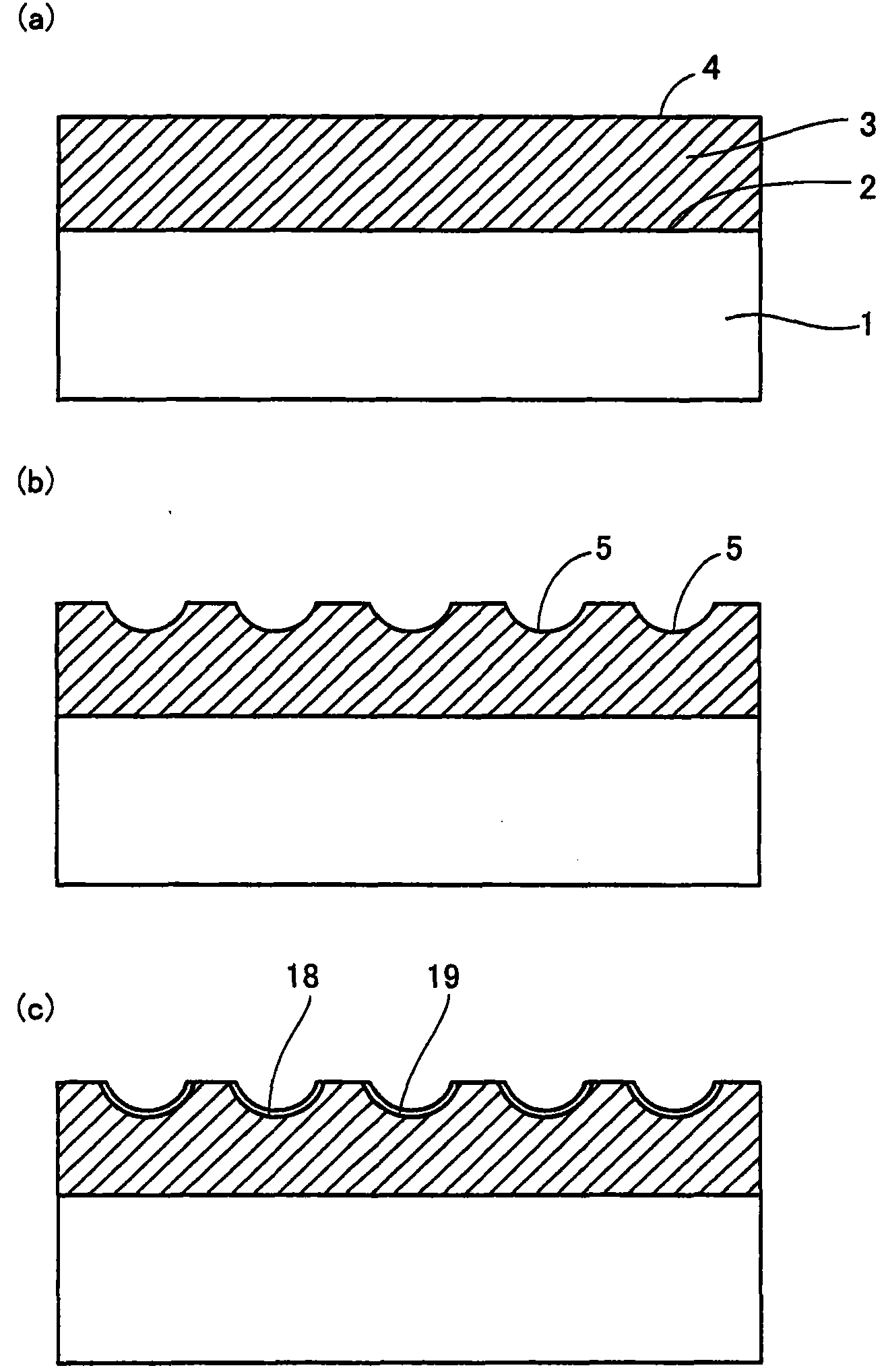

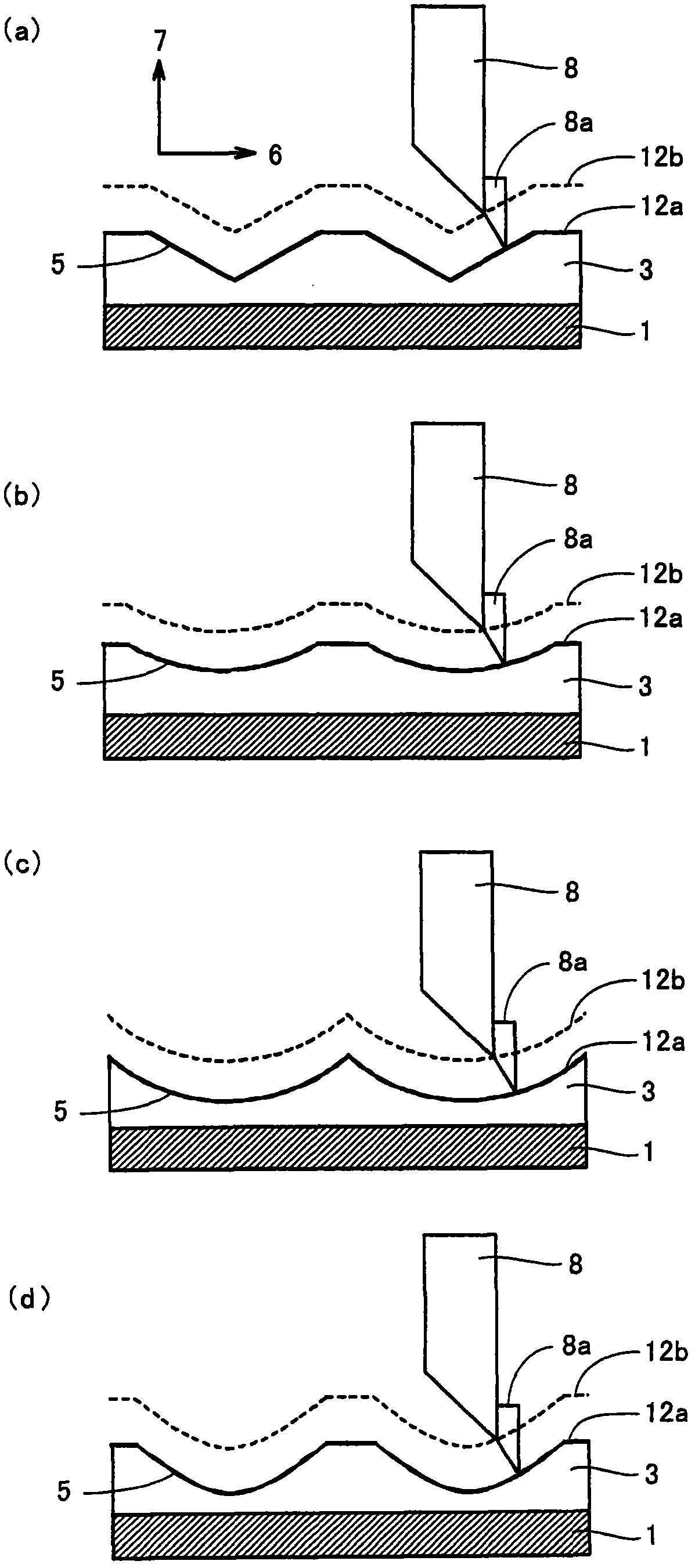

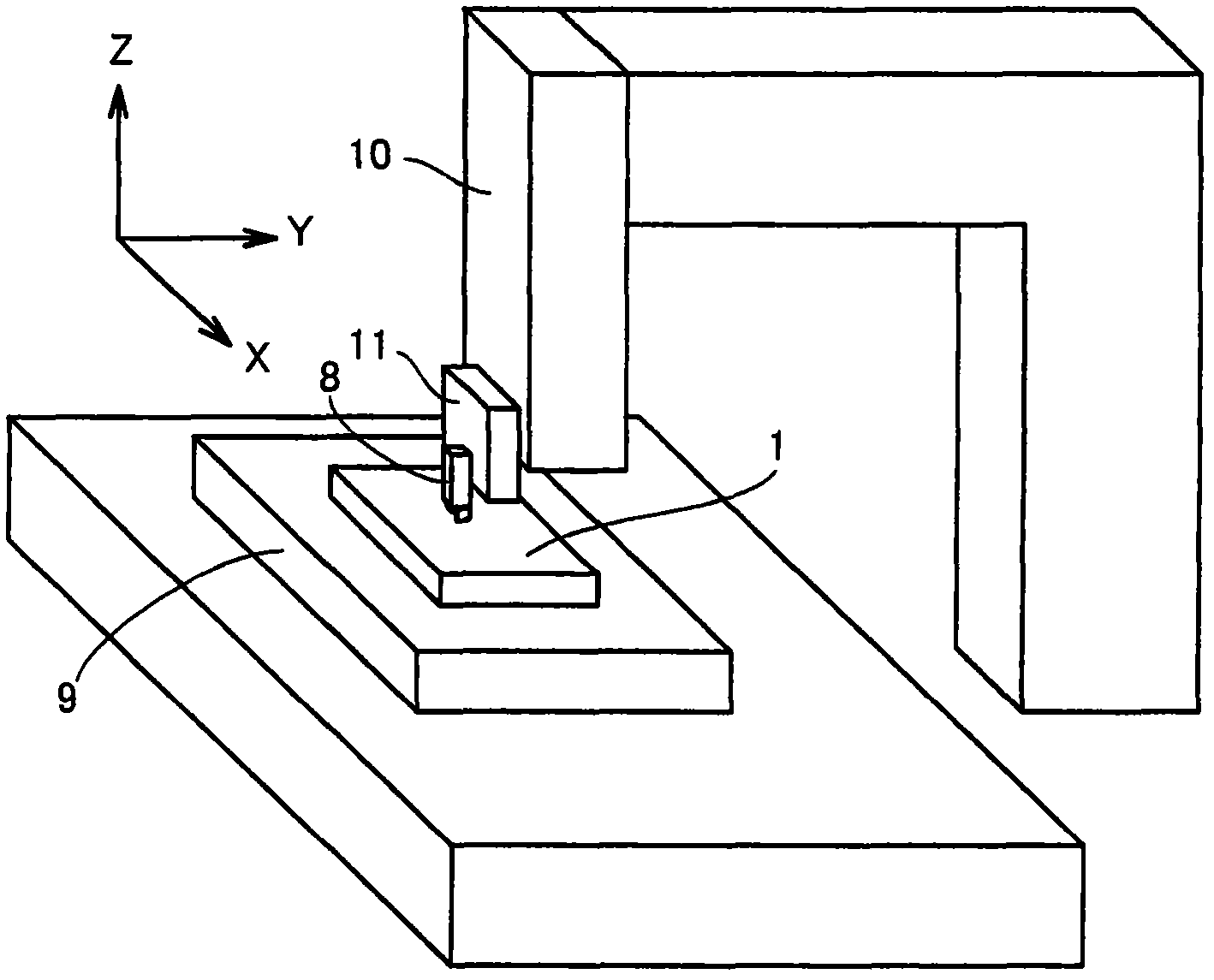

Method of manufacturing antiglare film and method of manufacturing mold thereof

InactiveCN102009329AReduce contrastLow anti-glareOptical articlesMetallic material coating processesTectorial membraneCopper plating

The present invention provides a method of manufacturing a mold for manufacturing an antiglare film with a fine convex-concave shape. The method comprises the following steps: a plating step of implementing copper plating or nickel plating on a surface of a substrate for the mold, a mirror surface processing step of implementing at least one selected from cutting and grinding on the surface which is implemented with copper plating or nickel plating through the plating step for forming a mirror surface with a surface roughness smaller than 0.1 mu m, a fine dent part forming step of forming a plurality of fine dent parts on the surface after mirror surface processing through cutting, and a protective film forming process of forming a protective film on the surface with the formed fine dent parts, wherein the cutting to the plurality of fine dent parts is performed through a cutting tool in the fine dent part forming step. The cutting tool moves linearly relatively to a direction which is parallel with a surface of the substrate for the mold and performs fine reciprocation in a direction that is vertical with the surface of the substrate for the mold, so the average most adjacent distance between the fine dent parts being cut, and the cutting depth satisfy a certain condition.

Owner:SUMITOMO CHEM CO LTD

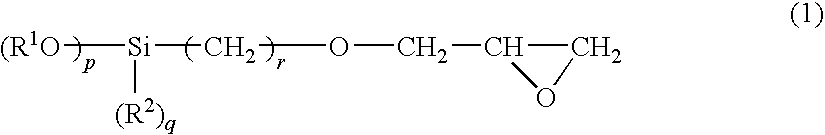

Method for producing water-repellent treated aluminum pigment dispersion, water-repellent treated aluminum pigment, and aqueous ink composition containing the same

InactiveUS20100242789A1PreventedGood water dispersibilityInksPigment treatment with organosilicon compoundsGlycylxylidideProduced water

A method for producing water-repellent treated aluminum pigment dispersion includes (a) adding a glycidyl group-containing compound represented by the following formula (1) to an aluminum pigment dispersion in which an aluminum pigment is dispersed in an organic solvent for reacting a hydroxyl group present on the surface of the aluminum pigment with the glycidyl group-containing compound represented by the formula (1) to form a covering layer on the surface of the aluminum pigment:(in the formula, p represents an integer of 1 to 3, q represents an integer that satisfies a relation of p+q=3, r is an integer of 2 to 10, and R1 and R2 independently represent an alkyl group having 1 to 4 carbon atoms).

Owner:SEIKO EPSON CORP

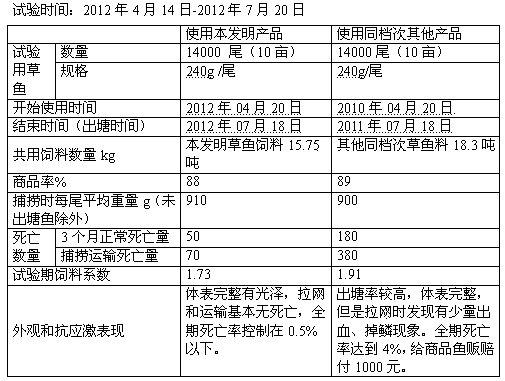

Mixed feed for improving stress resistance of grass carp

InactiveCN103504153AImprove utilization efficiencyAlleviate protein excessAnimal feeding stuffStress inducedAntioxidant

The invention relates to a mixed feed for improving stress resistance of grass carp, which can significantly reduce the stress-induced death of grass carp and increases the farming benefit. The mixed feed comprises the following materials in parts by weight: 160-200 parts of bean cake, 250-300 parts of rapeseed cake, 160-200 parts of flour, 100-140 parts of cotton cake, 40-50 parts of fish meal, 70-120 parts of cornstalk full ethyl alcohol grains, 20-25 parts of calcium dihydrogen phosphate, 15-20 parts of edible fat and oil, 1-2 parts of 50% of coated choline chloride, 0.05-0.15 part of high temperature-resistant complex enzyme preparation, 1-2 parts of complex microelements, 2-3 parts of 40% of coated lysine, 1-1.2 parts of vitamin complex for freshwater fish, 0.08-0.12 part of L-carnitine and 0.2-0.5 part of an antioxidant.

