Patents

Literature

50results about How to "Long term operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

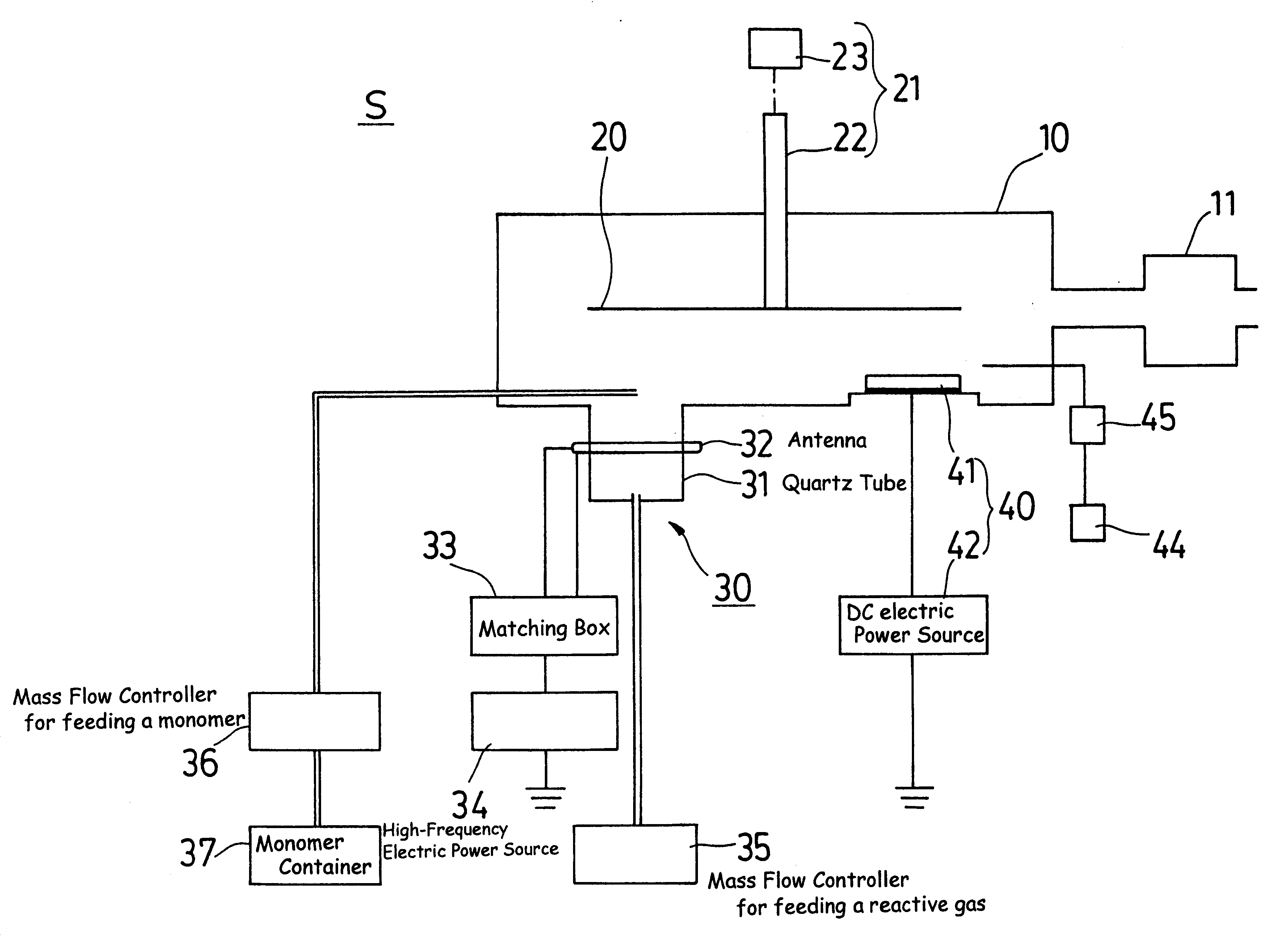

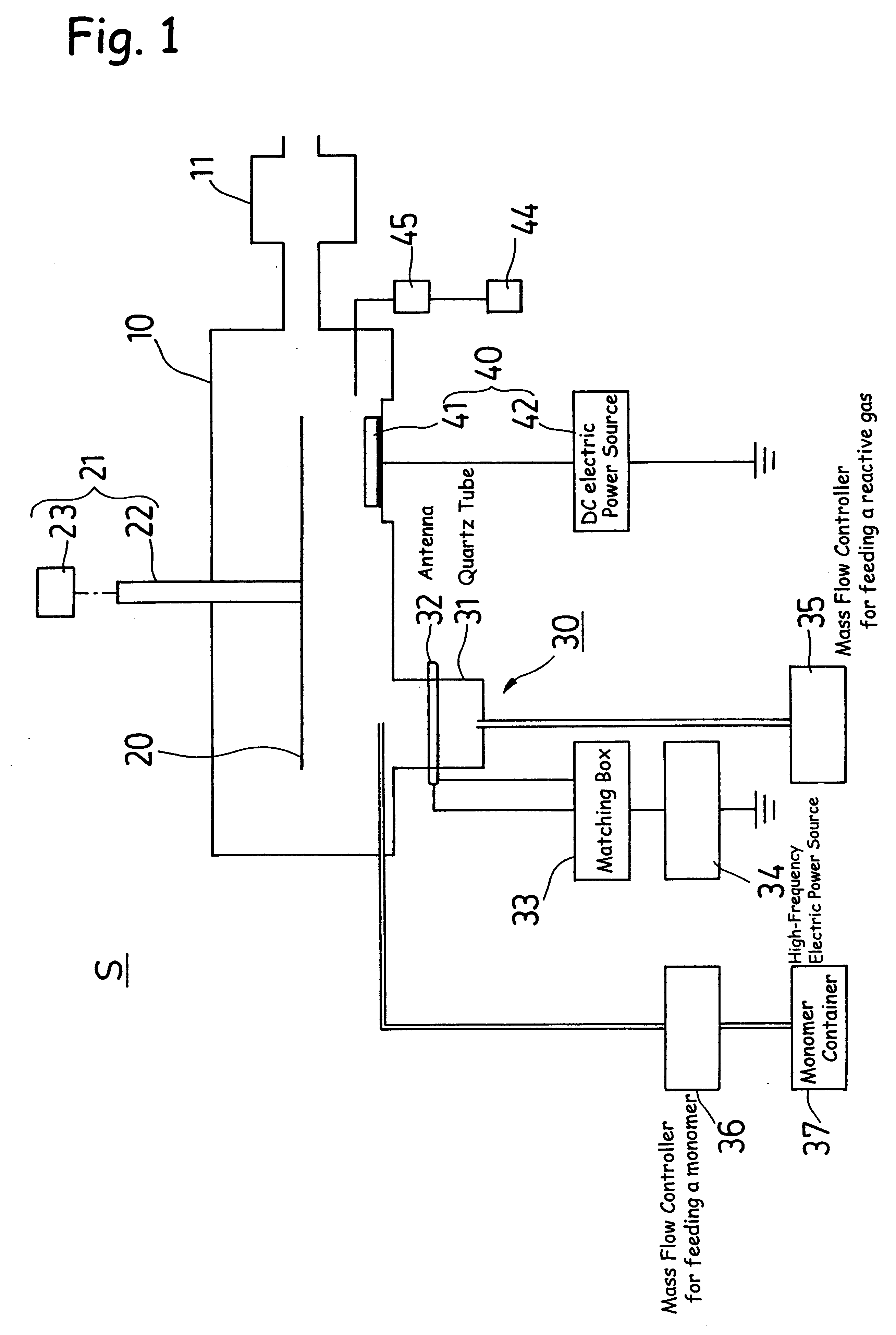

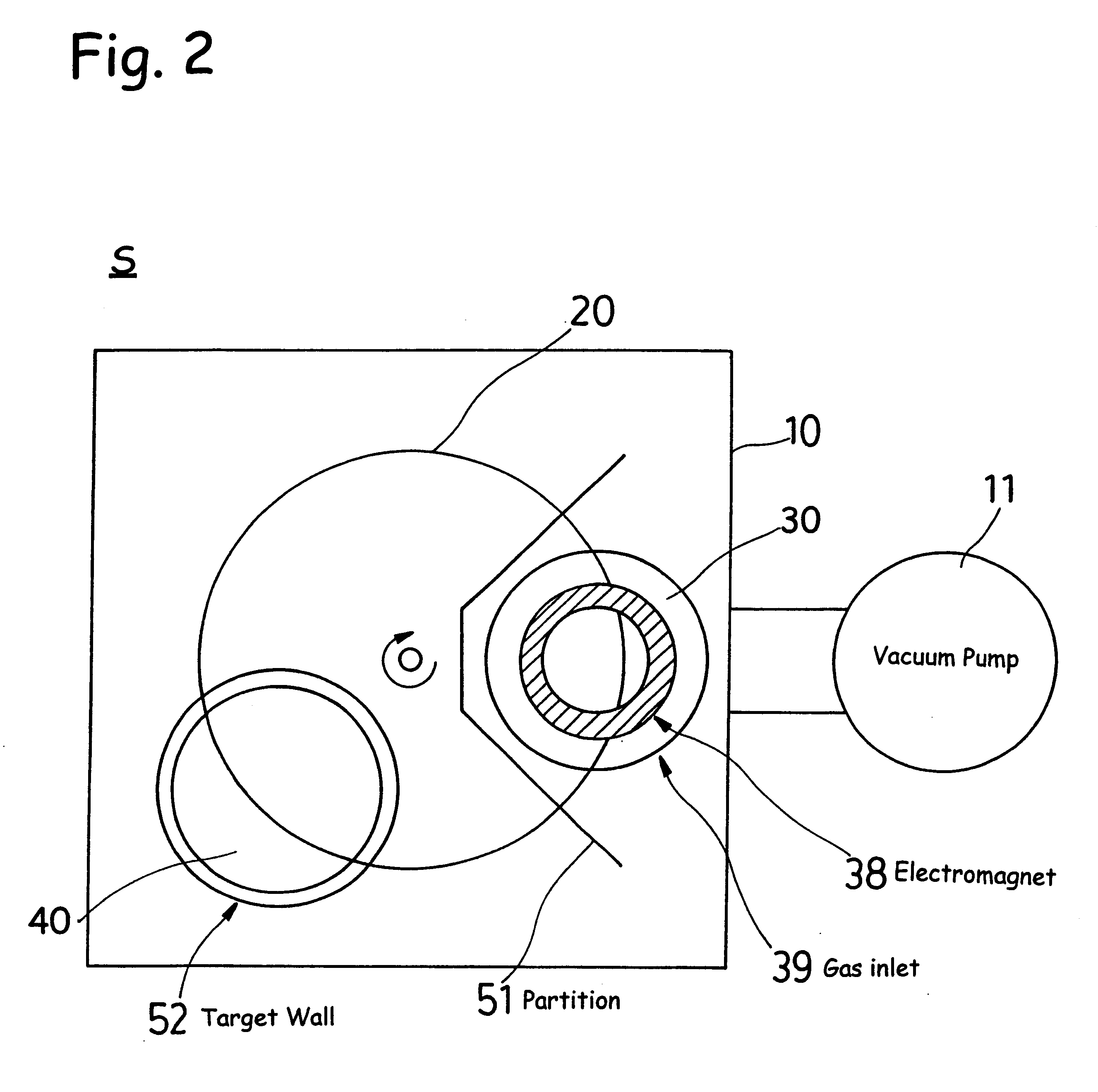

Apparatus and method forming thin film

InactiveUS6287430B1Long-term reproducibilityLong-term stable operationCellsElectric discharge tubesSputteringRefractive index

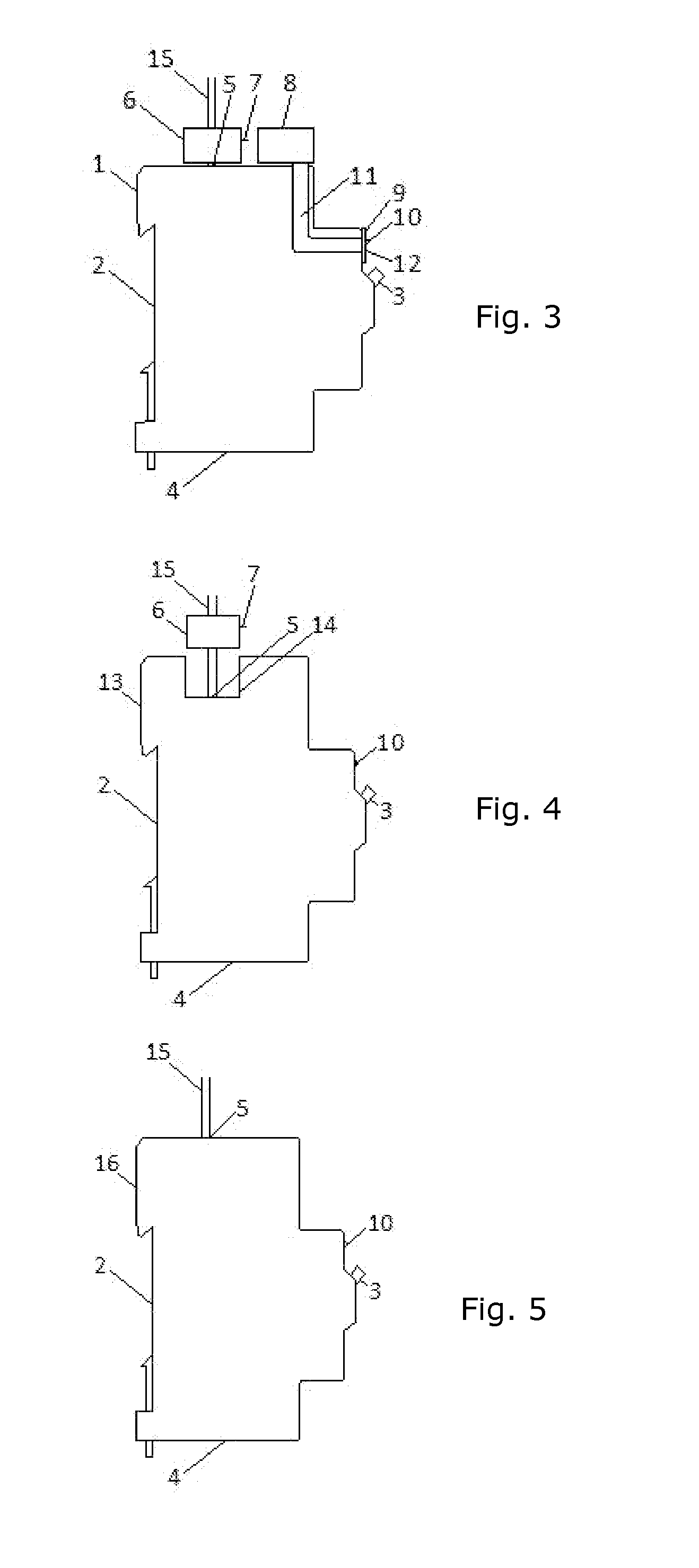

The present invention is drawn to an apparatus for forming a thin film. The apparatus includes a vacuum chamber; a vacuum apparatus connected to the vacuum chamber; a holder placed in the vacuum chamber, which holder holds a substrate and is rotated by means of a rotating mechanism; a plasma CVD apparatus; and a sputtering apparatus, wherein the plasma CVD apparatus and the sputtering apparatus are placed in a single vacuum chamber and a thin film having an medium refractive index is formed on the substrate held by the holder, by means of the plasma CVD apparatus and the sputtering apparatus. The method making use of such an apparatus is also disclosed.

Owner:SHINCRON KK

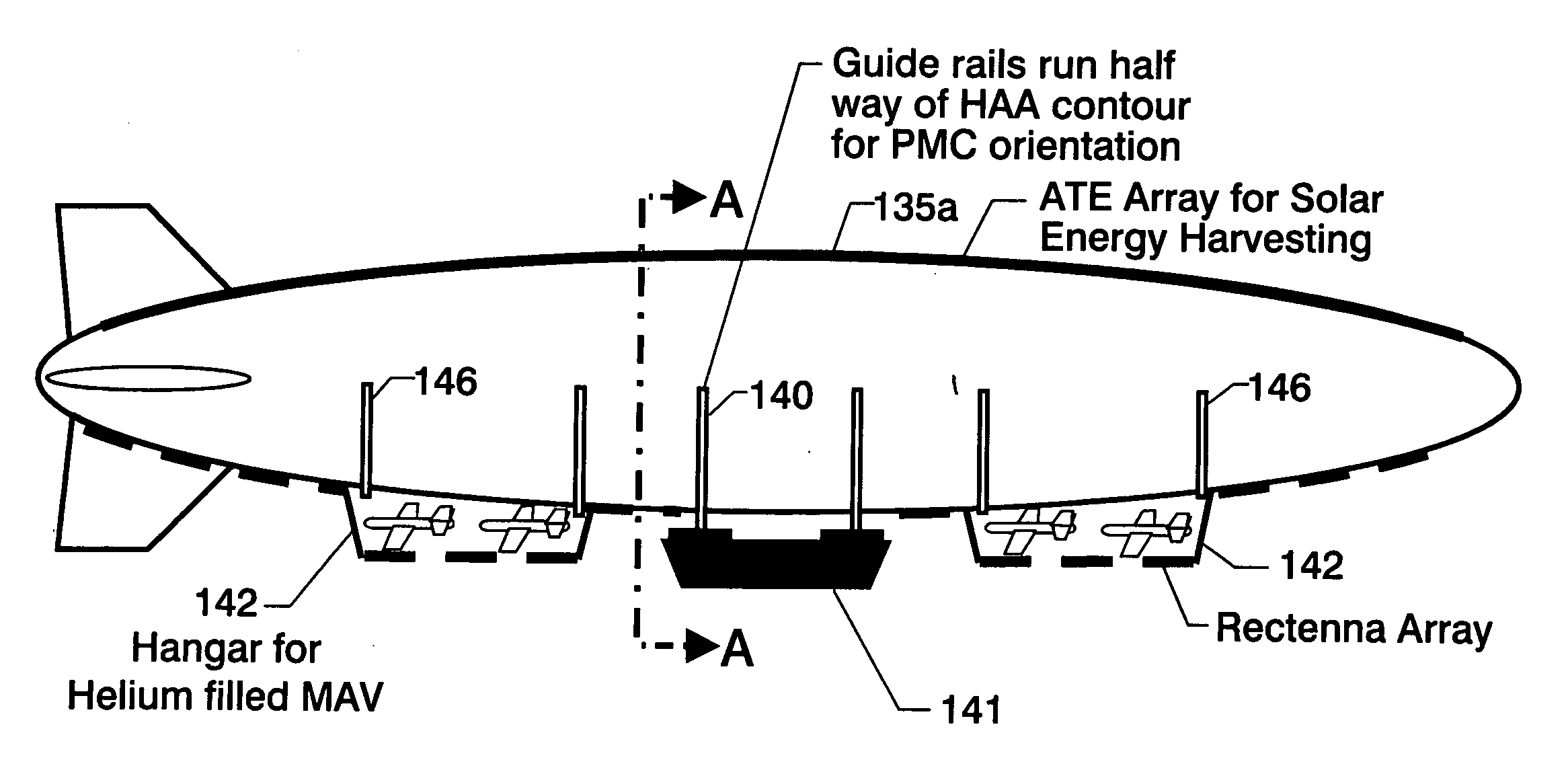

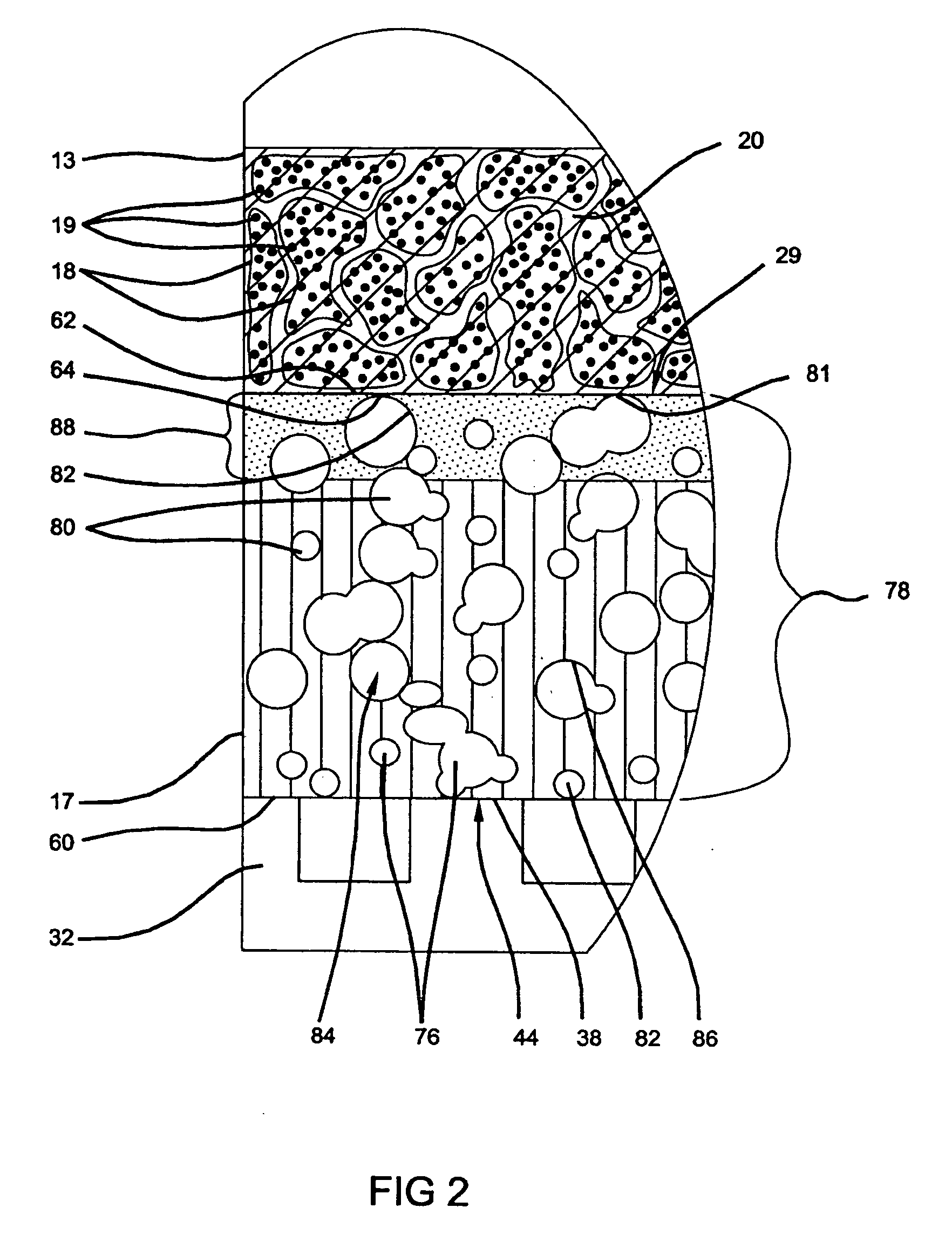

High Altitude Airship Configuration And Power Technology And Method For Operation Of Same

ActiveUS20090072078A1Maximize collectionEfficient cascadingThermoelectric device manufacture/treatmentUnmanned aerial vehiclesEnergy harvestingAutomotive engineering

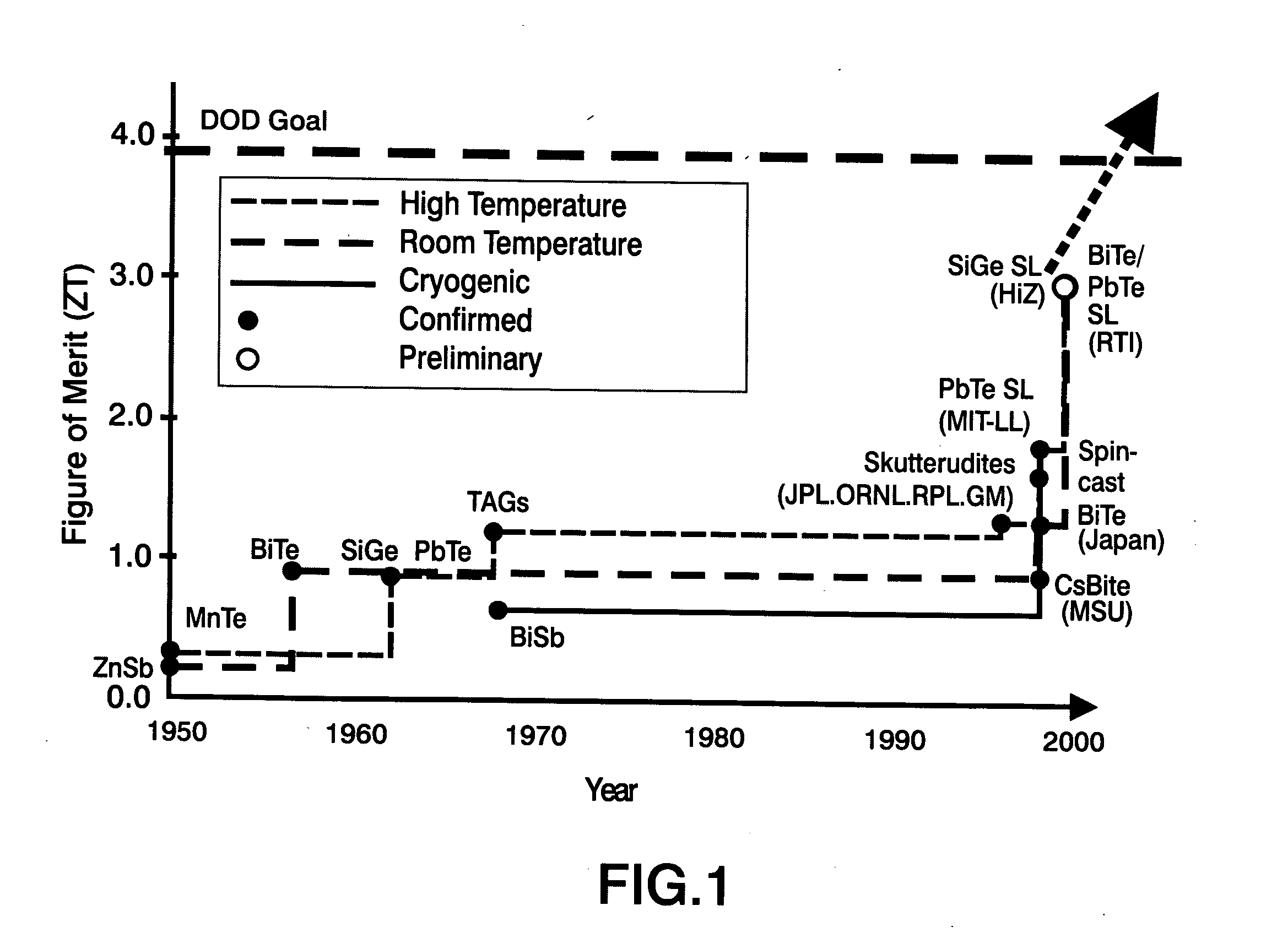

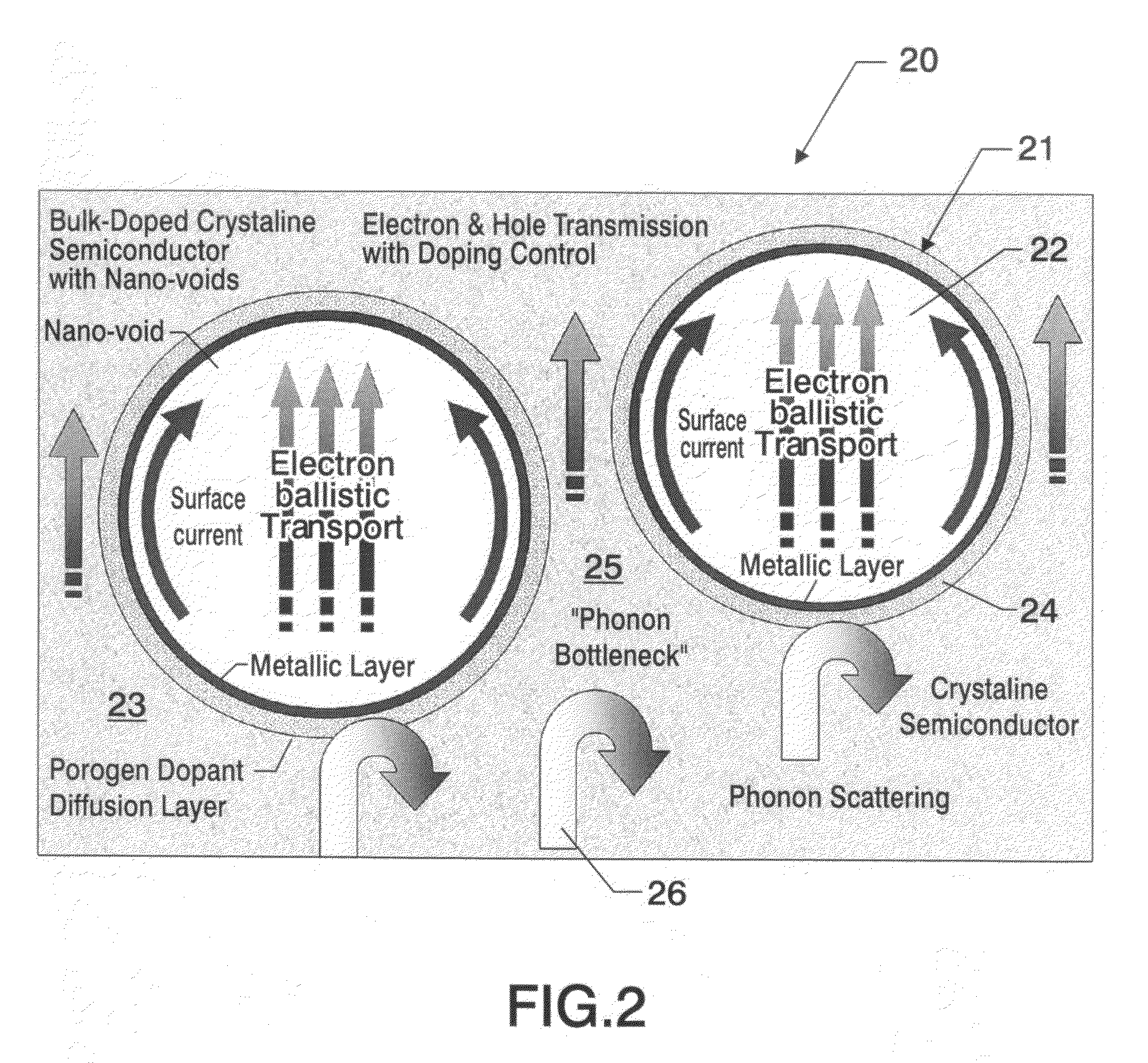

A new High Altitude Airship (HAA) capable of various extended applications and mission scenarios utilizing inventive onboard energy harvesting and power distribution systems. The power technology comprises an advanced thermoelectric (ATE) thermal energy conversion system. The high efficiency of multiple stages of ATE materials in a tandem mode, each suited for best performance within a particular temperature range, permits the ATE system to generate a high quantity of harvested energy for the extended mission scenarios. When the figure of merit 5 is considered, the cascaded efficiency of the three-stage ATE system approaches an efficiency greater than 60 percent.

