Press-fit type connector terminal

一种连接器端子、配型的技术,应用在连接、固定连接、夹紧/弹簧连接等方向,能够解决难以允许大量的电流流过、剥离、印刷电路板变白等问题,达到增强可重复性、降低制造成本、高屈服强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

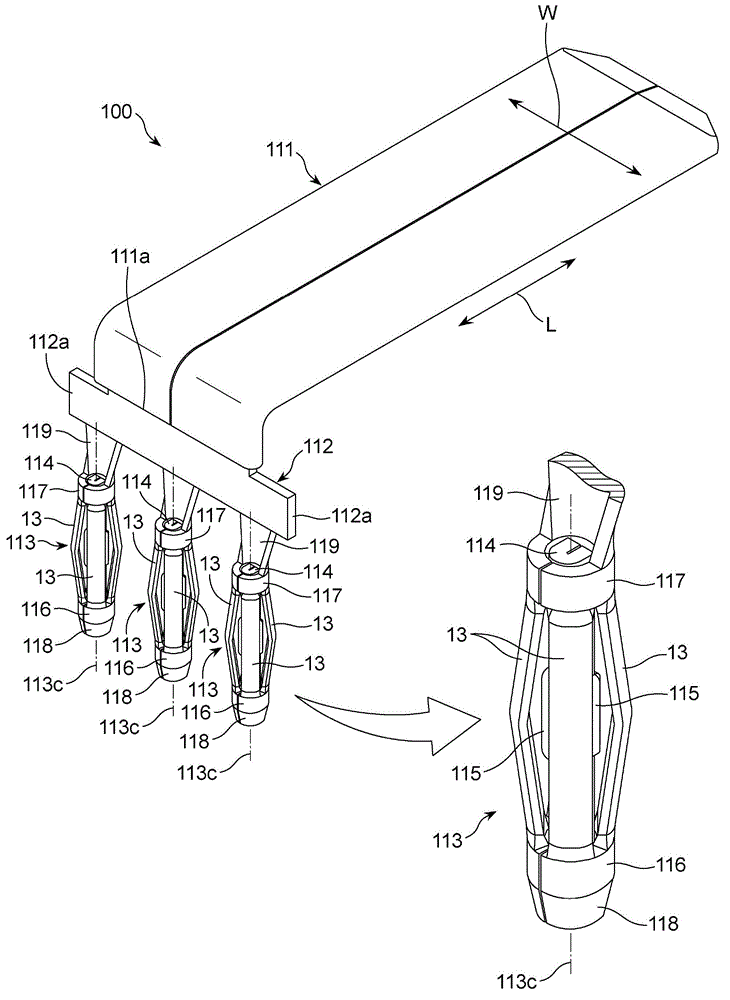

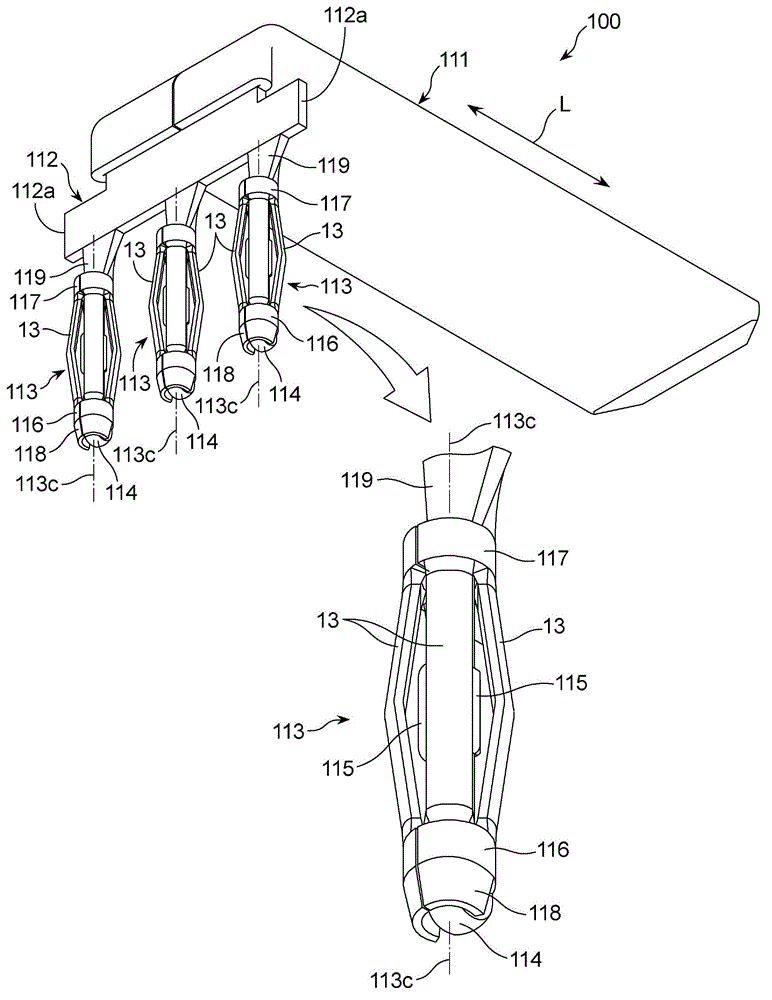

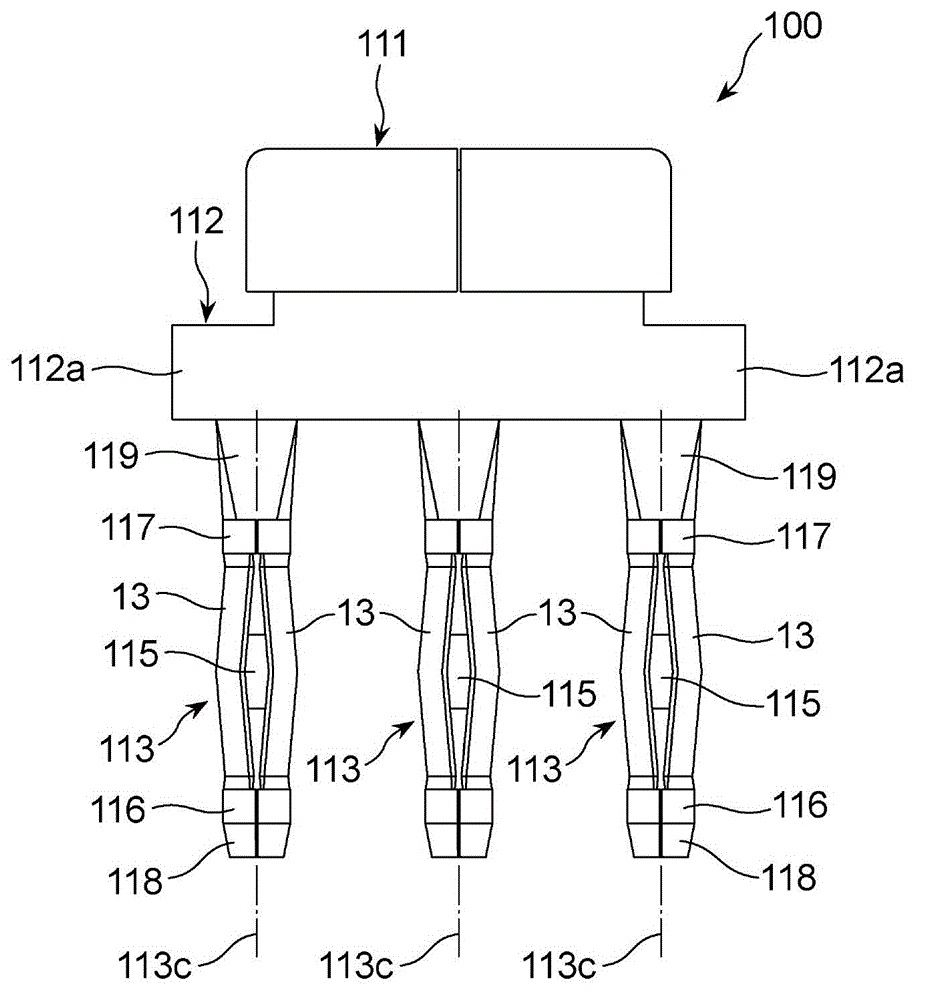

[0079] The following reference figure 1 To 8 illustrate the press-fit type connector terminal 100 according to the first embodiment of the present invention.

[0080] Such as Figure 1 to 5 As shown, by bending a single metal plate 110 with elasticity (see Figure 8A with 8B ) To form a press-fit connector terminal 100.

[0081] The press-fit type connector terminal 100 includes a pin portion 111 having a flat plate shape, a plurality of contact portions 113 continuous with the front end of the pin portion 111, and a flat shoulder 112 between the front end of the pin portion 111 and the contact portion 113 .

[0082] Each of the contact portions 113 includes a plurality of " The contact piece 13 in the shape of "<" extends along the imaginary centerline 113c and protrudes outward to surround the imaginary centerline 113c.

[0083] The inner shaft portion 114 continuous with the contact piece 13 is erected coaxially with the imaginary center line 113 c in each of the contact portions 1...

no. 2 example

[0101] The following reference Figure 9 to 32B The press-fit type connector terminals 200, 300, 400, 500, 600, 700, 800, and 900 according to the second to ninth embodiments are explained. versus figure 1 The parts or elements corresponding to the parts or elements of the press-fit connector terminal 100 shown in 8 to 8 are provided with the same reference numerals, and have the same reference numerals as the corresponding parts or elements in the press-fit connector terminal 100 Way to work, unless clearly stated below.

[0102] Figure 9 to 12 The illustrated press-fit type connector terminal 200 according to the second embodiment is designed to include a pin portion 211 having an unfolded flat plate shape. Insert and pull each of the contact portions 113 into and out of the through hole 21 of the printed circuit board 20 (see Image 6 ) Is parallel to the length direction of the pin portion 211.

[0103] By thus designing the pin portion 211, the press-fit type connector termi...

no. 3 example

[0105] Figure 13 to 1 The press-fit type connector terminal 300 according to the third embodiment shown in 7 is designed to include a shoulder 312 having a double-wall structure. Specifically, such as Figure 17A with 17B As shown, the metal plate 310 forming the press-fit type connector terminal 300 is designed to include the width direction of the pin portion 111 (see Figure 13 ) A strip-shaped fourth area 321 extending in parallel, the fourth area 321 is located between the first area 120 for forming the pin portion 111 and the sixth area 122 for forming the connecting portion 119 each. The shoulder 312 is formed by folding the fourth region 321 along two folding lines 329 extending parallel to the folding line 128. The two regions that extend outwardly beyond the fold line 329 define opposite ends 312 a of the shoulder 312. The opposite ends 312 a of the shoulder 312 protrude from the contact portions 113 at the left and right ends among the contact portions 113 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com