Owner:陕西华秦农牧科技有限公司

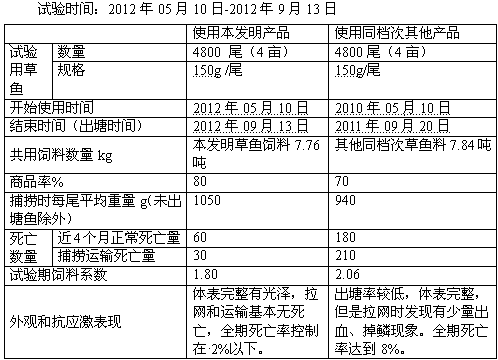

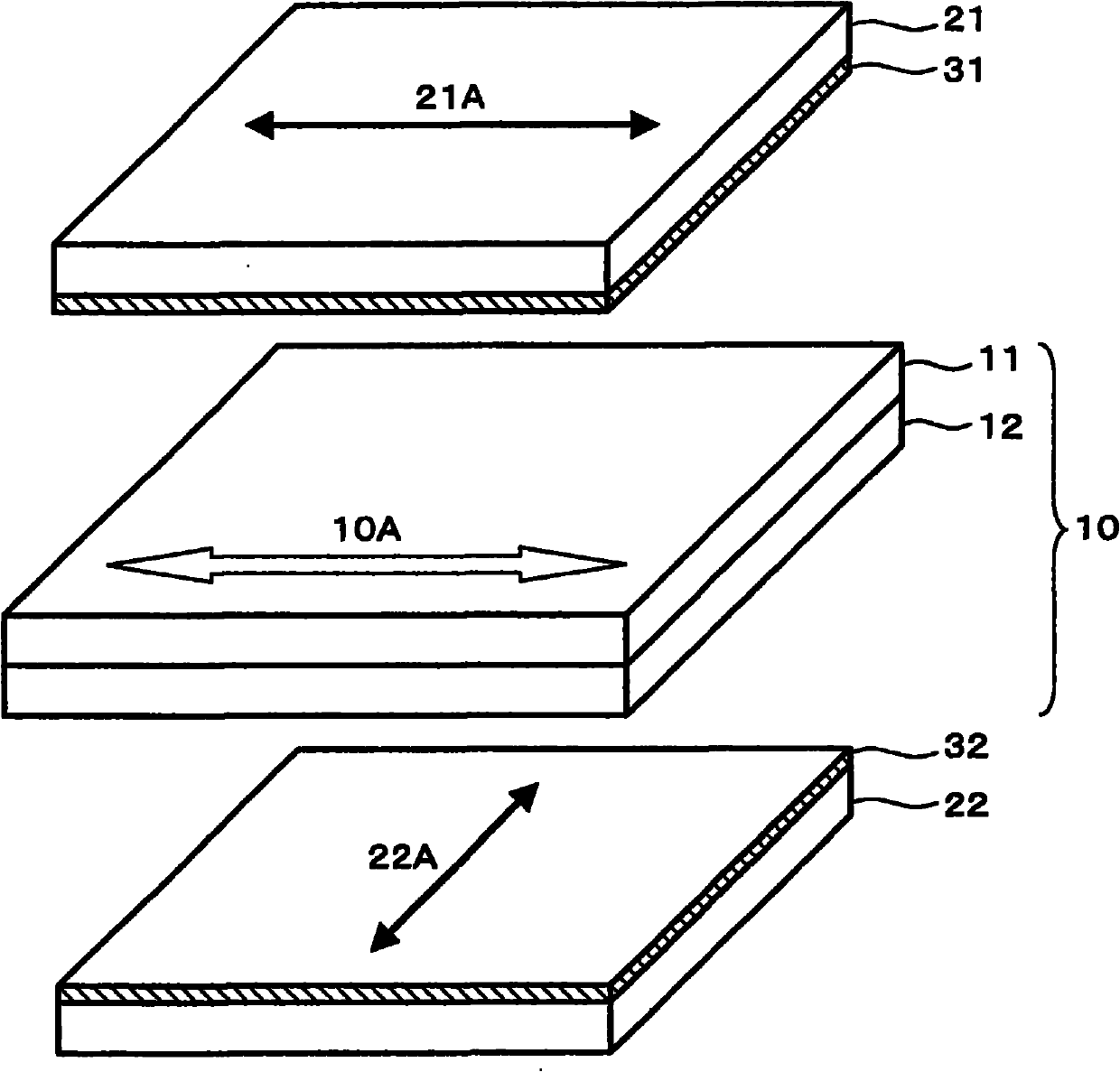

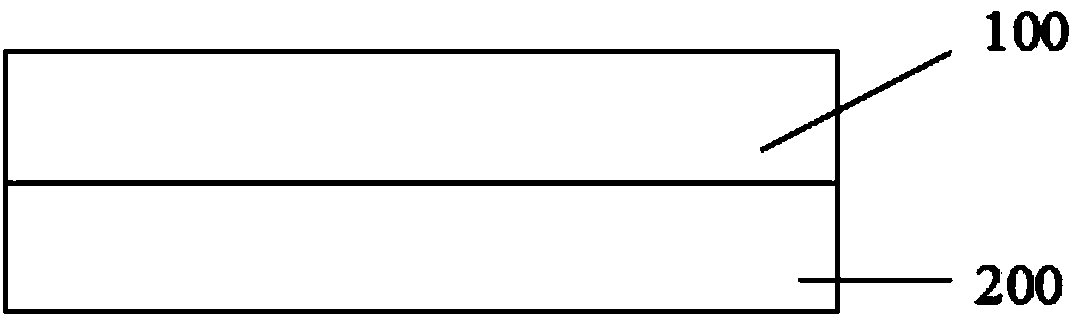

A liquid crystal panel

ActiveCN102033355APrevent optical defectsInhibit whiteningFilm/foil adhesivesPolarising elementsAcrylic resinPolarizer

The present invention provides a liquid crystal panel which is obtained through: adhibiting a first polarizing sheet (21) to one surface of a liquid crystal unit (10) through a first adhesive layer (31) with a mode that an absorption axis (21A) is parallel with a long edge (10A) of a liquid crystal unit, and adhibiting a second polarizing sheet (22) to the other surface of the liquid crystal unit (10) through a second adhesive layer (32) with a mode that an absorption axis (22A) is orthogonal with the absorption axis (21A) of the first polarizing sheet. At least one layer selected from the adhesive layers (31,32) is composed of the adhesive composition. The adhesive composition comprises 100 weight parts of acrylic resin (A) and 0.01-5 weight parts of crosslinking agent (B), wherein the acrylic resin is obtained through copolymerizing 80-96% by weight of (methyl)alkyl acrylate, 3-15% by weight of aromatic ring monomer and 0.1-15% by weight of polar functional groups and has 1000,000-2000,000 of weight average molecular weight and 3-7 of molecular weight distribution. The gel fractions of the adhesive layers are set to 60-99wt%. According to the liquid crystal panel, two surfaces of the liquid crystal unit are respectively adhibited with a pair of polarizing sheet through the adhesive layer. The liquid crystal panel can restrain white discharge even when size is enlarged.

Owner:SUMITOMO CHEM CO LTD

Method for producing water-repellent treated aluminum pigment dispersion, water-repellent treated aluminum pigment, and aqueous ink composition containing the same

ActiveUS8088859B2Excellent in water dispersibility and metallic glossAvoid whiteningDuplicating/marking methodsInksOrganic solventPolysilazane

A method for producing water-repellent treated aluminum pigment dispersion includes (a) adding a polysilazane solution in which a polysilazane is dissolved in a second organic solvent to an aluminum pigment dispersion in which an aluminum pigment is dispersed in a first organic solvent for reacting a hydroxyl group present on the surface of the aluminum pigment with the polysilazane to form a covering film on the surface of the aluminum pigment. The amount of the polysilazane in the reaction system for forming the covering film is 0.4 parts by mass or less based on 1 part by mass of the aluminum pigment, and the total addition amount of the polysilazane is from 0.2 to 0.6 parts by mass based on 1 part by mass of the aluminum pigment.

Owner:SEIKO EPSON CORP

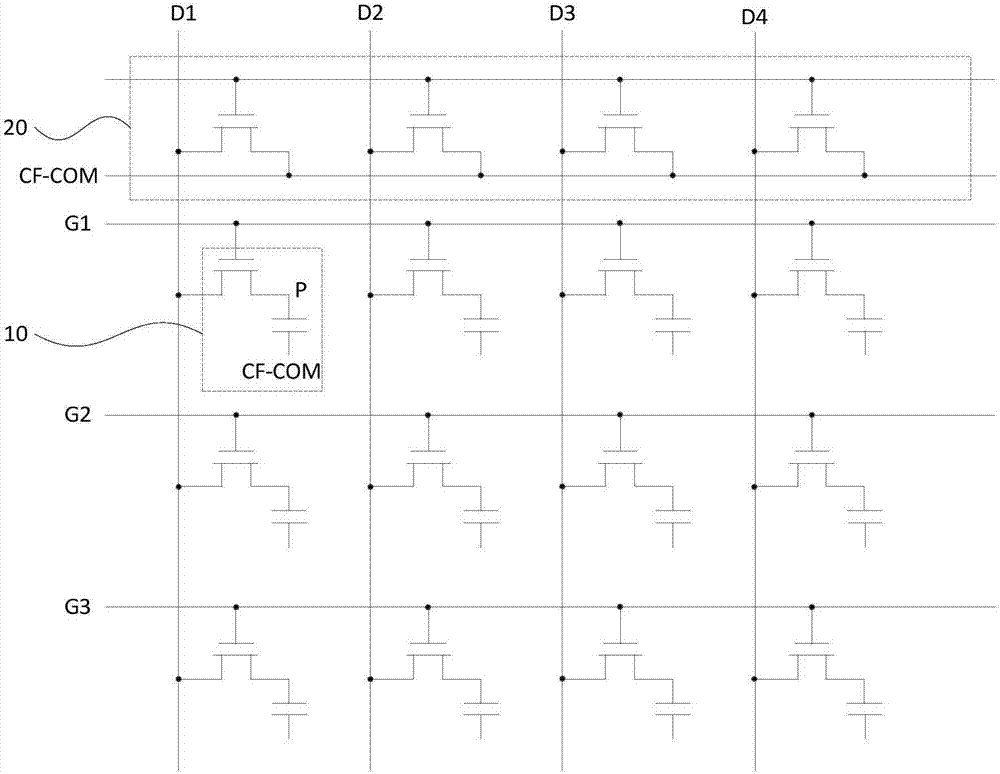

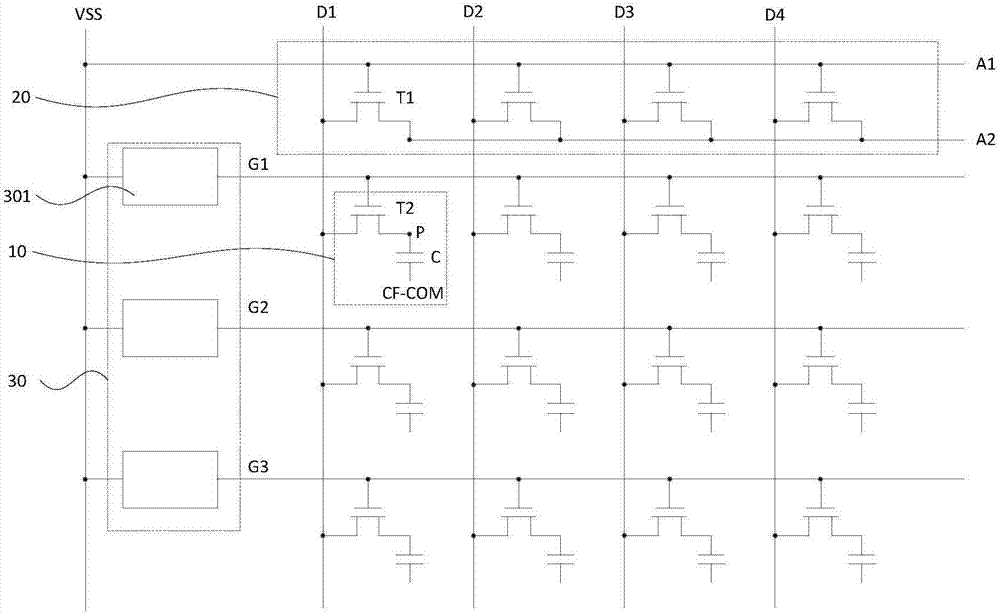

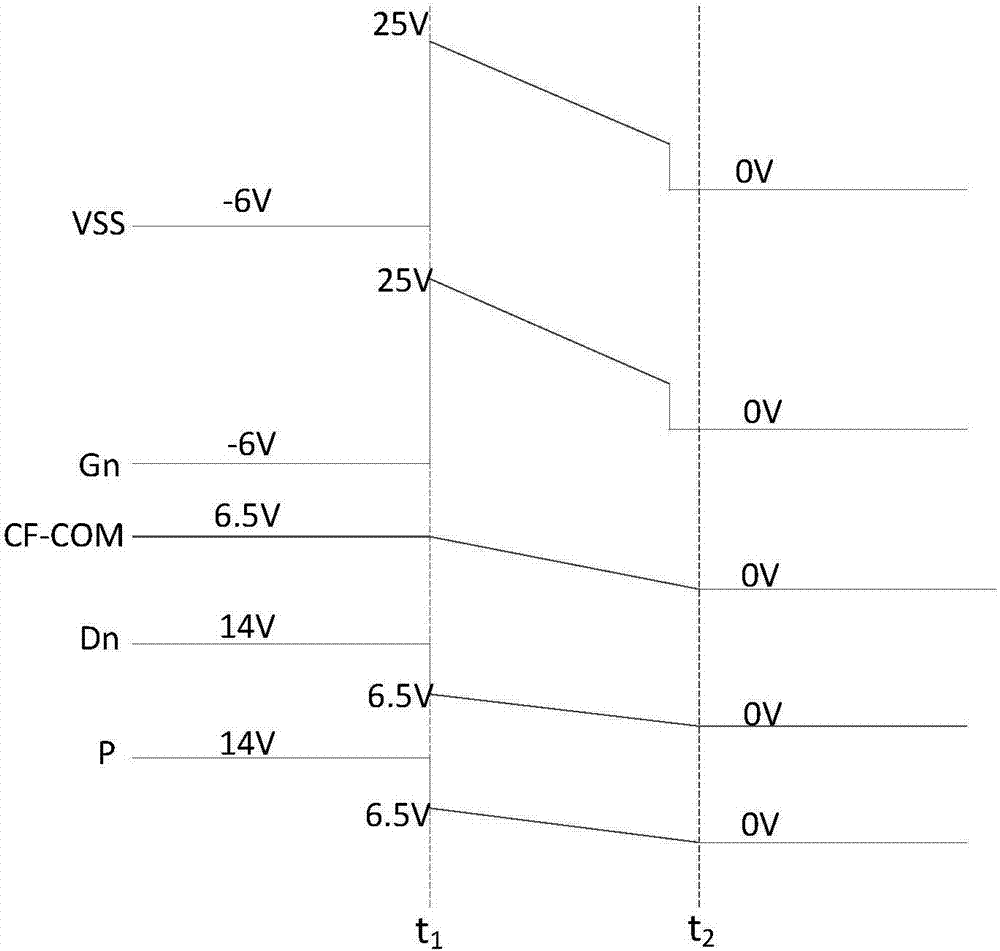

Array substrate and display panel

InactiveCN107193168AAvoid whiteningNo deflectionStatic indicating devicesNon-linear opticsControl circuitLiquid crystal