Owner:UNITED STATES OF AMERICA REPRESENTED BY SEC OF THE NAVY +1

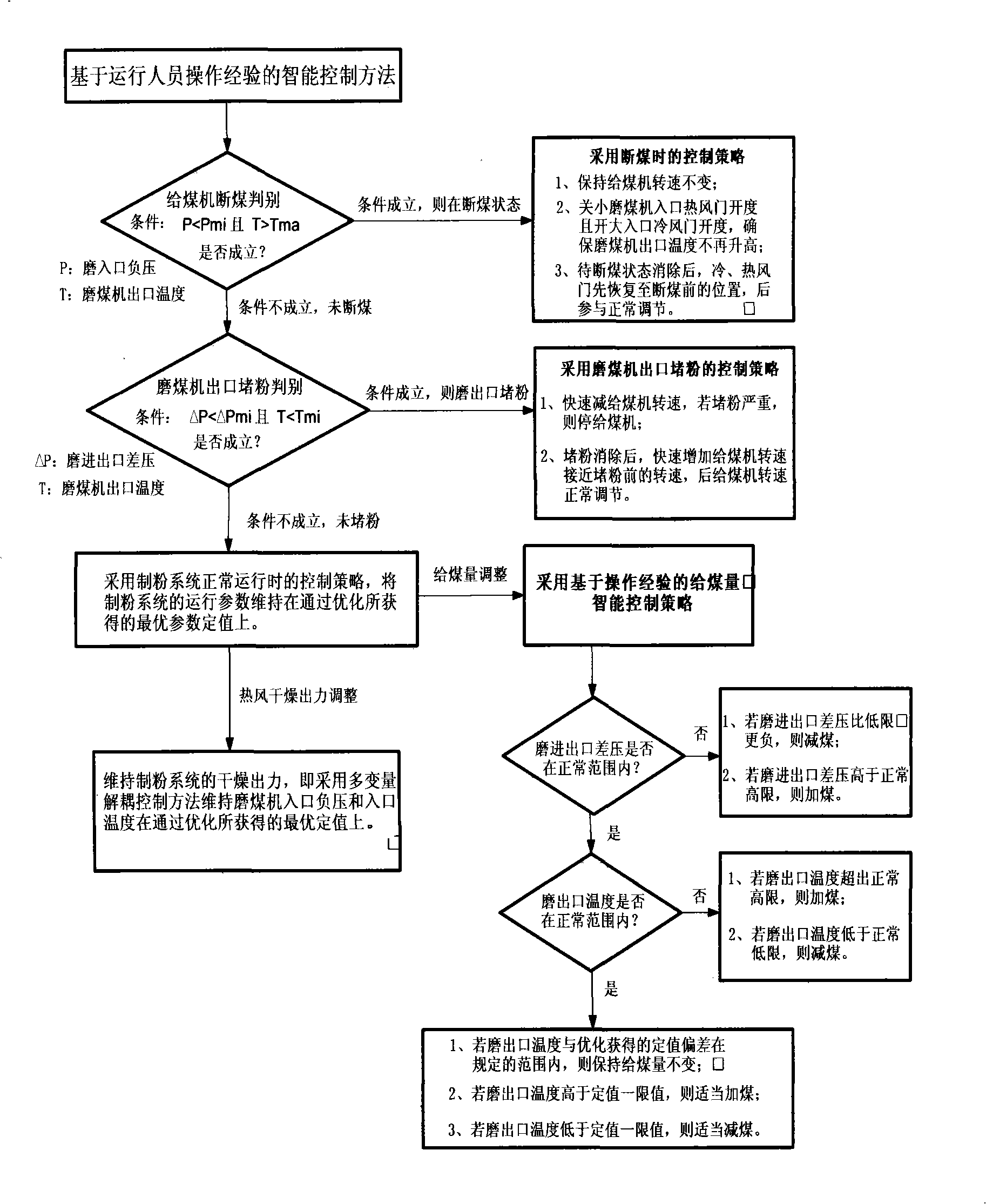

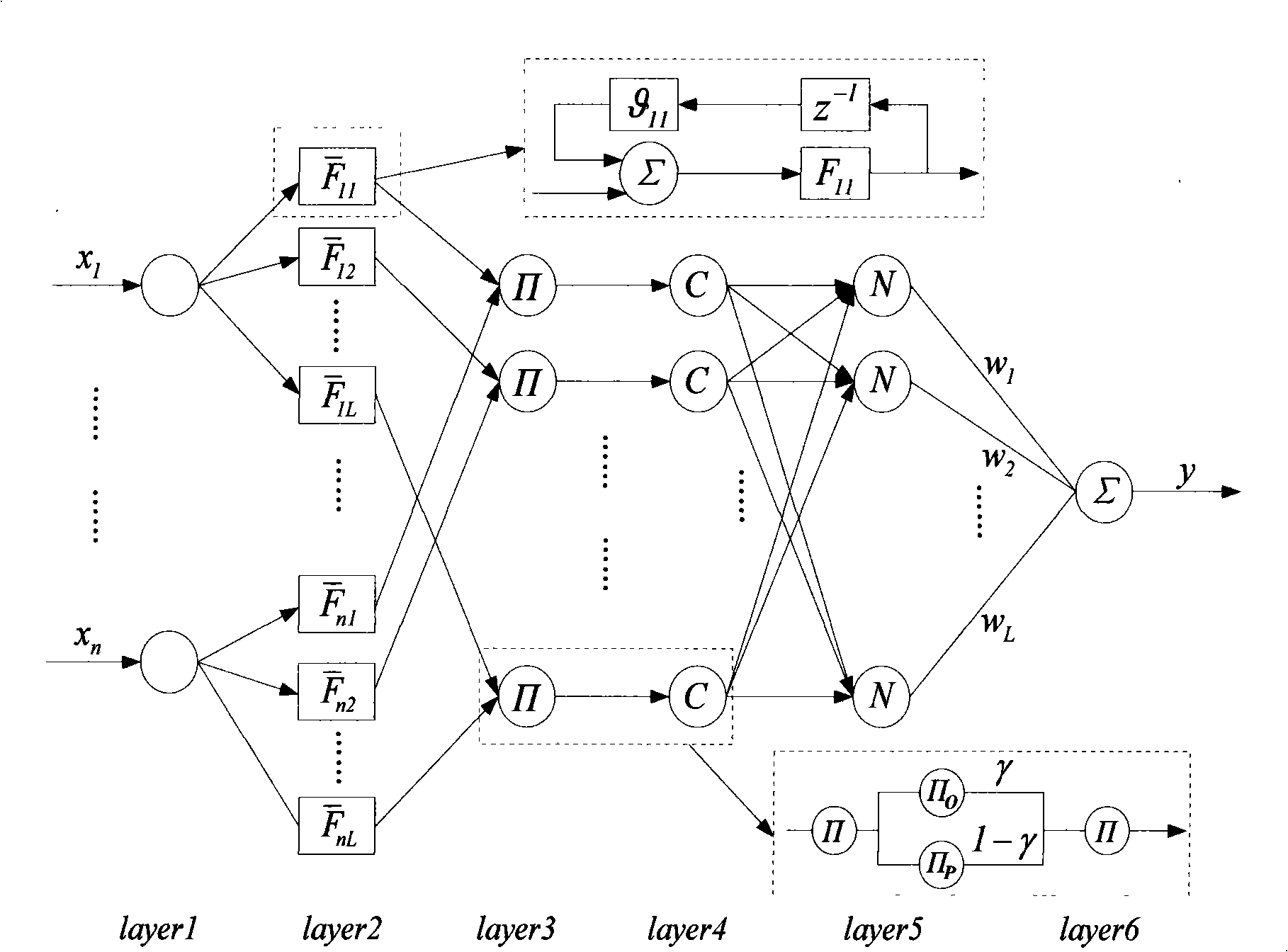

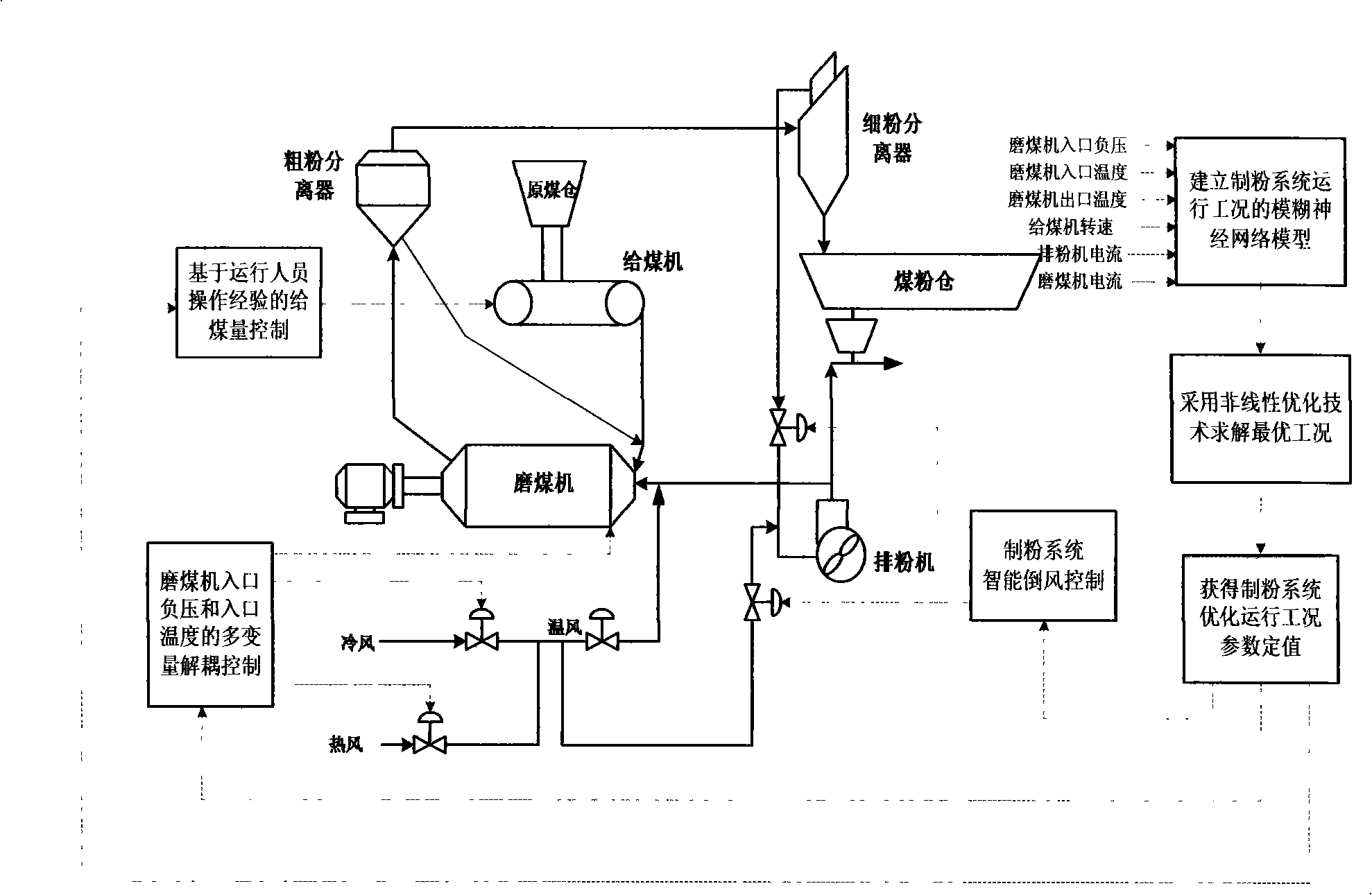

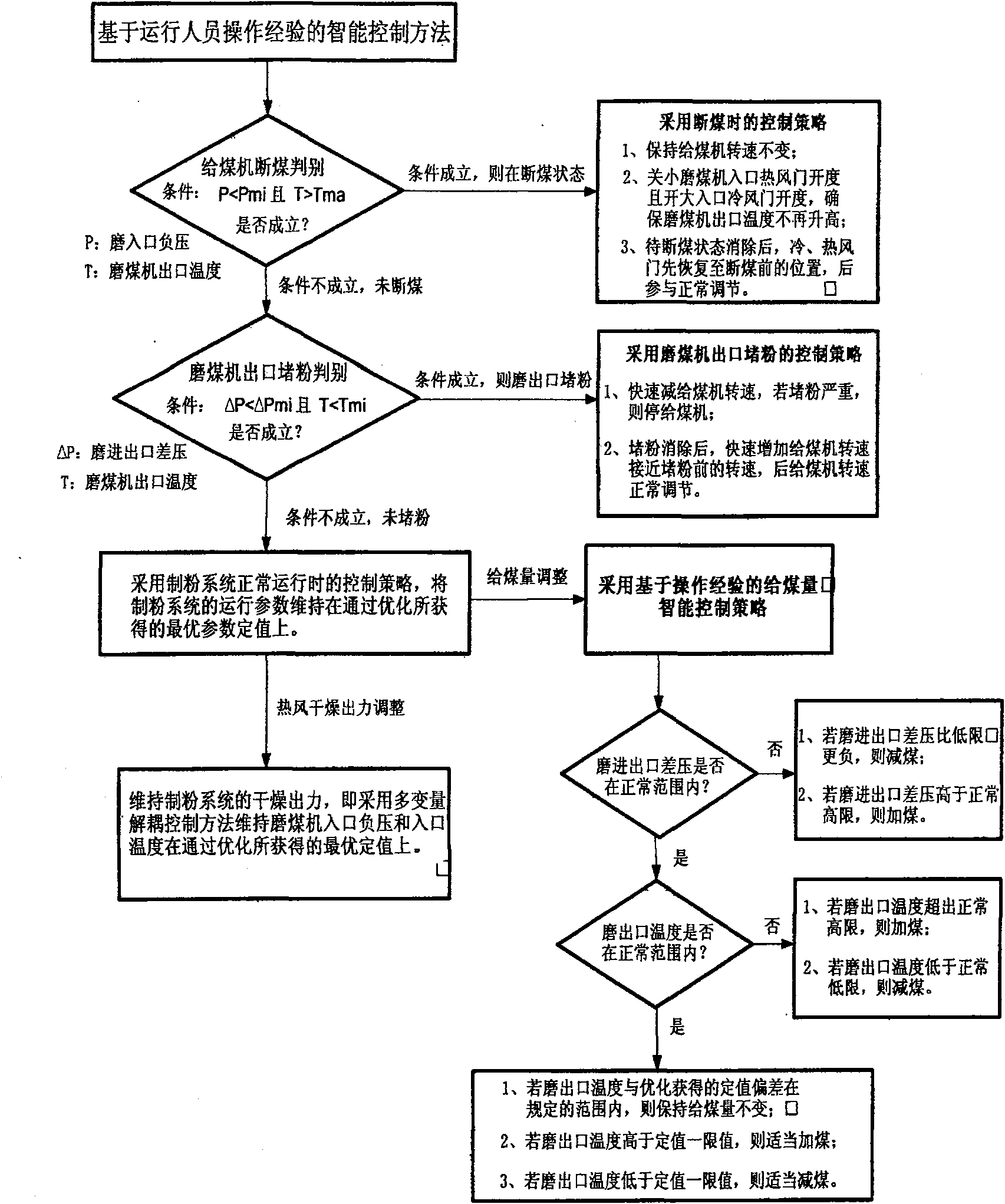

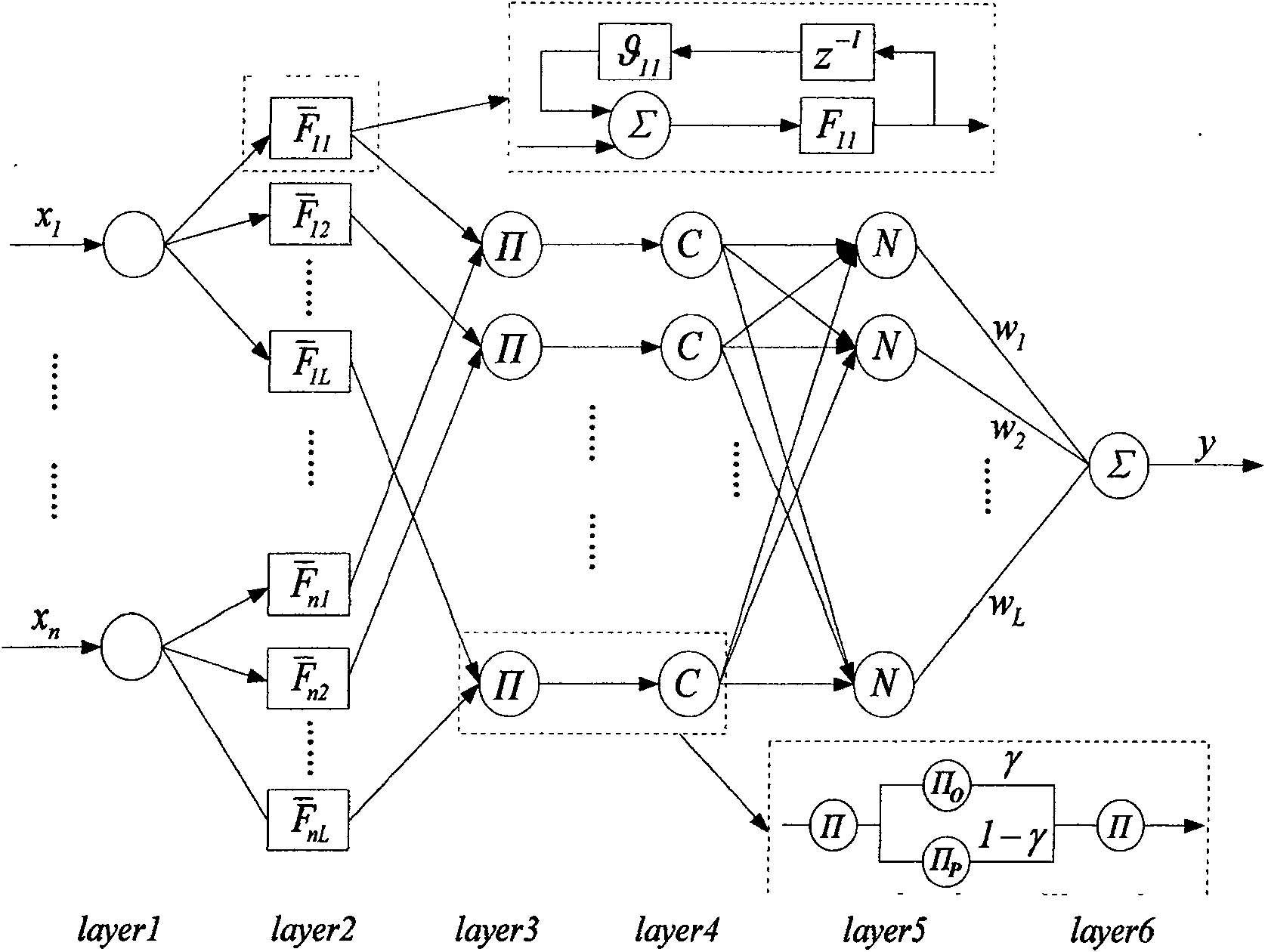

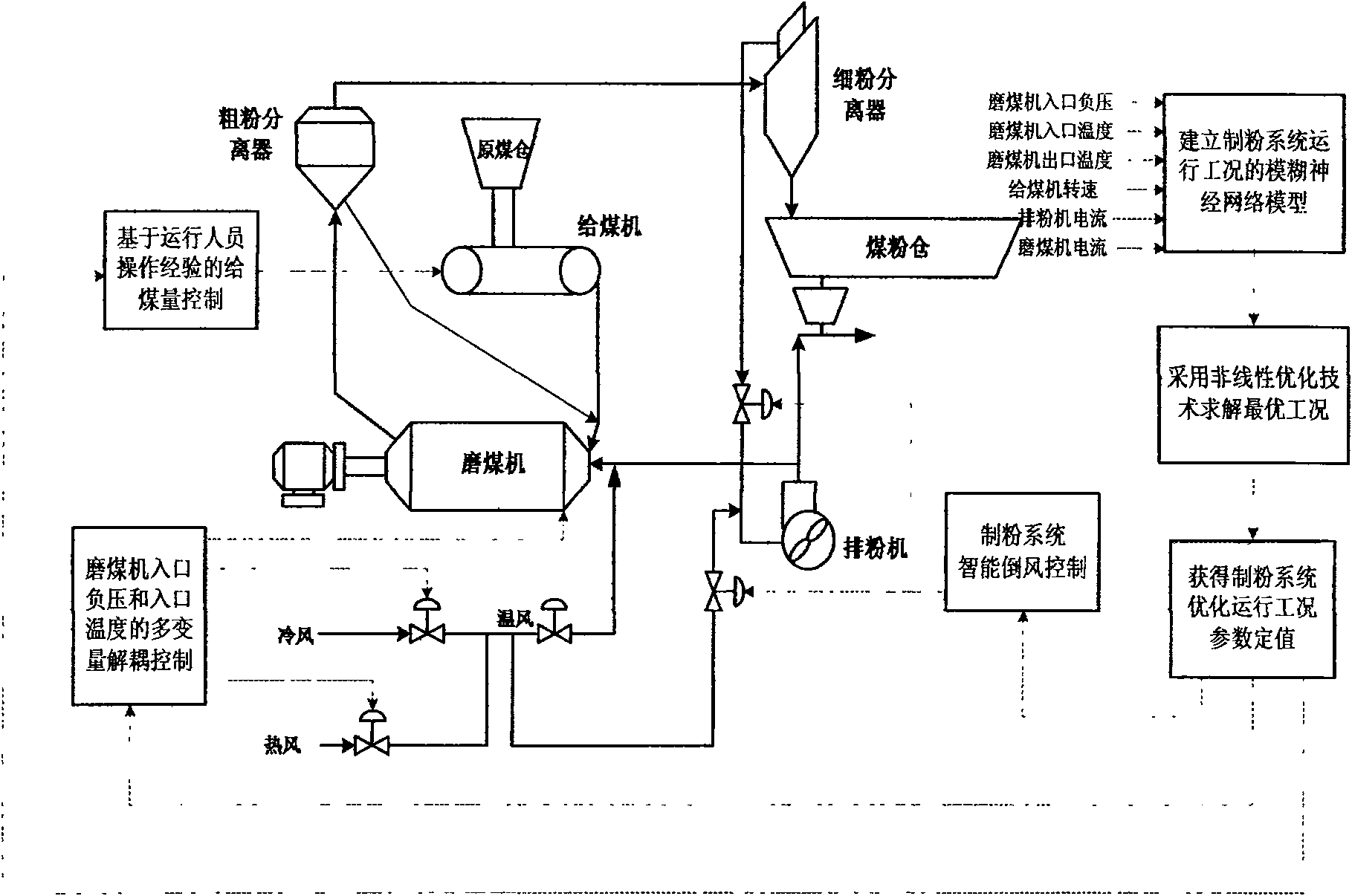

Operation optimizing and energy-saving control method for intermediate storage iron shot mill flour milling system

The invention relates to a method for the optimization of operation and control of energy conservation for a reserve ball-grinding powder system. Firstly, a non-linear neural network model about the consumption of powder of a powder-making system and operating parameters is established through collecting the service data of the powder-making system, then the negative pressure and the temperature at the entrance of a coal mill and the temperature at the outlet of the coal mill are obtained through the non-linear optimization with restricted conditions as a set value for controlling the system, wherein, the negative pressure, the temperature at the entrance and the outlet lead to lower consumption of powder; the entire optimized controlling of the powder-making system is carried out through the intelligent control of rotation of the coal mill and multivariable decoupling control of parameters at the entrance of the coal mill based on the operating experience as well as an intelligent down draft control technology, so as to ensure that the powder-making system strictly runs at an optimal condition and effectively reduces the powder consumption. The method provided by the invention can effectively inhibit the fluctuations of a primary air pressure in the on / off process of the powder-making system, put an end to serious accidents such as flameout in a boiler caused by down draft and effectively reduce the operating intensity for the staff.

