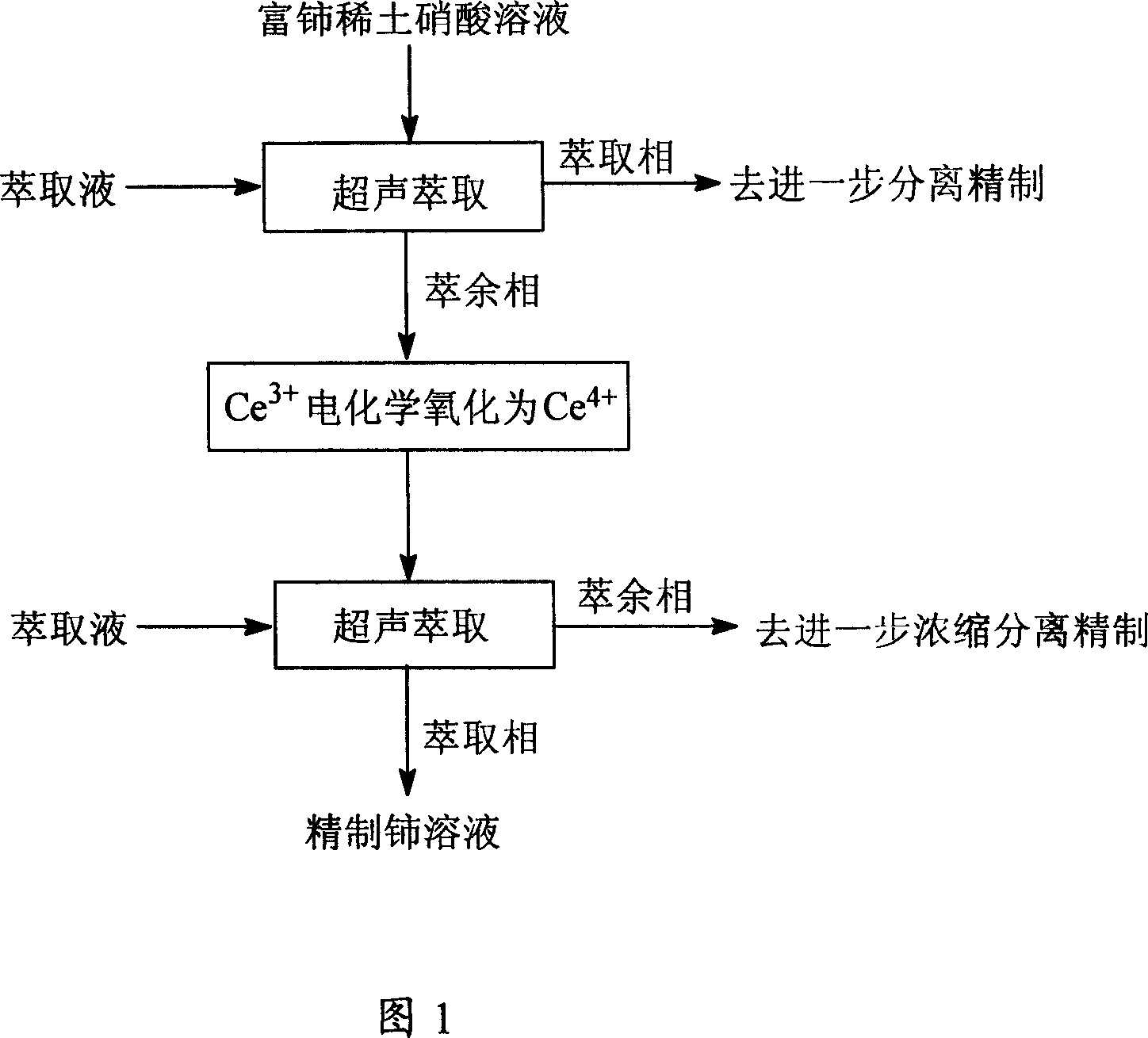

Ultrasonic strengthening extraction separation method of cerium-rich rare earth nitrate solution

A cerium-rich rare earth, ultrasonic strengthening technology, applied in the field of hydrometallurgy, can solve the problems of high average cell voltage, electrochemical reaction rate, current efficiency and low oxidation rate, achieve low power consumption, solve the contradiction between mixing and clarification , the effect of high apparent current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