The invention discloses an array substrate and a display panel. The array substrate comprises multiple scanning lines, data lines arranged to be crossed with the scanning lines so as to define multiple pixel areas and a control circuit which is connected with multiple data lines and used for making voltage on the data lines equal to that of a common electrode during shutdown and making voltage of pixel electrodes in the pixel areas equal to that of the data lines. Accordingly, the voltage difference between the pixel electrodes in the pixel areas and the common electrode during shutdown can be balanced, liquid crystals do not deflect, and white ghosting of a screen is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

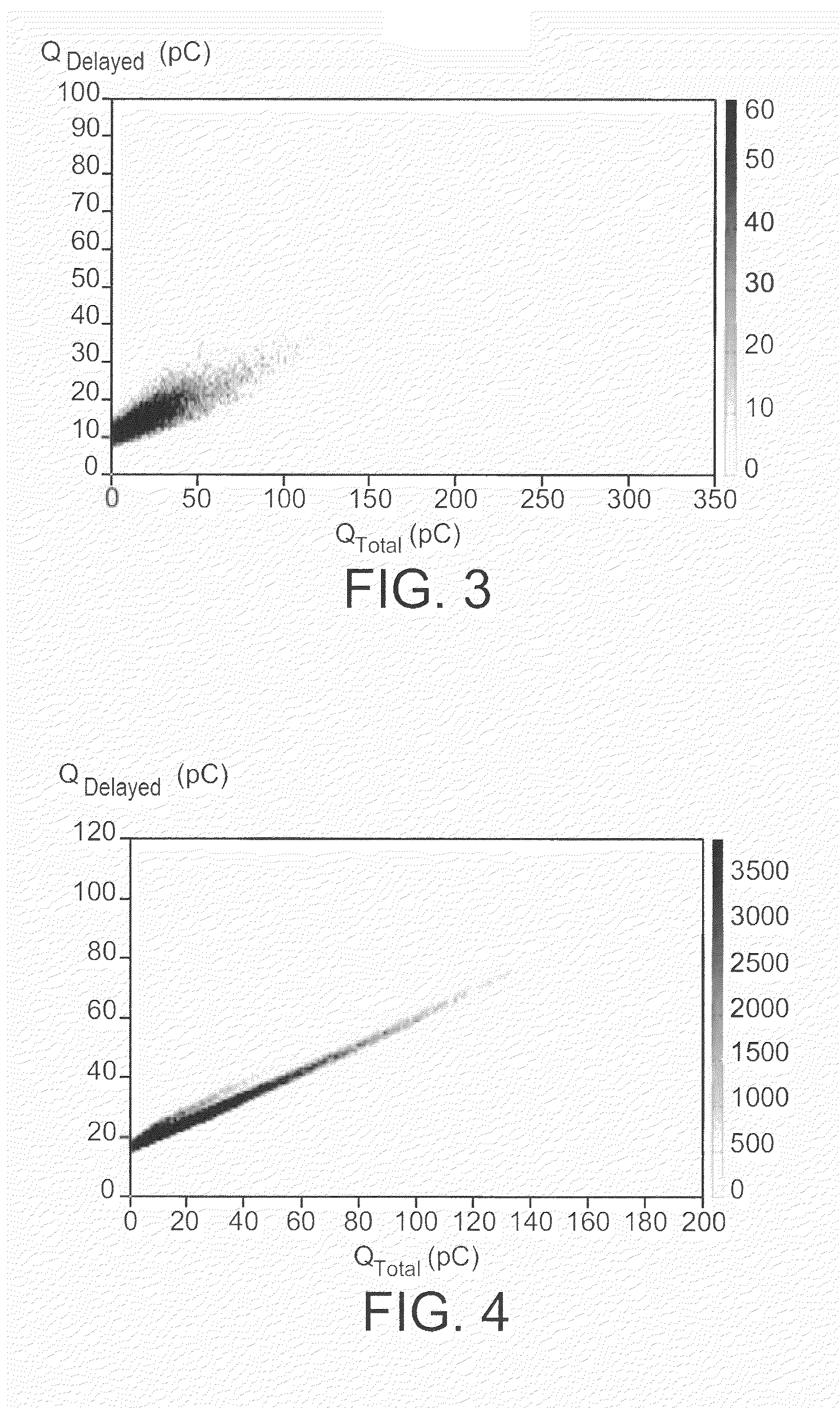

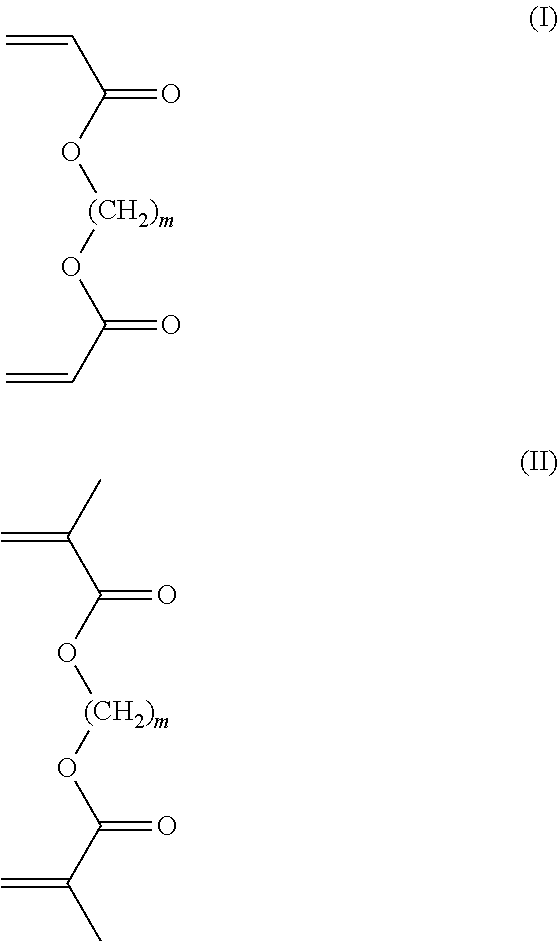

Plastic scintillator materials, plastic scintillators comprising such materials and method for distinguishing neutrons from gamma rays using said scintillators

ActiveUS20160017220A1Improve discriminationImprove rigidityMeasurement with scintillation detectorsMaterial analysis by optical meansCross-linkFluorescence

A plastic scintillator material comprising a polymeric matrix into which is Incorporated at least the one fluorescent compound at a mass concentration greater than or equal to 10% by mass of the total mass of the material, wherein the polymeric matrix consists of a crosslinked polymer obtainable by polymerization of a mixture comprising at least one aromatic monomer and at least one monomer playing the role of a cross-linking agent selected from among alkyl diacrylates, alkyl dimethacrylates, and mixtures thereof, the molar proportions of the monomer playing the role of a crosslinking agent and of the aromatic monomer in the mixture being from 10% to 50% and from 90% to 50%, respectively.A plastic scintillator prepared by shaping said material.A method for discriminating a signal due to fast neutrons, optionally a signal due to thermal neutrons, and a signal due to gamma rays in radiation comprising fast neutrons, optionally thermal neutrons, and gamma rays emitted by a mixed source, wherein the plastic scintillator is exposed to said radiation emitted by the mixed source and the signal due to fast neutrons is separated from the signal due to gamma rays, and optionally from the signal due to thermal neutrons by pulse shape discrimination (PSD).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