Owner:SOUTHEAST UNIV

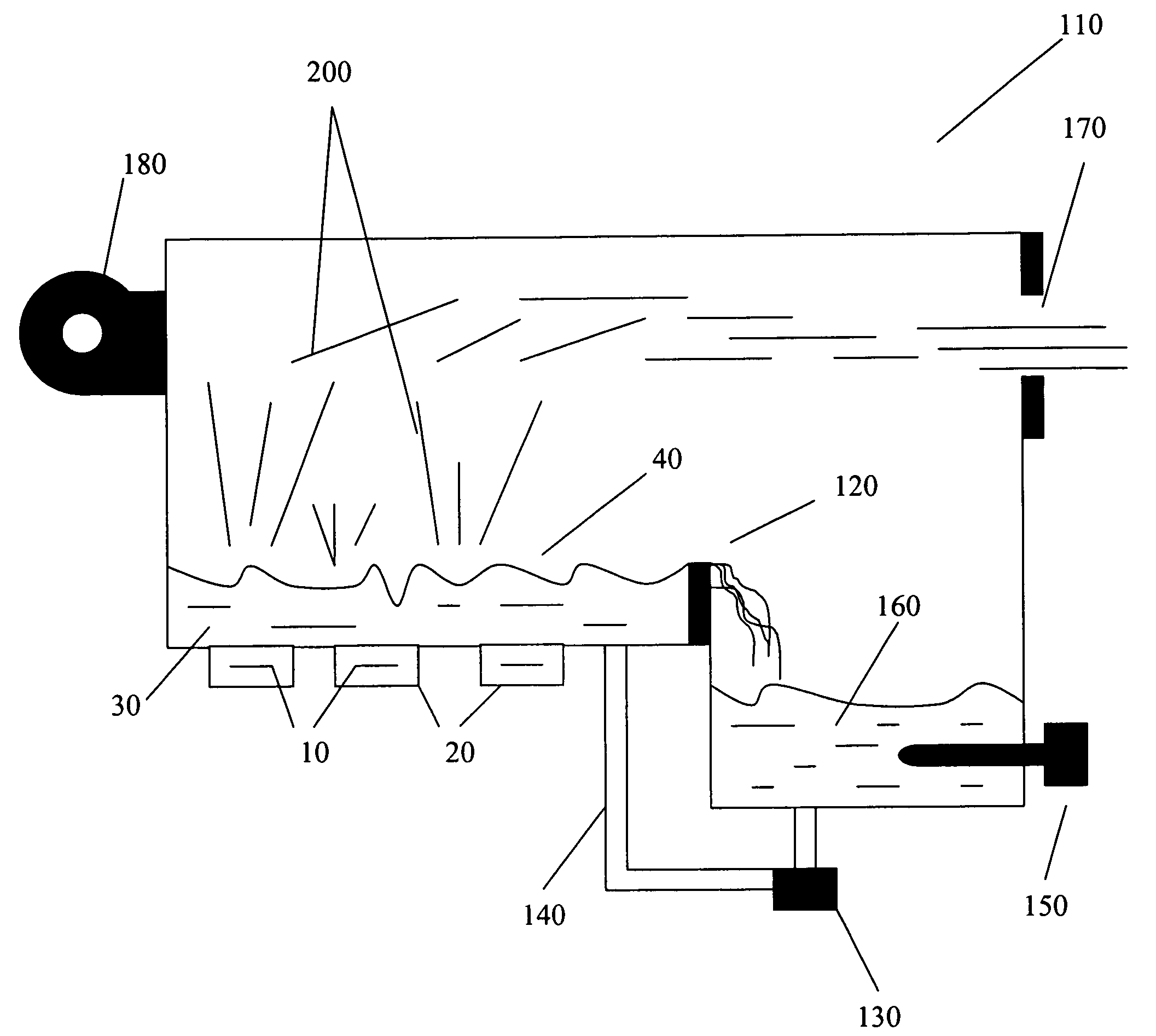

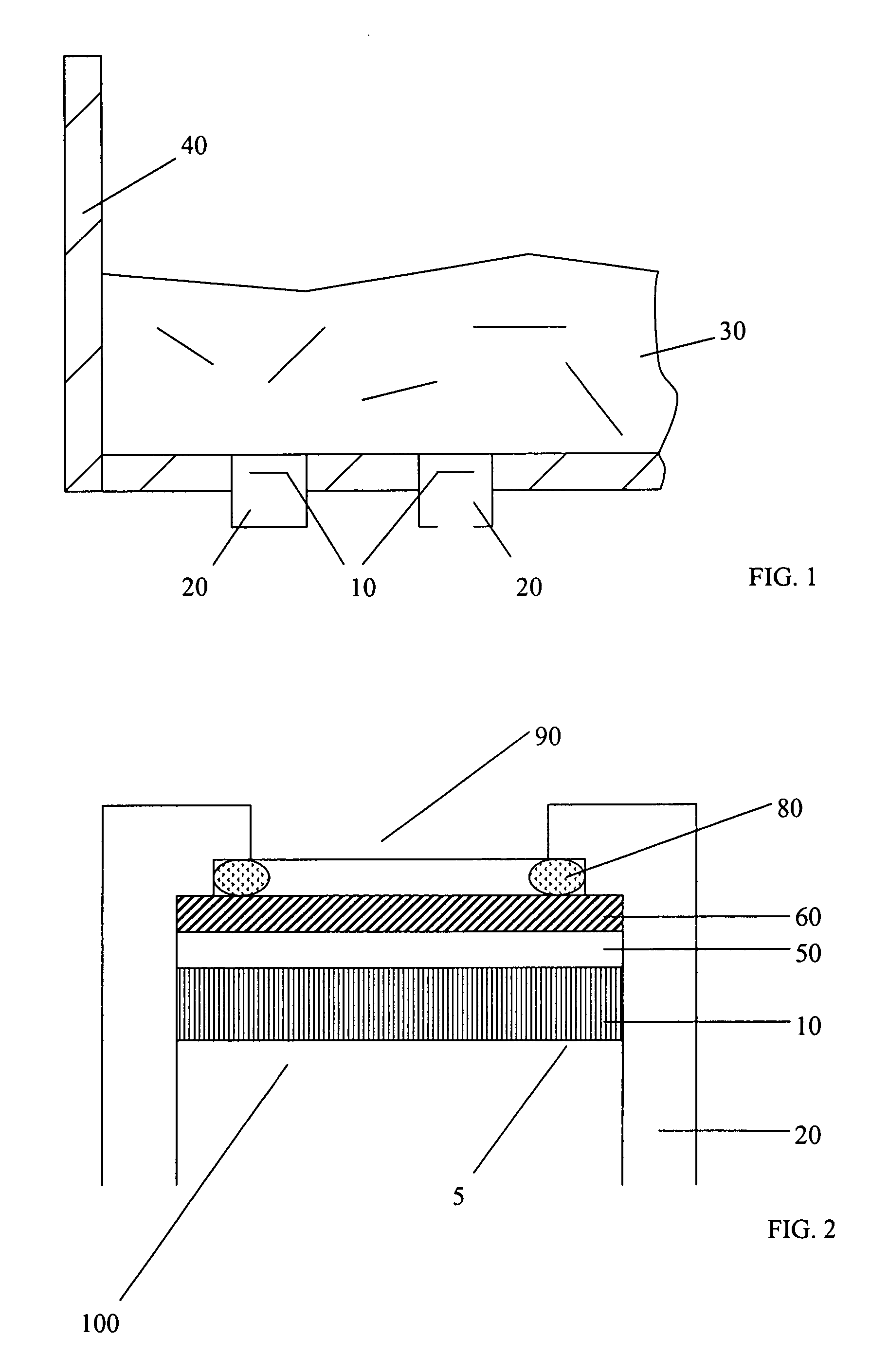

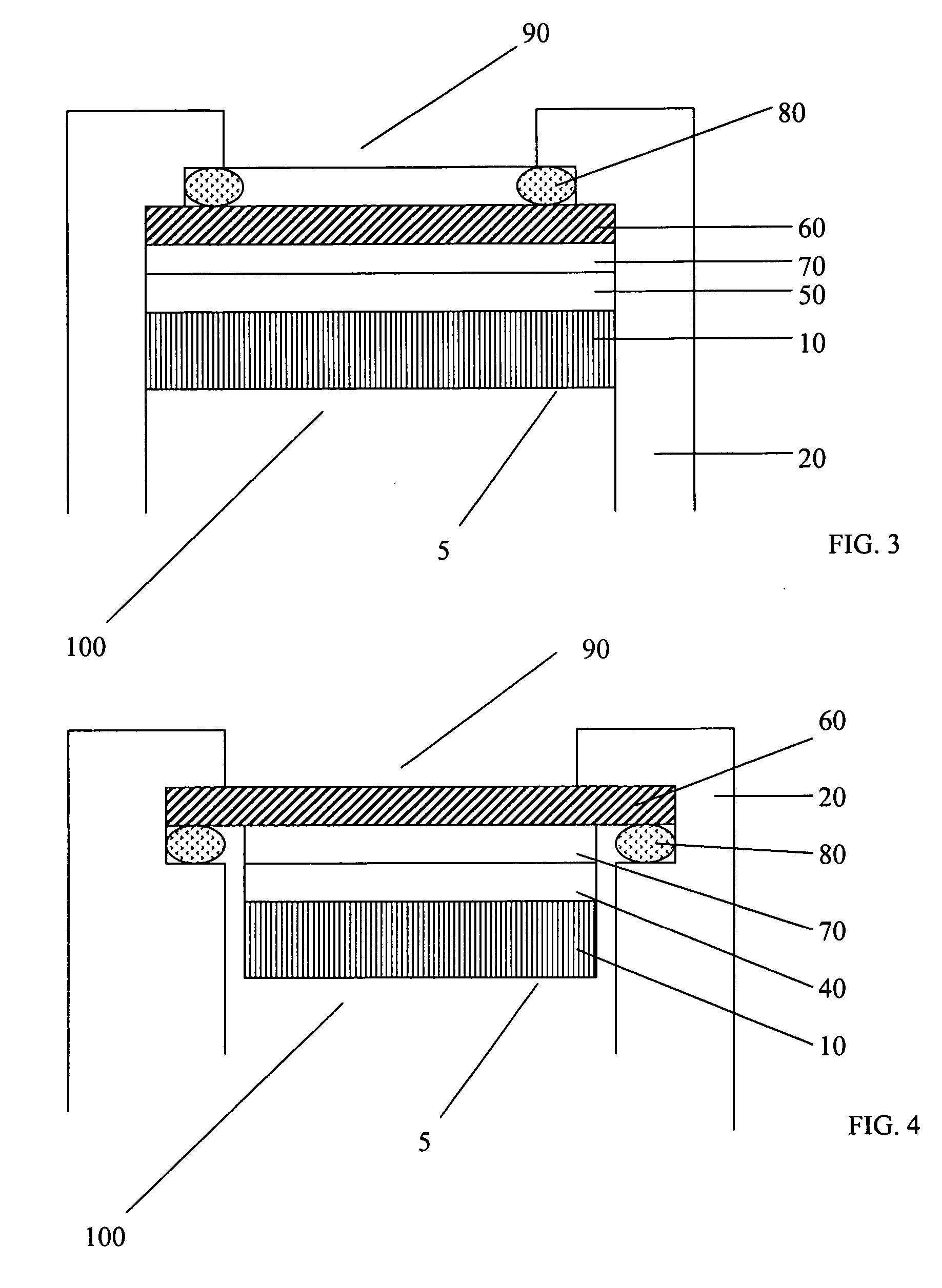

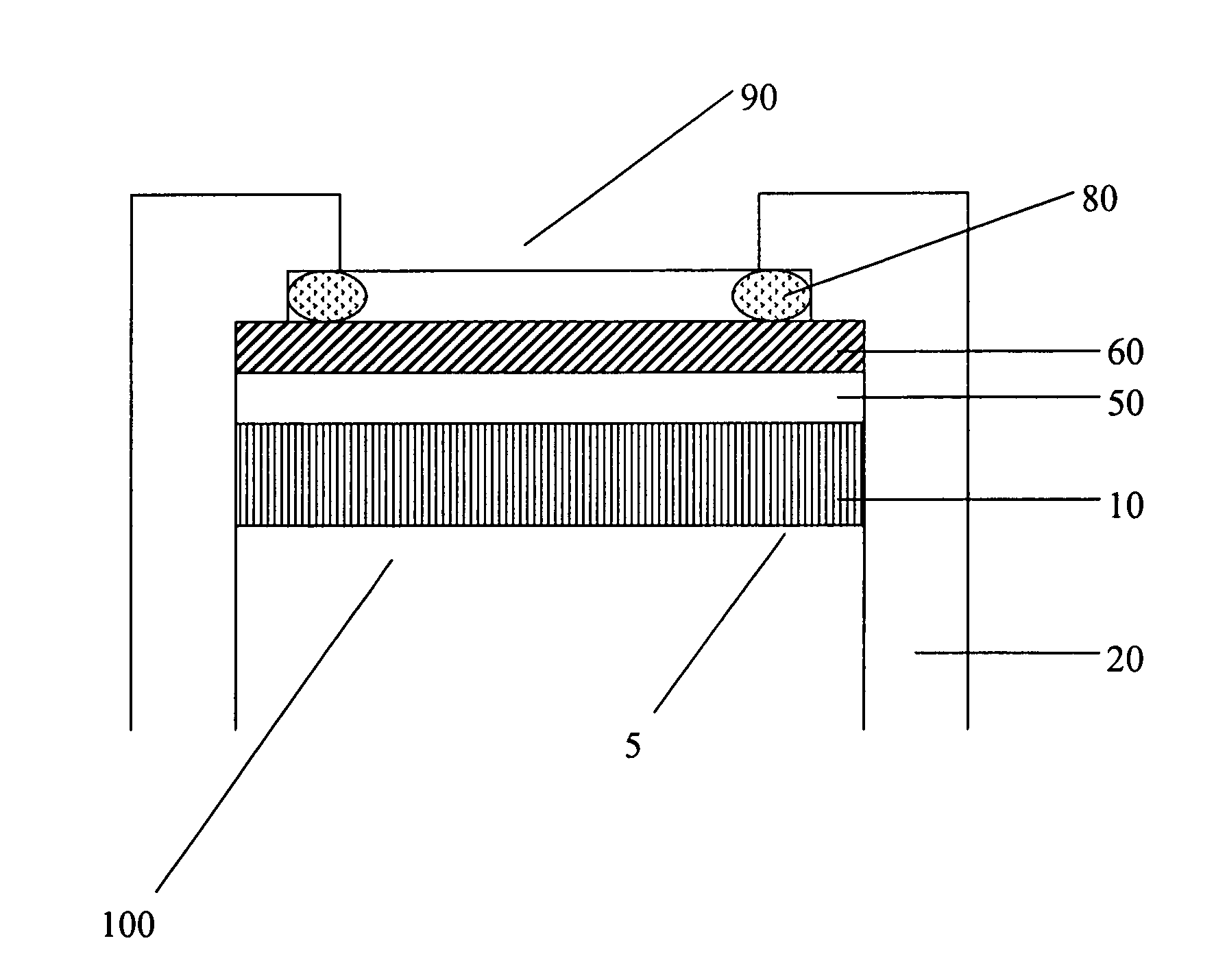

Method and apparatus for optimizing aerosol generation with ultrasonic transducers

ActiveUS20070053789A1Reduced effectivenessIncrease energy outputMovable spraying apparatusSpray nozzlesChemical reactionUltrasonic sensor

The invention is an apparatus and methods for optimizing the performance and protecting one or more aerosol generating transducers from deterioration while operating in a chemically reactive aqueous solution by utilizing one or more protective barrier techniques to eliminate chemical interaction between the aqueous solution and the transducers. The method of the present invention produces an aerosol producing transducer with the transducer housing and assembly to be constructed in such a way as to assure its efficient and effective long-term and problem free operation in an aqueous solution that is chemically reactive.

Owner:ALTAPURE

Distillation method of oxime

The present invention relates to a distillation method of oxime. Tower bottom materials are usually heated by still distillation, a U-shaped outer tube or a rotary film evaporator, long-term operation of the tower bottom is easy to coking, and the distillation efficiency is low. The invention is characterized in that: in the distillation and separation section of oxime, at least one high boiling point solvent is added in the distillation process, the content of the high boiling point solvent in the tower bottom is maintained in proportional to that of oxime, and finally oxime is effectively separated by distillation. Oxime is fed into a rectifying tower, and is distilled at an absolute pressure of 0-0.4 MPa and at 20-300 DEG C to collect fractions. The unevaporated liquid left in the tower bottom is subjected to the processes of removing water and impurities, and is recycled to the rectifying tower as a high boiling point solvent. The present invention can reduce total production costs, simplify operation processes, prevent the product from coking in the tower bottom or decomposing due to overheating, ensure product distillation to be efficient, continuous, safe and stable, and improve product quality.

Owner:ZHEJIANG SAINON CHEM

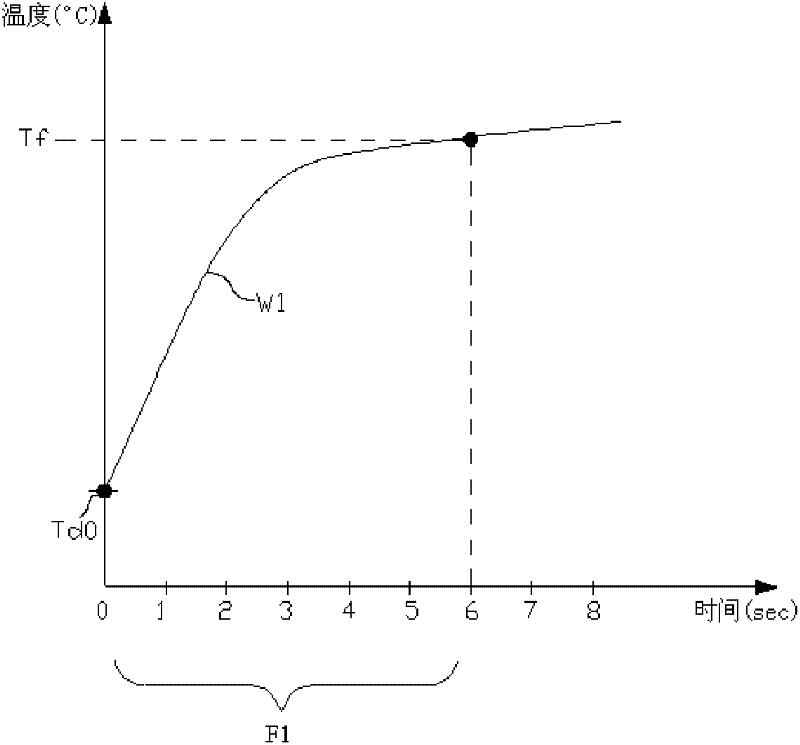

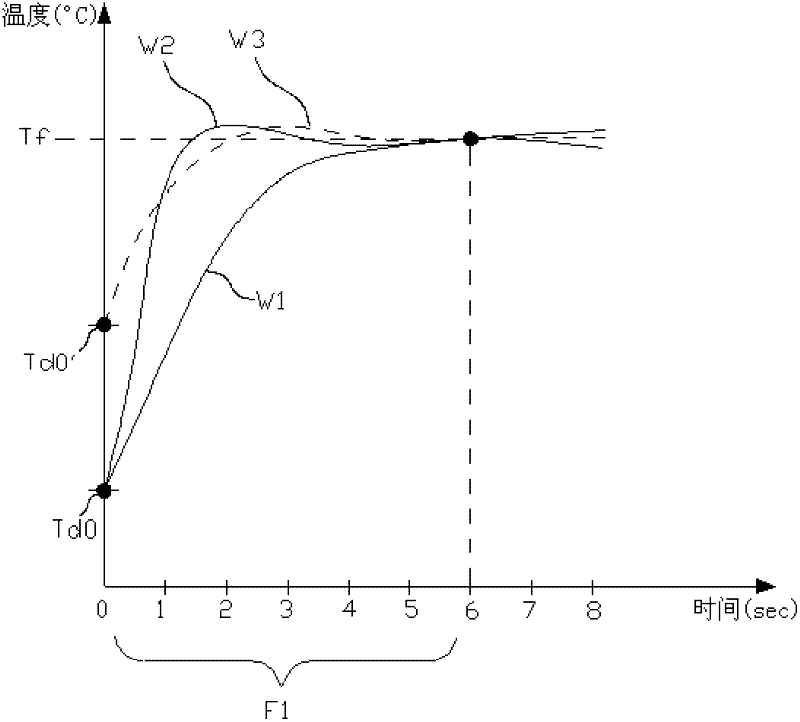

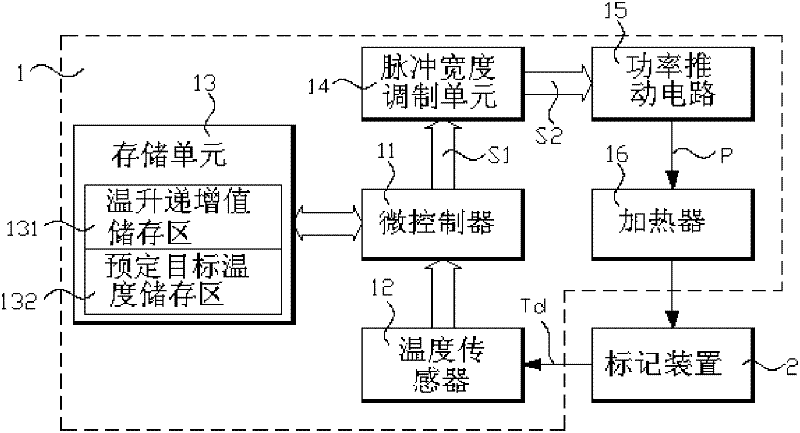

Device heating method

InactiveCN102176177AKeep abreast of temperature changes at any timeLong-term operationTemperature control using electric meansEngineeringHeating power

The invention discloses a device heating method. A marking device is heated to a target temperature by a plurality of temperature ranges. The method comprises the following steps of: sensing the current device temperature of the marking device; comparing the current device temperature with range set temperature in a current temperature rang to obtain a stage error value; regulating heating power according to the stage error value; heating the marking device with the heating power; progressively rising the range set temperature in the current temperature range by using a preset temperature progressive rising value to obtain the range set temperature of the next temperature range; and repeating the same steps in each temperature range until the range set temperature or device temperature reaches the target temperature.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

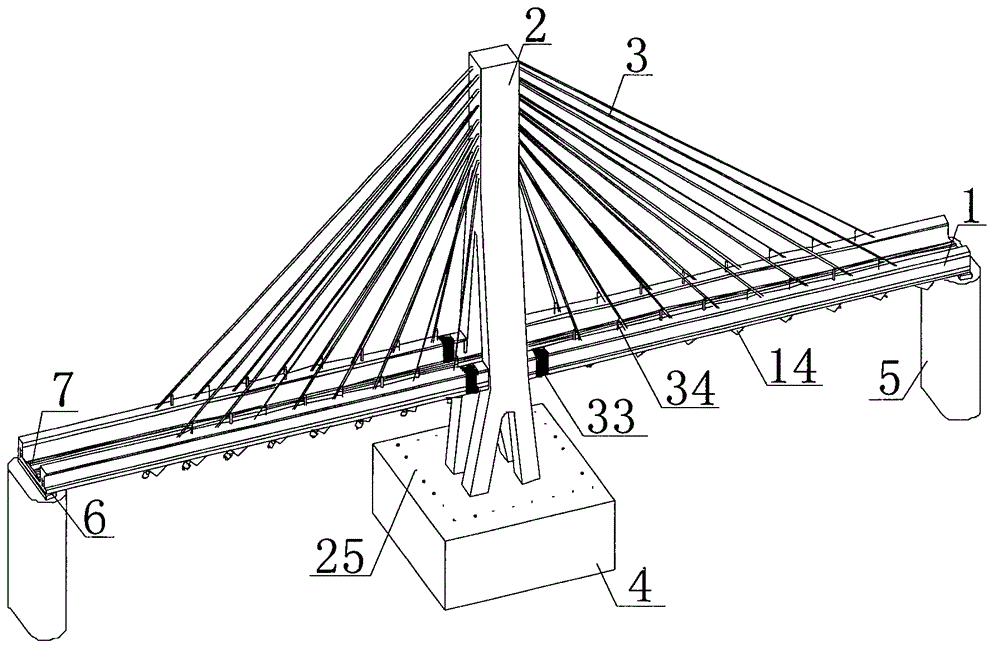

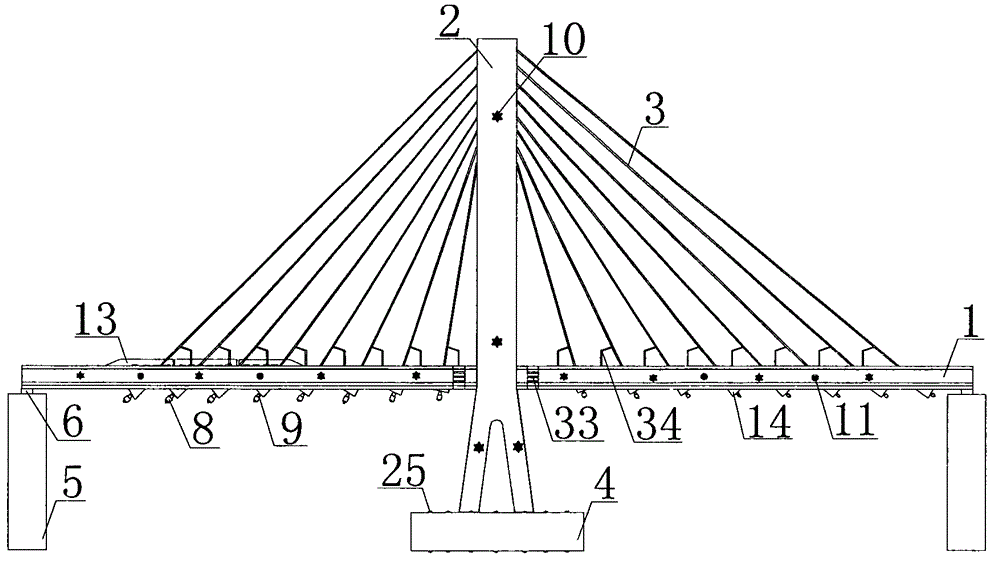

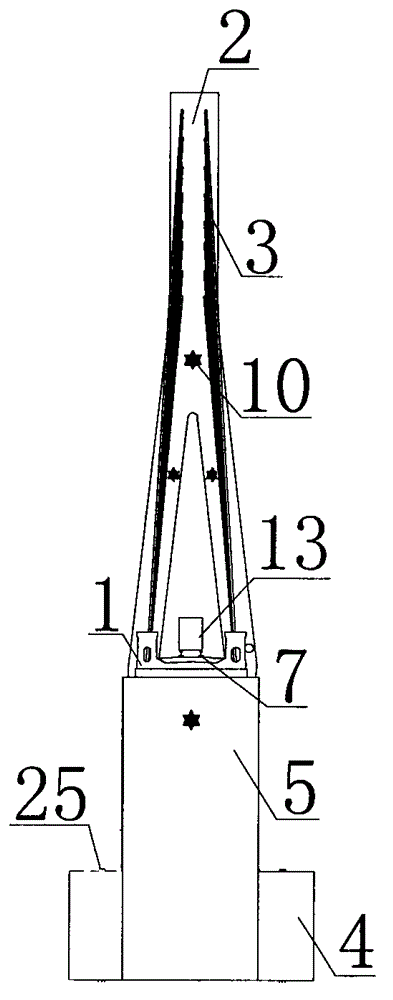

Railway cable-stayed bridge test model

InactiveCN104374597ALong term operationEasy to operateStructural/machines measurementReference testCable stayed

The invention relates to a railway cable-stayed bridge test model. The railway cable-stayed bridge test model comprises a railway cable-stayed bridge body, rigid bridge connectors and a steel rail, wherein the steel rail is paved on the railway cable-stayed bridge body and used for a test car to run thereon. The railway cable-stayed bridge body is manufactured sectionally and are combined and assembled by the rigid bridge connectors. A test loading device used for simulating static and dynamic load of a cable-stayed bridge and a data acquiring device used for acquiring test data are mounted on the railway cable-stayed bridge body. The railway cable-stayed bridge test model simulates static and dynamic load on the cable-stayed bridge using the test loading device and acquires bridge test data under the action of the static and dynamic load by the data acquiring device in time. The railway cable-stayed bridge test model can simulate structural responses of the cable-stayed bridge under working conditions of different loads and provides reference test data for bridge structure design and long-term and effective operation of the cable-stayed bridge is ensured.

