Beverage filling method and beverage filling device

A filling device and beverage technology, applied in the direction of cleaning methods and utensils, chemical instruments and methods, packaging, etc., can solve the problems of blow molding machine equipment complexity, reduced sterilization effect, difficult sterilization, etc., to prevent excessive adsorption Effects of hydrogen peroxide, reduction in usage and temperature, and reduction in irradiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〉

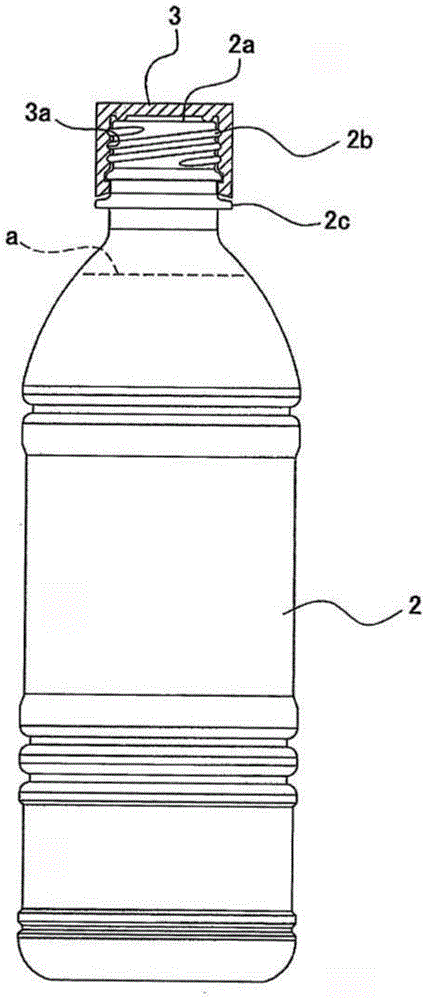

[0072] According to the online production system of the first embodiment, it is possible to manufacture figure 1 package shown.

[0073] Such as figure 1 As shown, the package has a bottle 2 as a container and a bottle cap 3 as a cap.

[0074] In this embodiment, the bottle 2 is manufactured using PET, but it is not limited to PET, and the bottle 2 may be manufactured using other resins such as polypropylene and polyethylene. The mouth 2a of the bottle 2 is formed with an external thread 2b.

[0075] The bottle cap 3 is formed by injection molding of resin such as polypropylene, and the internal thread 3a is formed simultaneously with the molding of the bottle cap 3 .

[0076] The bottle 2 is filled with the sterilized beverage a in a state where the inside of the bottle 2 has been sterilized in advance. After the beverage a is filled, the mouth 2a of the bottle 2 is covered with the bottle cap 3, and the mouth 2a of the bottle 2 is sealed by screwing the internal and exte...