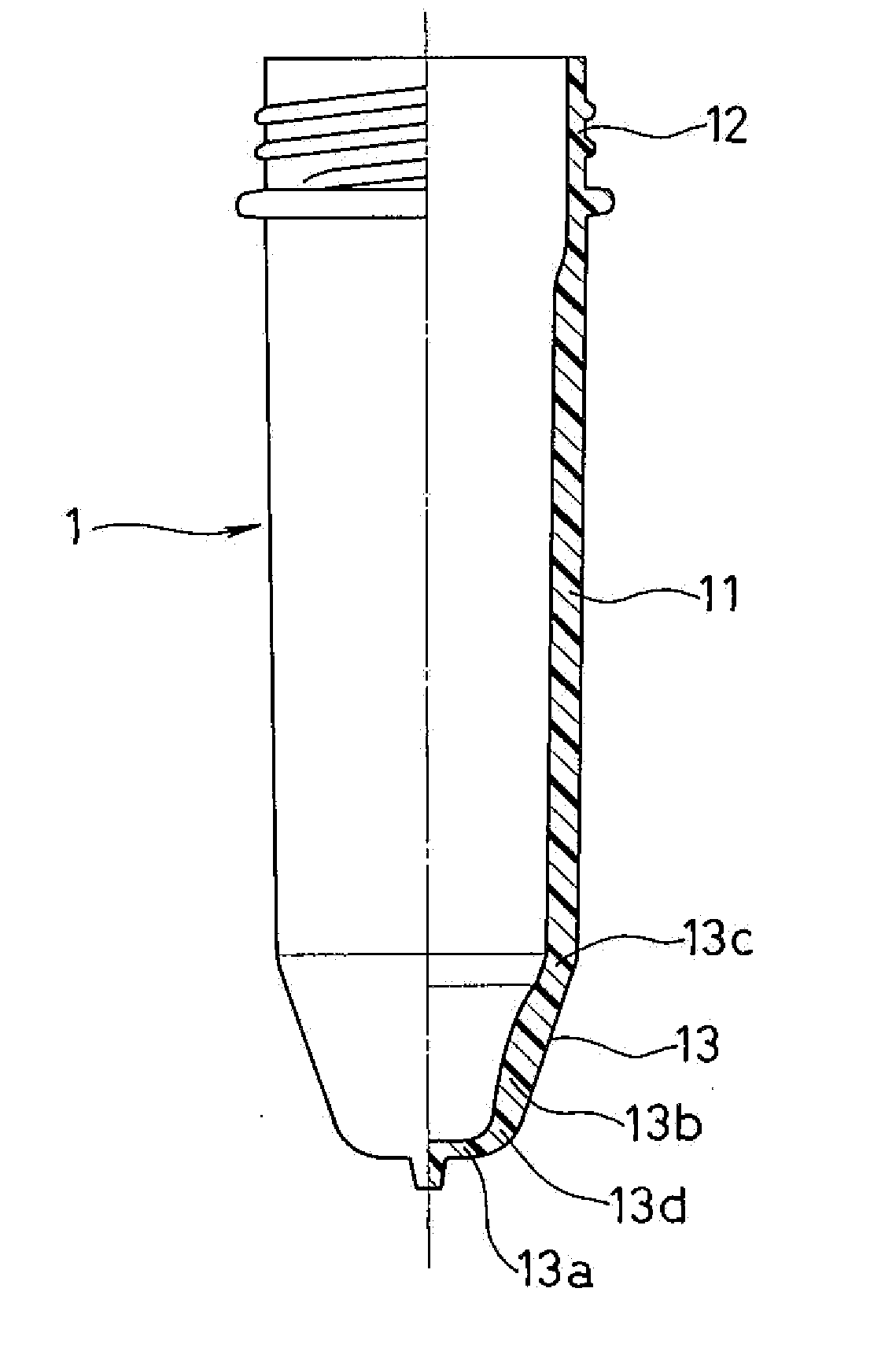

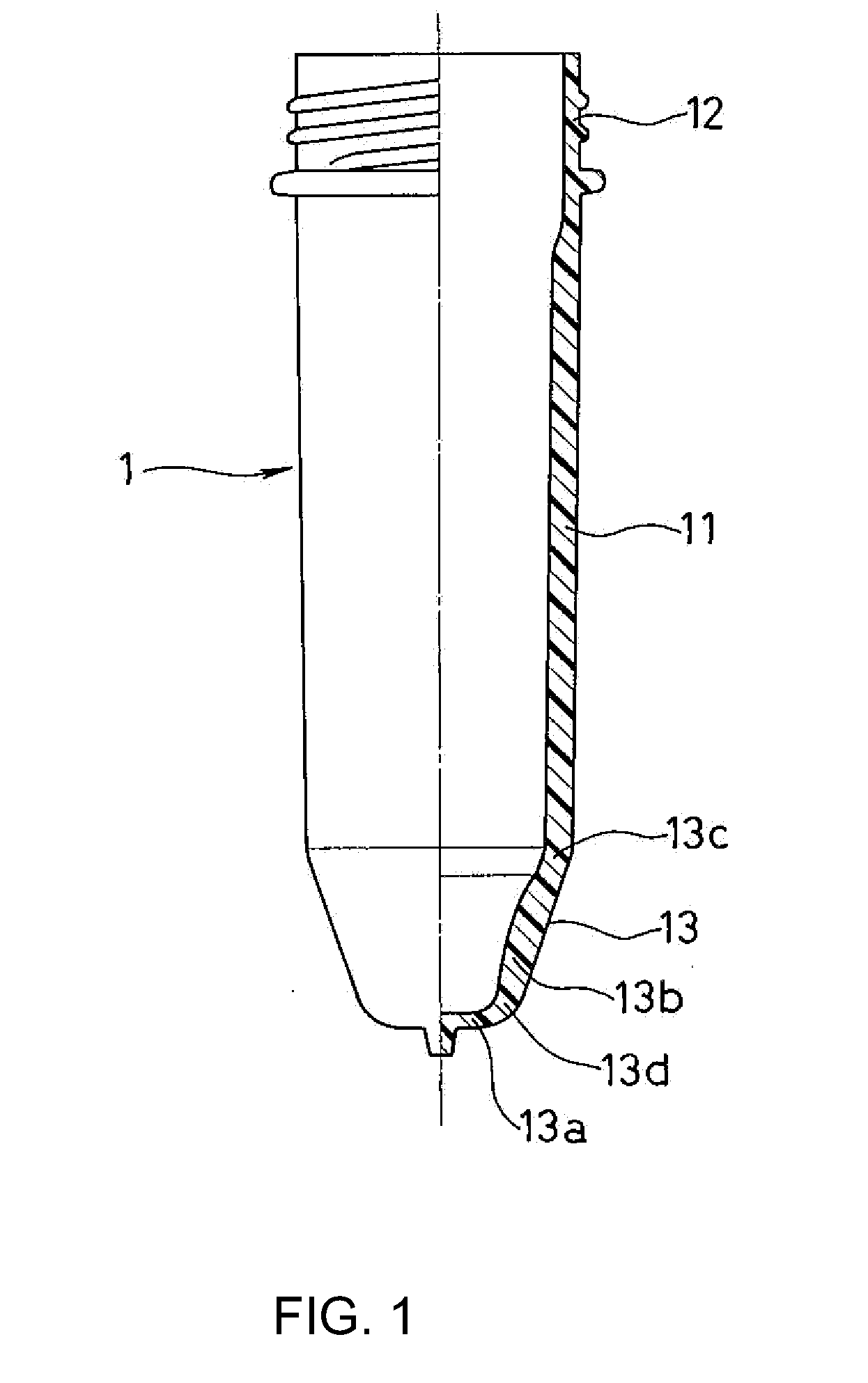

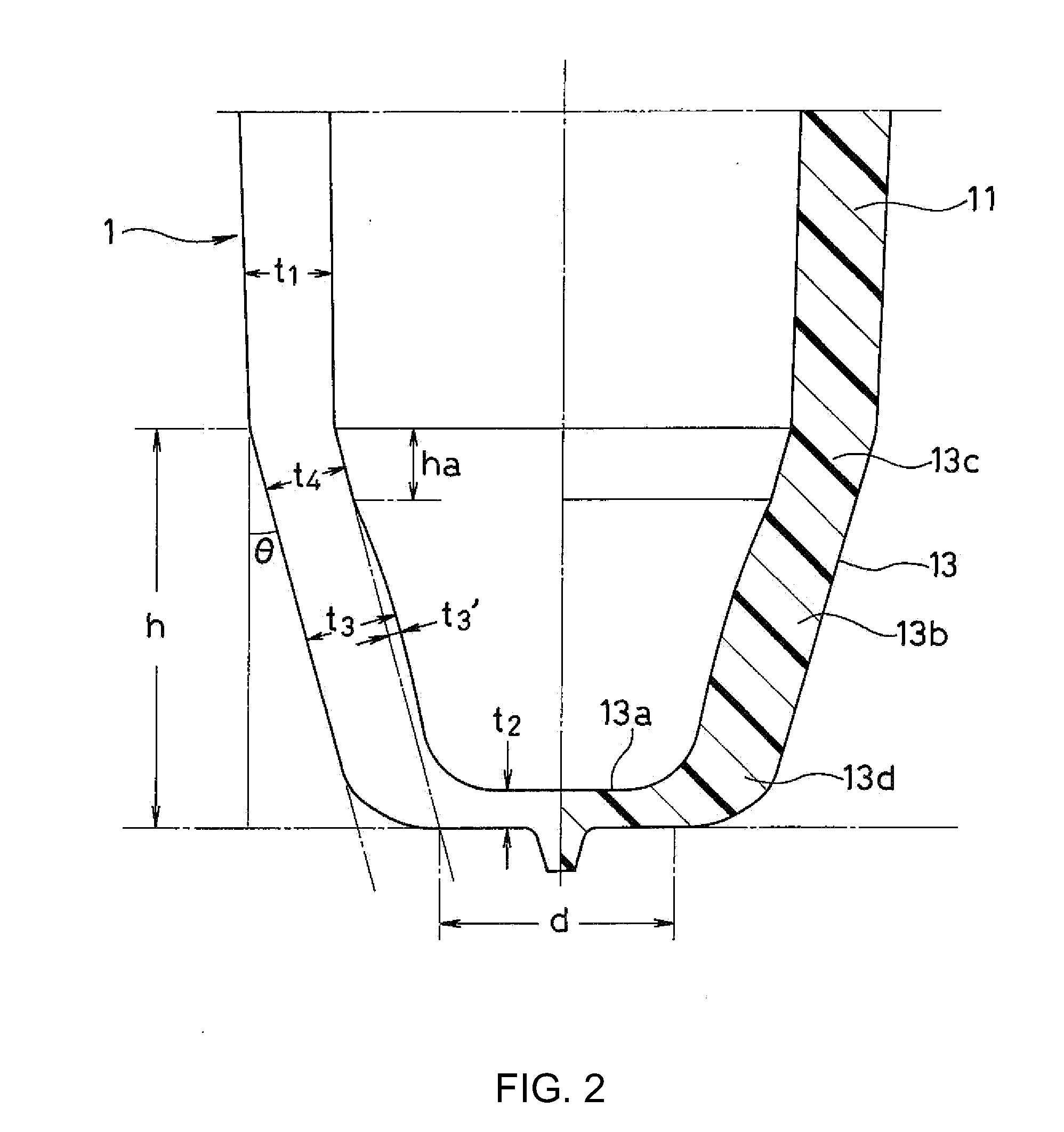

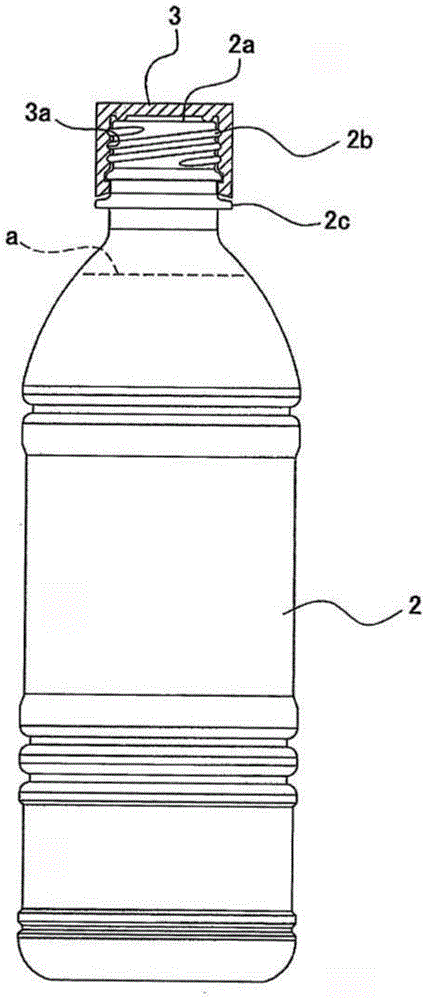

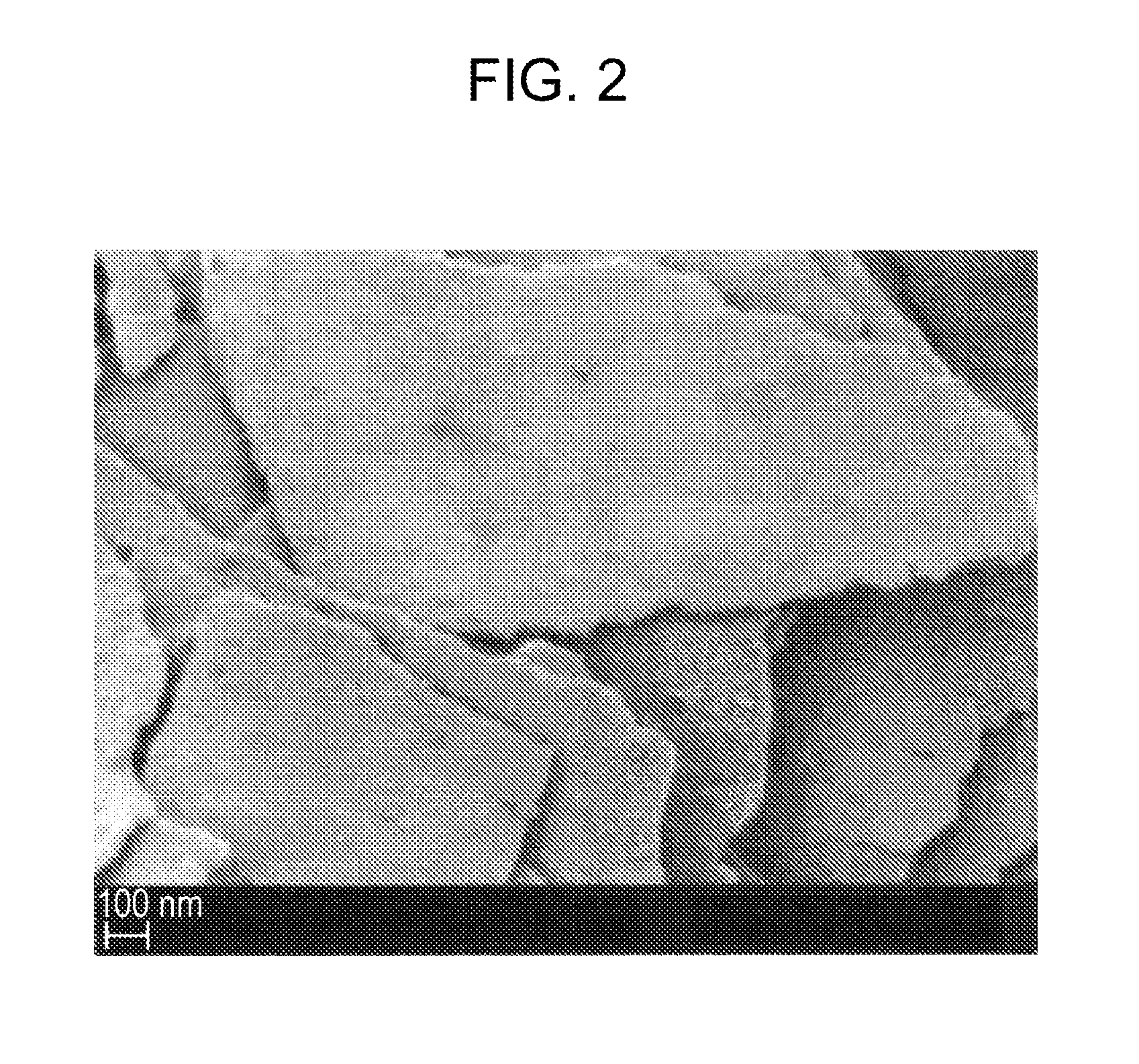

Preform for stretch blow-molded bottle

ActiveUS20100323136A1Increasing the thicknessReduce weightSynthetic resin layered productsDomestic articlesEngineeringBottle

A preform having an inverted truncated conical bottom section is used. The inclined inner surface of a bottle bottom surface-forming portion of the bottom section is formed into a gently curved convex surface that extends from the lower portion of a bottle bottom edge-forming portion of the bottom section to a curved portion in the lower portion of the bottom section so that the thickness of the bottle bottom surface-forming portion is greater than the thickness of the barrel section of the preform and the thickness of the bottle bottom edge-forming portion. The increase in thickness of the bottom section improves the efficiency of stretching the bottom section, and the circumferential wall of the bottom section can thereby be efficiently stretched. This allows a reduction in weight (thickness) of the bottom surface section of a stretch blow molded bottle, and a reduction in weight of the bottle is thereby achieved.

Owner:A K TECH LAB INC

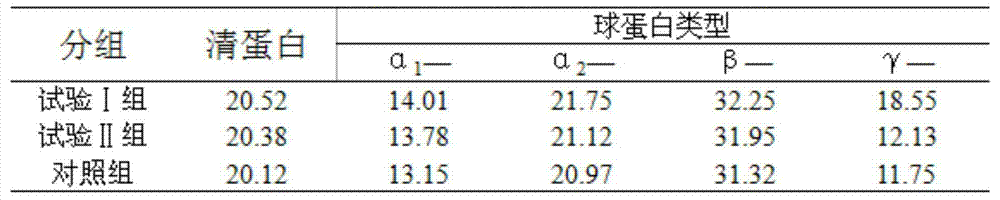

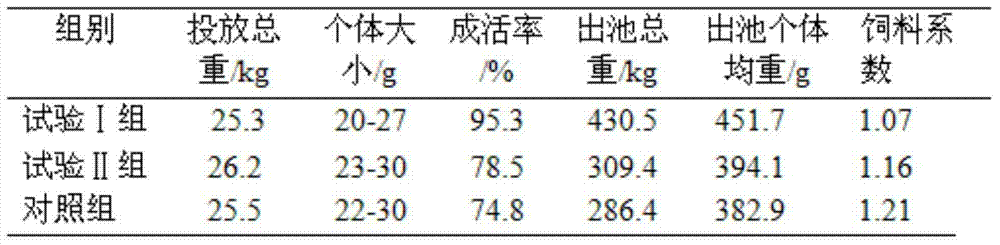

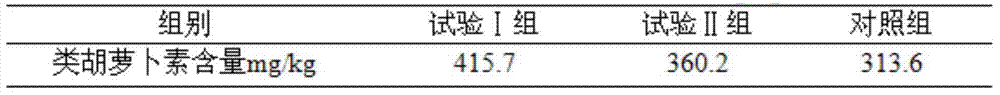

Chinese soft-shell turtle feed containing xanthophyll and preparation method thereof

ActiveCN104770588AImprove body colorImprove reproductive performanceFood processingClimate change adaptationZoologySoya bean

The invention discloses a Chinese soft-shell turtle feed containing xanthophyll and a preparation method thereof. The feed is prepared by mixing the following components in parts by weight: 20 to 40% of imported fish meal, 10 to 30% of domestic fish meal, 2 to 10% of chicken powder, 3 to 8% of extruded soybean, 3 to 8% of fermented soybean meal, 4 to 8% of beer yeast, 18 to 23% of alpha-starch, 2 to 5% of gluten powder, 2 to 5% of alga powder, 1 to 1.5% of xanthophyll, 1.2 to 2% of traditional Chinese medicine regulating composition, 0.1 to 0.2% of vitamin premix, 0.1 to 0.2% of mineral premix, 0.5 to 1.5% of calcium dihydrogen phosphate, and 0.1 to 0.3% of choline chloride. The formula is reasonable, the nutrients are comprehensive, the body color of the Chinese soft-shell turtle can be improved to prevent whitening, and moreover, the fecundity, viability and immunity of Chinese soft-shell turtle are enhanced.