Owner:CENT SOUTH UNIV

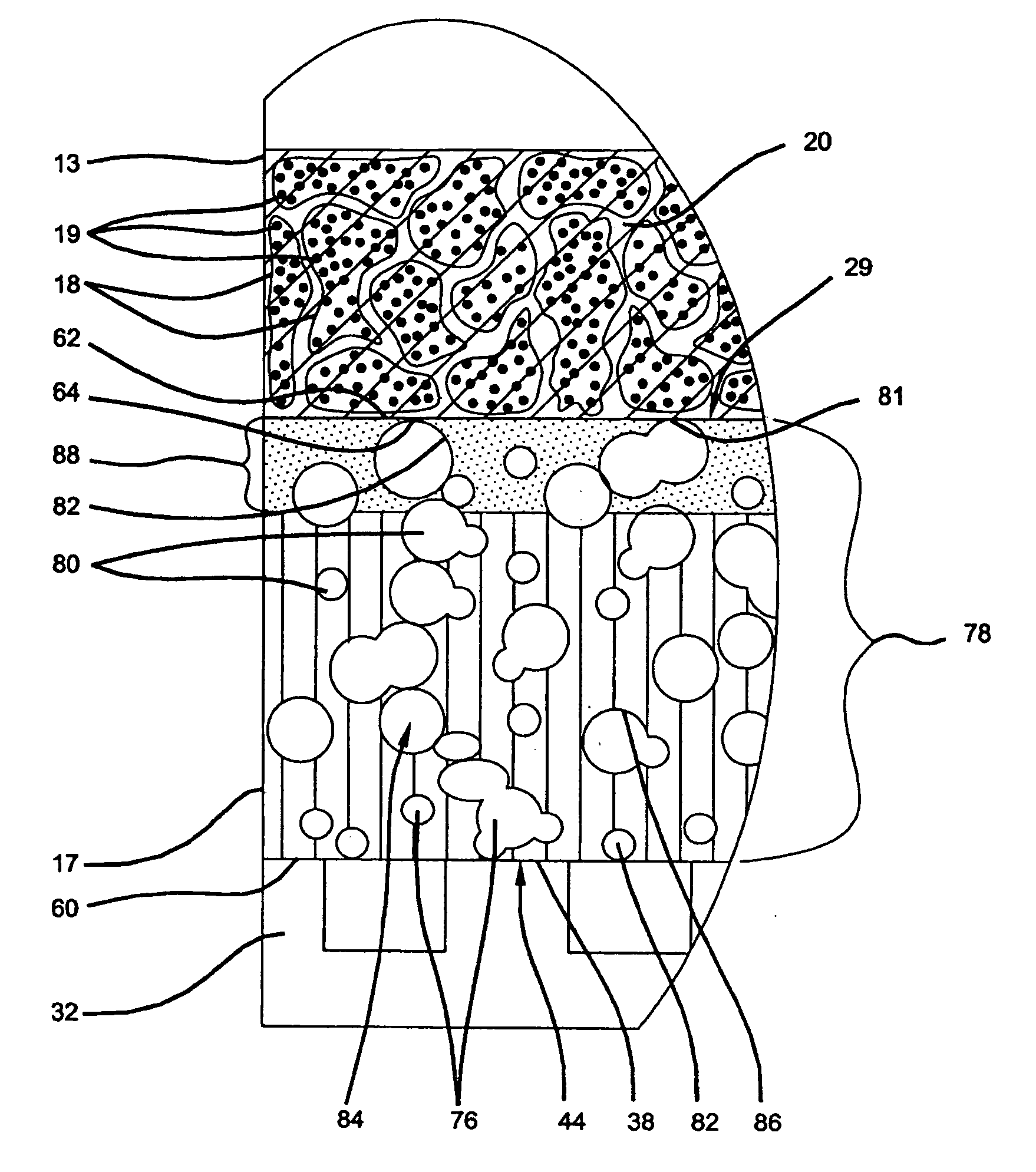

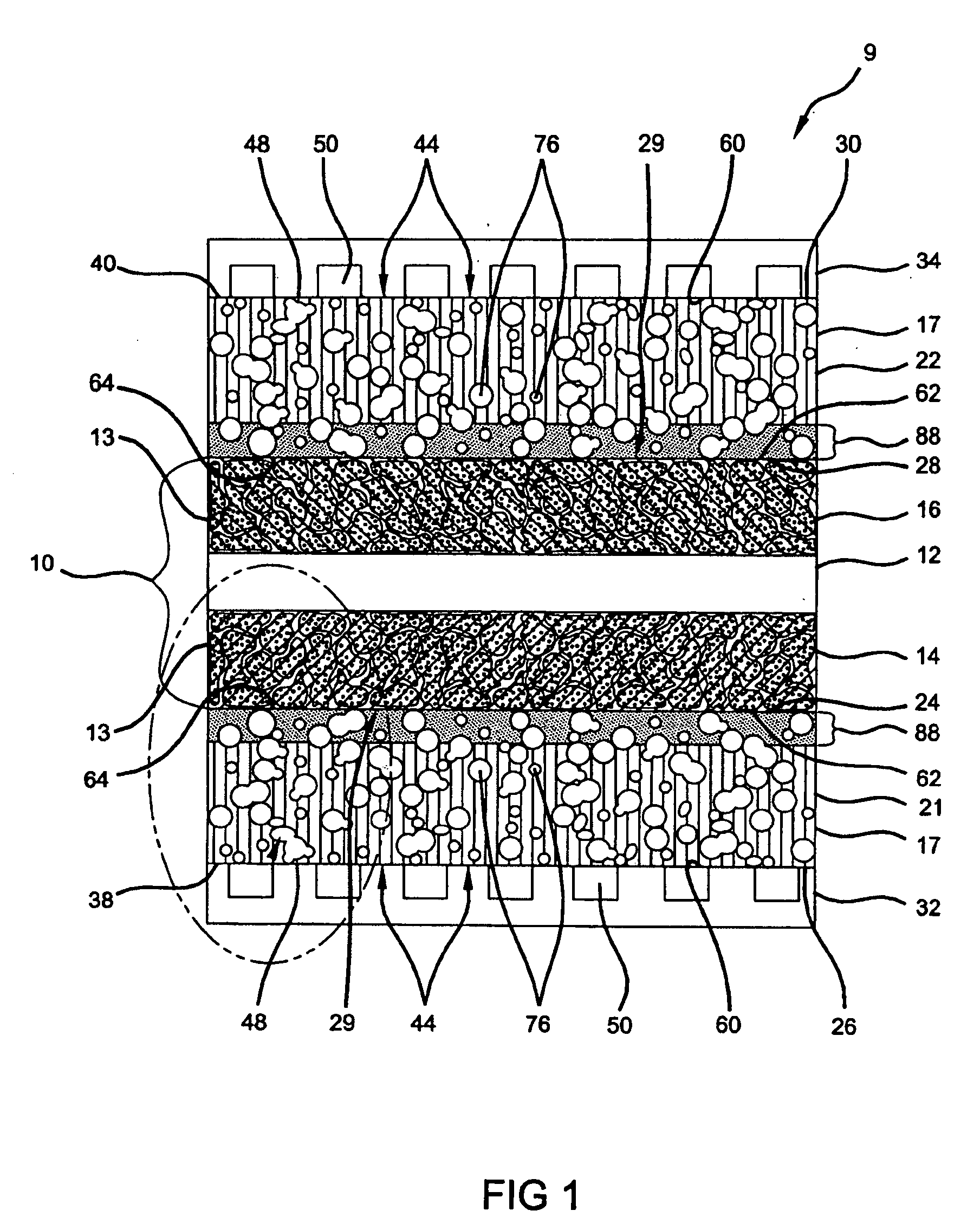

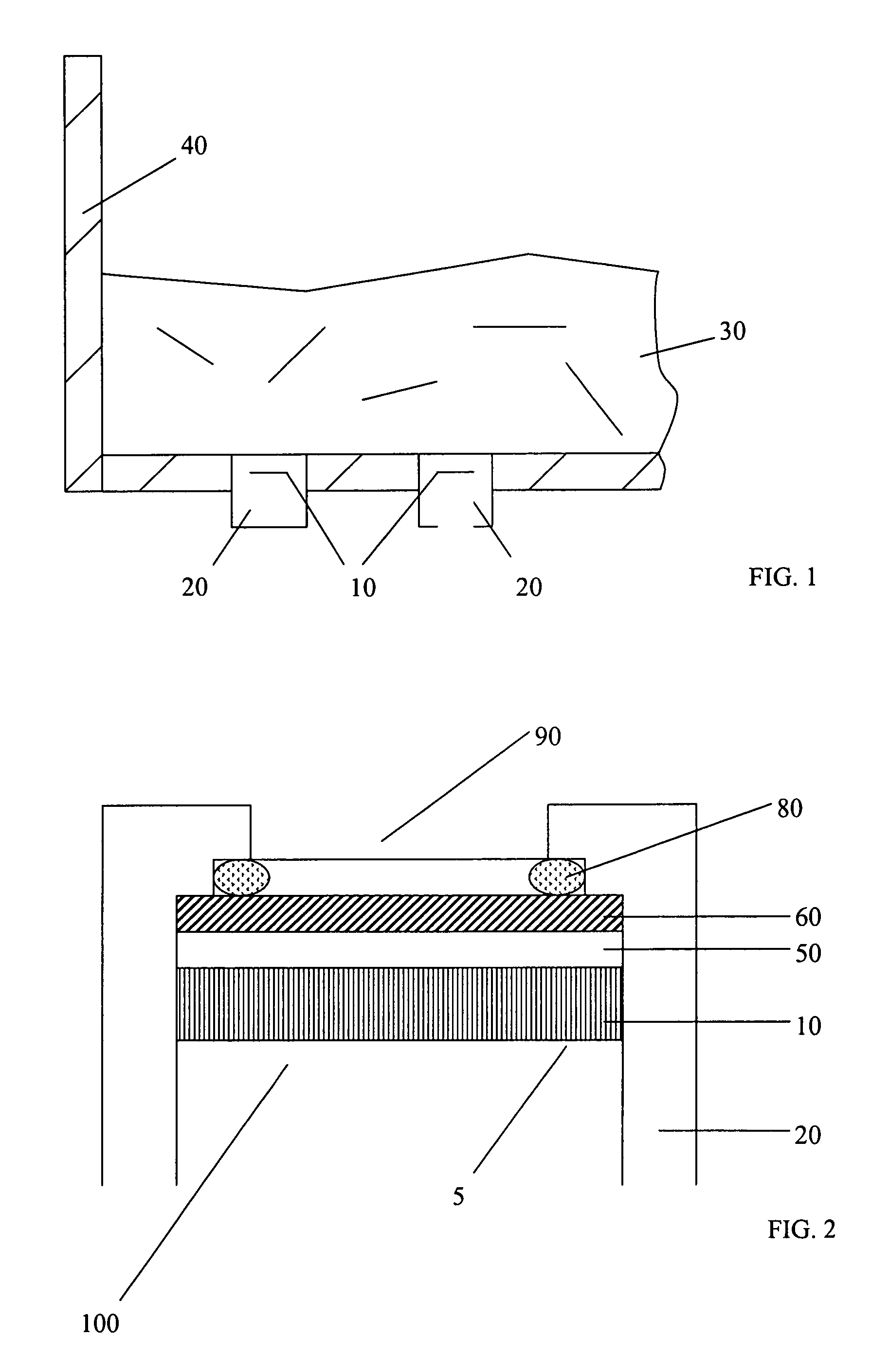

Novel membrane electrode assembly (MEA) architecture for improved durability for a PEM fuel cell

InactiveUS20060263668A1Long-term operationOptimal fuel efficiencyFuel cells groupingCell electrodesElectrically conductiveEngineering

An electrically conductive fluid distribution element for use in a fuel cell having a layer of a conductive non-metallic fiberless microporous media. In certain embodiments, an electrically conductive metal is deposited along a surface of the element to form one or more metallized regions. The metallized regions are arranged to contact a membrane electrode assembly (MEA) in a fuel cell assembly, and thus improve electrical conductance at contact regions between the MEA and the layer of media. Methods of making such a fluid distribution element and operating fuel cell assemblies are also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Methods and apparatus for optimizing aerosol generation with ultrasonic transducers

ActiveUS7641130B2Long-term operationLong-term performanceMovable spraying apparatusSpray nozzlesChemical reactionUltrasonic sensor

The invention is an apparatus and methods for optimizing the performance and protecting one or more aerosol generating transducers from deterioration while operating in a chemically reactive aqueous solution by utilizing one or more protective barrier techniques to eliminate chemical interaction between the aqueous solution and the transducers. The method of the present invention produces an aerosol producing transducer with the transducer housing and assembly to be constructed in such a way as to assure its efficient and effective long-term and problem free operation in an aqueous solution that is chemically reactive.

Owner:ALTAPURE

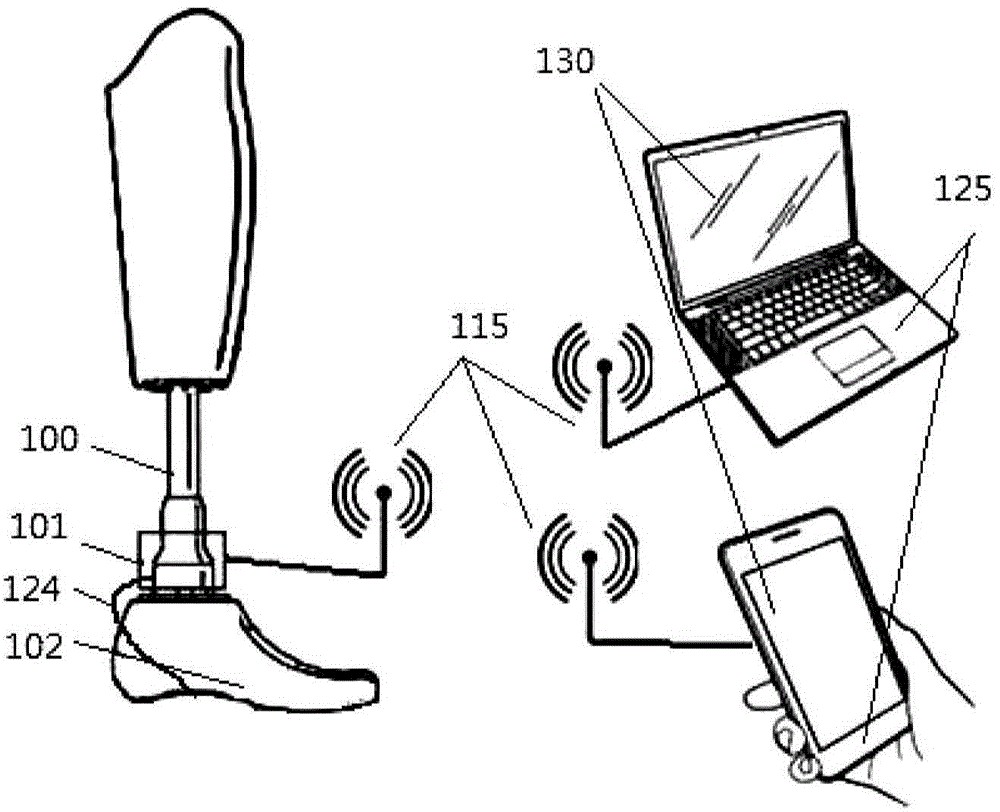

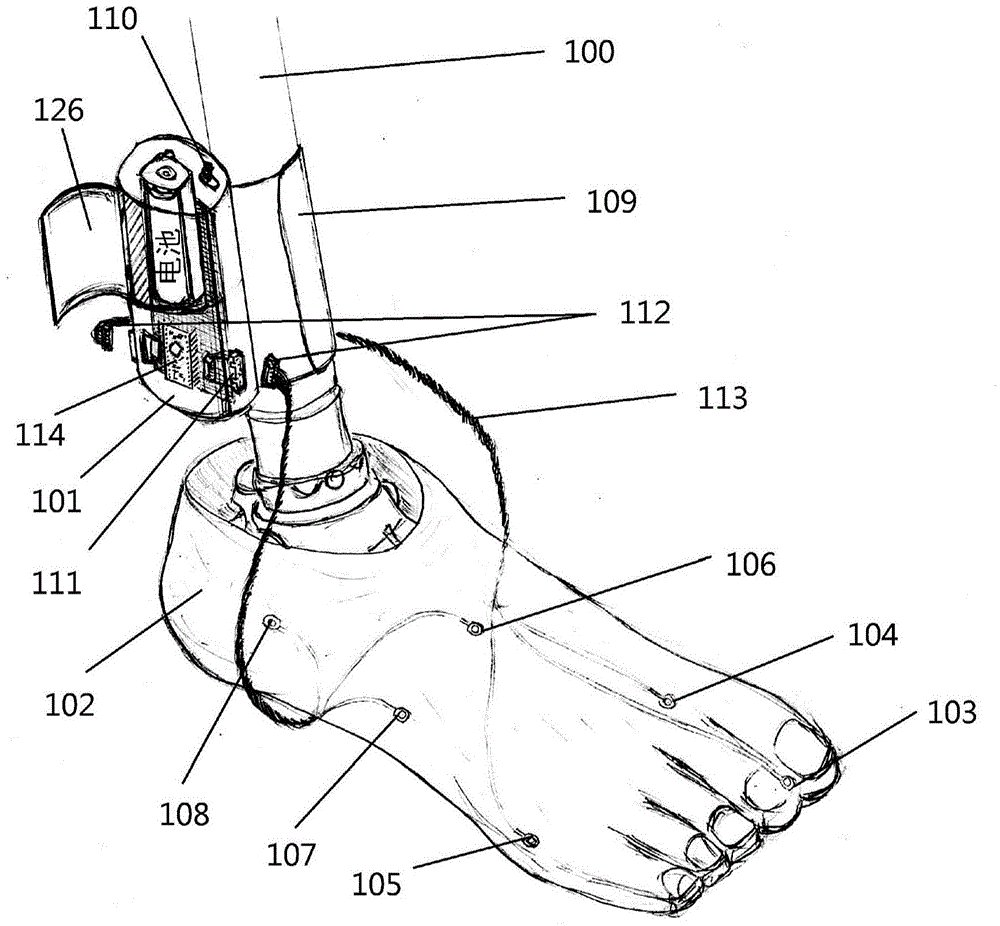

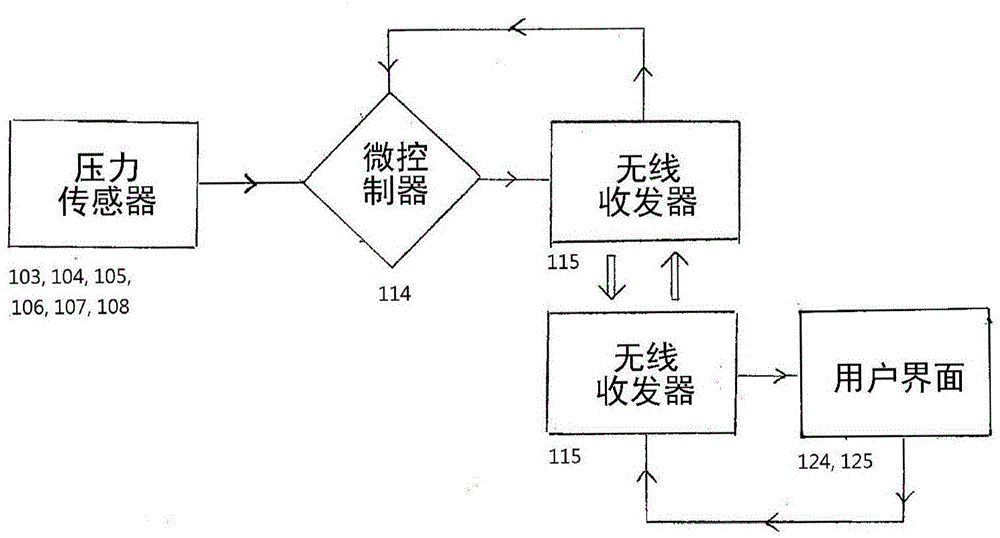

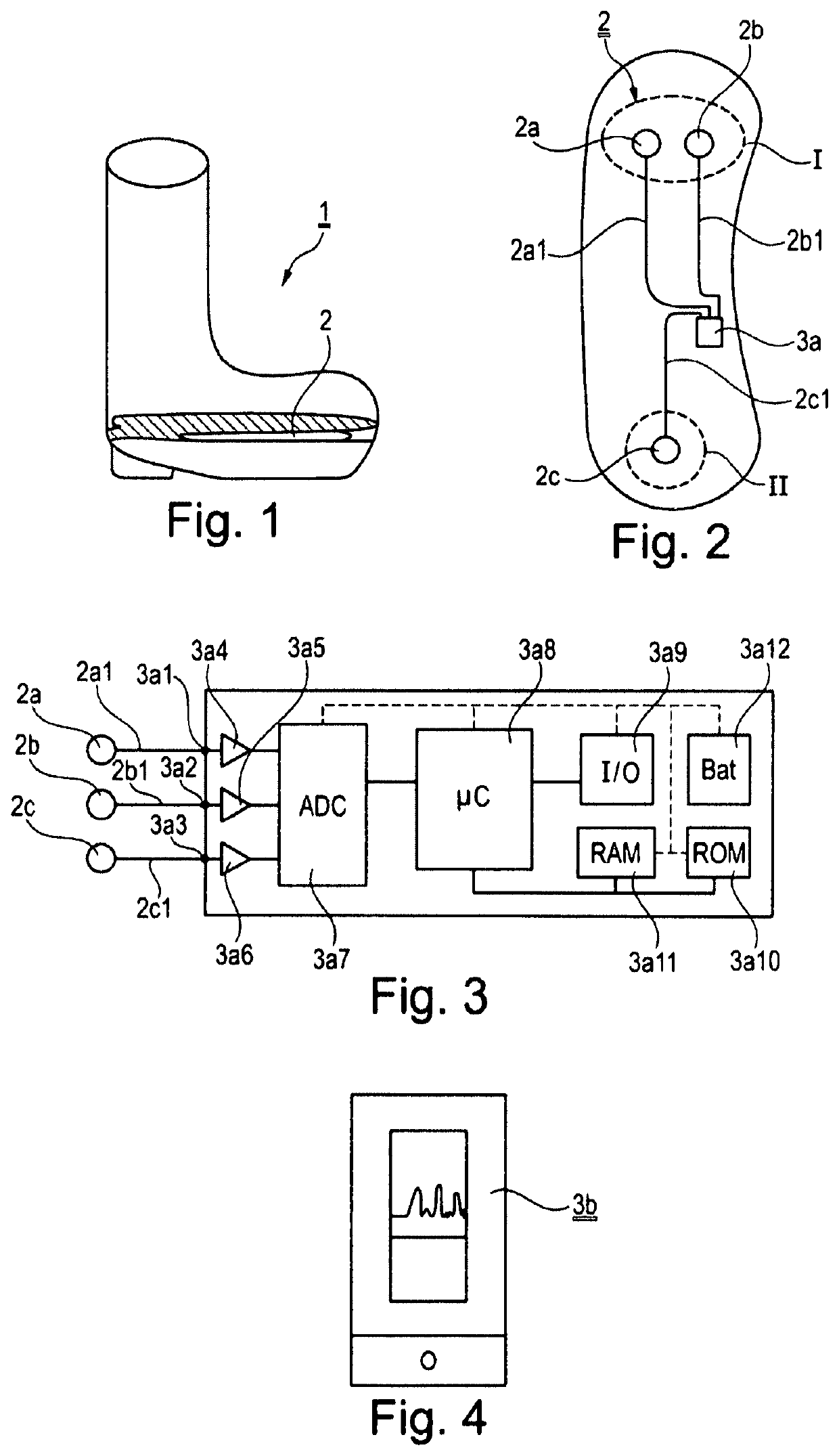

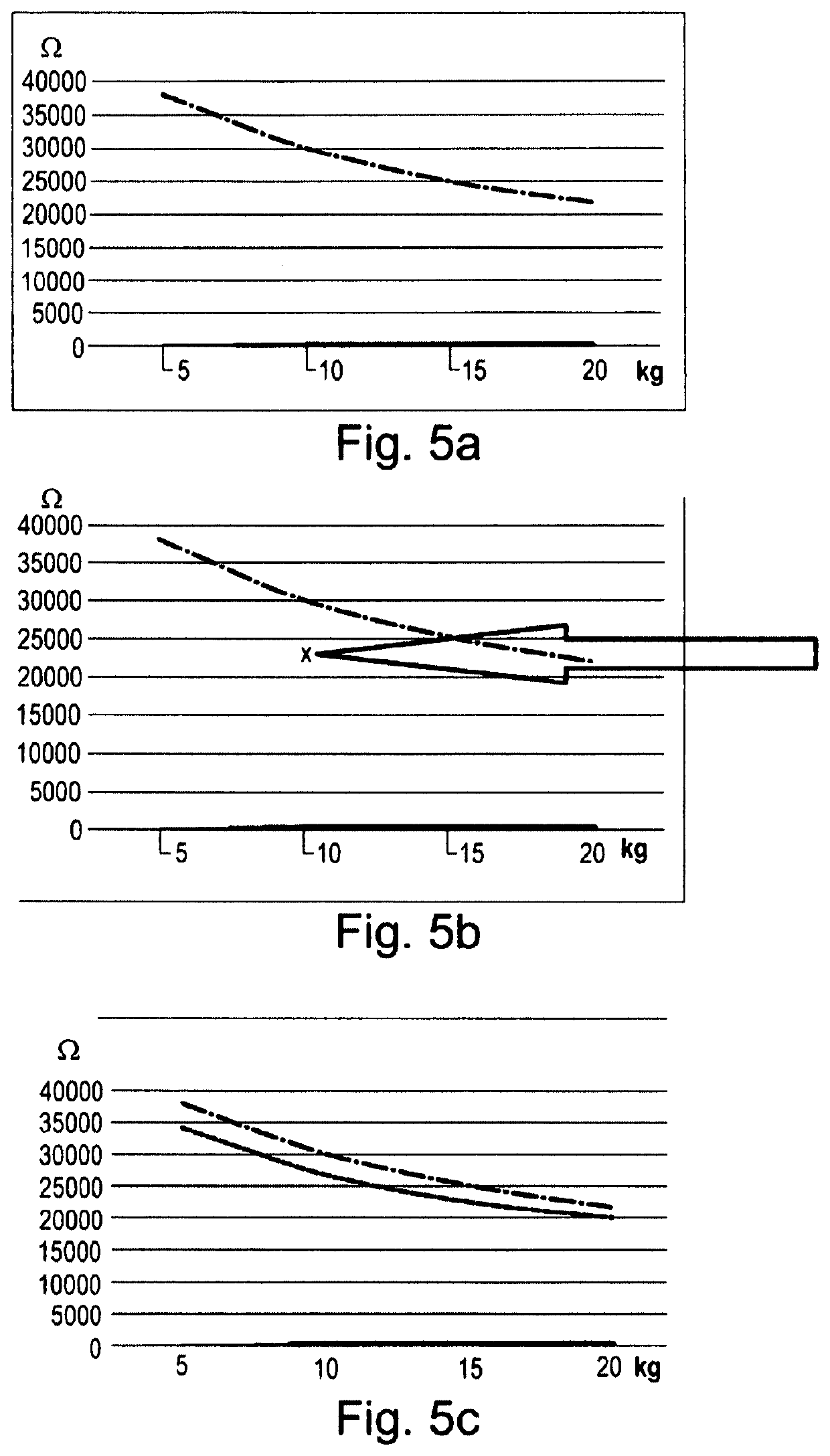

Lower-limb prosthesis alignment and gait analysis auxiliary system adopting foot pressure sensing technology

The invention provides an auxiliary system which is capable of assisting a limb prosthesis orthopedic doctor to assemble lower-limb prosthesis and helping an amputee to improve gait on the basis of a foot pressure signal of the amputee. The auxiliary system comprises a main circuit box, a sole pressure sensor assembly and an interface program, and the interface program is applied to a user interface. According to the auxiliary system, the main circuit box and the sole pressure sensor assembly are used together and are transmitted to the user interface in a wireless mode. The auxiliary system mainly operates on the basis of the principles of computing and displaying standing and swinging times of the amputee during walking as well as a reference pressure center path during walking and standing, and comparing with corresponding standard data, so as to suggest the orthopedic doctor in the adjustment of the lower-limb prosthesis alignment and the gait of the amputee. The auxiliary system disclosed by the invention is helpful for the limb prosthesis orthopedic doctor in the adjustment of the lower-limb prosthesis alignment, the assessment of the gait of the amputee after alignment and in the gait training of the amputee.