no. 2 approach 〉

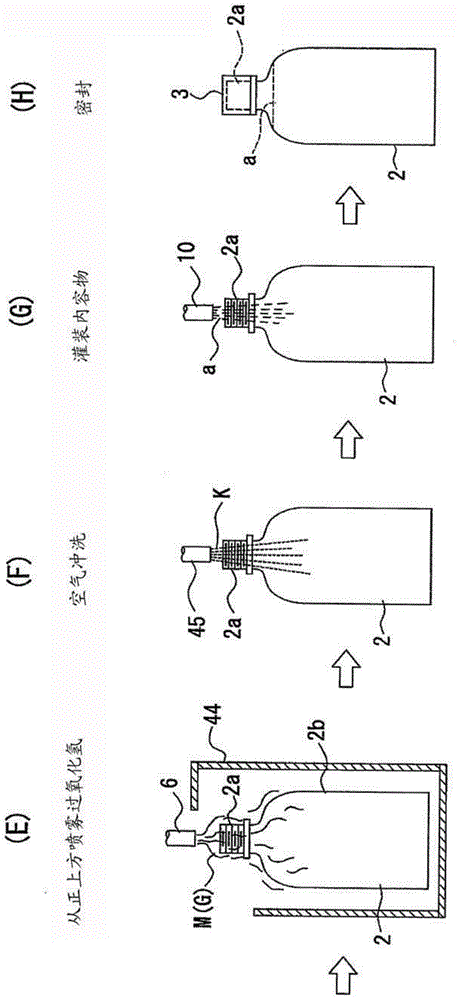

[0154] Such as Figure 6 As shown in (E), in the second embodiment, as figure 2 The bottle 2 taken out from the mold 4 as shown in (D) is rinsed with sterile hot water H to perform main sterilization. exist Figure 6 In (E), reference numeral 46 denotes a nozzle for hot water rinsing that sprays sterile hot water H. As shown in FIG. The temperature of the hot water H is maintained within a range such that the bottle 2 does not deform.

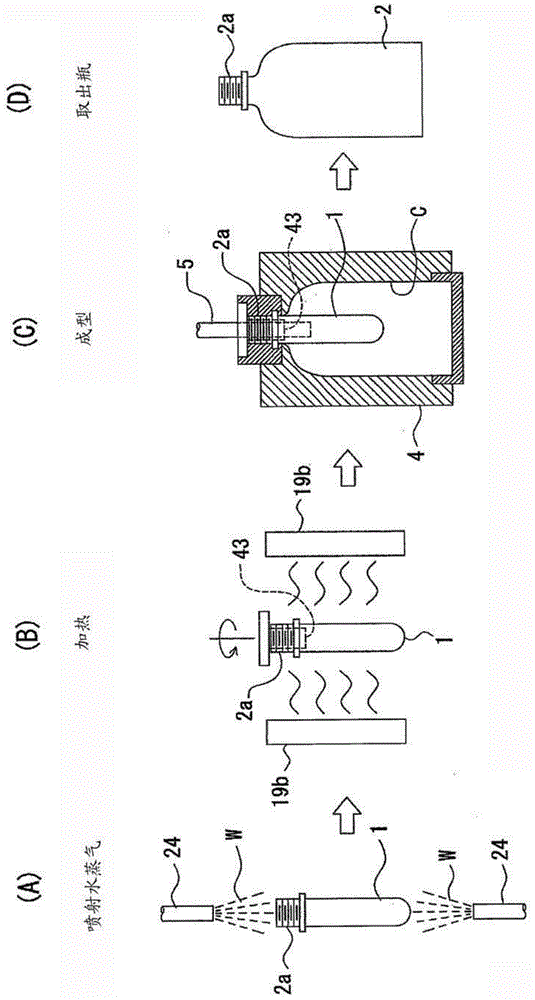

[0155] Bottle 2 is the same as the first embodiment, in figure 2 The stage of the preform 1 shown in (B) is sprayed with water vapor and then heated in a humid heat state to pre-sterilize almost all microorganisms except bacterial spores. Therefore, by this hot water rinsing, bacteria surviving in the molding stage of the above-mentioned bottle 2 are sterilized.

[0156] Such as Figure 6 Shown in (F), beverage a is filled in bottle 2 after being rinsed by hot water, and as Figure 6 Cap 3 on the bottle as shown in (G).

[0157] The f...

no. 3 approach 〉

[0163] According to the online production system of the third embodiment, it is also possible to manufacture figure 1 package shown.

[0164] The above-mentioned bottle 2 forms a container in the same procedure as described in the first embodiment, and forms a package through beverage filling and sealing. However, in the first embodiment, as figure 2 As shown in (A), water vapor W is sprayed from the nozzle 24 to the preform 1. In contrast, in the third embodiment, as Figure 8 As shown in (A), hydrogen peroxide mist or gas L is sprayed from the nozzle 24 to the preform 1 .

[0165] From the hydrogen peroxide mist or gas L sprayed from this nozzle 24, utilize and Figure 4 Shown mist generator 7 is generated by the mist generator of the same structure.

[0166] By spraying hydrogen peroxide mist or gas L, the surface of the preform 1 is attached and formed at 0.0035 μL / cm 2 ~0.35μL / cm 2 Coagulation film of hydrogen peroxide in conversion of 35% by weight in the range. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com