Owner:HUZHOU HAIHUANG BIOTECH

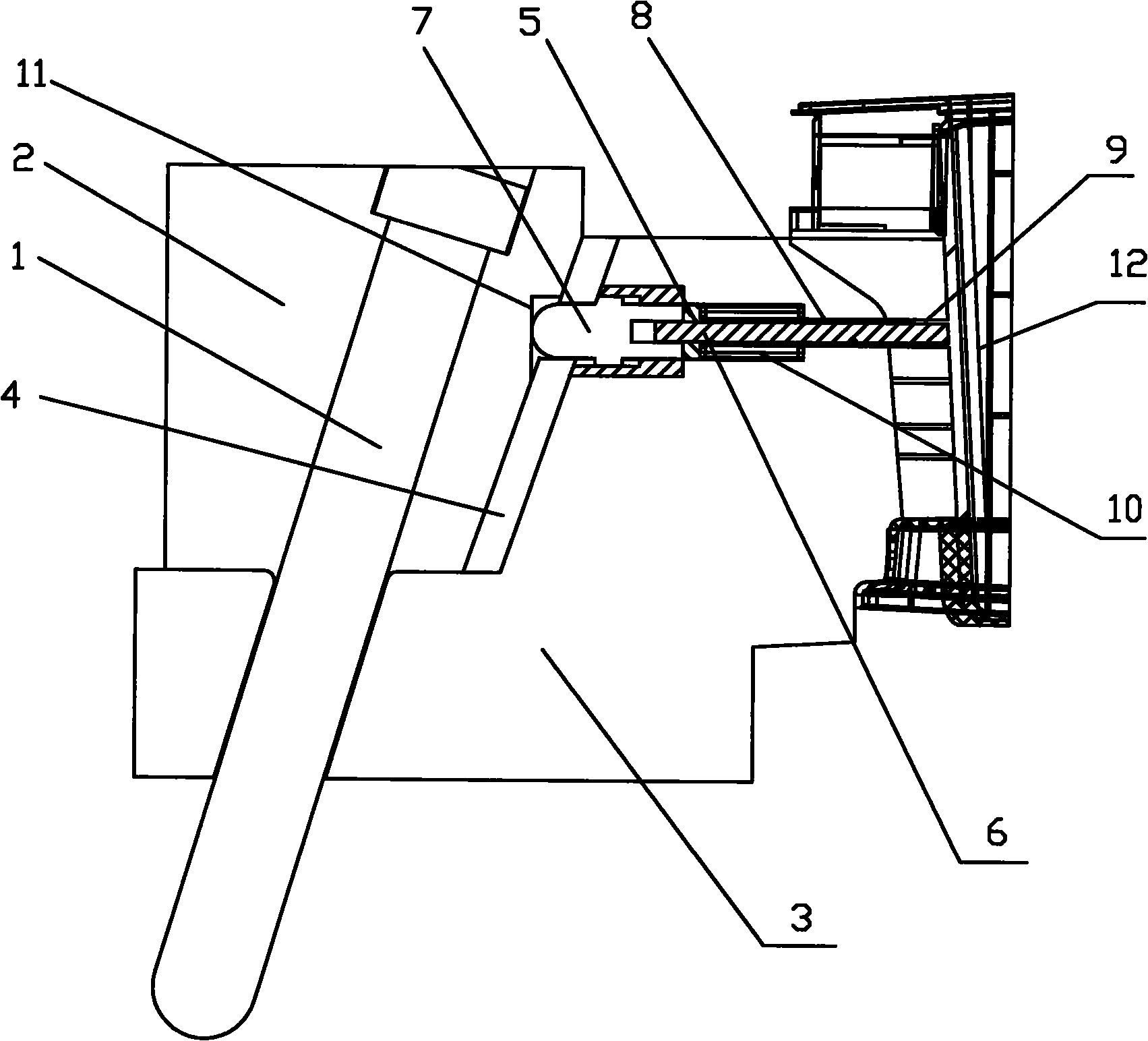

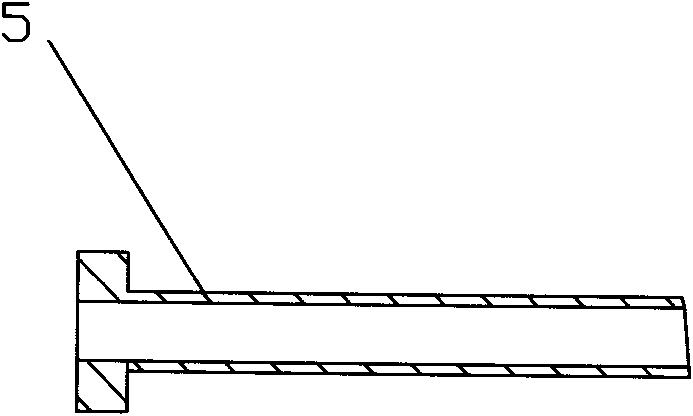

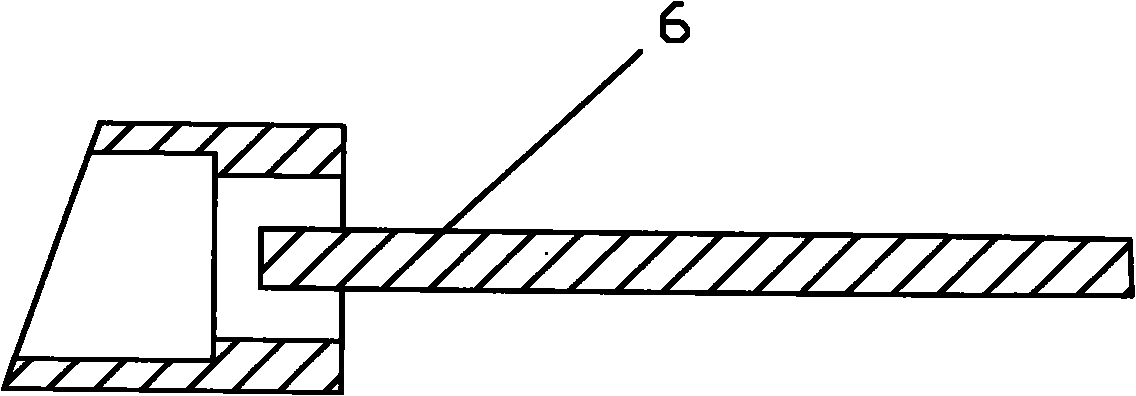

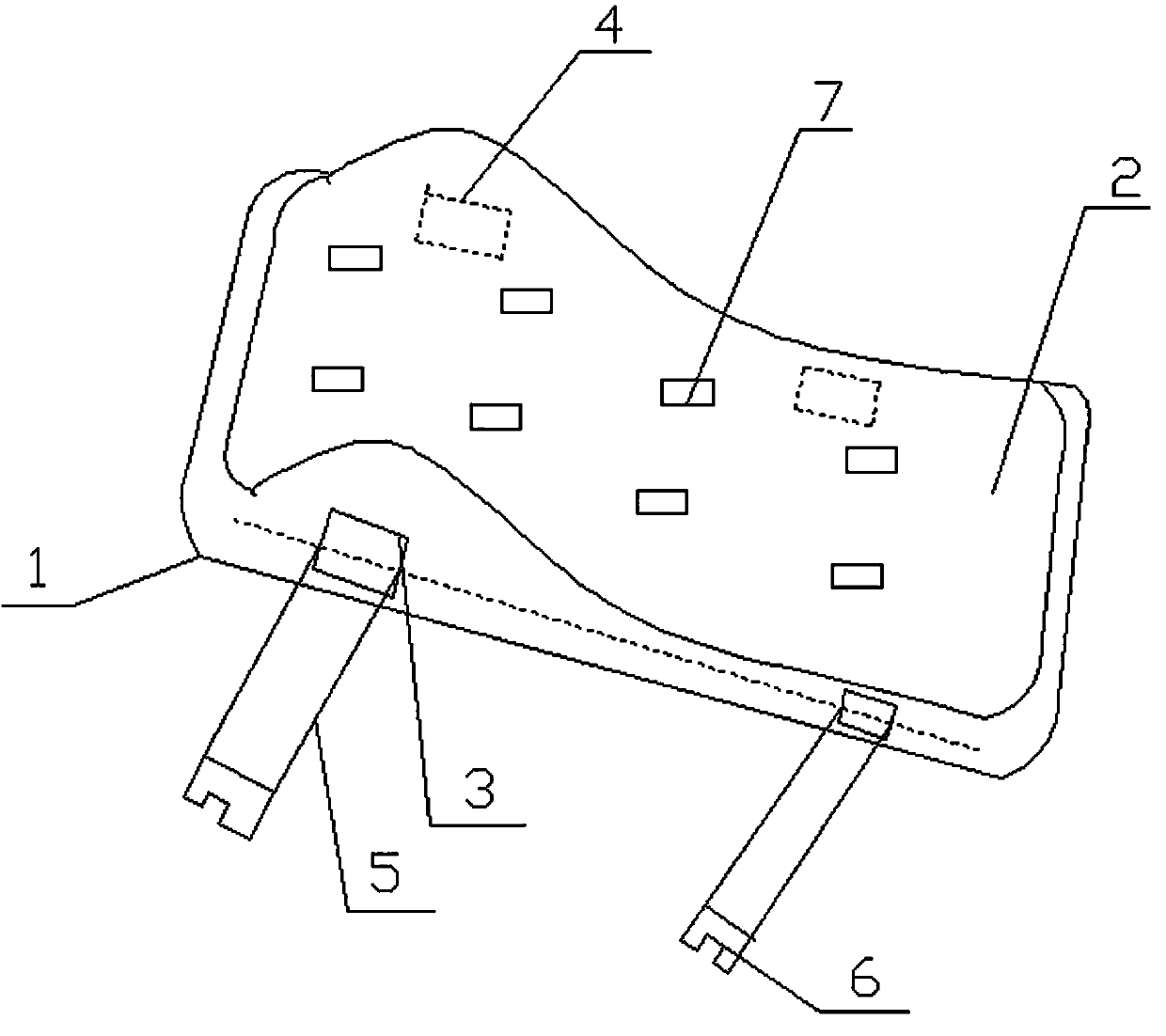

Ejector sleeve ejecting structure in plastic mould slide block

The invention discloses an ejector sleeve ejecting structure in a plastic mould slide block. The ejector sleeve ejecting structure comprises an inclined guide column (1), a locking block (2), the slide block (3), an ejector sleeve (5), an insert pin (6) and a jacking block (7), wherein an ejector sleeve mounting hole (8) is formed in the slide block (3); the ejector sleeve (5) passes through the ejector sleeve mounting hole (8) in the slide block (3) and is pressed against a product column hole (9), and the outer side of the ejector sleeve (5) is also sleeved with a spring (10); the insert pin (6) is arranged in the ejector sleeve and pressed by a wear plate (4); the right side surface of the locking block (2) is provided with a vertical sliding surface (11); and the right end of the jacking block (7) is sleeved into the tail part of the insert pin (6), and the left end of the jacking block (7) passes through the wear plate block (4) and is pressed against the vertical sliding surfaceof the locking block. The ejector sleeve ejecting structure has the advantages of effectively avoiding the strain of a plastic product and an ejector mark, along with good demolding effect and high reliability.

Owner:宁海县现代模具有限公司

Preparation method of carambola-kiwi fruit-cherry blended liquor

InactiveCN104498288AExtended eating timeEasy to transportAlcoholic beverage preparationFruit juiceAlcohol

The invention discloses a preparation method of carambola-kiwi fruit-cherry blended liquor. The preparation method comprises the following steps: A. pre-treating carambola; B. pre-treating kiwi fruit; C. pre-treating cherry; D. separating juice from pulp; B. preparing base liquor; and C. blending the finished liquor, and the like. The flavoured juice with carambola, kiwi fruit and cherry is mixed with low-alcohol liquor, thus the eating time of the south fruits is prolonged, transport is facilitated, and the carambola-kiwi fruit-cherry blended liquor has the medicinal effects of preventing cancer, whitening, fading spots, removing pimples, detoxifying and resisting ageing, losing weight and building body, enhancing immunologic function and the like, and thus multiple purposes are achieved.

Owner:吴肖颜

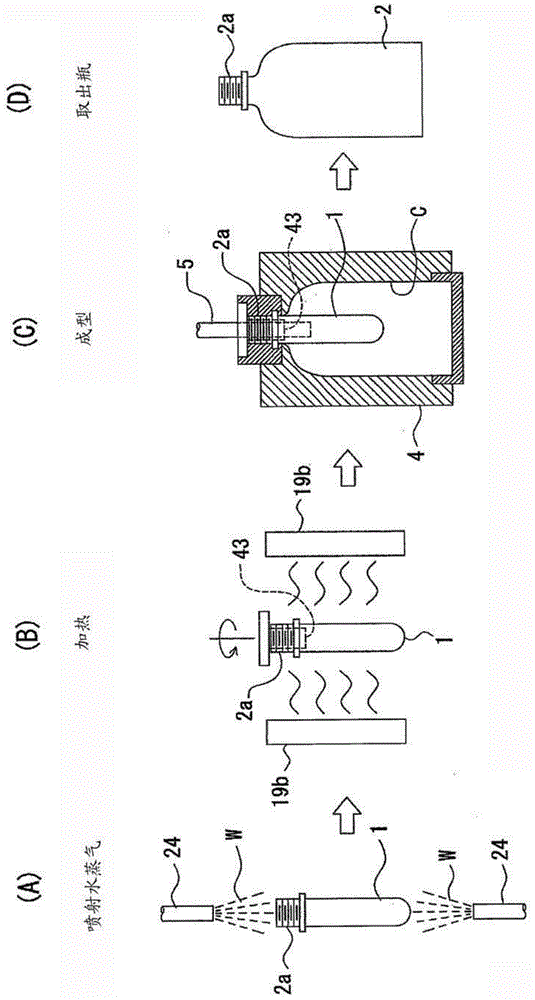

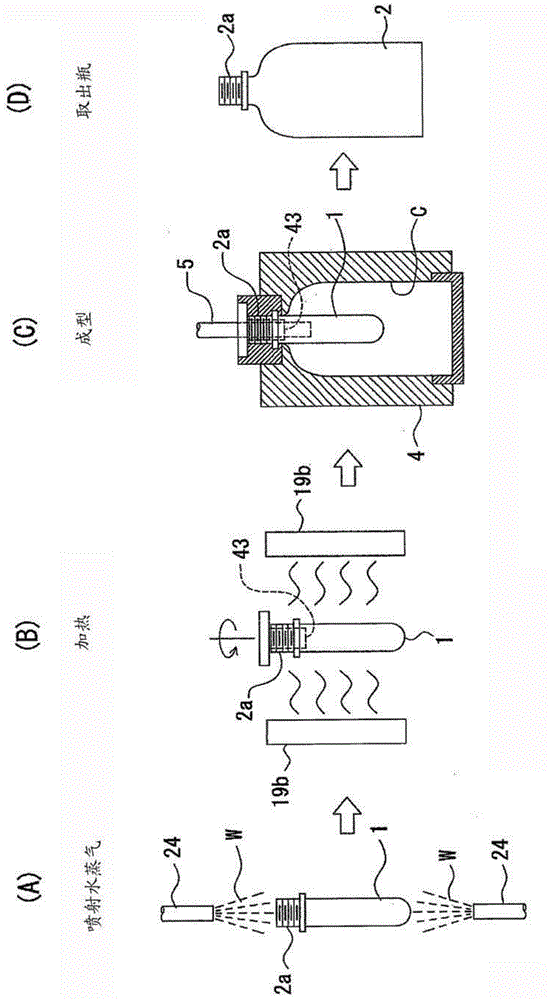

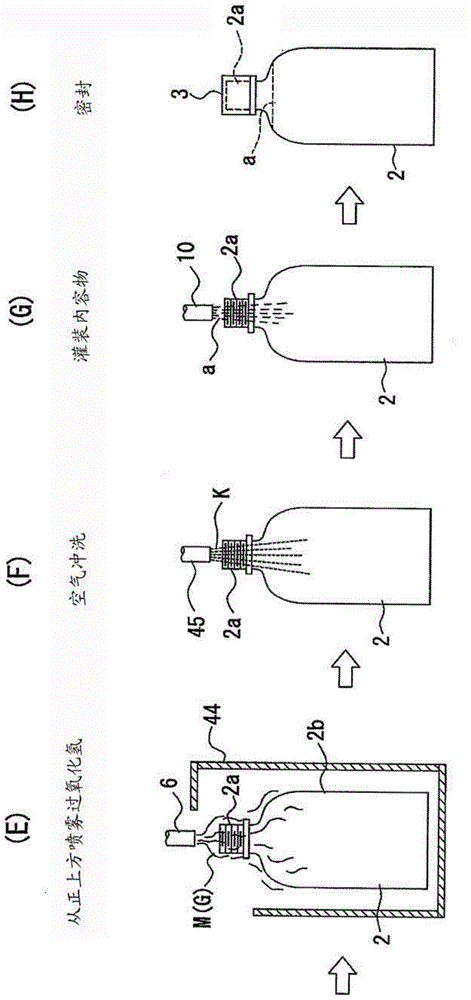

Beverage filling method and beverage filling device

ActiveCN104944346AAvoid adsorptionReduce usageSynchronising machinesHollow article cleaningBlow moldingTransfer molding

Water steam is sprayed to preforms 1 while continuously transferring the preforms 1, the preforms are preliminarily sterilized by heat application, bottles are produced by blow-molding the thus preliminarily sterilized performs in a molding die 4 which is continuously transferred with the preforms, the bottles are taken out from the continuously transferring molding die, condensed mist M or gas G of hydrogen peroxide is sprayed to the bottle in a time when the heat remains, an air rinsing process is performed, beverage fills the bottles during the continuous transferring, and the bottles are sealed with caps. The bottle sterilization processes can be simplified in an inline system.