Owner:THE HONG KONG POLYTECHNIC UNIV

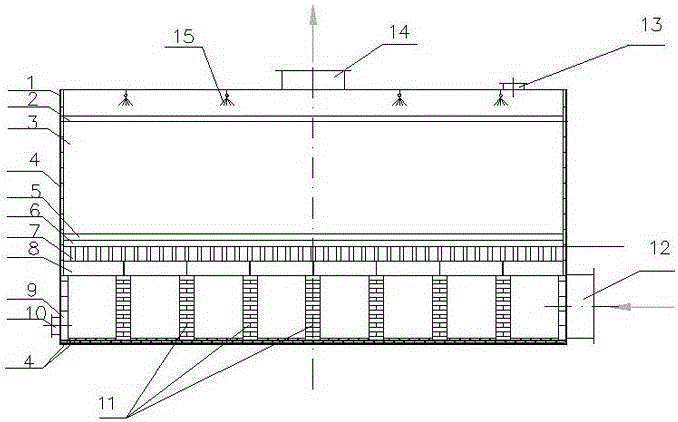

Glass fiber reinforced plastic filler-type catalytic desulfurization tower

The invention discloses a glass fiber reinforced plastic filler-type catalytic desulfurization tower and belongs to the technical field of catalytic desulphurization equipment. The glass fiber reinforced plastic filler-type catalytic desulfurization tower mainly solves the problem that the existing desulfurization tower produces severe desulphurization corrosion, has a high maintenance cost and easily produces secondary pollution. The glass fiber reinforced plastic filler-type catalytic desulfurization tower is characterized in that a tower unit comprises a glass fiber reinforced plastic tower, nozzles, a flue gas outlet, a filler layer, a structured filler layer, a grating, strip beams, a main beam, stand columns, a circulation solution outlet and a flue gas inlet, the nozzles, the flue gas outlet, the filler layer, the structured filler layer, the grating, the strip beams, the main beam, the stand columns, the circulation solution outlet and the flue gas inlet are orderly arranged in the tower from top to bottom, the glass fiber reinforced plastic tower is composed of glass fiber reinforced plastic and an outer carbon steel by reinforcement, the flue gas outlet is arranged in the center of the top end of the tower, the nozzles are uniformly distributed below the tower top, the main beam is fixed to the stand columns and transverse wedge bricks, the main beam is orderly provided with the strip beams, the grating and the structured filler, and the flue gas inlet and the circulation solution outlet are arranged at the side of the lower part of the tower. The glass fiber reinforced plastic filler-type catalysis desulfurization tower has the characteristics of simple processes, desulfurizer recycle, no secondary pollutant and good desulphurization effects and can be used for desulphurization of flue gas with a concentration of several hundreds or many thousands ppm in a large-scale heat-engine plant and a chemical plant.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

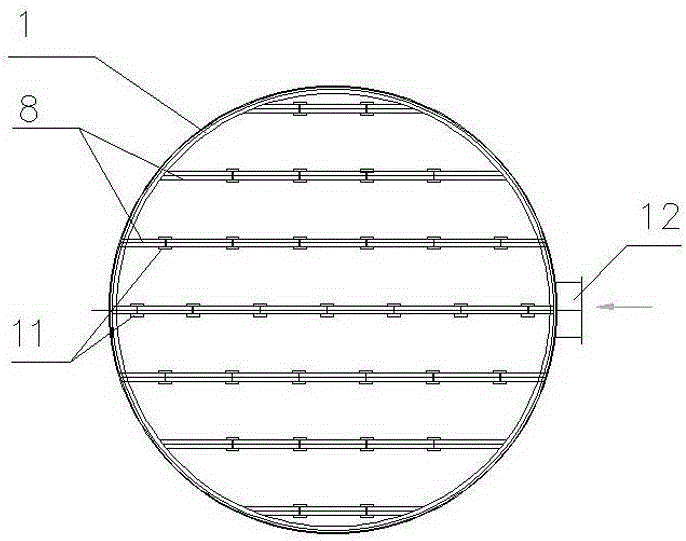

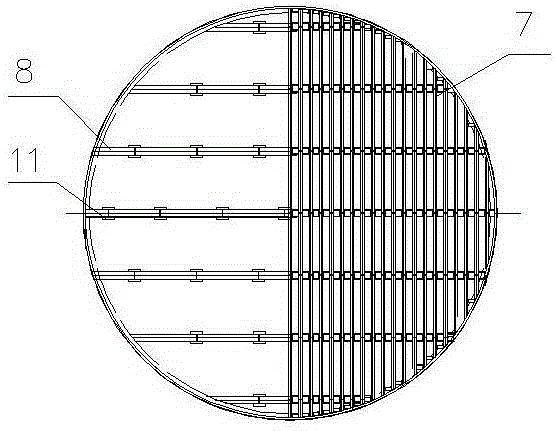

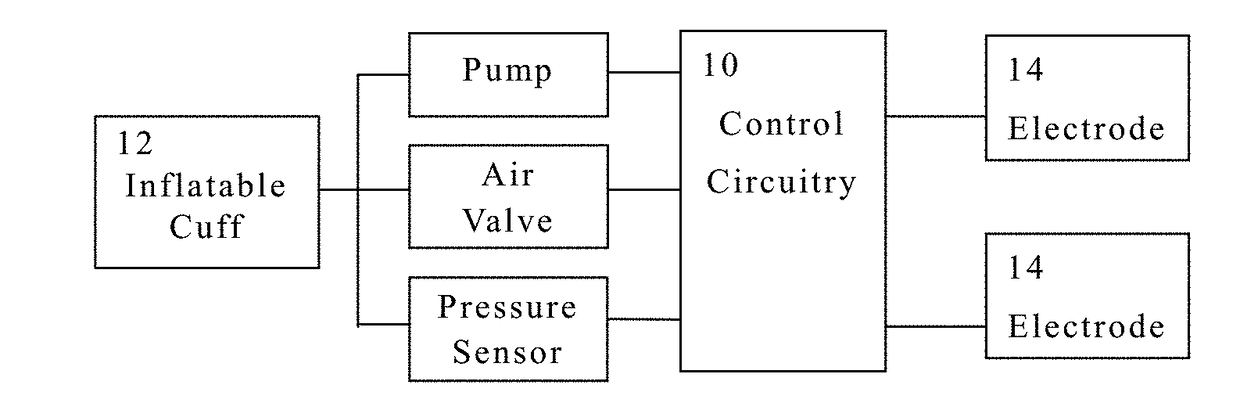

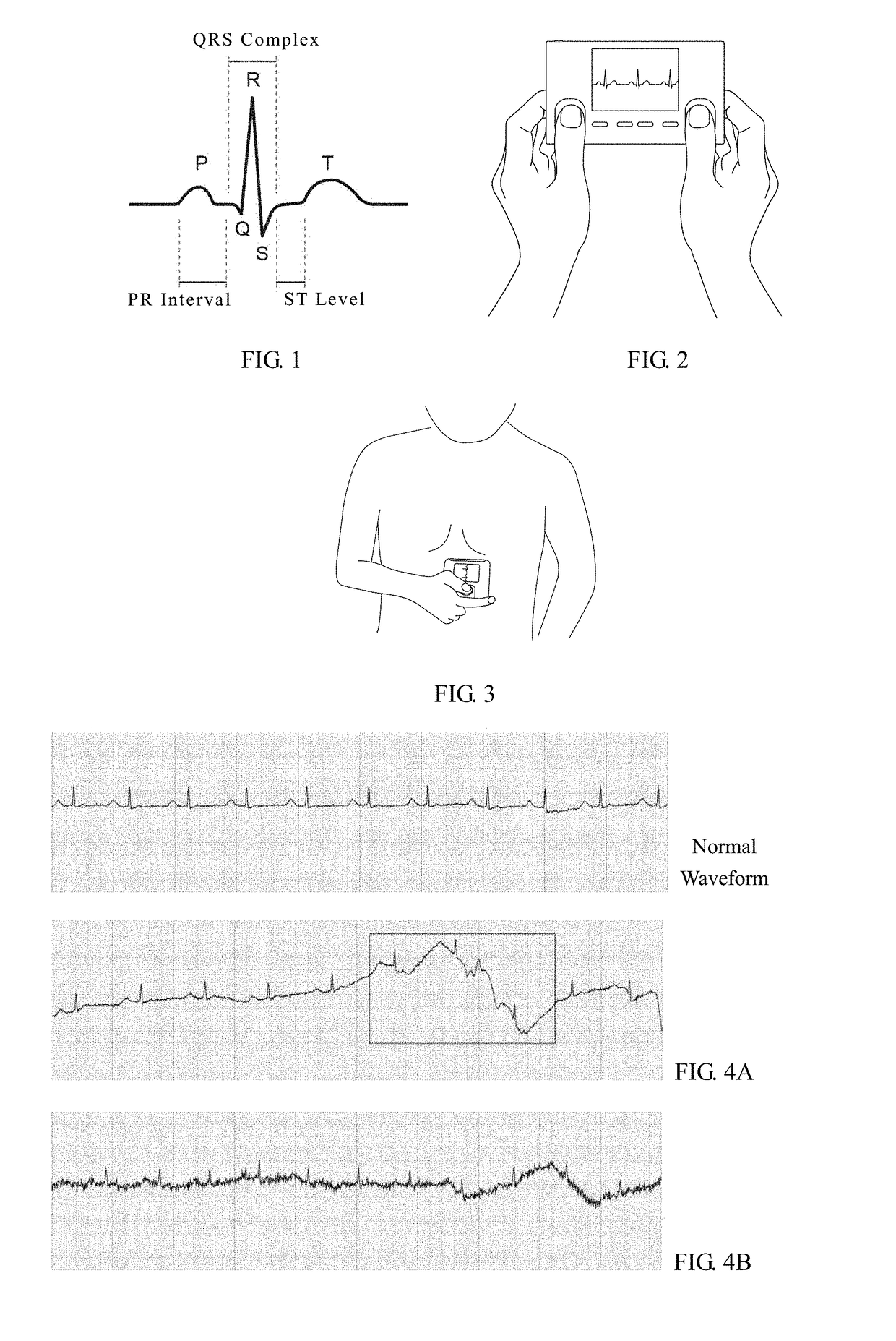

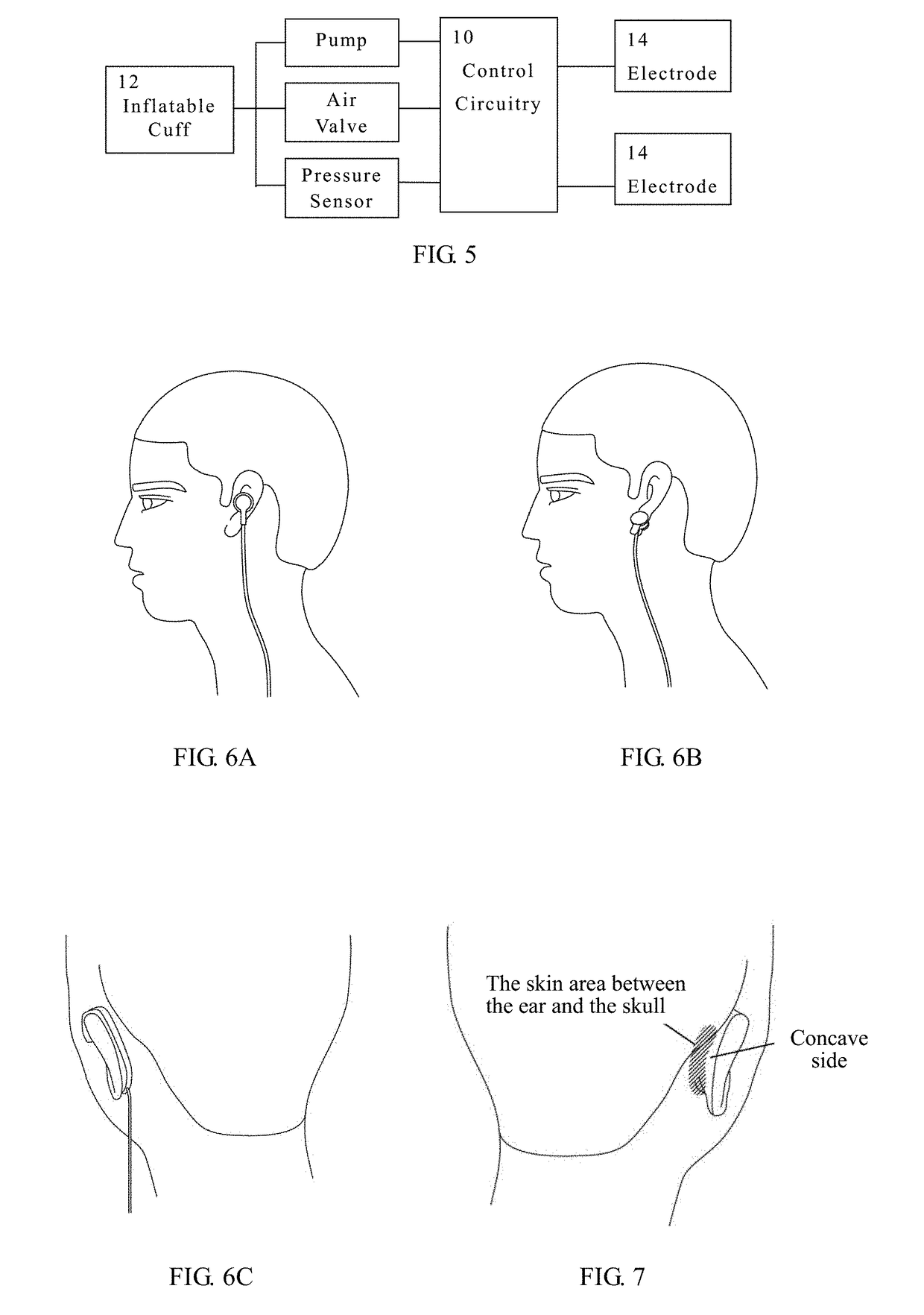

Apparatus for monitoring cardiovascular health

An apparatus and a method for monitoring cardiovascular health are provided. The apparatus includes a housing, a control circuitry, an inflatable cuff for surrounding an upper limb of a user, a pump contained in the housing, at least a first electrode and a second electrode, and an ear-worn structure having the first electrode mounted thereon. When performing blood pressure measurement, the processor controls the pump to inflate and deflate the cuff, for measuring blood pressure of the user. When performing electrocardiographic signal measurement, through mounting the ear-worn structure on an ear of the user, the first electrode contacts the skin of the ear or around the ear, and through mounting the cuff surrounding the upper limb, the second electrode contacts the skin of the upper limb, enabling the processor to acquire electrocardiographic signals through the first electrode and the second electrode.

Owner:CHOU

Emulsion antioxygen and preparation method thereof

The invention belongs to the field of antioxygen, in particular to an emulsion antioxygen and a preparation method thereof. The emulsion antioxygen is emulsified and compounded by the following raw material reagents at the proportion: main antioxygen, auxiliary antioxygen, emulsifying agent, dispersing agent and defoaming agent. The emulsion antioxygen has better oxidation resistance than other similar antioxygens and can achieve the optimal oxidation resistance effect, and the total solid content of the emulsion antioxygen is more than 52%. The emulsion antioxygen has the advantages of good oxidation resistance effect, big activity, low volatility, high durability, no pollution and the like and is especially suitable for protecting tint and pollution-free color polymer thereof. The emulsion antioxygen can be favorably dispersed in ABS (Acrylonitrile Butadiene StyreneAcrylonitrile Butadiene Styre) rubber latex, is ideal antioxygen used preparing ABS by emulsion polymerization and has excellent dispersibility. According to the emulsion antioxygen, the heating oxygen aging time of the ABS resin can be prolonged in the ABS production, the oxidation inducing temperature of the ABS resin is improved, the phenomenon that the ABS resin becomes yellows in the production and processing process thereof can be prevented, the strength of a product can be improved, and the oxidation resistance problem for preparing ABS by emulsion polymerization can be solved.

Owner:唐东波

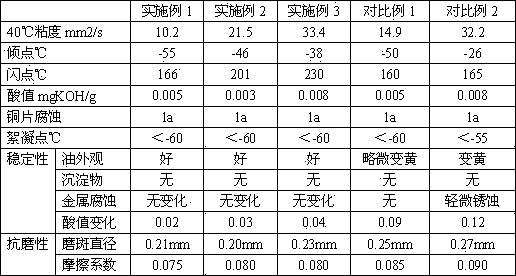

Refrigerating machine oil composition

The invention describes a refrigerating machine oil composition. The refrigerating machine oil composition is applicable to lubrication of a refrigerating compression system using a hydrocarbon working medium refrigerant. The refrigerating machine oil composition consists of 80-99.5wt% of alkyl naphthalene base oil and 0.5-20wt% of additives used for improving the property of an oil product. The refrigerating machine oil composition has a kinematic viscosity of 2-100mm<2> / s at 40 DEG C. The refrigerating machine oil composition has excellent high-temperature stability and oxidization resistance, has good compatibility with a refrigerant at a low temperature, is outstanding in abrasion resistance and can be used stably in a refrigerating system for a long time under a high-temperature and high-pressure condition.

Owner:WUHAN UN LUBRICANT TECH

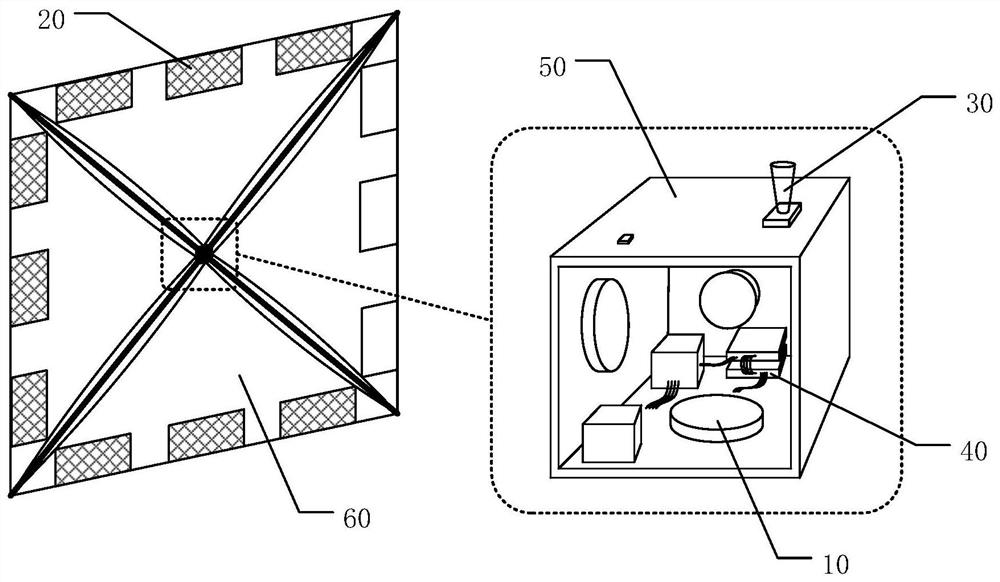

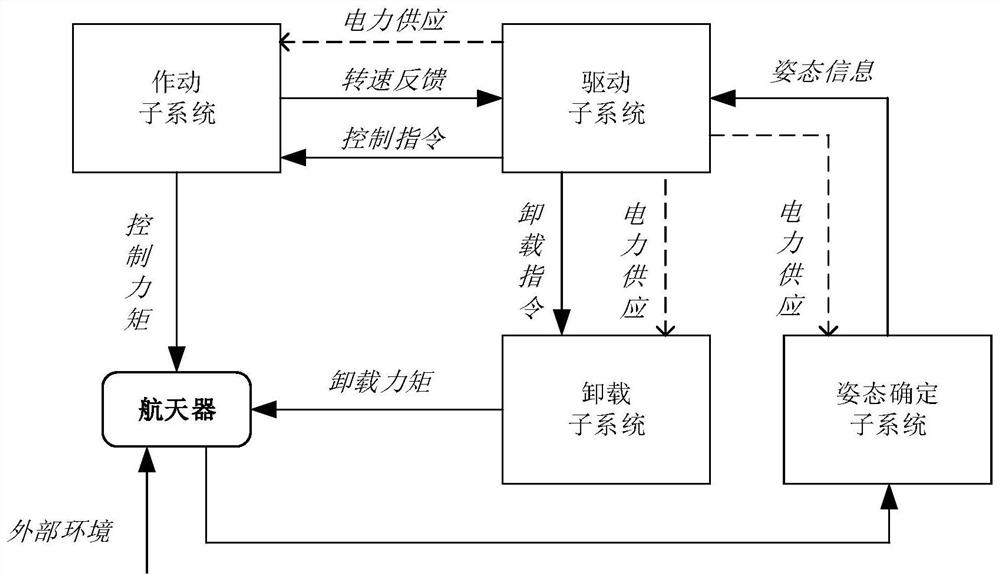

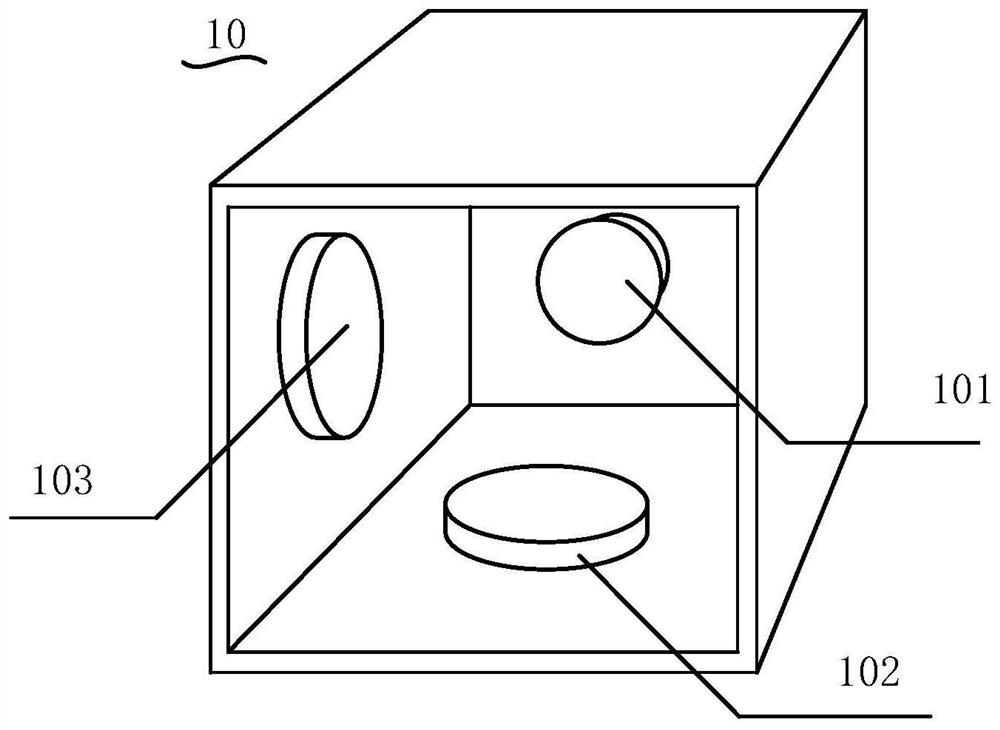

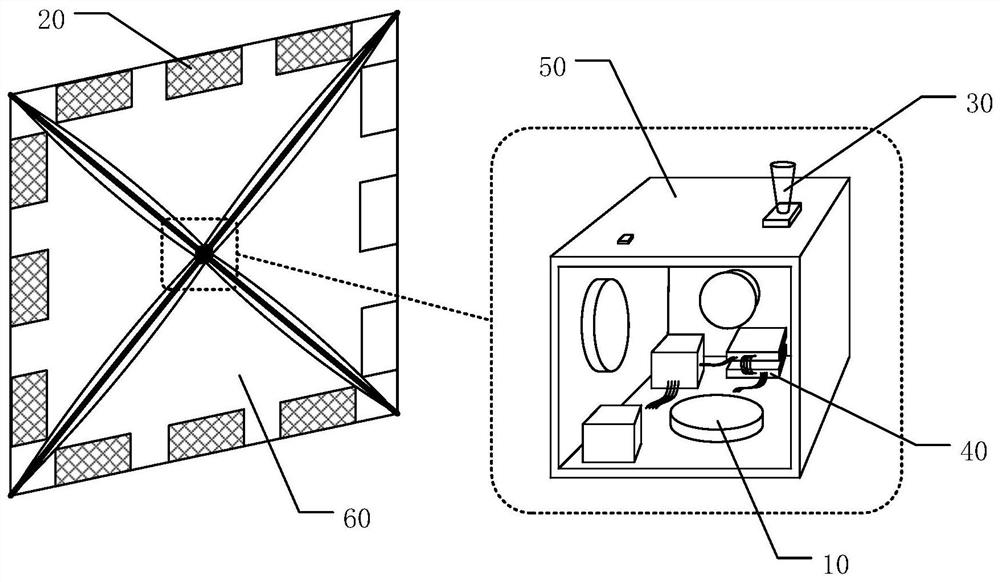

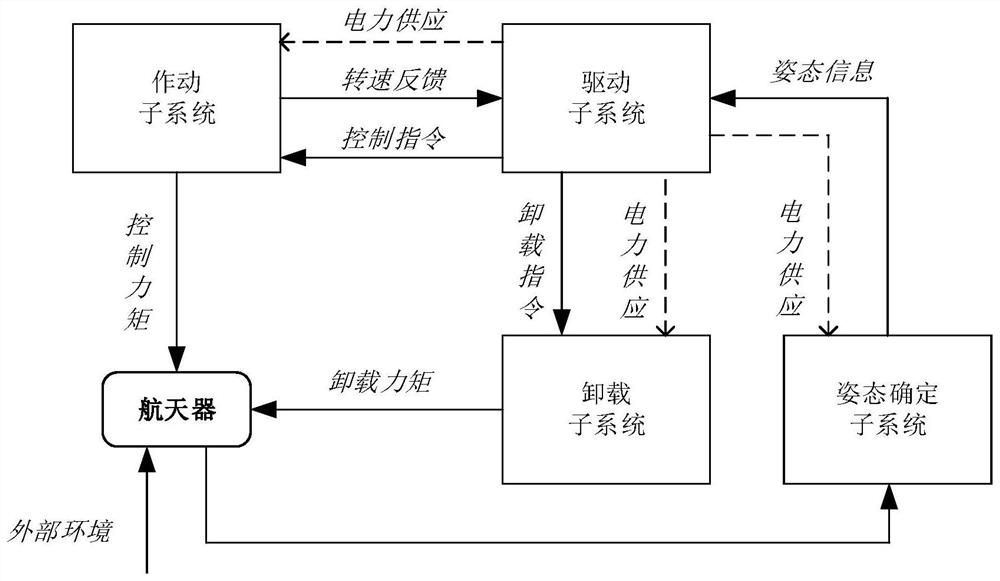

Spacecraft attitude control system based on momentum wheel and reflectivity control device

ActiveCN112572838AExtend your lifeStrong control abilityCosmonautic vehiclesSpacecraft guiding apparatusAttitude control systemAttitude determination

The invention discloses a spacecraft attitude control system based on a momentum wheel and a reflectivity control device, and belongs to the technical field of spacecraft attitude control. The spacecraft attitude control system comprises an actuation subsystem, an unloading subsystem, an attitude determination subsystem and a drive control subsystem. According to the attitude control system, a momentum wheel is adopted as an actuating mechanism for spacecraft attitude control, an emissivity control device capable of autonomously adjusting reflectivity is adopted to generate an unloading torque, and the momentum wheel tending to be saturated is selectively unloaded. According to the spacecraft attitude control system based on the system scheme assembly, an attitude control capability can beguaranteed, dependence on traditional unloading methods such as geomagnetic moment unloading and thruster unloading can be avoided, and a spacecraft is made to have an ultra-long-term service condition in the space environment far away from a medium-high orbit.

