Technique for preparing beverage contg. lactic acid fermentation sweet waxy corn and product thereof

A technology of lactic acid bacteria fermentation and sweet waxy corn, applied in the direction of plant protein processing, food science, etc., to achieve the effect of helping digestion, pure color and improving immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

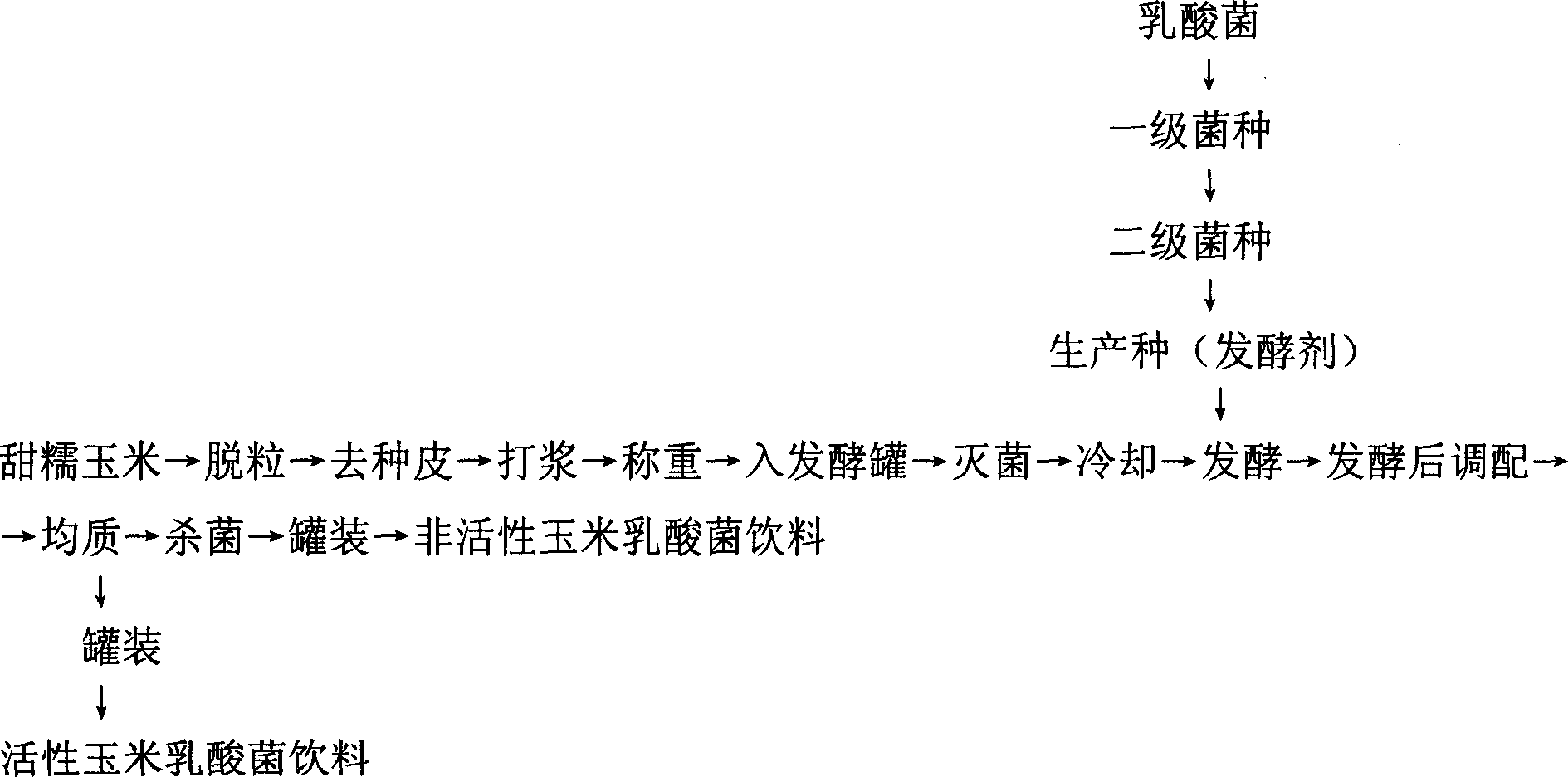

Method used

Image

Examples

Embodiment 1

[0033] Take fresh sweet waxy corn as raw material, weigh 1000g after threshing and peeling off the seed coat, beat it, put it into a fermenter, then add 1500g of pure water, sterilize at 100°C for 30 minutes, then cool to 30°C; 125 grams of lactic acid bacteria starter, lactic acid bacteria starter is Lactobacillus L 041 with L 042 The starter compounded by 1:1, the inoculation amount is 5% of the fermentation broth, sealed, the fermentation temperature is controlled to be 28±2°C, the fermentation cycle is 72 hours, and the terminal pH value of the fermentation is 2.9-3.3; Add 250 grams of granulated sugar and 50 grams of honey to the fermented liquid, homogenize and fill to obtain an active corn lactic acid bacteria drink with lactic acid bacteria activity, or sterilize the homogenized fermented liquid for 5-6 minutes at 125°C, cool, and pack in cans , producing non-active corn lactic acid bacteria drinks with a shelf life of 6 months; about 2500 grams of corn lactic acid ba...

Embodiment 2

[0035] Take fresh sweet waxy corn as raw material, weigh 1000g after threshing and peeling off the seed coat, beat it, put it into a fermenter, then add 2000g of pure water, sterilize at 100°C for 35 minutes, then cool to 32°C; 180 grams of lactic acid bacteria starter, the lactic acid bacteria starter is Lactobacillus L 041 with L 042 The starter compounded by 1:1, the inoculation amount is 6% of the fermentation broth, sealed, the controlled fermentation temperature is 28°C, the fermentation cycle is 80 hours, and the terminal pH value of the fermentation is 2.9-3.3; after the fermentation is stopped, the fermentation broth Add 300 grams of granulated sugar and 60 grams of honey, homogenize and fill to obtain an active corn lactic acid bacteria beverage with lactic acid bacteria activity, or sterilize the homogenized fermented liquid for 5-6 minutes at 135 ° C, cool and can, and produce The inactive corn lactic acid bacteria drink with a shelf life of 6 months; about 3000 g...

Embodiment 3

[0037] Use fresh sweet waxy corn as raw material, weigh 1000g after threshing and peeling off the seed coat, beat it, put it into a fermenter, then add 1300g of pure water, sterilize at 100°C for 25 minutes, then cool to 28°C; 115 grams of lactic acid bacteria starter, lactic acid bacteria starter is Lactobacillus L 041 with L 042 The starter compounded by 1:1, the inoculation amount is 5% of the fermentation broth, sealed, the controlled fermentation temperature is 26°C, the fermentation cycle is 70 hours, and the fermentation terminal pH value is 2.9-3.3; after the fermentation is stopped, the fermentation broth Add 230 grams of granulated sugar and 46 grams of honey, homogenize and fill to obtain an active corn lactic acid bacteria beverage with lactic acid bacteria activity, or sterilize the homogenized fermented liquid for 5-6 minutes at 130 ° C, cool, and canned to produce The inactive corn lactic acid bacteria drink with a shelf life of 6 months; about 2300 grams of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com