Production method of yellow water vinegar beverage

A technology of vinegar drink and vinegar mother, which is applied in the production field of yellow water vinegar drink, can solve the problems that the additional benefits of yellow water have not been maximized, environmental pollution, etc., and achieve low production costs, broad market prospects, and enhanced additional benefits. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

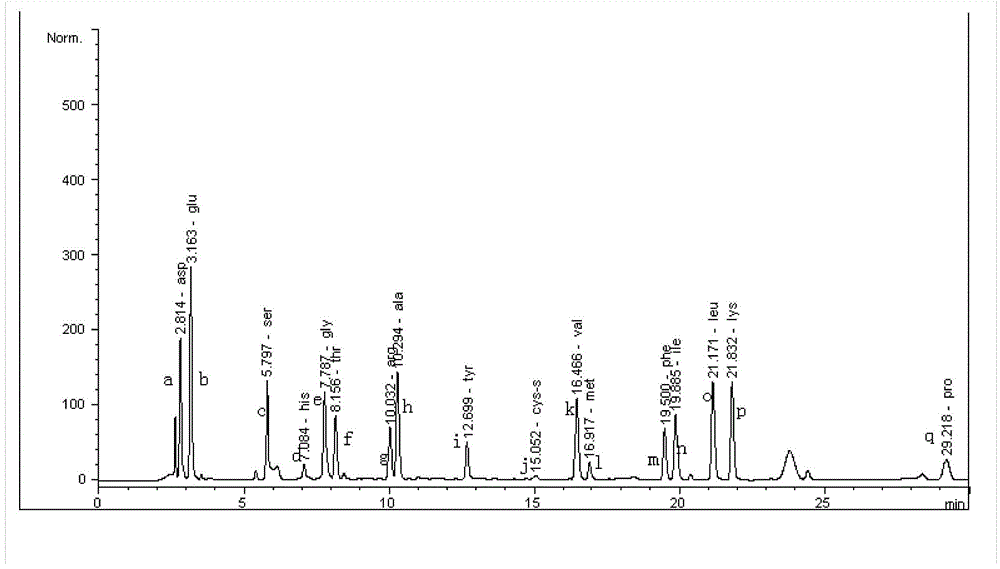

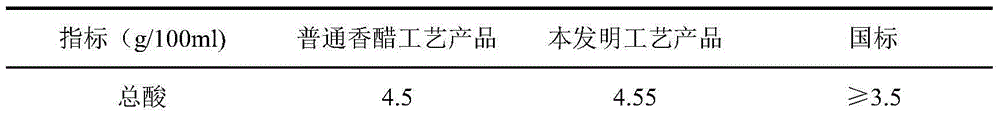

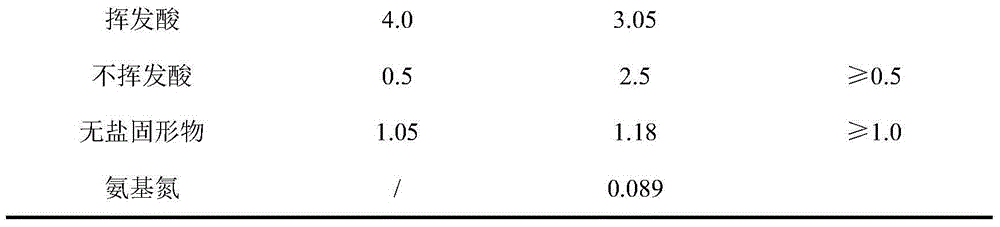

Image

Examples

Embodiment 1

[0036] Embodiment 1 produces yellow water vinegar drink according to the following steps:

[0037] (1) Preparation of lactic acid bacteria liquid: prepare 700ml of MRS medium, adjust pH to 6.3, distribute into seven 300ml Erlenmeyer flasks, autoclave at 121°C for 30min, and cool to room temperature; Lactobacillus plantarum subsp. Lactobacillus plantarum subsp.plantarum) CGMCC NO.1.2158 Under aseptic conditions, pick 3 rings from each conical flask and inoculate them with an inoculation loop, culture at 31°C for 48 hours to obtain lactic acid bacteria seed solution; add to a 10L fermenter 7L medium (fermenter medium is composed of MRS medium and yellow water, MRS: yellow water volume ratio = 7:3) was sterilized at 121°C and 0.15Mpa for 30min, cooled to room temperature, and 8% ( The ratio of v / v) was inserted into the lactic acid bacteria seed solution in a triangular flask, and cultured at 31°C for 42 hours to obtain 7L lactic acid bacteria solution.

[0038] (2) Preparation ...

Embodiment 2

[0044] Embodiment 2 produces yellow water vinegar drink according to the following steps:

[0045] (1) Preparation of lactic acid bacteria liquid: prepare 700ml of MRS medium, adjust the pH to 6.4, divide into seven 300ml Erlenmeyer flasks, autoclave at 121°C for 30min, and cool to room temperature; the lactic acid bacteria (CGMCC NO.1.2158) Under sterile conditions, pick 4 loops and insert them with inoculation loops in each triangular flask, and cultivate them at 32°C for 48 hours to obtain lactic acid bacteria seed liquid; add 7L culture medium to a 10L fermenter (fermenter culture medium is provided by MRS Composition of culture medium and yellow water, MRS: yellow water = 7:3 (v / v)) sterilized at 121°C and 0.15Mpa for 30 minutes, cooled to room temperature, and inoculated according to the ratio of 9% (v / v) under sterile conditions Put the lactic acid bacteria seed liquid into the triangular flask, 32 ℃, static culture for 44 hours, to obtain 7L lactic acid bacteria liquid...

Embodiment 3

[0052] Embodiment 3 produces yellow water vinegar drink according to the following steps:

[0053] (1) Preparation of lactic acid bacteria liquid: Prepare 700ml of MRS medium, adjust the pH to 6.5, divide into seven 300ml Erlenmeyer flasks, autoclave at 121°C for 30min, and cool to room temperature; the lactic acid bacteria (CGMCC NO.1.2158) Under aseptic conditions, pick 5 rings and insert them with inoculation loops in each triangular flask, and cultivate them at 33°C for 48 hours to obtain lactic acid bacteria seed liquid; Culture medium and yellow water (7:3 (v / v) composition); sterilized at 121°C and 0.15Mpa for 30 minutes, cooled to room temperature, and inserted into a triangular flask with lactic acid bacteria at a ratio of 10% (v / v) under sterile conditions The seed liquid was cultured statically at 33° C. for 45 hours to obtain 7 L of lactic acid bacteria liquid.

[0054] (2) Preparation of wine mother: Prepare 300ml corn mash medium, adjust pH to 4.5, divide into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com