Operation optimizing and energy-saving control method for intermediate storage iron shot mill flour milling system

A technology of operation optimization and energy-saving control, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of low utilization rate, lack of elaboration, and poor use effect of the control system, and achieve stable operation parameters, The effect of reducing operation intensity and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

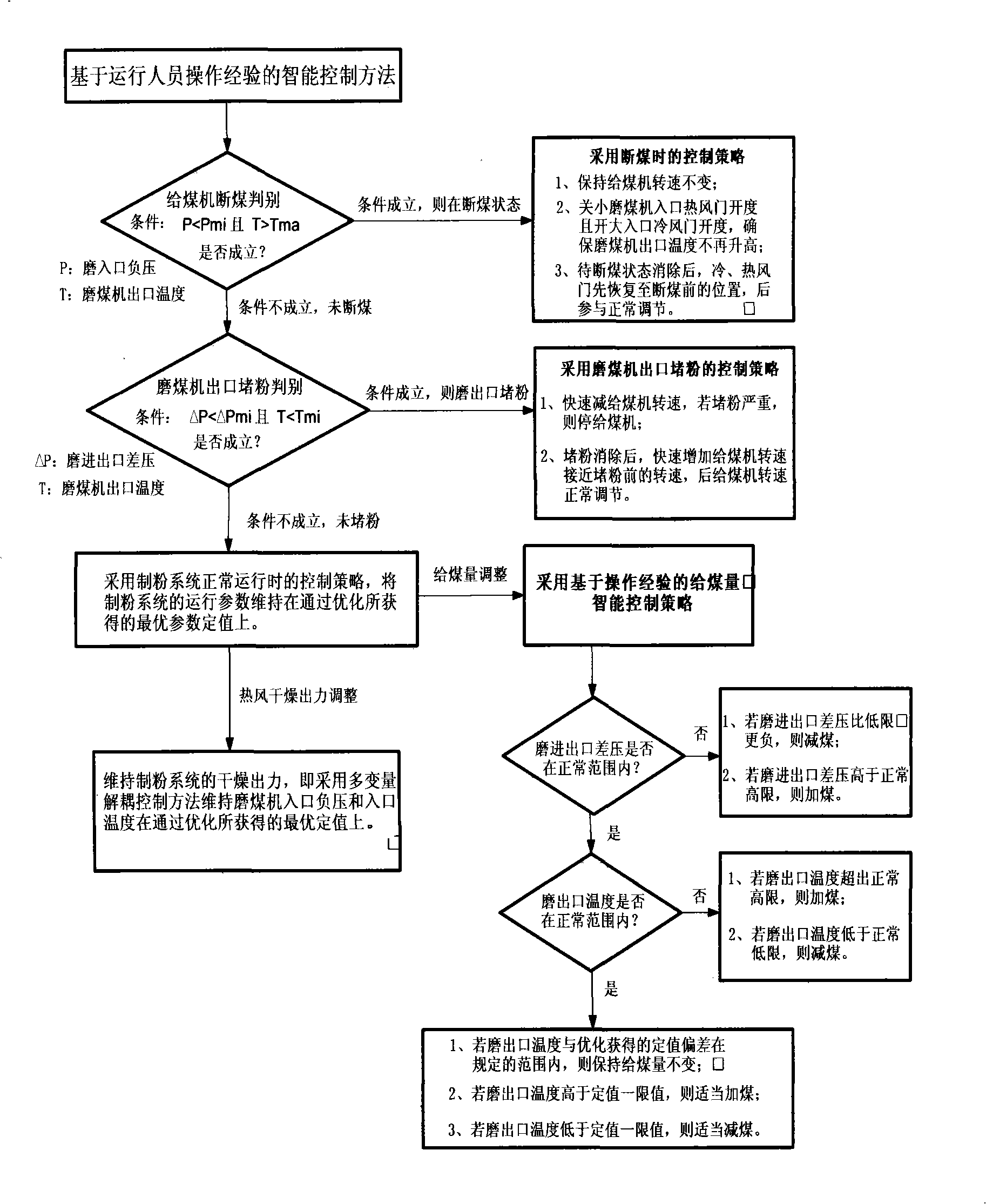

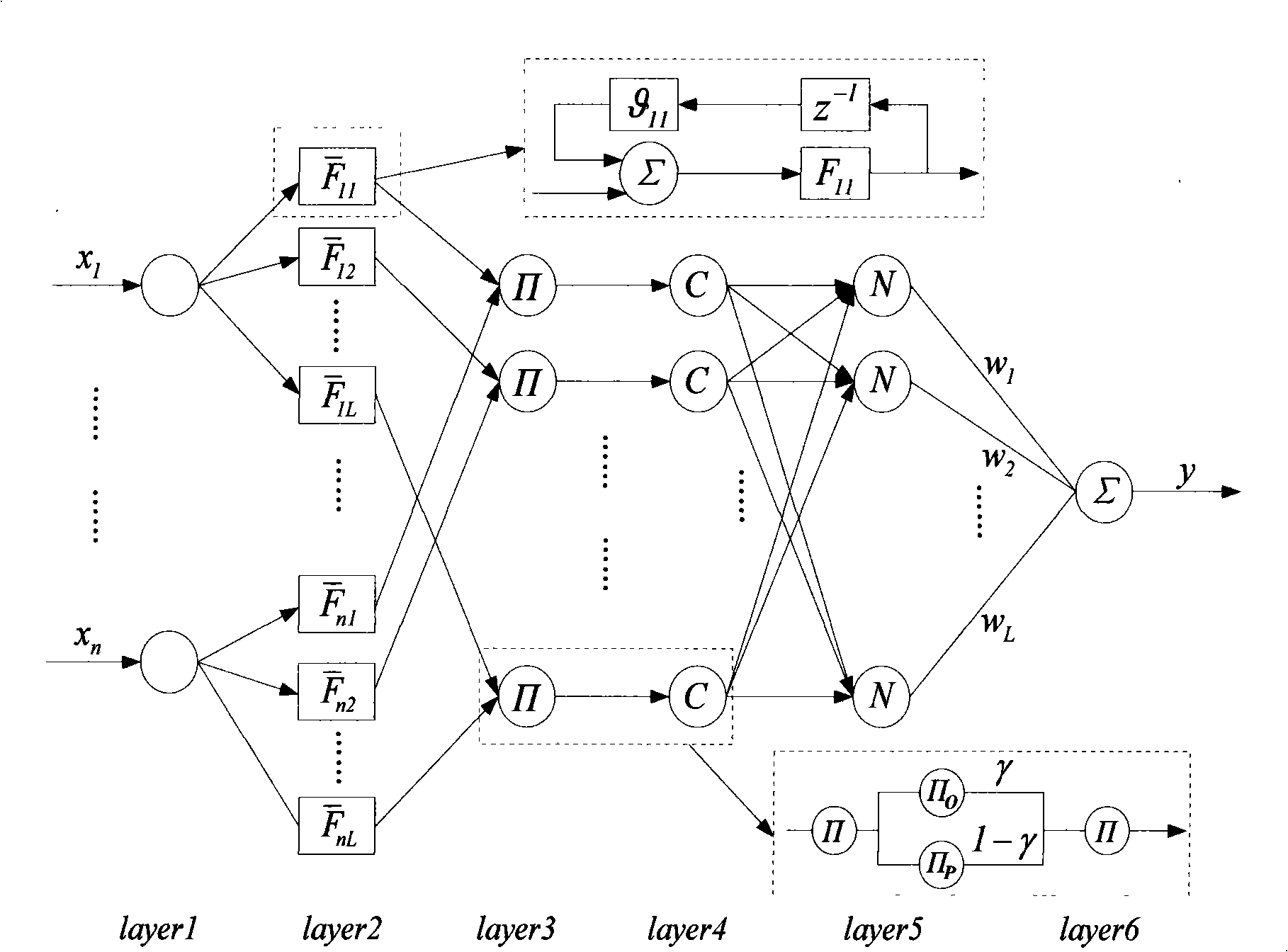