Owner:NAT UNIV OF DEFENSE TECH

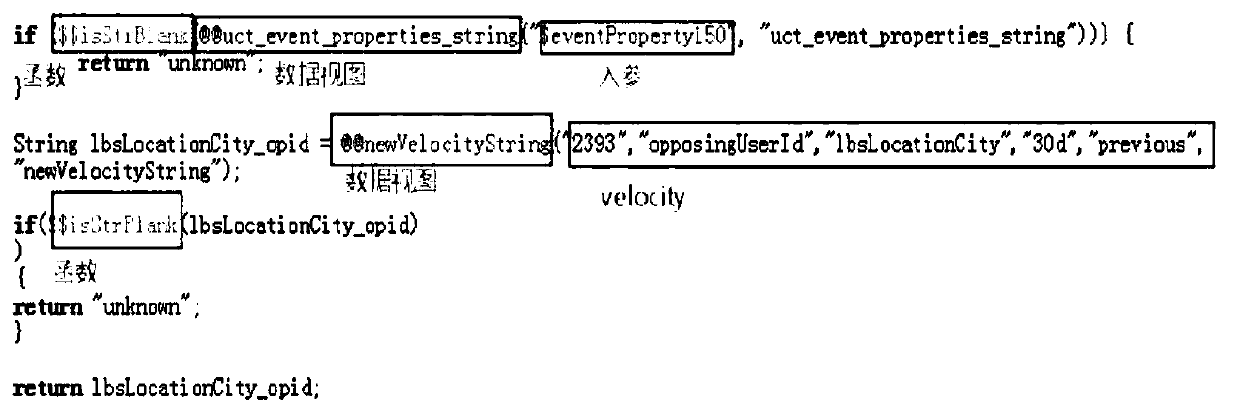

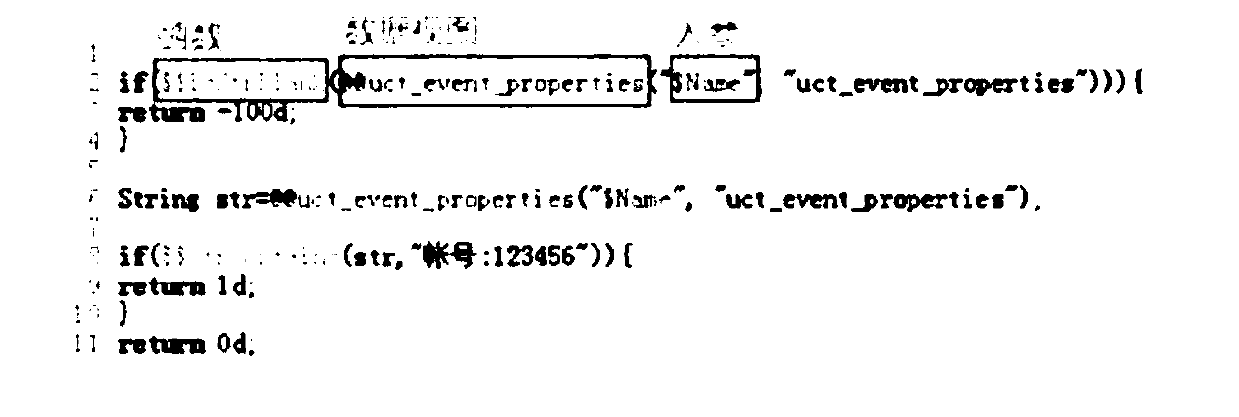

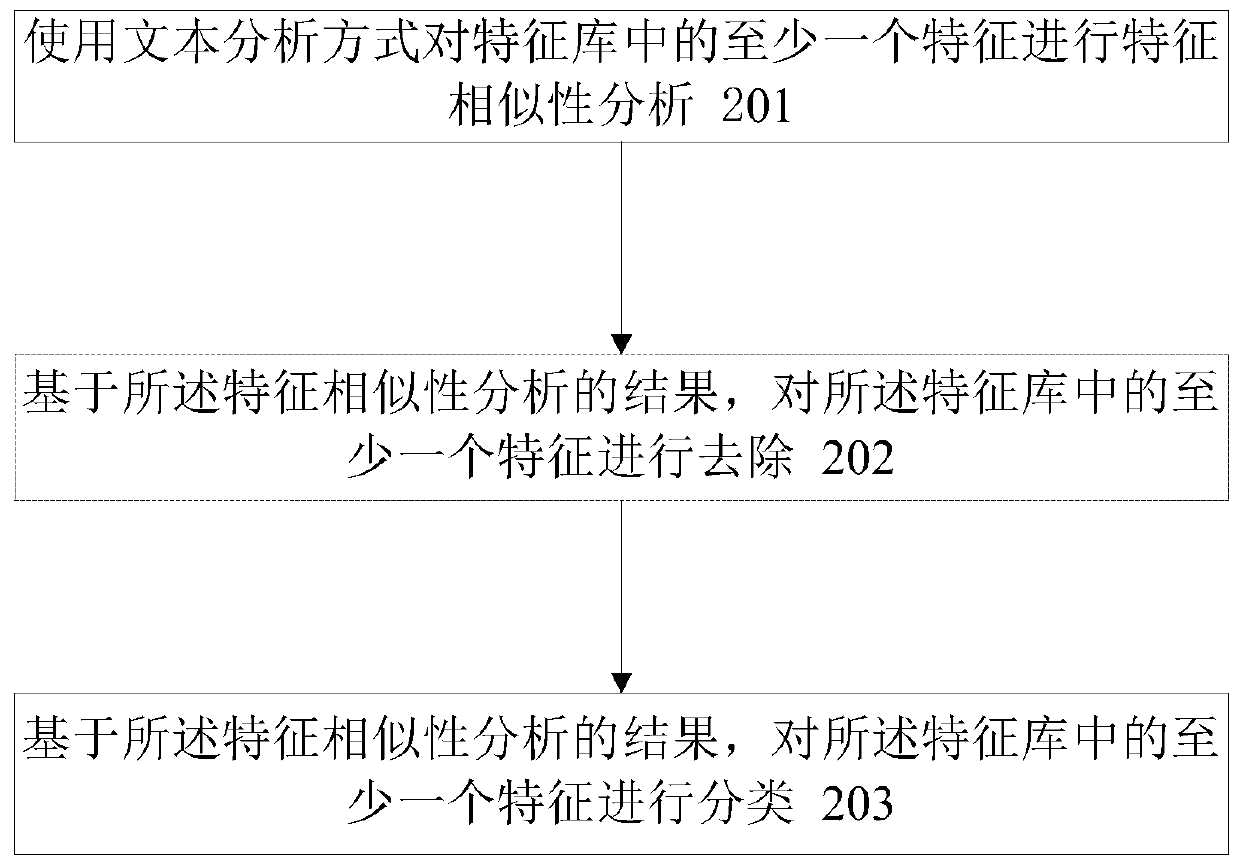

Method, apparatus, and non-transitory machine-readable medium for processing feature library

PendingCN109992666AFast and flexible analysisSave computing resourcesText database clustering/classificationPattern recognitionSimilarity analysis

Methods, apparatuses, and non-transitory machine-readable media for feature library processing are provided. According to application, at least one feature in a feature library is subjected to featuresimilarity analysis in a text analysis mode, and each feature in the feature library is represented in a code form. Moreover, based on the result of the feature similarity analysis, at least one feature in the feature library is classified.

Owner:ADVANCED NEW TECH CO LTD

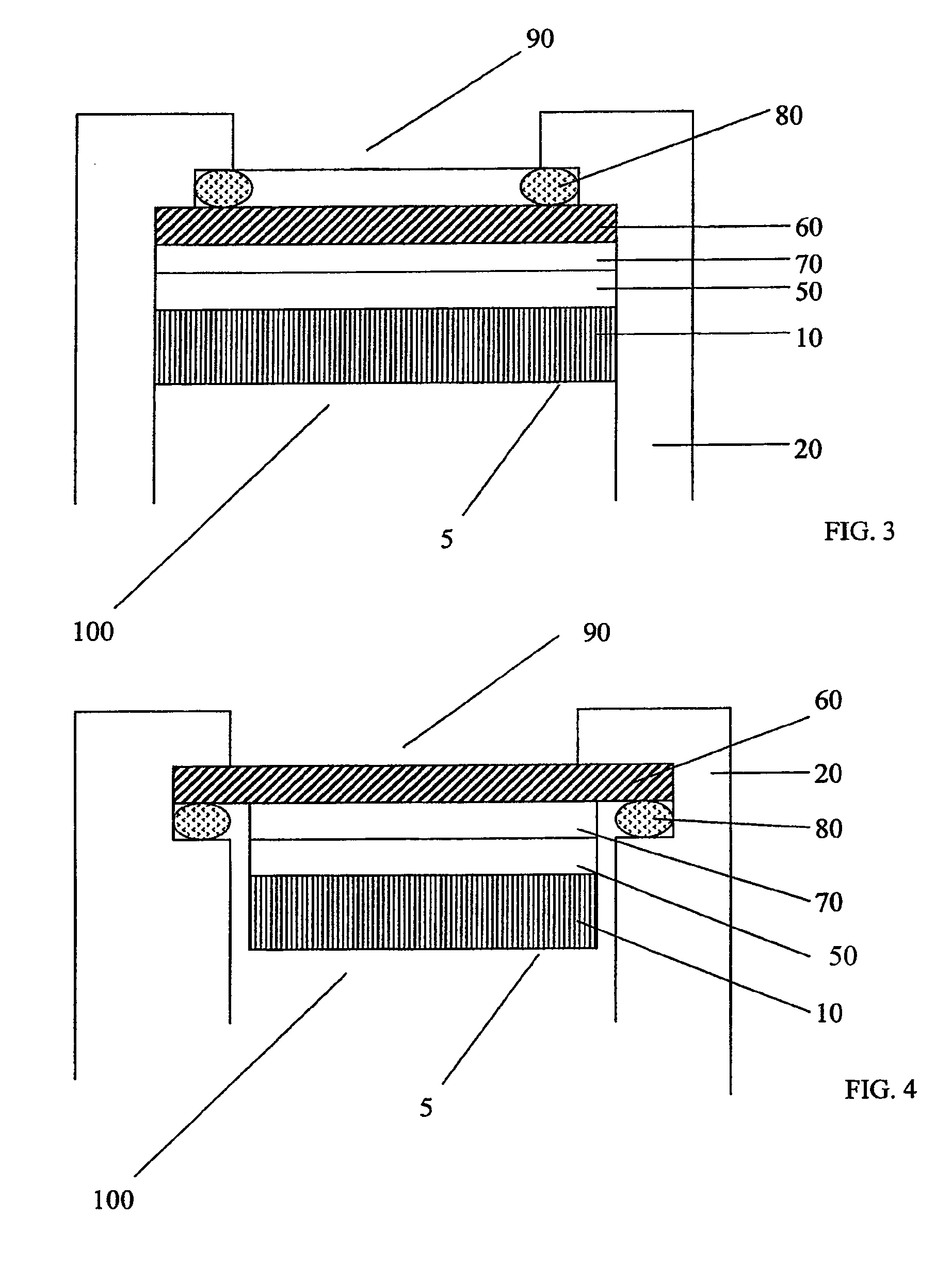

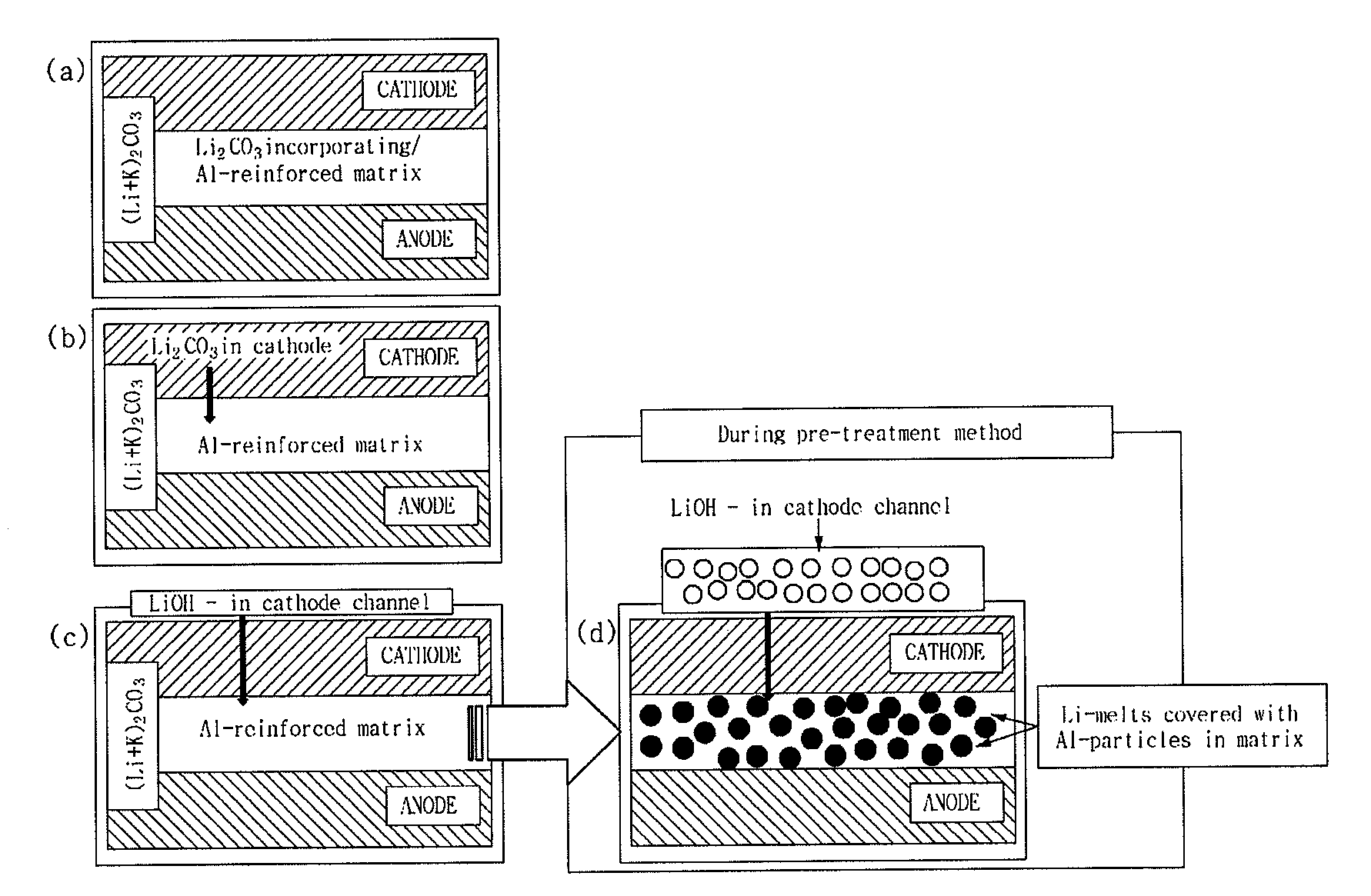

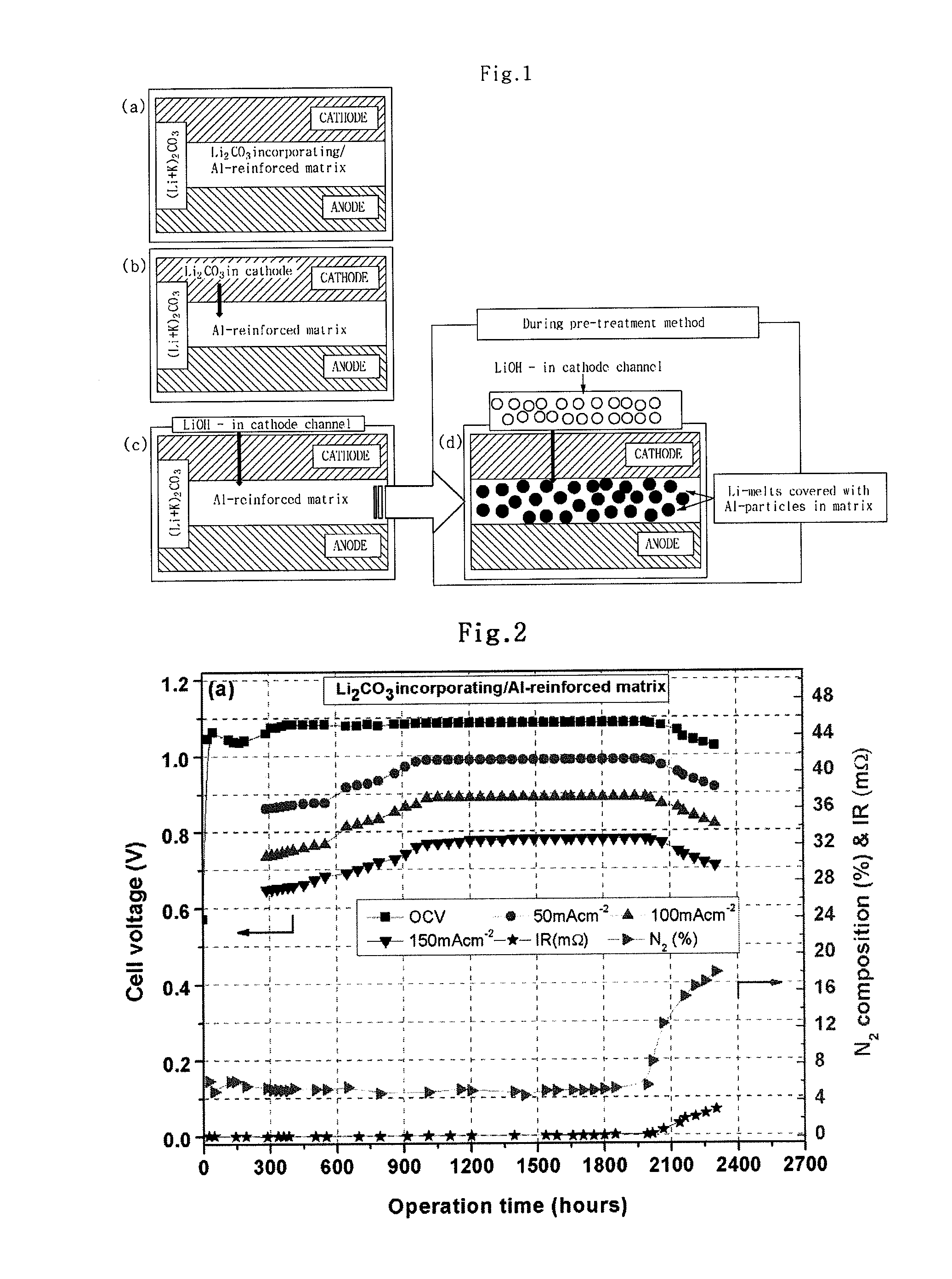

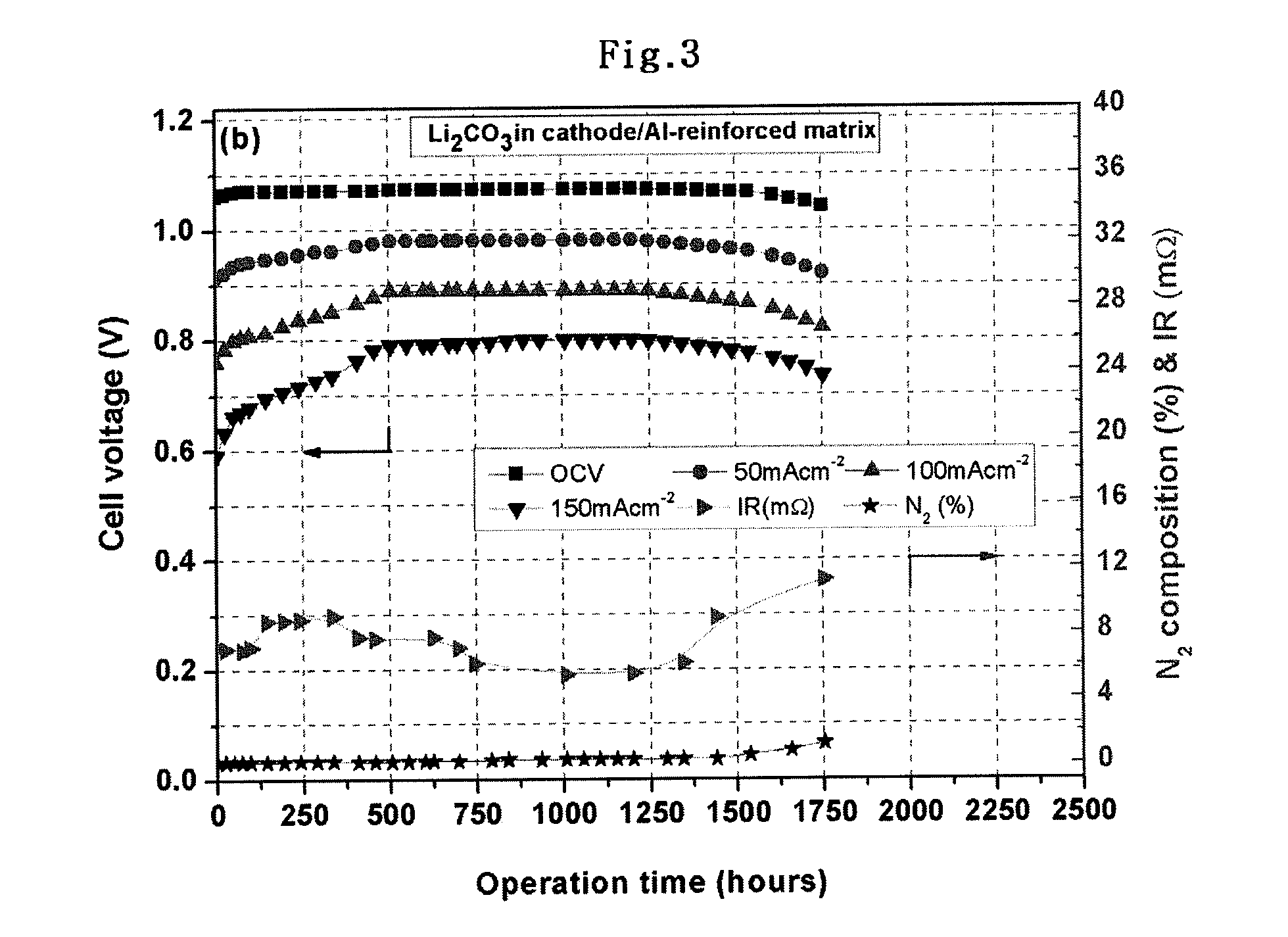

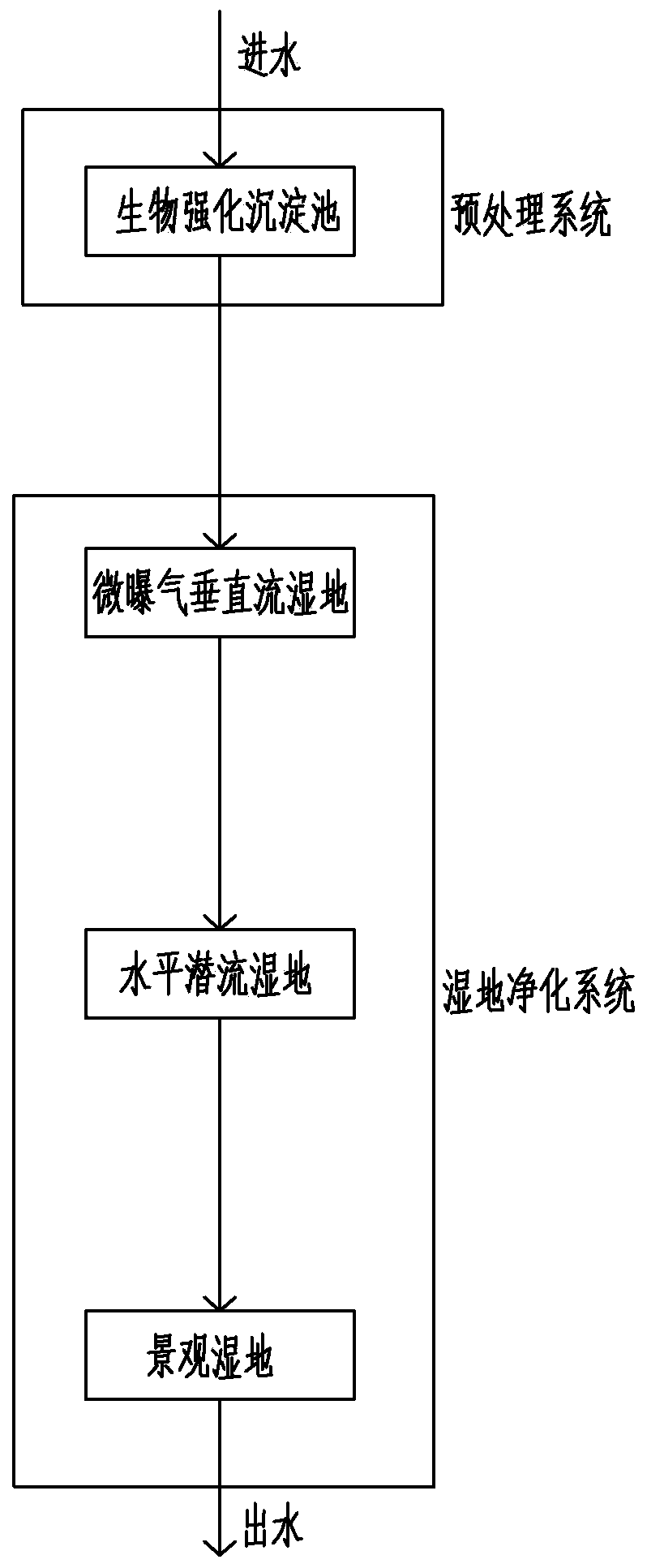

Molten carbonate fuel cells including reinforced lithium aluminate matrix, method for preparing the same, and method for supplying lithium source

InactiveUS20120196204A1High mechanical strengthLong-term operationElectrolyte holding meansFinal product manufactureCarbonateFuel cells

Disclosed is a molten carbonate fuel cell comprising a reinforced lithium aluminate matrix, a cathode, an anode, a cathode frame channel and an anode frame channel, wherein at least one of the cathode frame channel and the anode frame channel is filled with a lithium source. Disclosed also are a method for producing the same, and a method for supplying a lithium source. The molten carbonate fuel cell in which a lithium source is supplied to an electrode has high mechanical strength and maintains stability of electrolyte to allow long-term operation.