Owner:DAI NIPPON PRINTING CO LTD

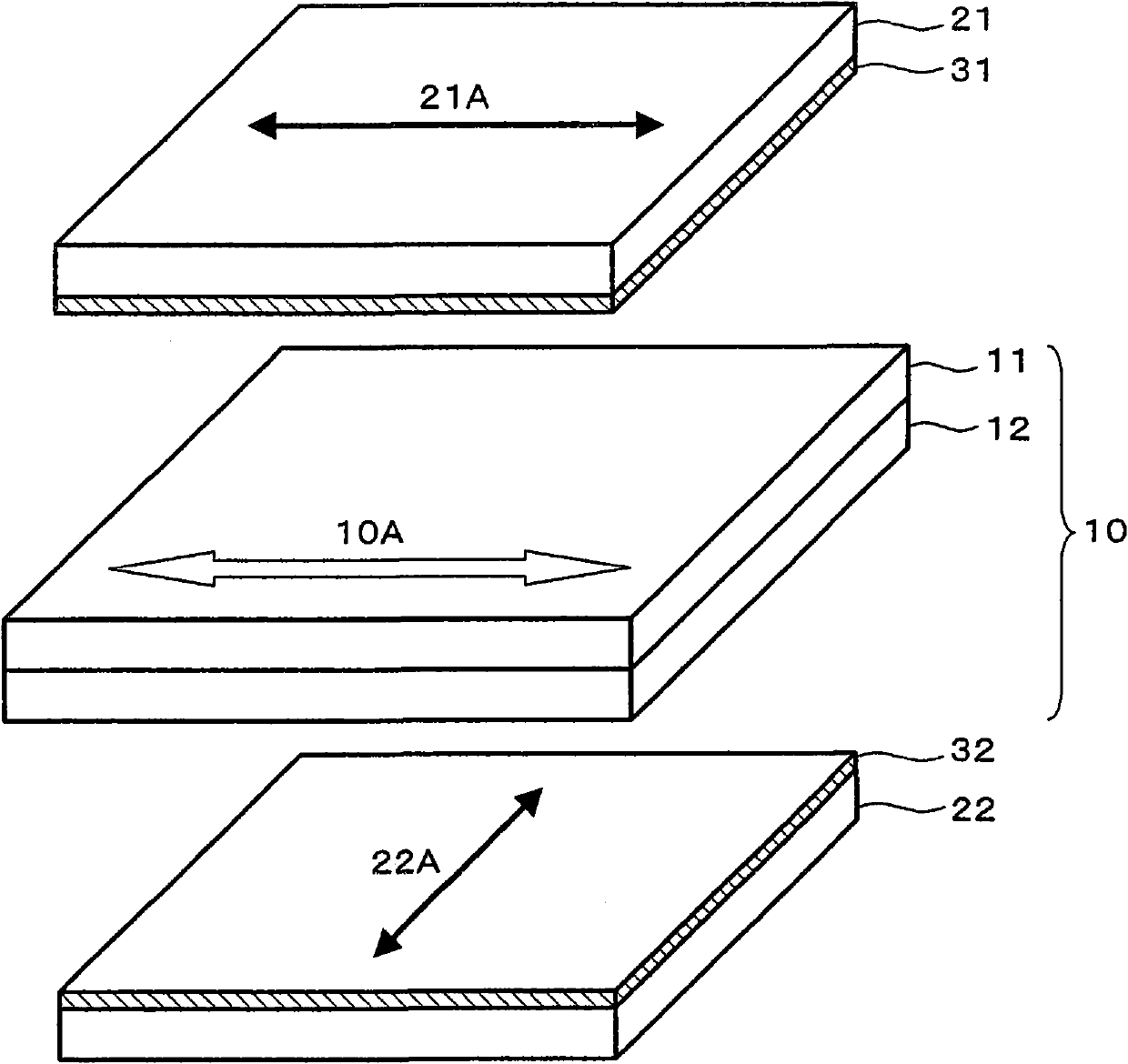

Polaroid, liquid crystal panel and liquid crystal display

ActiveCN104280811AIncrease contrastImprove clarityPolarising elementsNon-linear opticsLiquid-crystal displayLiquid crystal

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

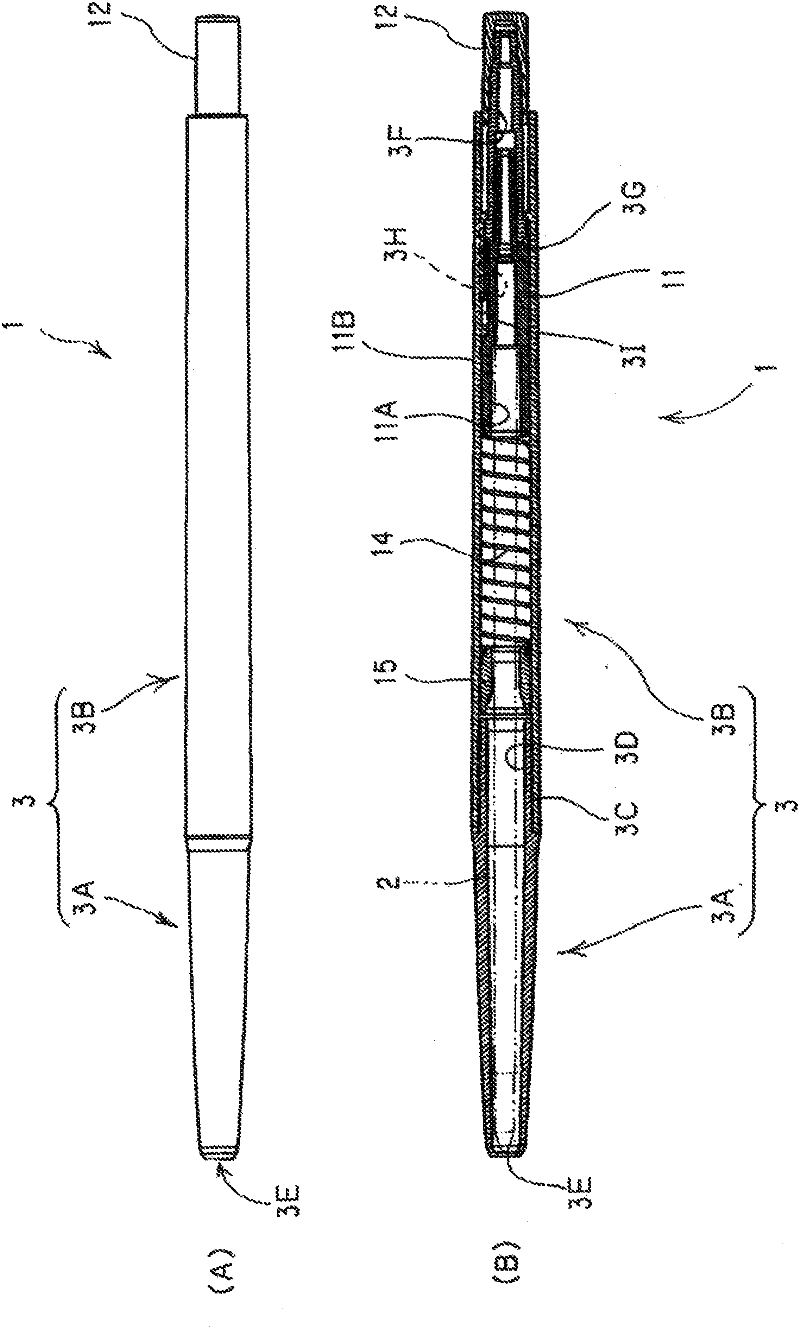

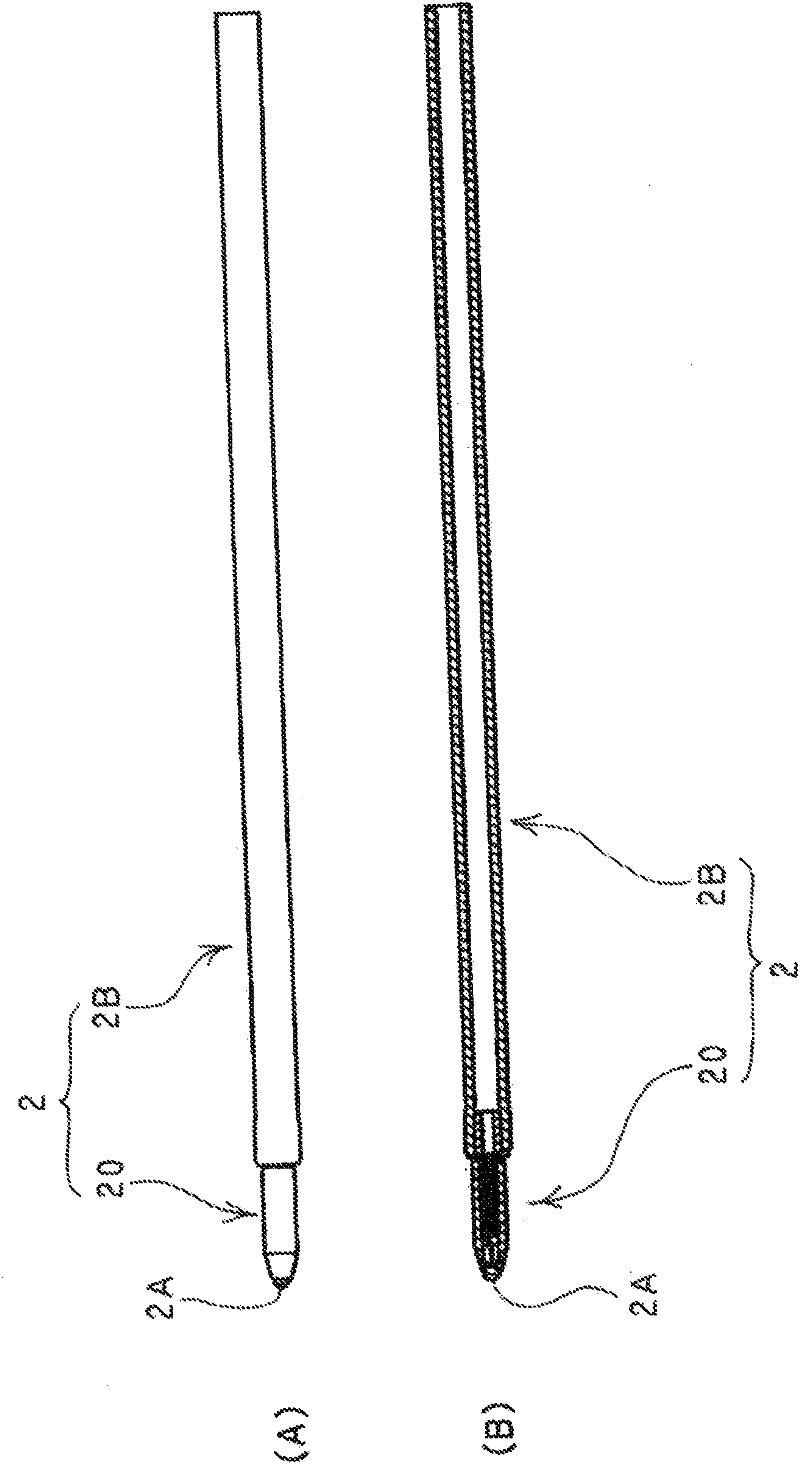

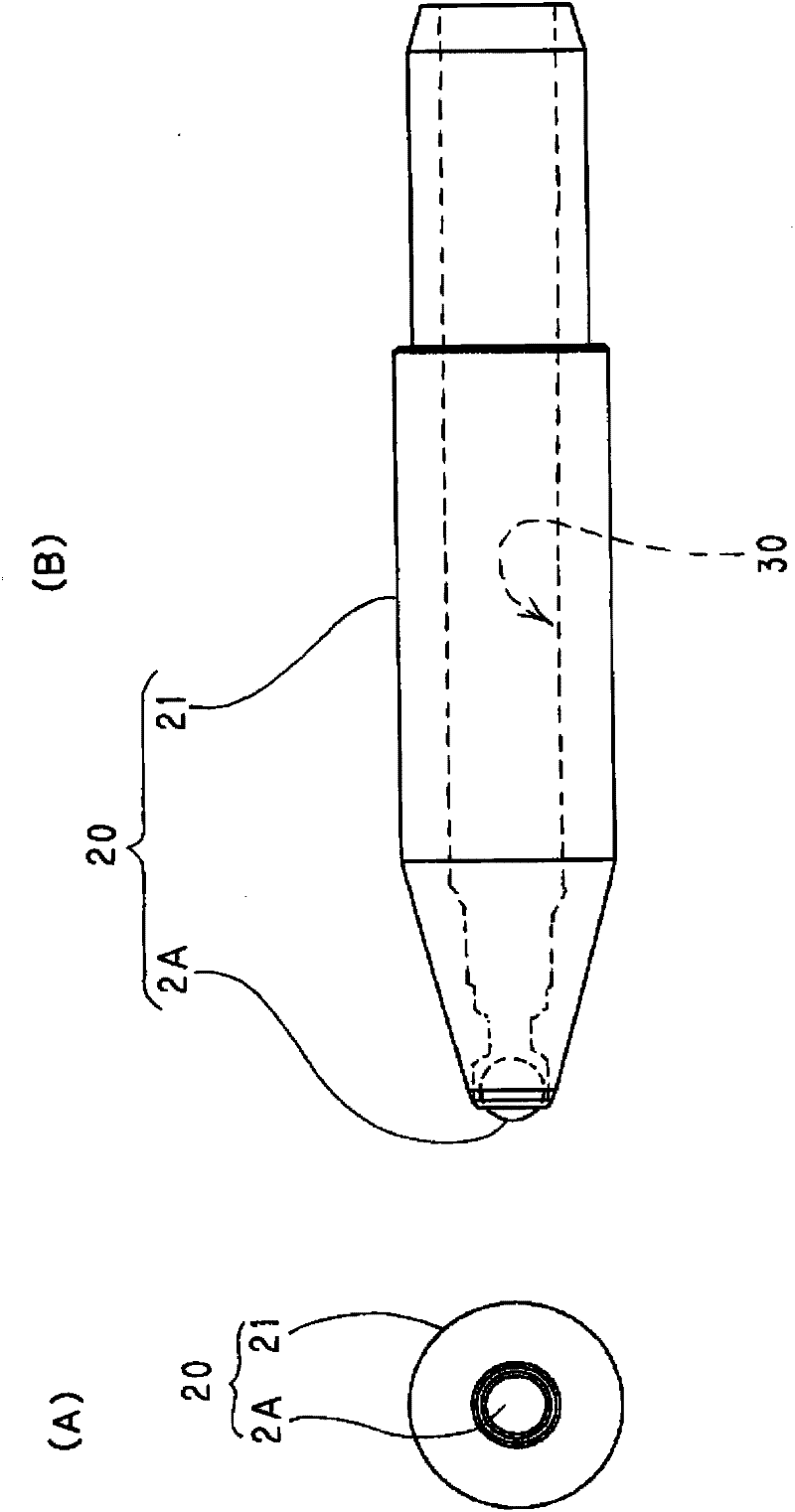

Ballpoint pen tip, ballpoint pen refill, ballpoint pen, and method of manufacturing ballpoint pen tip

