Ejector sleeve ejecting structure in plastic mould slide block

A technology of plastic molds and sliders, applied in the field of plastic molds, can solve the problems of inability to open molds, uneven force at column holes, poor reliability, etc., to prevent plastic products from being pulled, good demoulding effect, and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

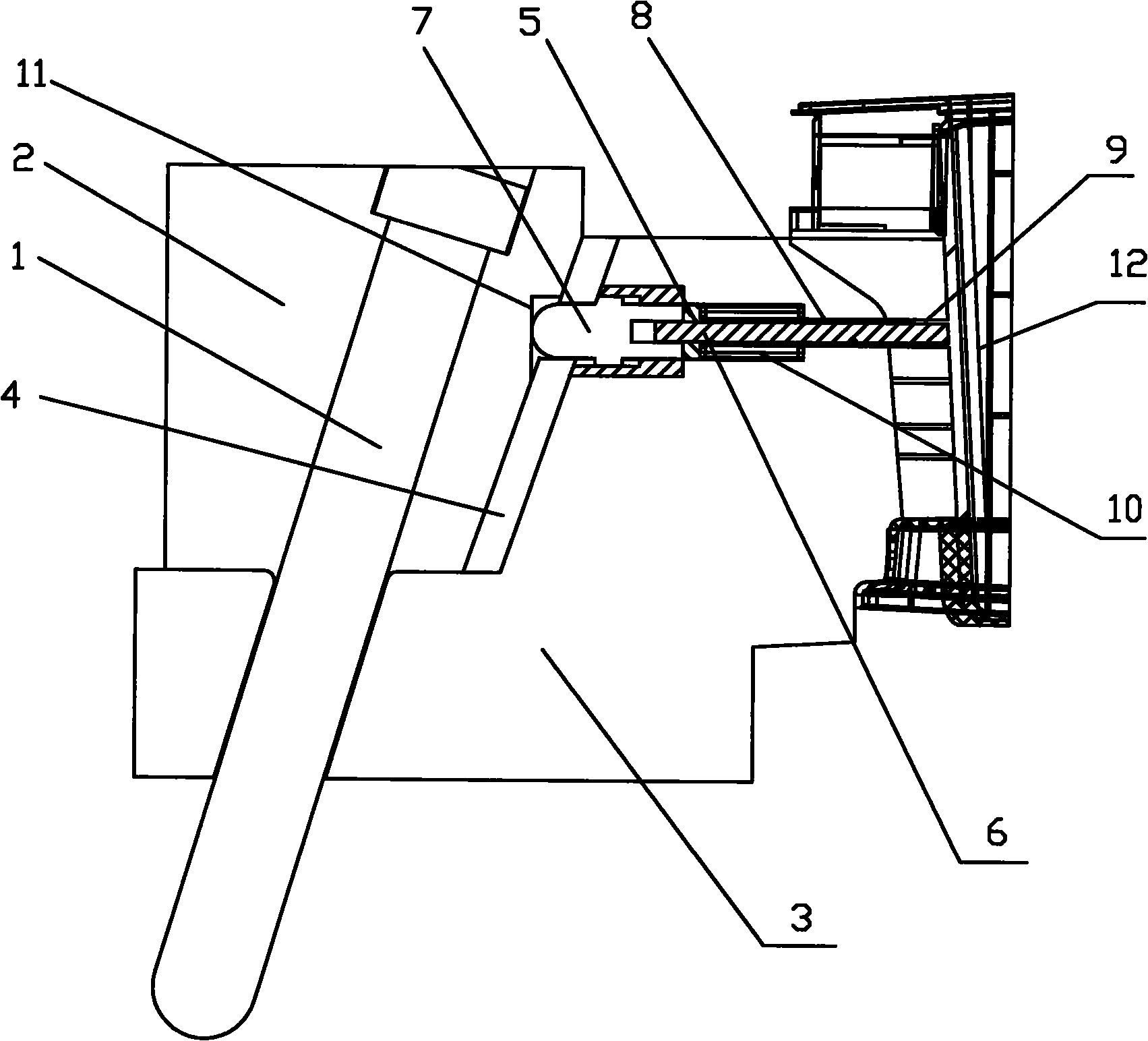

[0015] The cylinder ejection structure in the plastic mold slider of the present invention includes an oblique guide post 1, a locking block 2, and a slider 3. The oblique guide post 1 is obliquely fixed in the locking block 2, and the oblique guide post 1 Pass through the slider 3 obliquely, the right side of the locking block 2 is an inclined surface, the lower end of the slider 3 is close to the locking block 2, and the upper end of the slider 3 passes through the wear-resistant block 4 and The right sides of the locking block 2 are close together.

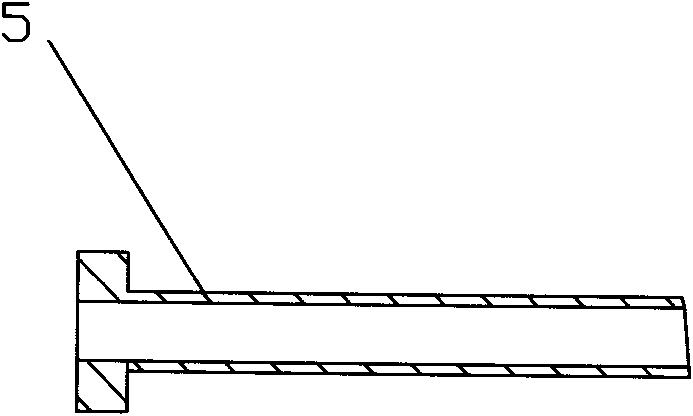

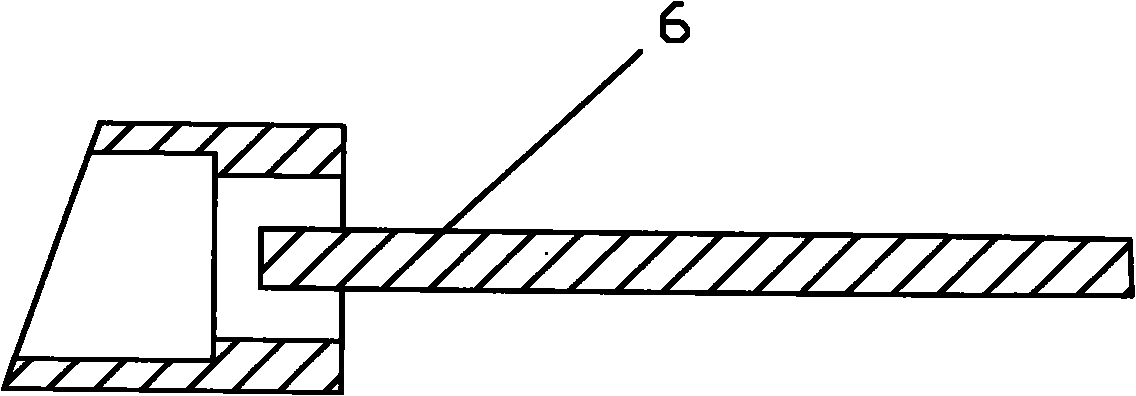

[0016] The ejecting structure of the cylinder also includes a cylinder 5, an insert 6, and a top block 7. A cylinder installation hole 8 is provided in the middle of the slider 3, and the cylinder 5 passes through the cylinder in the slider 3. The barrel installation hole 8 is against the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com