Owner:KOREA INST OF SCI & TECH

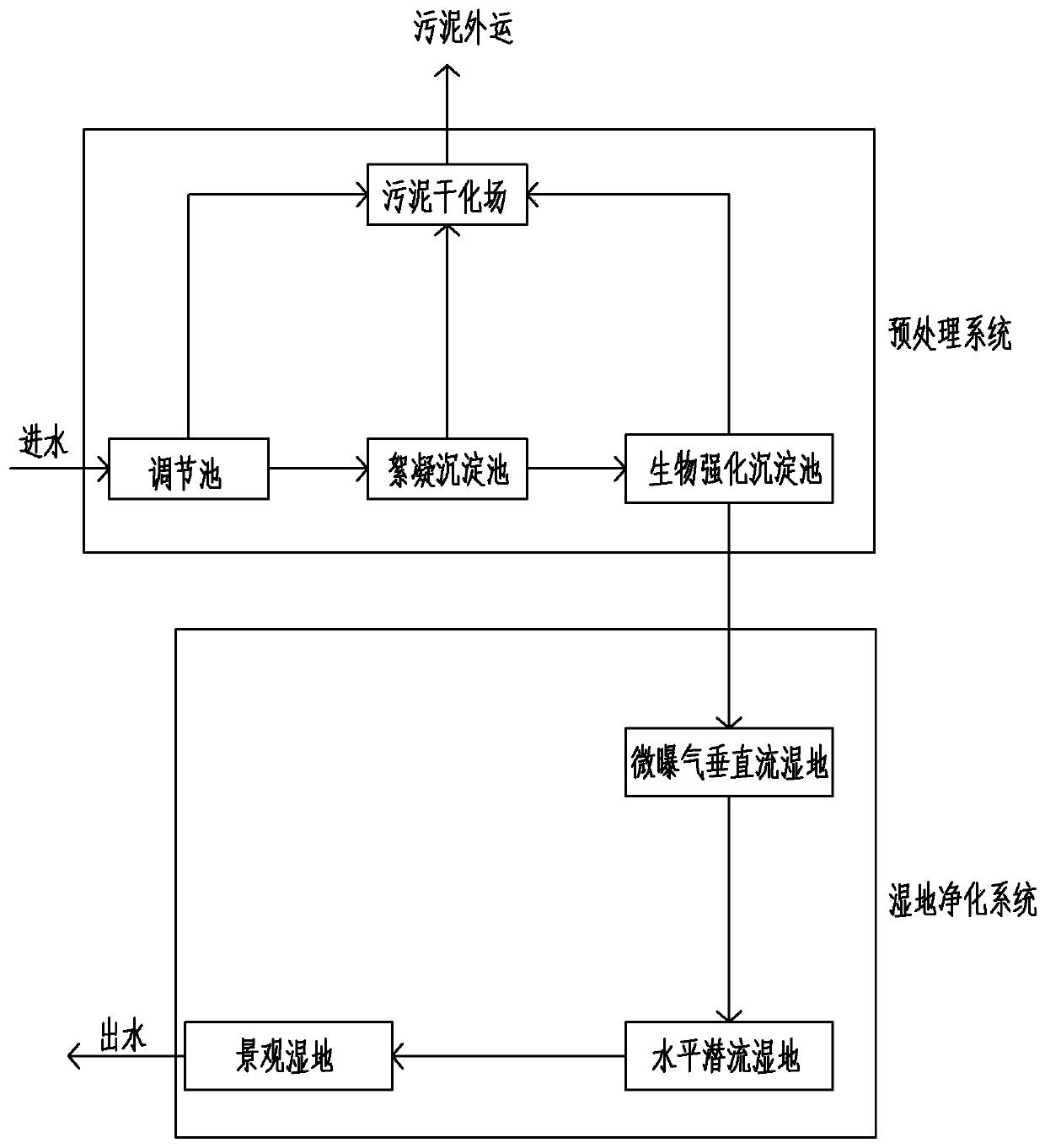

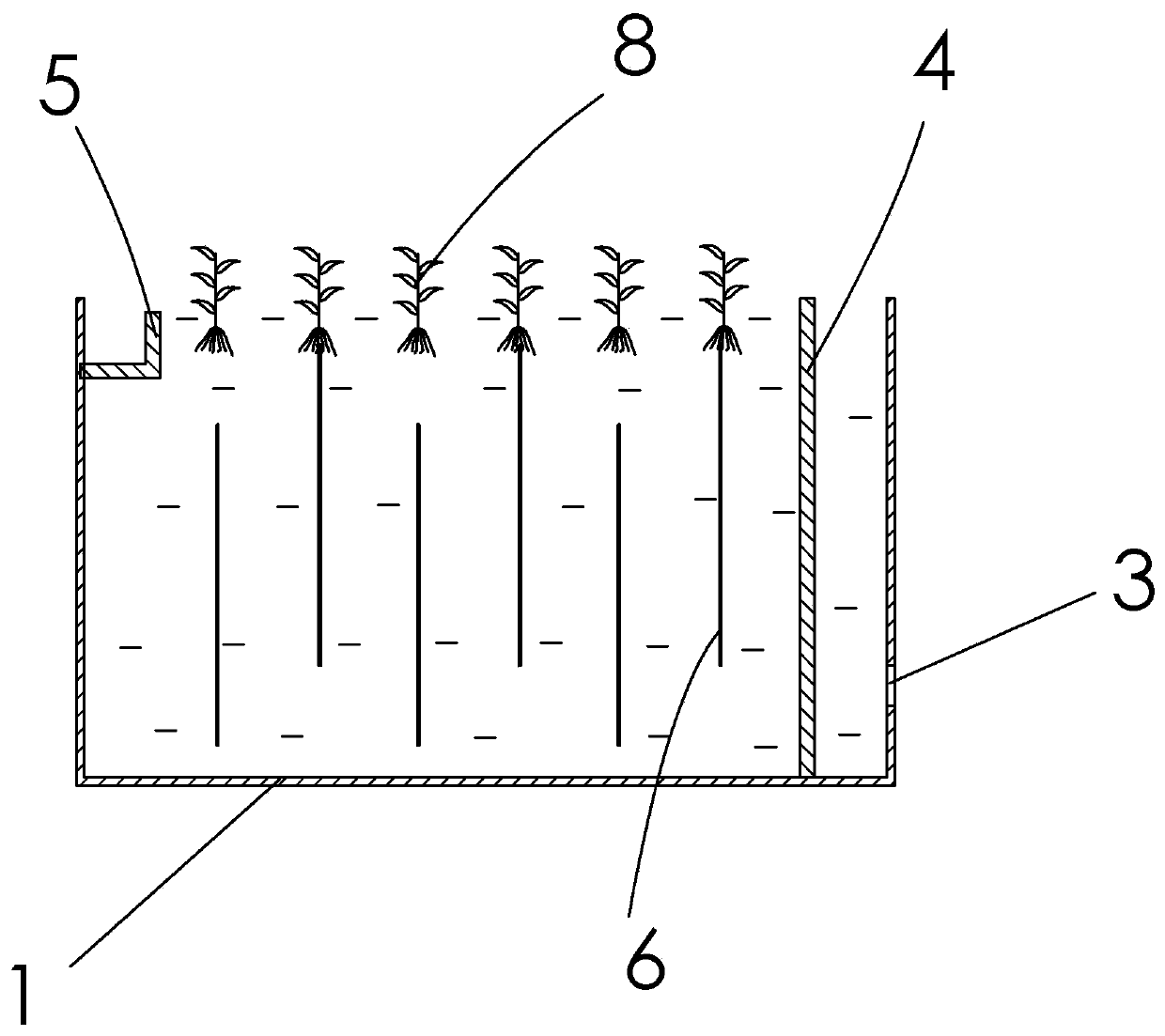

Water purification comprehensive wetland system

InactiveCN110194532AEasy constructionLow costSludge treatment by de-watering/drying/thickeningTreatment involving filtrationWater qualityWetland

The invention provides a water purification comprehensive wetland system. According to the system, based on urban sewage treatment plant tail water, a pretreatment system and a wetland purification system are constructed, the suspended solids are removed from the tail water by using a biologically enhanced precipitation pool, the nitrogen is removed from the raw water by combining a micro-aerationvertical flow wetland and a horizontal underground flow wetland through nitrification-denitrification, and the phosphorus is removed from the raw water through a landscape wetland, such that the treatment of the raw water is completely through the water purification comprehensive wetland system; and based on the domestic sewage in rural areas lacking sewage collection and treatment facilities, anadjusting pool, a flocculation precipitation pool and a sludge treatment device are additionally arranged in the pretreatment system to further remove debris and suspended solids so as to treat the sludge and prevent the clogging. According to the present invention, the system has advantages of convenient construction, utilization of vacant space, low cost, long-term operation and water purification, and is suitable for promotion.

Owner:南京泽辉环保科技有限公司

Amplification technology for amblyseius eharai amitai et swirski domestication population and application thereof

The invention relates to an amplification technology for an amblyseius eharai amitai et swirski domestication population. The technology is implemented by the following specific steps: feeding carpoglyphus lactis with a mixture of yeast and vitamin E as a compound food; feeding amblyseius eharai amitai et swirski with the carpoglyphus lactis fed in the last step as a substitute food forcibly; screening individuals which develop normally after taking the substitute food, lay a large number of eggs and are long in service lives from a natural population of amblyseius eharai amitai et swirski in multiple generations; raising the screened individuals in a centralized way to obtain a primary domestication population; performing tetranychidae feeding habit on the primary domestication population to obtain individuals having strong predation on carpoglyphus lactis and tetranychidae; raising the screened individuals in a centralized way to obtain a final domestication population; amplifying the final domestication population by taking the carpoglyphus lactis fed with the compound food of yeast and vitamin E as a substitute food on the basis.

Owner:INST OF PLANT PROTECTION FAAS

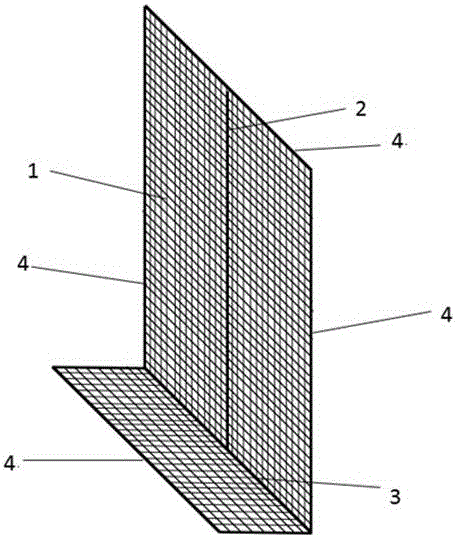

Rodent pest prevention method of traditional Chinese medicinal material land

The invention relates to a rodent pest prevention method of a traditional Chinese medicinal material land, migration and diffusion ways of subterranean rodents are interdicted by using a steel wire gauze to divide a traditional Chinese medicinal material cultivated land into regions, detection on shockwave by the subterranean rodents is interfered by the steel wire gauze , marriage and breeding and normal activities of the subterranean rodents are restricted. The biology characteristics and ecology characteristics of a zokor are combined by the invention, the living space is narrowed down by using the steel wire gauze divided regions to interdict the migration way; the detection on the shockwave by the zokor is interfered by the steel wire gauze, so that normal marriage and breeding and the like of the zokor are effectively prevented, the growth speed of the population is decreased; the rodent pest prevention and control effect is improved by the steel wire gauze divided regions control, and migration and invasion of exogenous rodents resource such as surrounding farmland and the like are also prevented. By means of performing fixed-point artificial elimination and fixed-point medical prevention under the steel wire gauze divided regions space, the defects of the existing prevention method is overcome so that the aim of effective prevention on the traditional Chinese medicinal material cultivated land subterranean rodent pest is achieved. The invention has the advantages that traditional Chinese medicinal materials loss and harm caused by the subterranean rodents are reduced, and the yield of the traditional Chinese medicinal materials is greatly improved.

Owner:GANSU AGRI UNIV

Plum beverage production method using semi plum product containing little salt

InactiveCN1541571AKeep active ingredientsAvoid or reduce ulcerationFood scienceFruit juiceFRUIT PUNCH

The present invention is the plum beverage making process with less salty pickled plum and the making process includes six steps. Compared with available technology, the pickled plum has much less salt contained. The plum beverage is more tasty compared with plum beverage produced with dry dark plum and through squeezing process. The making process is simple, no power consumption, low in cost and suitable for large scale production.

Owner:赵宁

Efficient treatment method for high-concentration organic wastewater

ActiveCN109592828AImprove solar utilizationPromote migrationWater/sewage treatment by irradiationOther chemical processesPorosityHigh concentration

The invention relates to an efficient treatment method for high-concentration organic wastewater, belonging to the field of water treatment. A traditional absorption method is combined with a photocatalysis method, a bacterial cellulose adsorbent and visible-light responded semiconductor graphite-phase carbon nitride (g-C3N4) into a film, a large number of organic matters in wastewater are adsorbed through the porosity and large surface area of the adsorbent, organic matters adsorbed to the surface are photocatalytically degraded and are converted into pollution-free CO2 and water, and meanwhile, active sites of the adsorbent can be regenerated to continuously play a role of adsorption, so that the long-term operation is realized. The COD of the high-concentration organic wastewater treated by virtue of the method can be decreased to be 80mg / L and can be accordant with the national emission standard. After a composite graphite-phase carbon nitride (g-C3N4) / polythiophene film covered with bacterial cellulose works for 100 hours, the adsorption degradation performance is not obviously degraded.

Owner:泰州禾益新材料科技有限公司

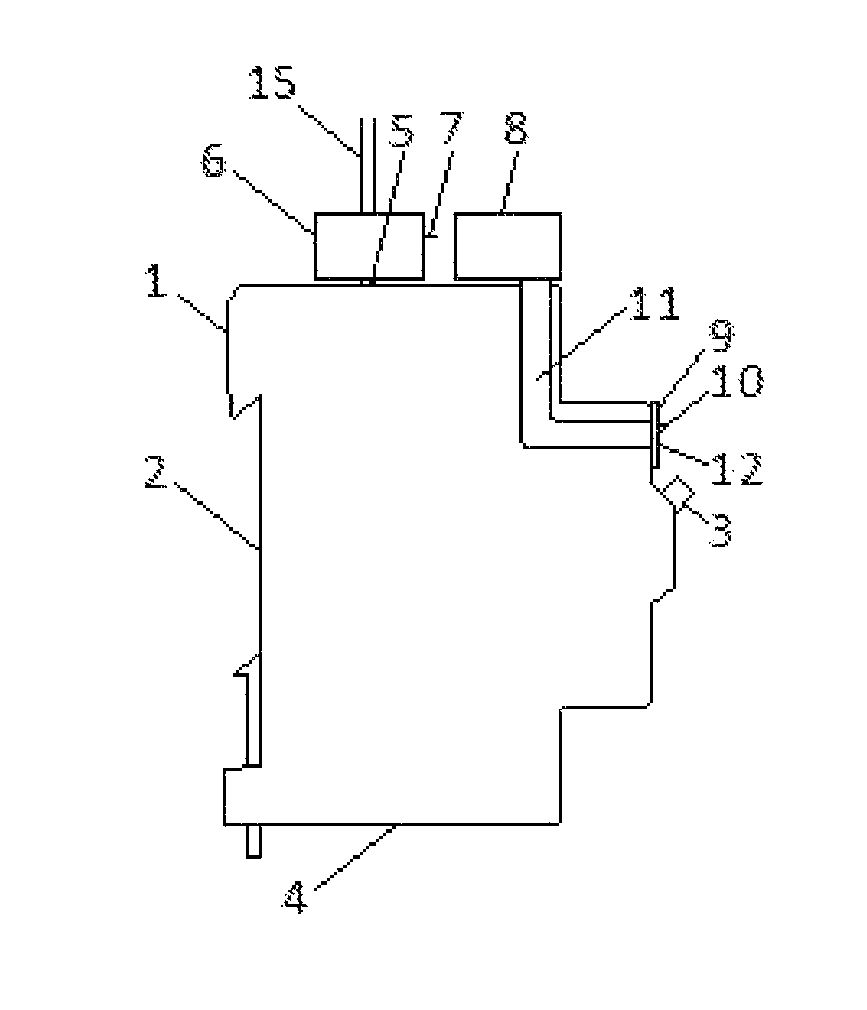

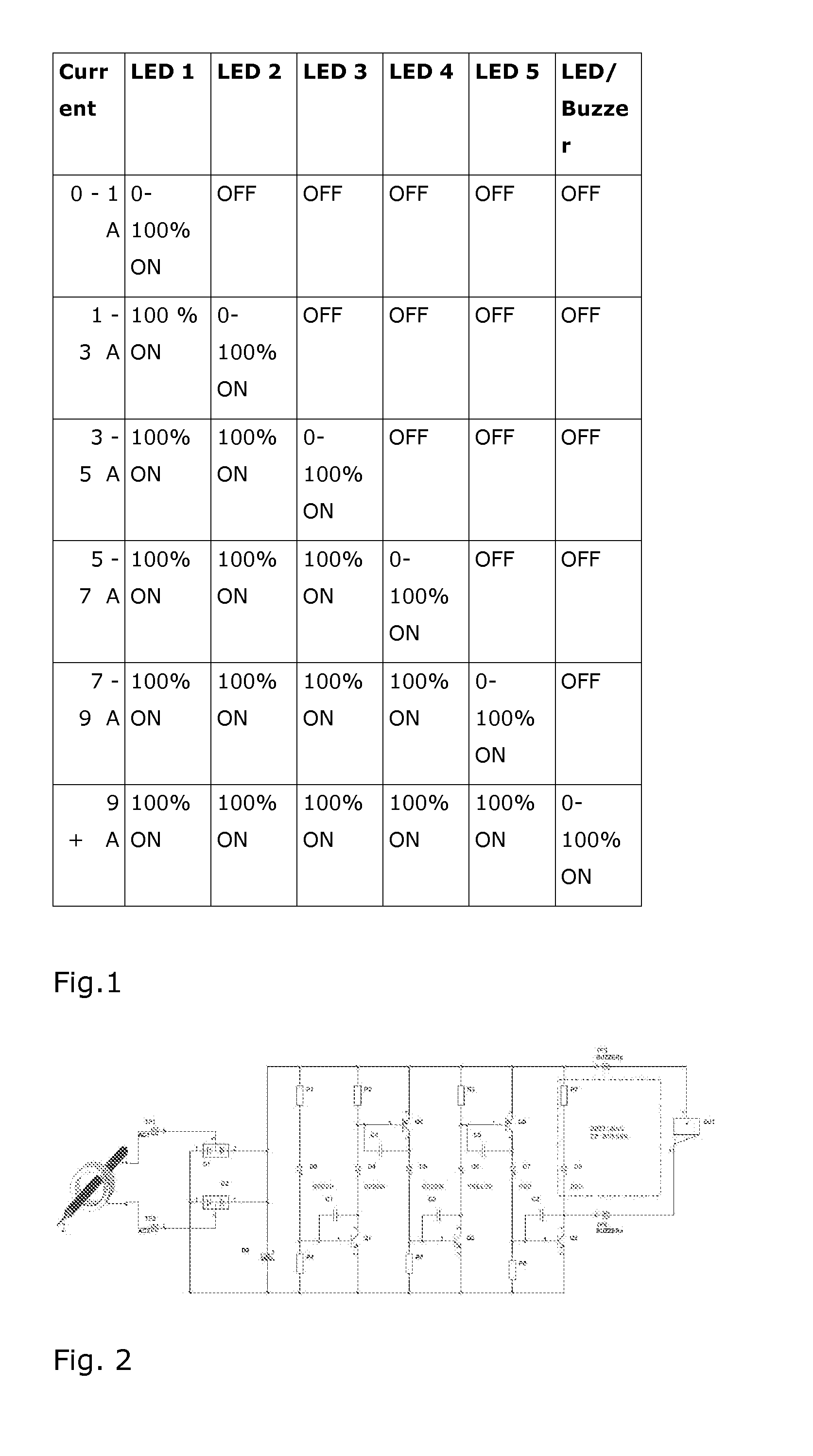

Circuit board meter for circuit breakers

InactiveUS20130222962A1Long-term operationReduce currentCircuit-breaking switches for excess currentsProtective switch detailsElectronic circuitEngineering

A current measuring device for circuit breakers with an improved electronic circuit arrangement by way of arrangement and method for displaying electrical line current by a circuit breaker wherein measurements are made by at least one current transformer. Indications of the magnitude of electrical current are displayed by at least one LED and by the intensity of illumination by each LED. The current measuring device is placed onto a circuit breaker wherein at least one LED of the improved circuit is made accessible by sight at the front face of the current measuring device attached to the circuit breaker. A current transformer is located inside the current measuring device attached to the circuit breaker for measuring the current flowing through the conductor applied to the circuit breaker. The current transformer supplies the improved electronic circuit with a reduced electrical current in proportion to the electrical current flowing through the conductor displaying the magnitude of the current by strength of illumination by at least one LED.

Owner:REMAKE ELECTRIC EHF

Implantable sensor element and method for detecting at least one analyte in a body fluid

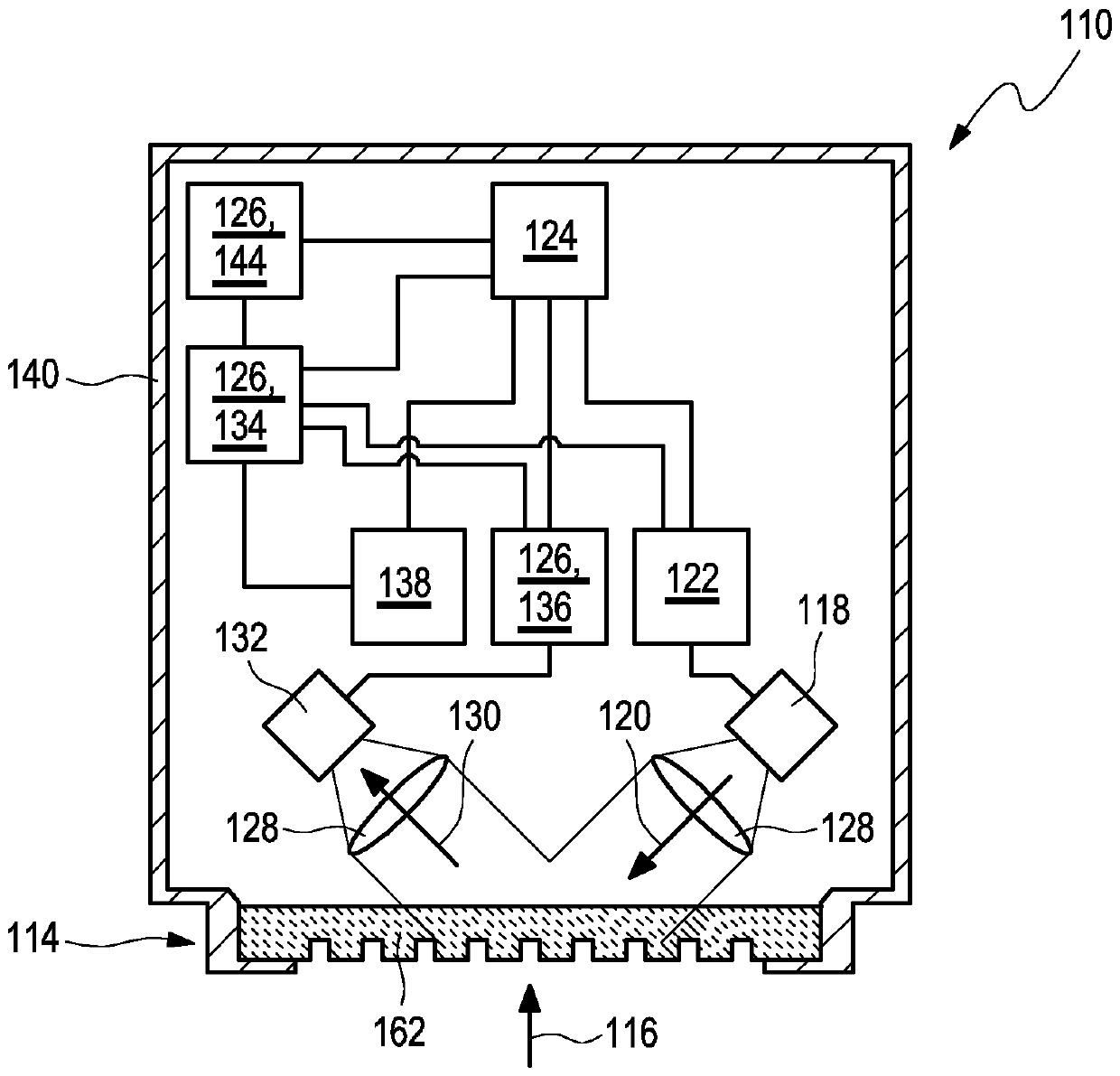

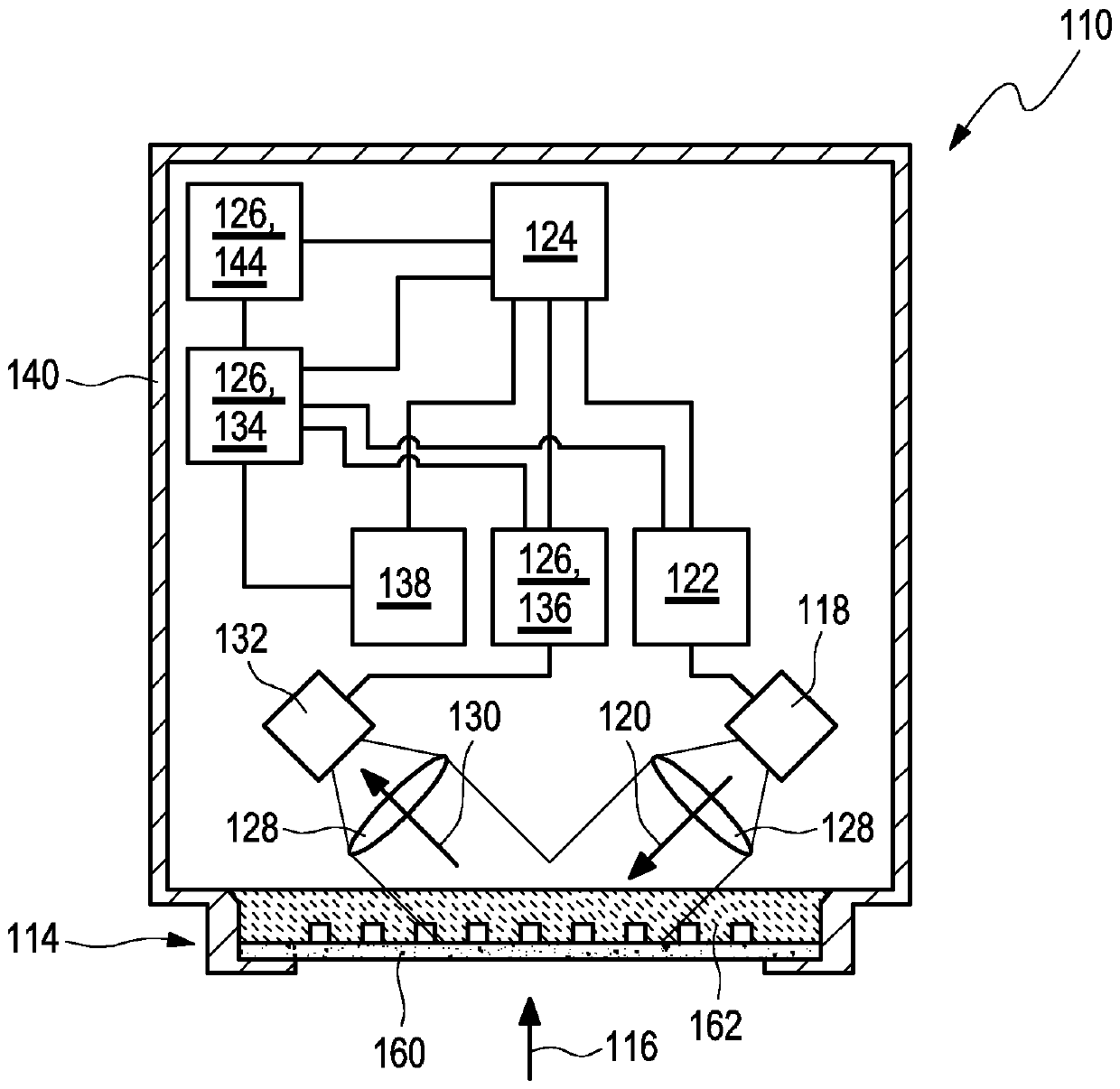

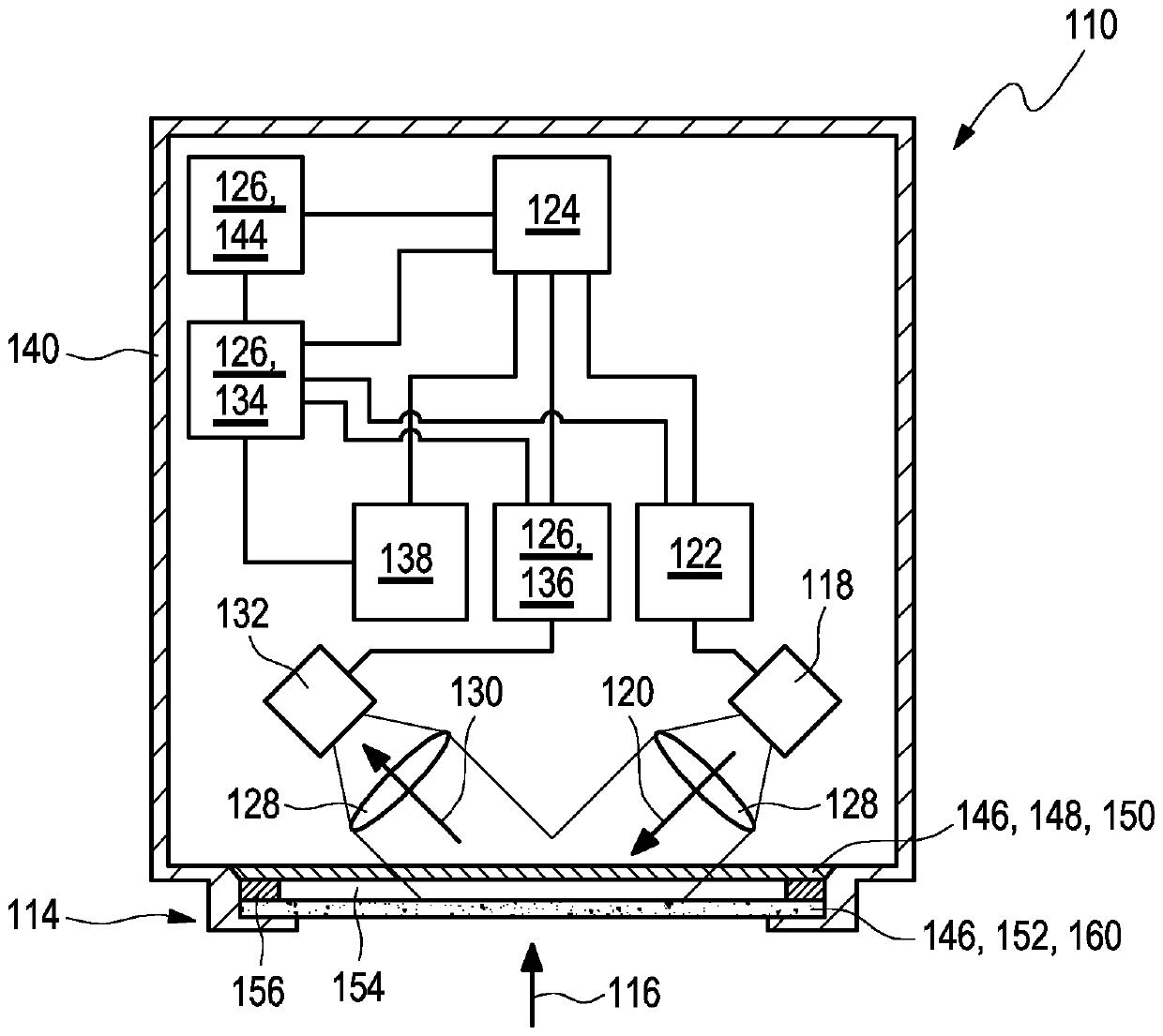

An implantable sensor element (110) for detecting at least one analyte in a sample of body fluid is disclosed. The sensor element (110) comprises at least one measurement chamber plate (114) adapted to receive the sample of bodily fluid. The sensor element (110) comprises at least one illumination source (118) designed to generate at least one illumination light beam (120) in at least one spectralrange and to transmit the illumination light beam (120) to the measurement chamber plate (114) such that the illumination light beam (120) at least partially illuminates the measurement chamber plate(114). The measurement chamber plate (114) is designed to generate at least one reflection light beam (130) in response to the illumination by the illumination light beam (120) such that the reflection light beam (130) at least partially illuminates the sample of body fluid within the measurement chamber plate (114). The sensor element (110) comprises at least one optical detector (132) designed to detect at least one property of the reflection light beam (130) and to generate at least one sensor signal dependent on the presence of the analyte. The sensor element (110) furthermore comprises atleast one control unit (126) designed to evaluate the sensor signal.