InactiveCN102348560AReduce coefficient of frictionFree to changeBall-point pensWriting unitsEngineeringMechanical engineering

Provided are a ballpoint pen tip which can, even if ink having properties which assures that the amount of supply of the ink to the pen tip by shear of a writing ball is sufficient is adopted, prevent partially faint written traces from occurring and provide smooth writing, a ballpoint pen refill, a ballpoint pen, and a method of manufacturing a ballpoint pen tip. A triangular pyramid-shaped recess (42) gradually tapered toward an ink guide hole (36) is provided in the bottom of a ball housing (31), and troughs (44) formed in the recess (42) are utilized as ink reservoirs and ink paths. Because the troughs (44) have sufficient length, width, and depth, the amount of containment of the ink and the amount of supply of the ink are increased. Also, even if ink which is supplied to the pen point mainly by shear of a writing ball (2A) is adopted, the supply of the ink to the pen point is not interrupted, the occurrence of partially faint written traces of ink is sufficiently prevented, and friction between the writing ball and a ball receiving seat surface can be reduced.

Owner:MITSUBISHI PENCIL CO LTD

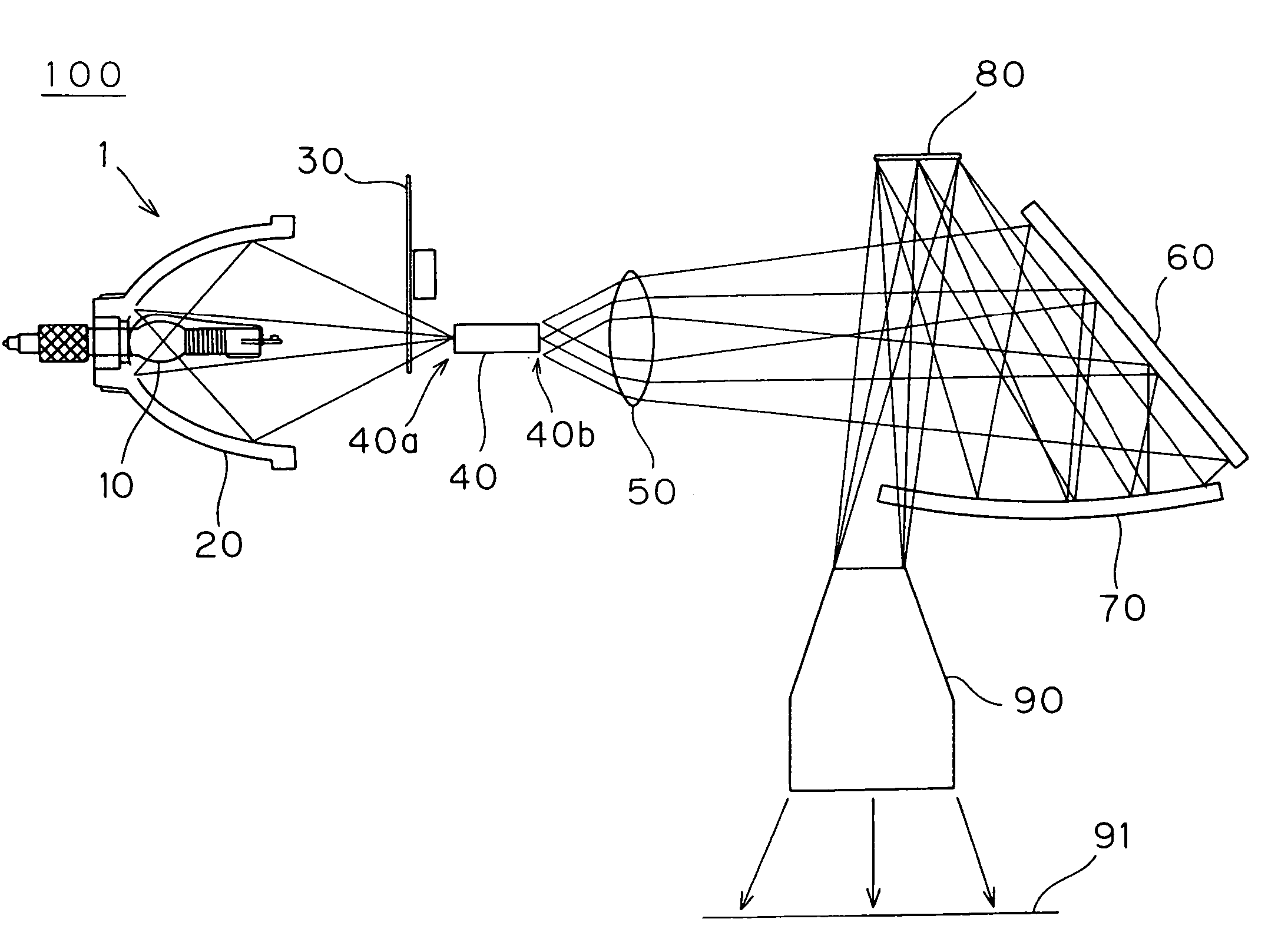

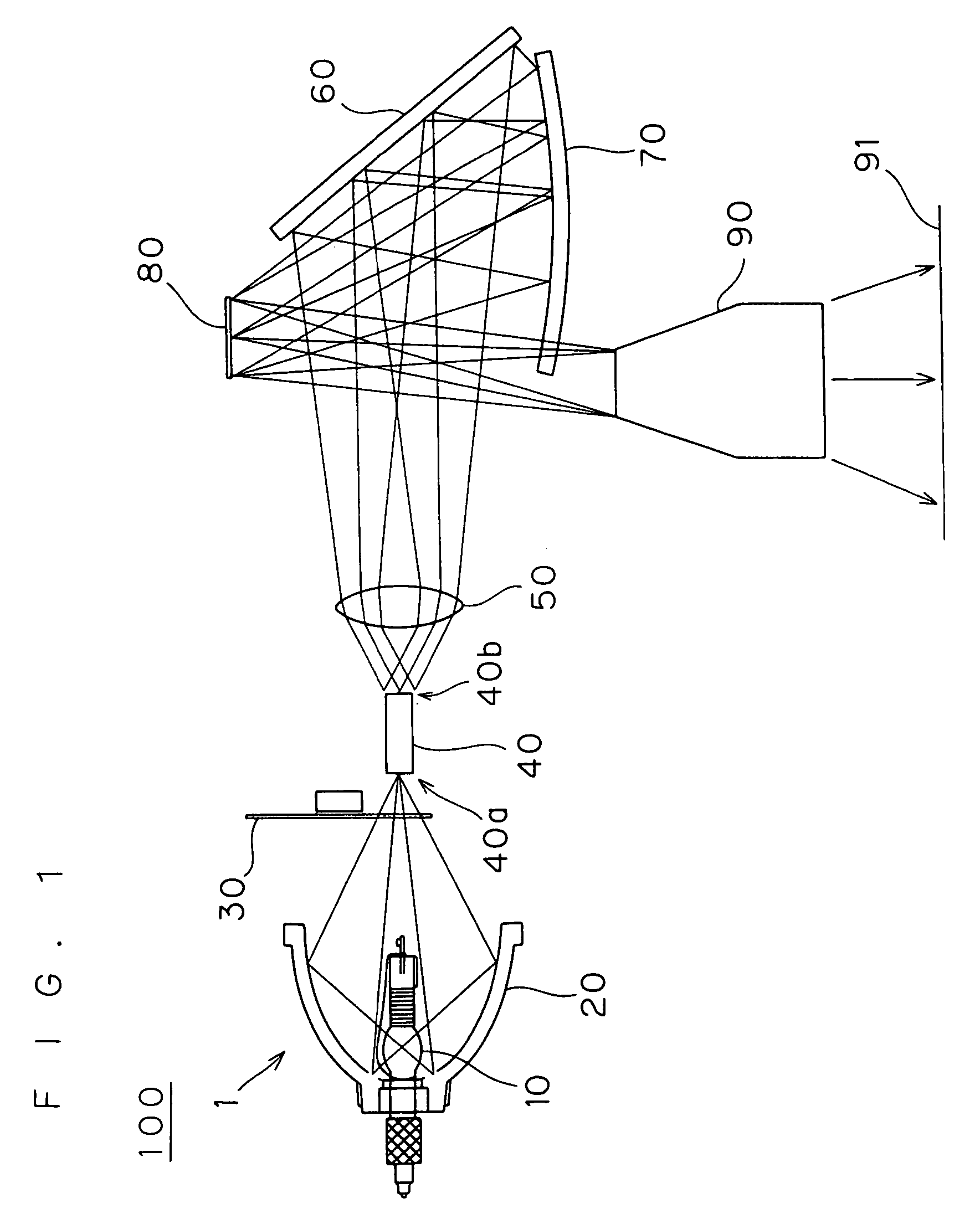

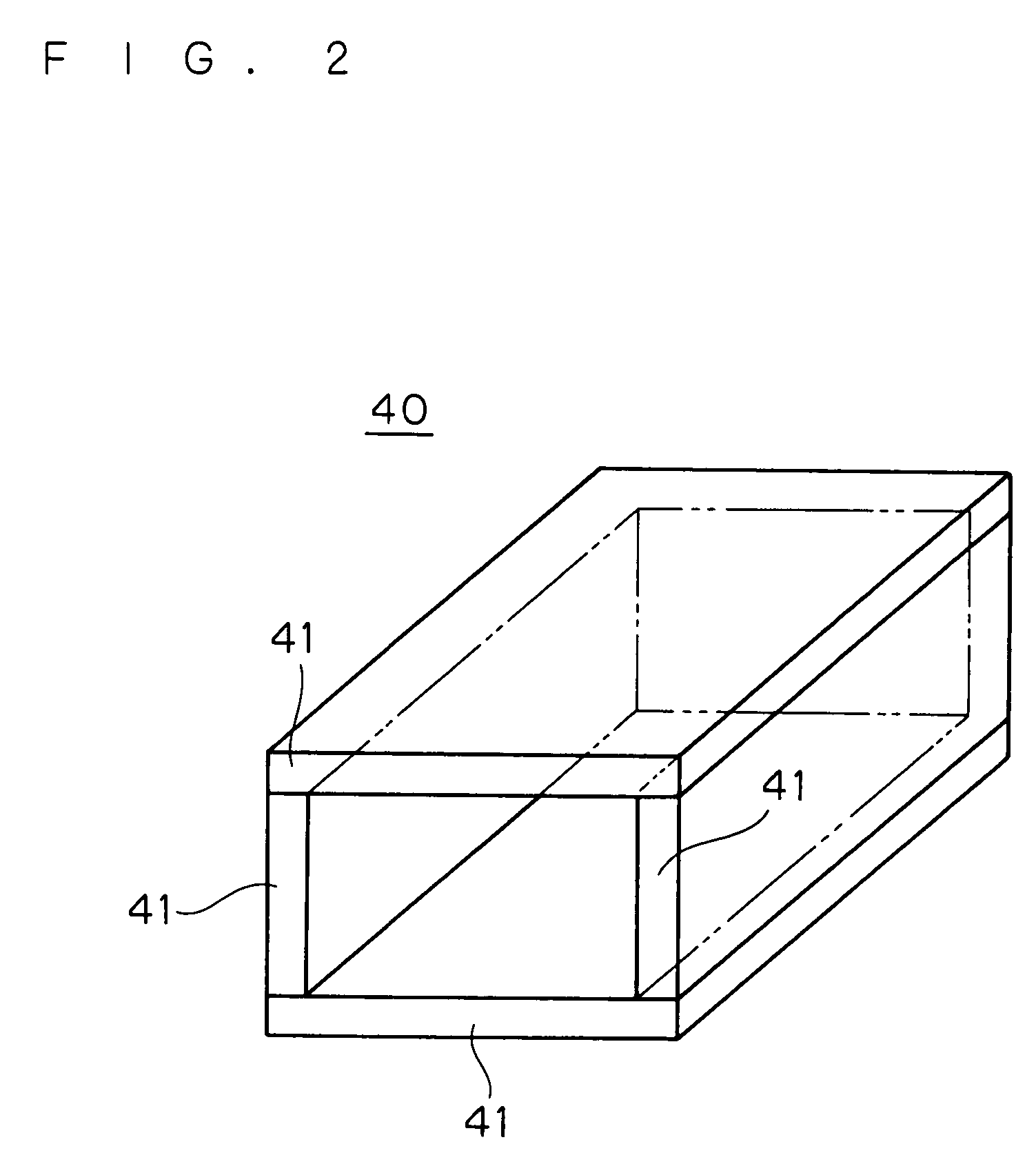

Optical system and projection type image display apparatus equipped with optical system

InactiveUS7033031B2Preventing whitening phenomenonGood video effectTelevision system detailsProjectorsLight guideDisplay device

A light guiding member (40) for reflecting therein light entering through a light entering surface (40a) several times to cause light having a uniform illumination distribution to outgo from a light outgoing surface (40b) is inserted into an optical path between a lamp source (10) and a reflection type display device (80). The light outgoing surface (40b) of the light guiding member (40) is formed in a dissimilar shape with an image display region of the reflection type display device (80), and a region irradiated with light in the image display region of the reflection type display device (80) is formed smaller than the image display region. This prevents a whitening phenomenon in a projected image undisplay region and improves video effects given to viewers as well as effectively utilizing light emitted from a light source for images to be projected to display projected images brightly.