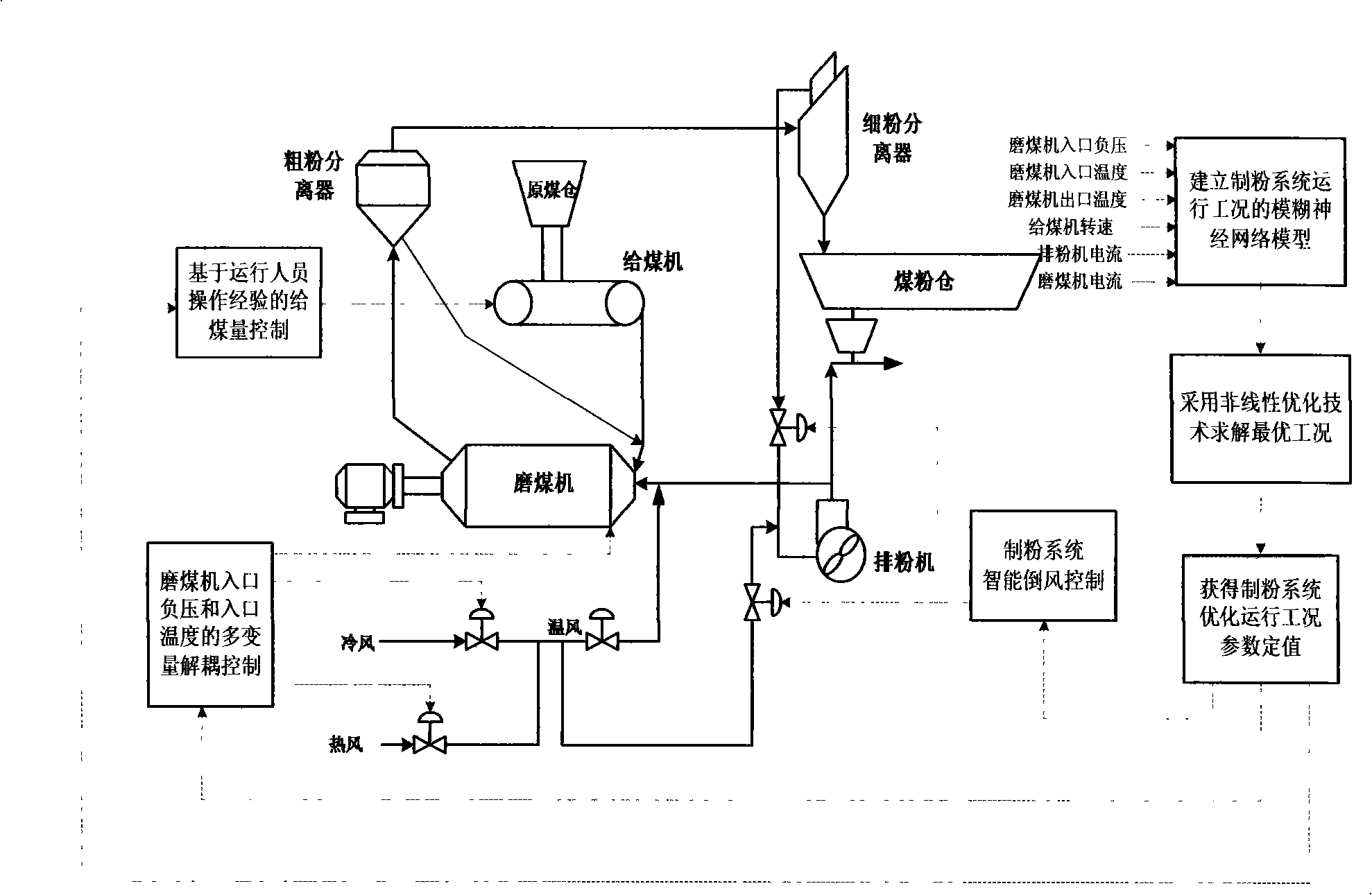

[0053] The operation optimization and energy-saving control method of the medium-storage steel ball mill pulverization system in this embodiment adopts the optimized operation condition of the pulverization system and the optimization control of the pulverization system to control the operation of the pulverization system with low energy consumption. The intelligent control method proposed in this embodiment is as attached figure 1 As shown, the present invention is mainly divided into two aspects: one is to determine the optimal operating condition through nonlinear optimization on the basis of establishing the operating condition model of the pulverizing system, that is, to provide the optimal parameter setting value for the control system . The second is to design and realize the automatic control system of the pulverizing system according to the actual situation of the mid-storage steel ball mill pulverizing system, and control the relevant operating parameters in the pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com