Owner:F HOFFMANN LA ROCHE & CO AG

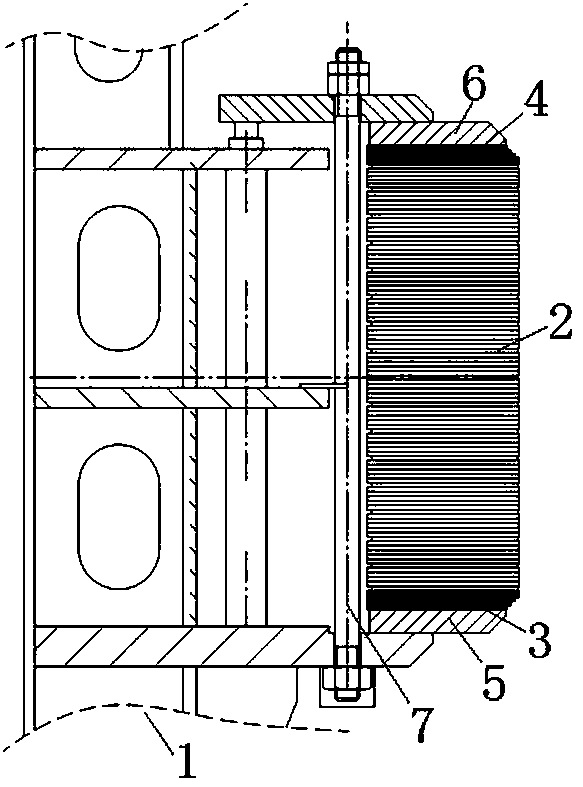

A stator iron core structure of a hydrogenerator and a molding method thereof

PendingCN109088488AIncrease the difficulty of assembly technologyIncrease the difficulty of processing technologyMagnetic circuit stationary partsService conditionSilicon

The invention discloses a stator iron core structure of a hydrogenerator and a molding method thereof. The stator iron core structure comprises a plurality of silicon steel sheets; according to the arrangement position of the silicon steel sheets on a stator base, the silicon steel sheets are divided into a middle iron core assembly and end iron core assemblies at the two axial ends; each siliconsteel sheet of the end iron core assembly is bonded and assembled into an integral annular structure according to the arrangement order, the silicon steel sheets of the middle iron core assembly are stacked and arranged between the end iron core assemblies of the integral annular structure at both ends in the arrangement order, and the end core assemblies at both ends respectively bear the axial locking force of the stator core pressing mechanism to the stator core structure in the axial direction. The present invention not only does not obviously increase the technical difficulty of processing and assembling the stator iron core structure, but also can meet the technical requirements of the service condition, and can effectively solve the technical problem that the axial locking force ofthe stator iron core structure on the stator frame is liable to be destroyed, which is favorable for the long-term safe and stable operation of the hydrogenerator.

Owner:DONG FANG HENG YUN ELECTRICAL MACHINERY

Load-detecting orthosis

PendingUS20220000392A1Long-term operationReliable warningNon-surgical orthopedic devicesTelemetric patient monitoringRegion detectionElectronics

A loading-detecting orthosis includes a sensor that generates sensor signals and that has sensor elements in pressure areas. The loading-detecting orthosis further includes sensor signal-evaluating electronics that are designed to indicate critical loading. The sensor signal-evaluating electronics are designed to ascertain characteristic values regarding pressure loading events detected at least per pressure area by way of the sensor elements, to form a sum value into which the characteristic values are incorporated by amount in weighted form such that at least three different weights are used, and to generate an alert signal when the sum value exceeds a certain amount.

Owner:GOLEX AG

Operation optimizing and energy-saving control method for intermediate storage iron shot mill flour milling system

InactiveCN100594066CReduce the power consumption of millingStable operating parametersGrain treatmentsAdaptive controlControl systemFlameout

The invention relates to a method for the optimization of operation and control of energy conservation for a reserve ball-grinding powder system. Firstly, a non-linear neural network model about the consumption of powder of a powder-making system and operating parameters is established through collecting the service data of the powder-making system, then the negative pressure and the temperature at the entrance of a coal mill and the temperature at the outlet of the coal mill are obtained through the non-linear optimization with restricted conditions as a set value for controlling the system,wherein, the negative pressure, the temperature at the entrance and the outlet lead to lower consumption of powder; the entire optimized controlling of the powder-making system is carried out throughthe intelligent control of rotation of the coal mill and multivariable decoupling control of parameters at the entrance of the coal mill based on the operating experience as well as an intelligent down draft control technology, so as to ensure that the powder-making system strictly runs at an optimal condition and effectively reduces the powder consumption. The method provided by the invention caneffectively inhibit the fluctuations of a primary air pressure in the on / off process of the powder-making system, put an end to serious accidents such as flameout in a boiler caused by down draft andeffectively reduce the operating intensity for the staff.

Owner:SOUTHEAST UNIV

Spacecraft Attitude Control System Based on Momentum Wheel and Reflectivity Control Device

ActiveCN112572838BWide applicabilityExtend your lifeCosmonautic vehiclesSpacecraft guiding apparatusSpace environmentSpacecraft attitude control

The invention discloses a spacecraft attitude control system based on a momentum wheel and a reflectivity control device, and belongs to the technical field of spacecraft attitude control. The spacecraft attitude control system includes an actuation subsystem, an unloading subsystem, an attitude determination subsystem, and a drive control subsystem; the attitude control system adopts a momentum wheel as the actuation mechanism for spacecraft attitude control, and adopts an autonomously adjustable The emissivity control device of the reflectivity generates an unloading torque, and selectively unloads the momentum wheel that tends to saturate. The spacecraft attitude control system based on the system solution components can not only ensure the attitude control ability, but also get rid of the dependence on traditional unloading methods such as geomagnetic moment unloading and thruster unloading, so that the spacecraft can operate in the space environment beyond the medium and high orbit. With super long-term service conditions.

Owner:NAT UNIV OF DEFENSE TECH

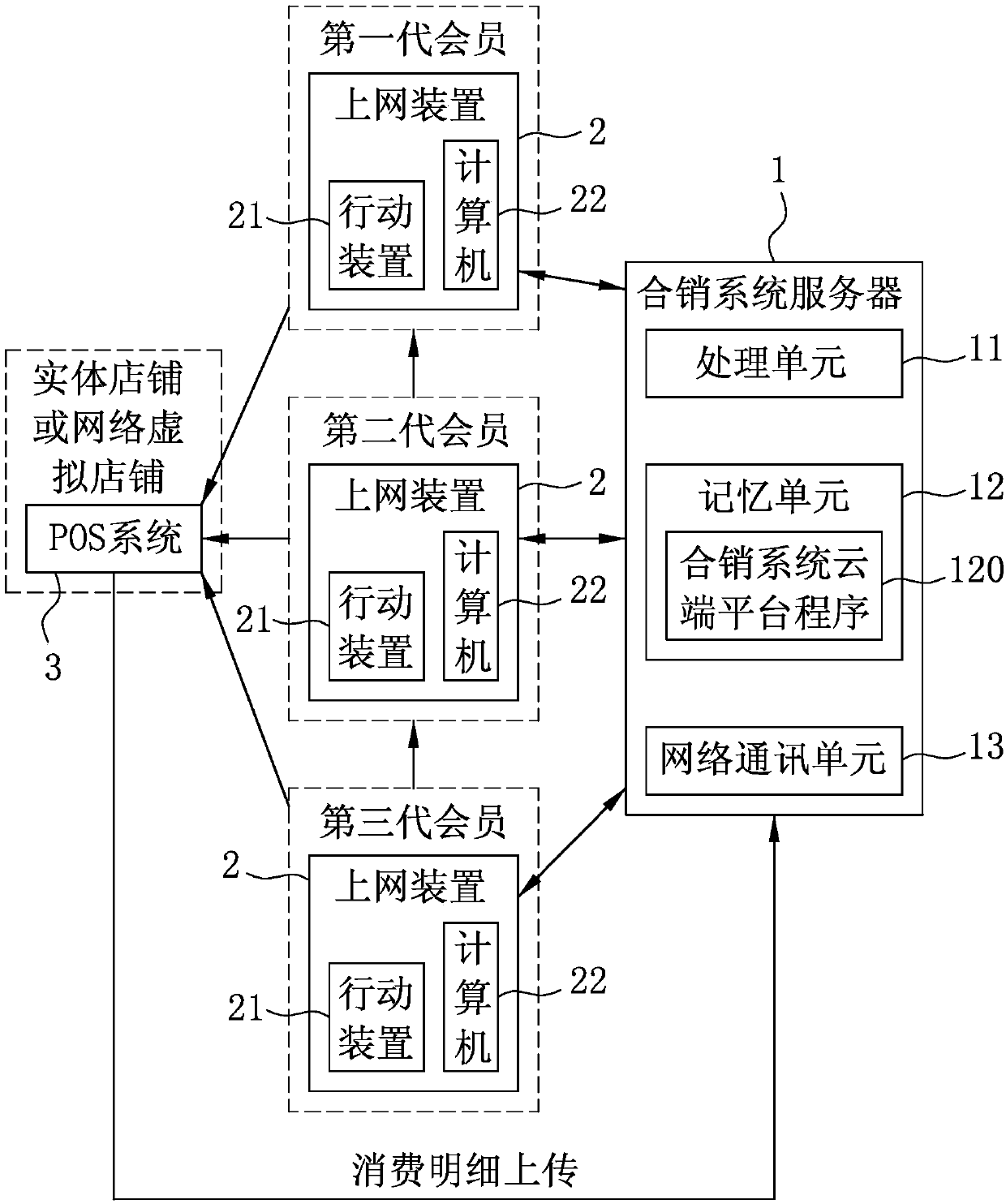

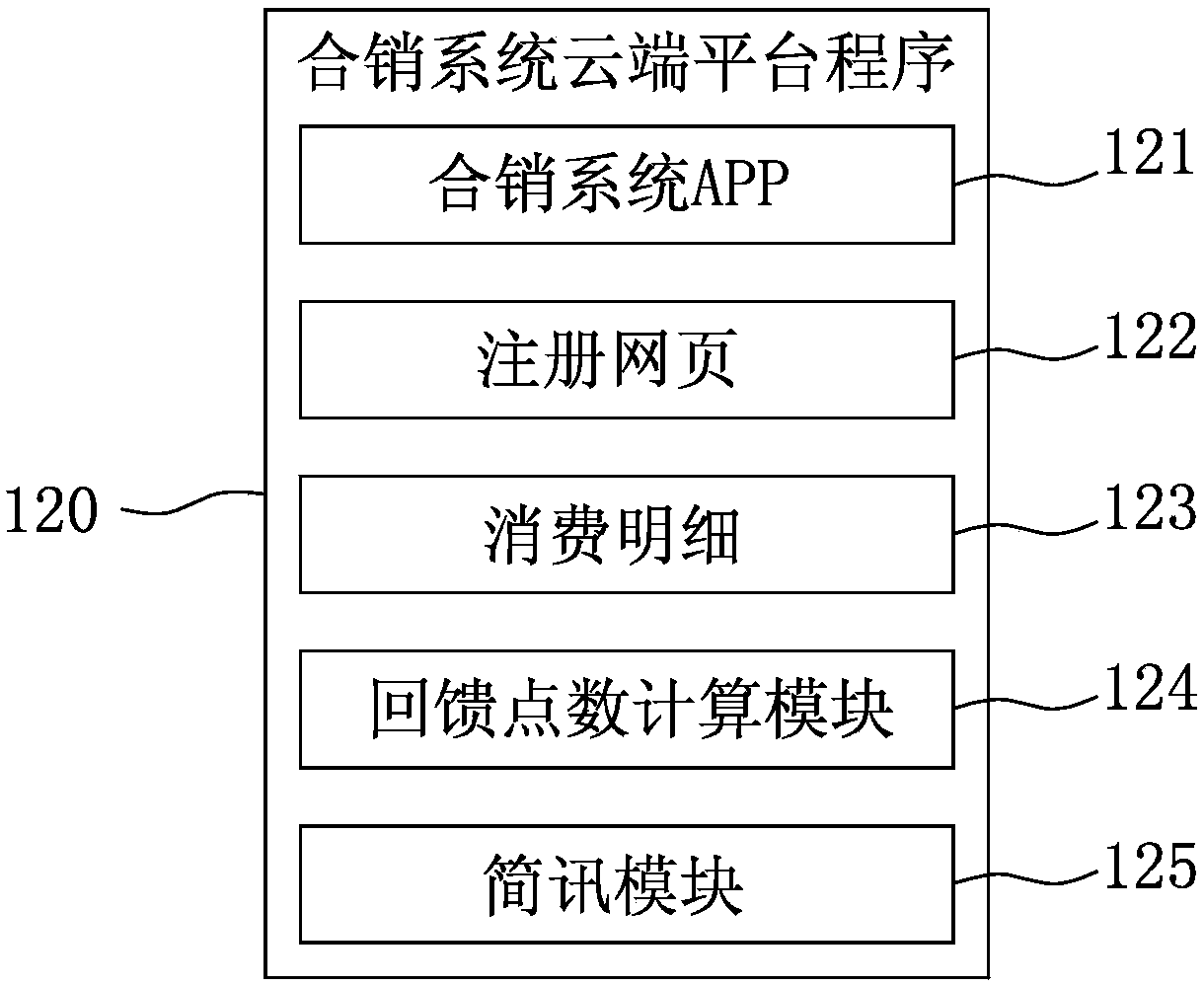

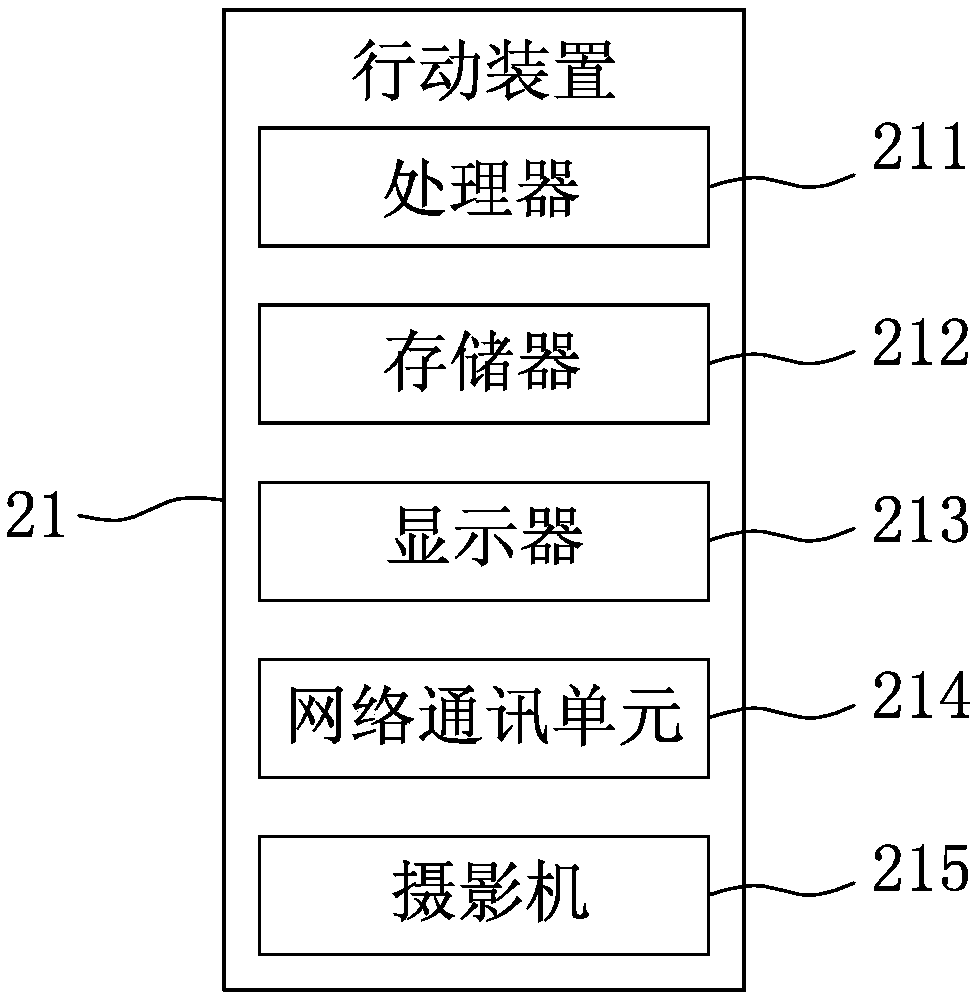

Operating method of combined sales system

The invention relates to an operation method of a combined sales system. The method comprises the following steps: (a) a combined sales system server calculates the consumption amount of a member in aspecified date interval; (b) the combined sales system server judges whether the member has accumulated feedback points in a previous appointed date interval or not; and (c) if the judgment result ofthe step (b) is yes, the combined sales system server calculates that the feedback cash to be issued to the member is equal to the sum of the consumption amount and the cash feedback proportion. By using the method, the consumption amount of the member can be settled into the member and the online feedback point number of the member; and the member can change the number of feedback points from the consumption amount to obtain feedback cash, so that the member can obtain feedback bonus from the consumption amount of the member each time as long as the member has a continuous offline consumption behavior, and the method belongs to a brand-new direct and sales system which can be operated for a long time.

Owner:颜世祥 +2

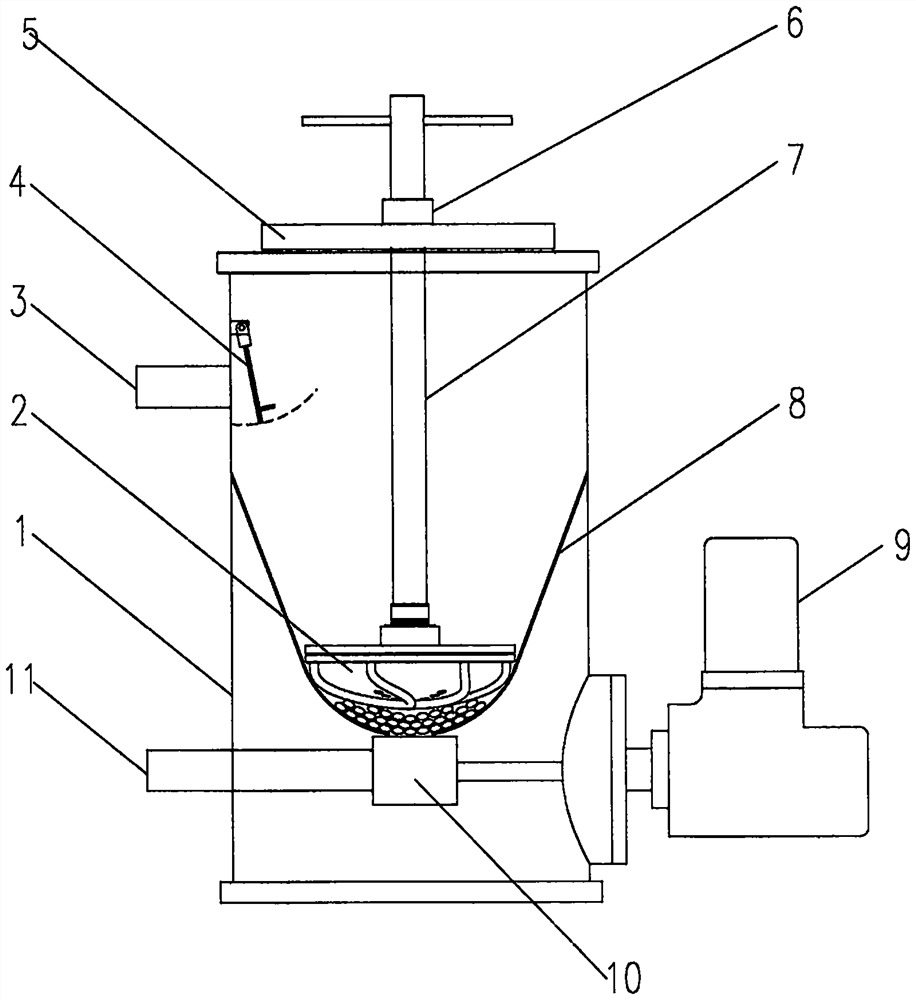

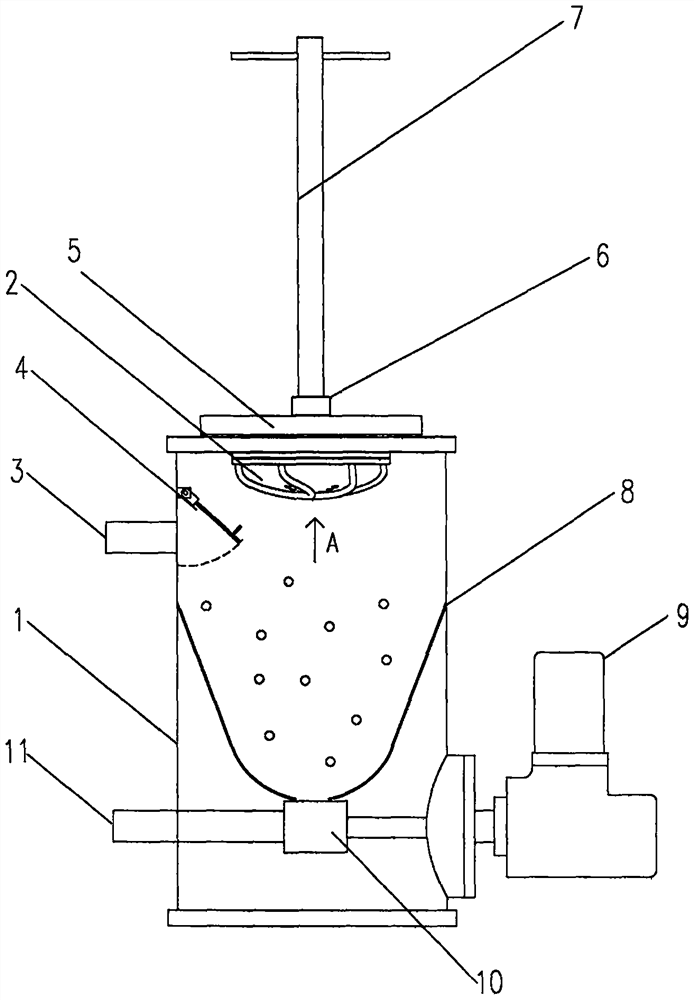

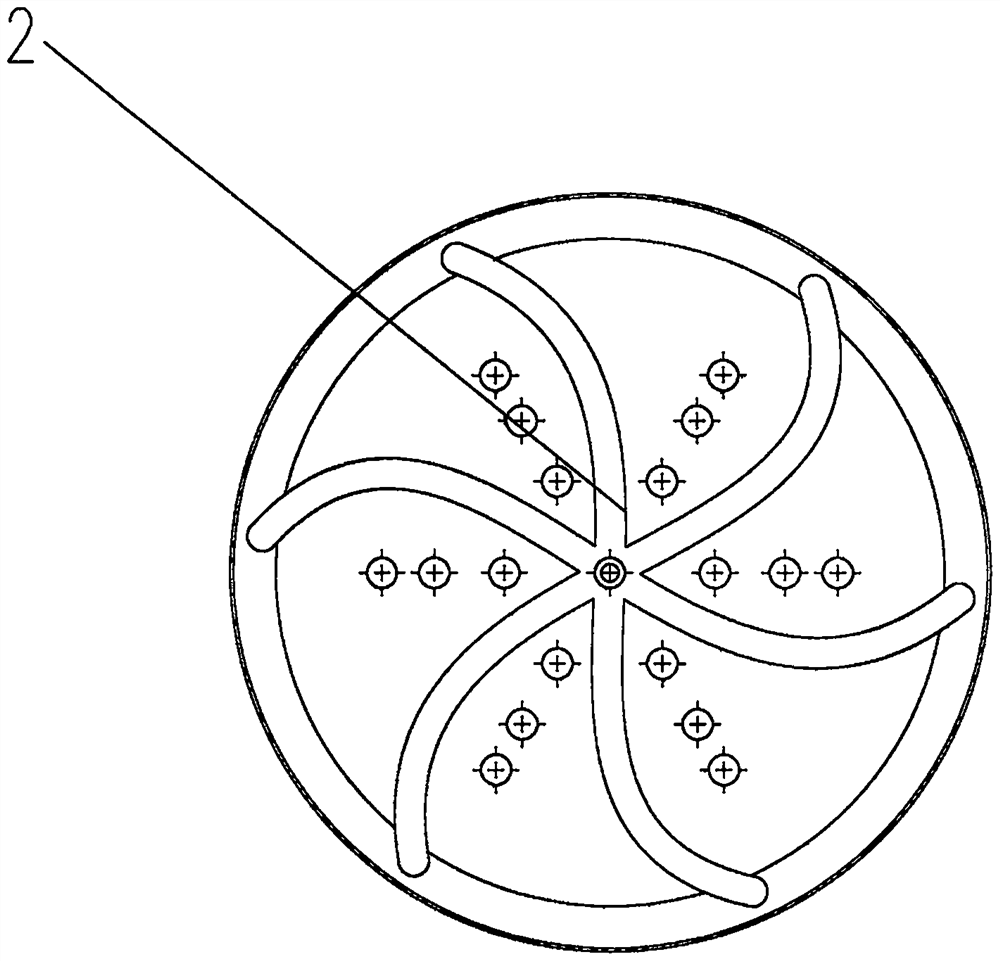

Ball adding device capable of rapidly soaking and automatically cleaning rubber balls

PendingCN114413678ALong-term operationImprove cleaning efficiencyNon-rotary device cleaningCirculating pumpMechanical engineering

The invention relates to a ball adding device with functions of quickly soaking and automatically cleaning rubber balls, and aims to provide a ball adding device which is additionally arranged in an original condenser rubber ball cleaning device system, is connected between an outlet pipe of a rubber ball circulating pump and a rubber ball spraying pipe and has the functions of quickly soaking and automatically cleaning the rubber balls. Qualified sponge rubber balls are sprayed and recycled on line, the cleaning efficiency of the condenser can be greatly improved, meanwhile, the sponge rubber ball cleaning work efficiency of the condenser rubber ball cleaning device can be improved, and it can be guaranteed that the sponge rubber balls are put into use for a long time.

Owner:程朝卿 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com