Coconut flesh softening method

A technology of coconut meat and coconut coating, which is applied in the fields of application, food preparation, food science, etc., can solve the problems that the softening of mature coconut meat has not been effectively solved and has not been reported, and achieves a significant softening effect, which is convenient for popularization and application. Effect of improving processability and mouthfeel characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

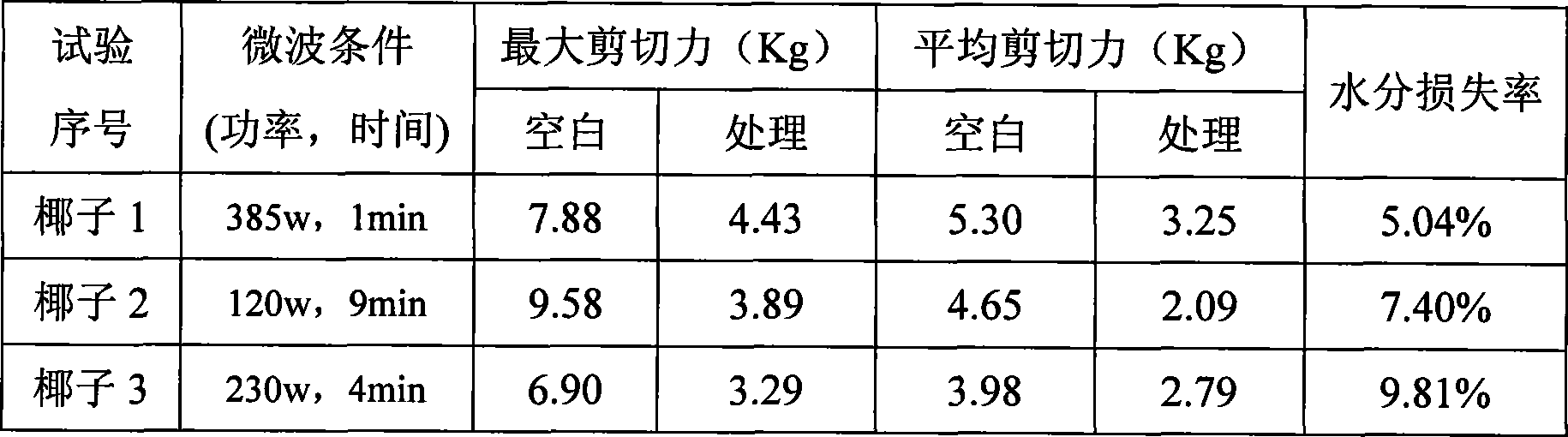

Embodiment 1

[0023] Remove the coconut shell, break the coconut shell, peel off the seed coat, cut the coconut meat of the whole coconut into 4 pieces according to certain requirements, take 50kg block coconut meat and place it in a -18°C freezer for slow freezing until the coconut meat is completely Freeze, then soak the coconut meat in 30°C water for 1 hour, then take out the coconut meat, drain the water and put the coconut meat in a microwave heater in batches, each batch of 1.5kg coconut meat, set the microwave power to 120W, microwave treatment The time is to take out coconut meat after 8min, obtain altogether the coconut flesh after 45.3kg softening. Observe the coconut meat and find that the processed coconut meat is obviously soft, with no obvious cracks on the surface and no burnt smell. The processed coconut meat is packaged for storage and transportation or followed up immediately.

Embodiment 2

[0025] Remove the coconut shell, break the coconut shell, peel the seed coat, cut the whole coconut meat into small pieces with a width of about 3cm according to certain requirements, put 20kg of block coconut meat in a -30°C freezer, and freeze the coconut meat After 15 minutes, take it out and place it at room temperature for 10 minutes, then put it in a -30°C freezer until the coconut meat is completely frozen, soak the coconut meat in warm water at 35°C for 0.5 hours, then take out the coconut meat, drain the water and divide the coconut meat in batches Put in a microwave heater, each batch of 2kg coconut meat, set the microwave power to 230W, microwave treatment time is 4min, take out a piece of coconut meat and observe the coconut meat, it is found that the coconut meat after treatment is obviously soft, there is no obvious crack on the surface and no burnt smell , the coconut meat is taken out completely, obtains altogether the coconut meat after the softening of 18.0g. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com