Owner:MITSUBISHI ELECTRIC CORP

Improved infusion fixing board for children

InactiveCN103585703AFree to adjust the lengthEasy dischargeIntravenous devicesClamp connectionEngineering

The invention discloses an improved infusion fixing board for children. The improved infusion fixing board comprises a base board and a curved board in clamping connection with the base board, the front portion of the curved board is convex, the rear portion of the curved board is concave, openings are formed in the front end and the rear end of one side of the base board respectively, inserting openings are formed in the positions, corresponding to the openings, of the other side of the base board respectively, two rolling shafts are arranged in an internal cavity of the base board and an internal cavity of the curved board, a flat elastic telescopic band is wound on each rolling shaft, the free ends of the elastic telescopic bands penetrate out of the corresponding openings, and the penetrating ends are provided with clamping buckles matched with the inserting openings. A plurality of vent holes are formed in the curved board and the base board. Locking buckles capable of fixing the corresponding elastic telescopic bands are arranged on the outer sides of the openings. Through the structure, the elastic telescopic bands can fix a fixed board and the hands, and can automatically retract back to the internal cavity of the base board when not used, and using is convenient. The locking buckles can freely adjust the length of the elastic telescopic bands, and the phenomenon that the children are fixed too tightly and the skin turns pale is prevented from occurring.

Owner:RAYNET TECH

Method for producing oil paint

ActiveCN104449025AWith weak magneticImprove antistatic performanceMagnetic paintsAnti-corrosive paintsAcrylic resinAdhesive

The invention discloses a method for producing an oil paint, and relates to the field of chemical processes. The method comprises the following steps: feeding, premixing, grinding, mixing a paint, introducing oxygen, filtering and the like, namely adding materials to a twin-cylinder high-speed disperser in opening mixing during feeding; firstly adding 1 / 5 of polyurethane acrylic resin to a first cylinder to render; adding a little of conductive carbon black, chlorinated paraffin, magnetic iron powder, zeolite powder and nickel powder, adding part of polyurethane acrylic resin at an interval of 1 minute, and completely adding the residual polyurethane acrylic resin for 3-4 times; adding a mixed solution of double distilled water, butanol, an organic silicone resin fluid and an isocyanate adhesive to a second cylinder, and carrying out hydrolytic crosslinking reaction; and adding nano powder, and carrying out catalytic reaction, mixing the materials which are processed in the first cylinder and the second cylinder at the ratio, thus various defects of the oil paint can be improved; resources can be reasonably distributed; and the method is economic and applicable.

Owner:丹阳恒安化学科技研究所有限公司

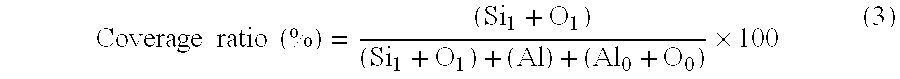

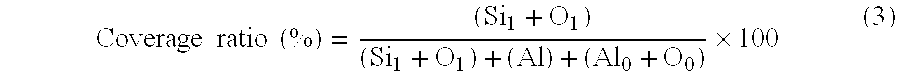

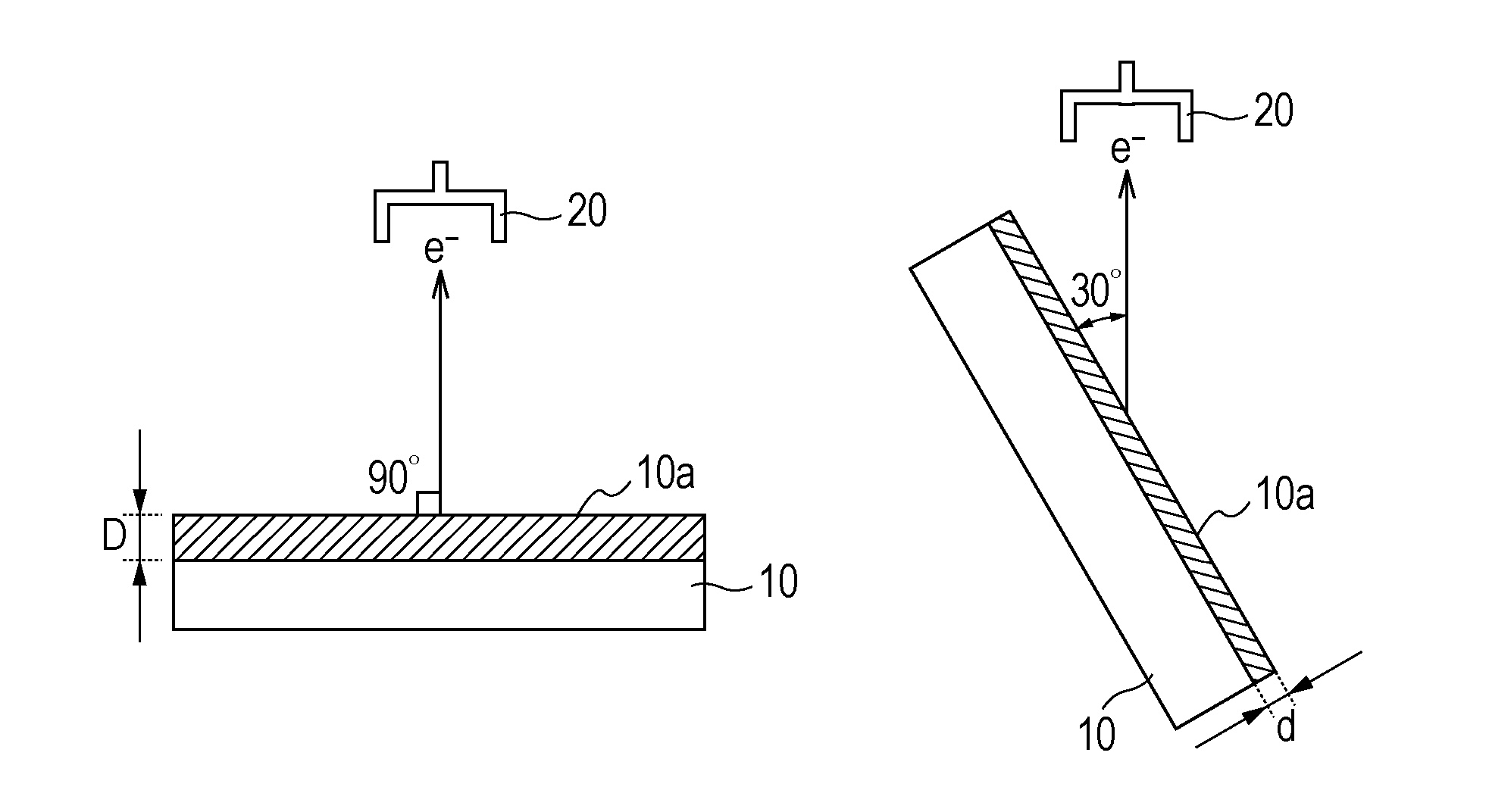

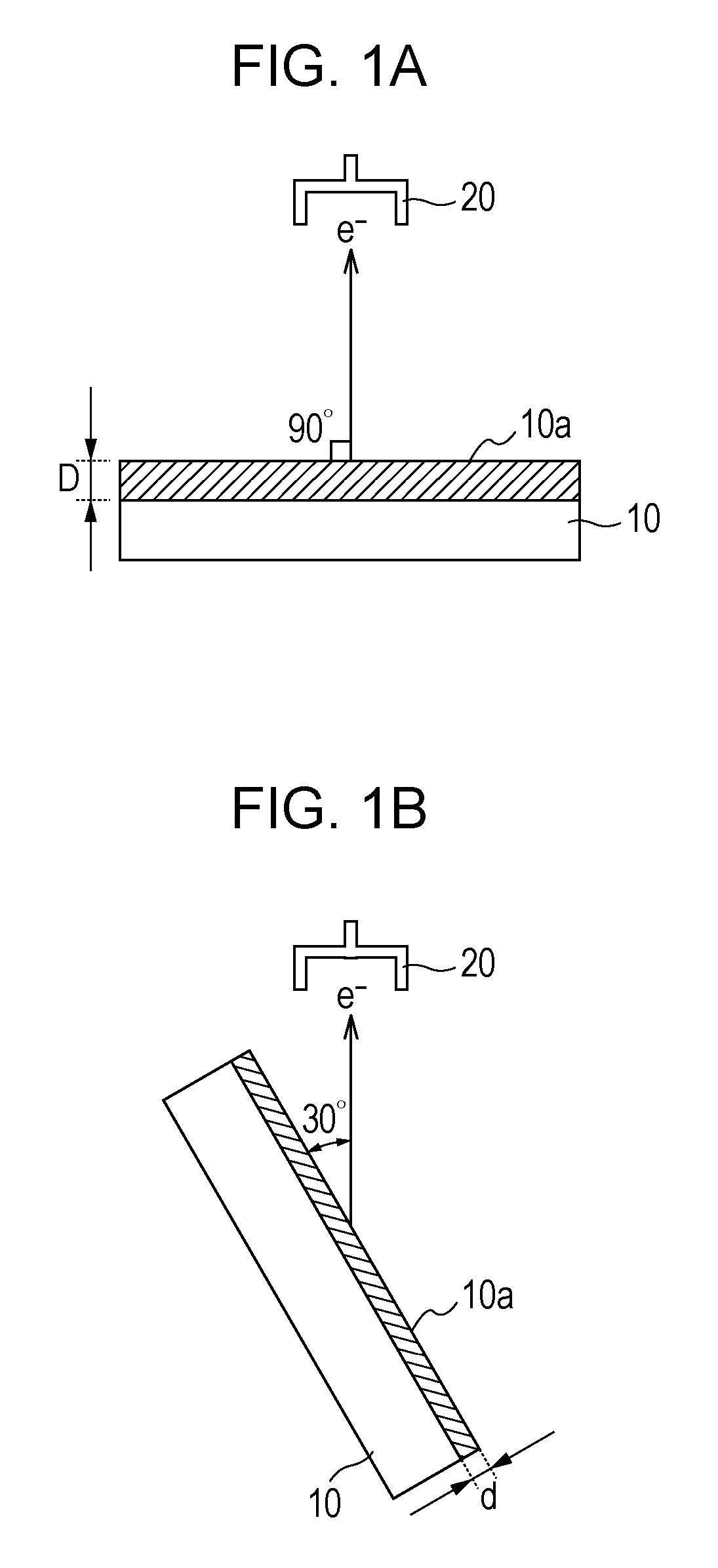

Water resistant aluminum pigment dispersion, aqueous ink composition containing the same, and method for manufacturing water resistant aluminum pigment dispersion

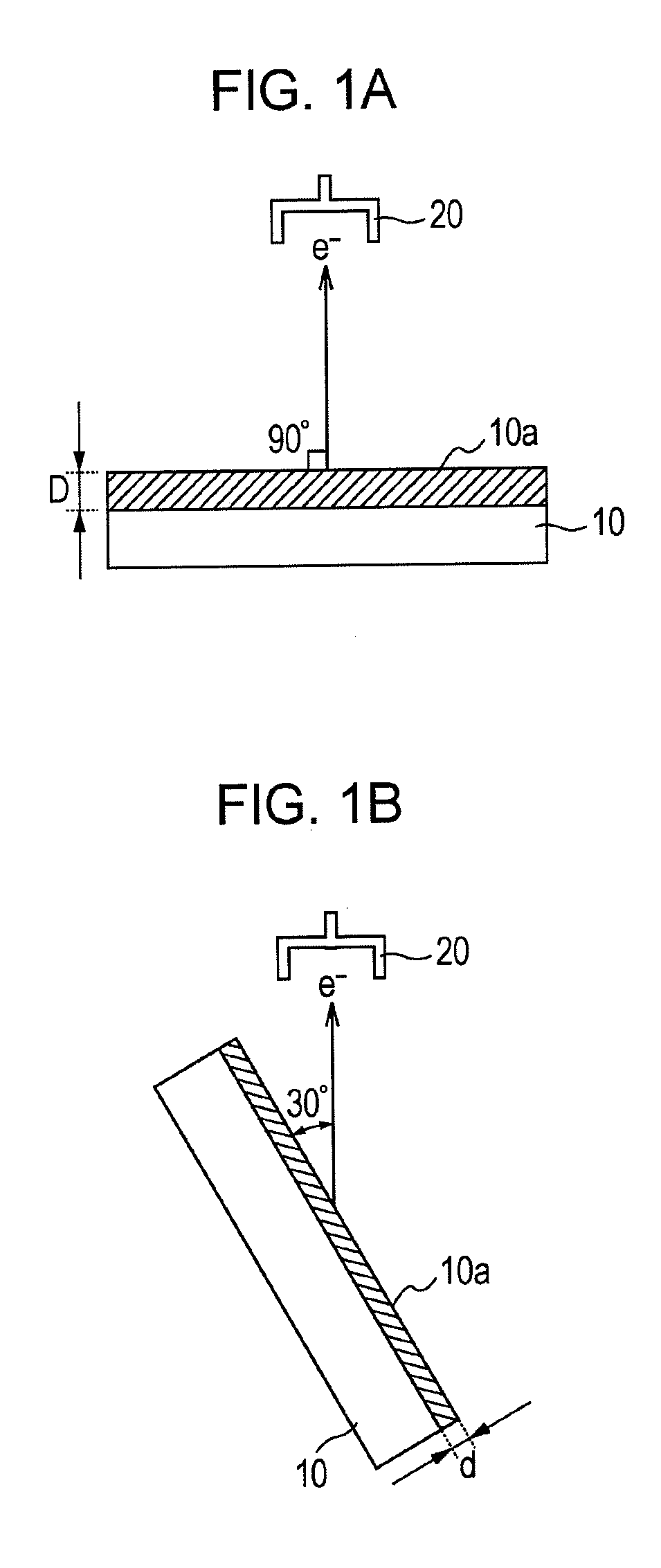

ActiveUS8702861B2Good water dispersibilitySuperior metallic glossMaterial nanotechnologyDuplicating/marking methodsCoverage ratioPigment dispersion

An ink composition includes a water resistant aluminum pigment and water. The water resistant aluminum pigment is formed of an aluminum pigment and a covering film that contains Si and is formed on the surface of the aluminum pigment. A 50% average particle diameter of a corresponding circle obtained by calculation from areas of X-Y plain surfaces of the aluminum pigment is in a range from 0.5 pm to 3 pm. The coverage ratio of the covering film on the surface of the aluminum pigment, calculated from presence ratios of C, O, Al, and Si detected by XPS measurement at an incident angle of 30°, is in a range from 30% to 90%.

Owner:SEIKO EPSON CORP

Beverage filling method and device

ActiveCN104944345AAvoid adsorptionReduce usageSynchronising machinesHollow article cleaningBlow moldingTransfer molding

Water steam is sprayed to preforms 1 while continuously transferring the preforms 1, the preforms are preliminarily sterilized by heat application, bottles are produced by blow-molding the thus preliminarily sterilized performs in a molding die 4 which is continuously transferred with the preforms, the bottles are taken out from the continuously transferring molding die, condensed mist M or gas G of hydrogen peroxide is sprayed to the bottle in a time when the heat remains, an air rinsing process is performed, beverage fills the bottles during the continuous transferring, and the bottles are sealed with caps. The bottle sterilization processes can be simplified in an inline system.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com