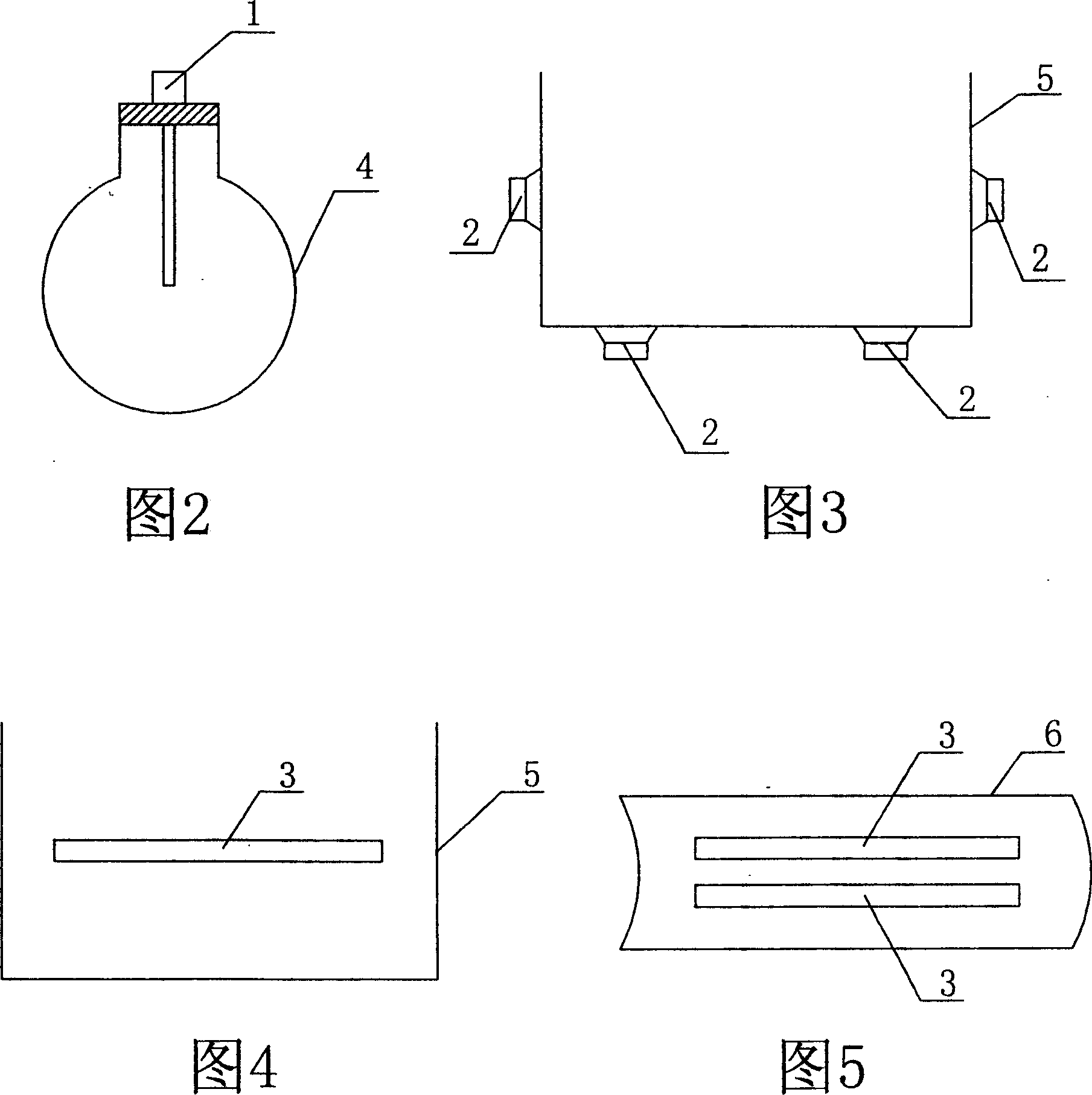

[0030] Embodiment 1: Main equipment: 1000ml stirred tank, probe type ultrasonic generator, fixed bed ion-exchange membrane electrochemical reactor, analytical testing instrument etc.

[0031] Main raw materials: nitric acid, TBP extractant, kerosene, cerium-rich rare earth nitrate solution.

[0032] The processing steps described in the present embodiment are as follows:

[0033] (1) Ultrasonic extraction: Add 600ml of cerium-rich rare earth nitrate solution, 120ml of extract mixed with TBP and kerosene into the ultrasonic extraction equipment, REO=200g / L in the cerium-rich rare earth nitrate solution, CeO 2 / REO=47%, place the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature at 5°C, adjust the ultrasonic generator, adjust the frequency to 19kHz, and the ultrasonic intensity is 0.2W / cm 2 , under the action of an ultrasonic generator, the extraction and separation operation is carried out. After ultrasonic extraction and sep...

Embodiment 2

[0036] Embodiment 2: main equipment: 1500ml stirred tank, probe type ultrasonic generator, fixed-bed ion-exchange membrane electrochemical reactor, analytical testing instrument etc.;

[0037] Main raw materials: nitric acid, TBP extractant, kerosene, cerium-rich rare earth nitrate solution;

[0038] The processing steps described in the present embodiment are as follows:

[0039] (1) Ultrasonic extraction: Add 600ml of cerium-rich rare earth nitrate solution, 600ml of extract mixed with TBP and kerosene into the ultrasonic extraction equipment, REO=200g / L in the cerium-rich rare earth nitrate solution, CeO 2 / REO=47%, place the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature to 40°C, adjust the ultrasonic generator, adjust the frequency to 25kHz, and the ultrasonic intensity to 2.0W / cm 2 , under the action of an ultrasonic generator, the extraction and separation operation is carried out. After ultrasonic extraction and s...

Embodiment 3

[0042] Embodiment 3: main equipment: 2500ml stirred tank, probe type ultrasonic generator, fixed bed ion-exchange membrane electrochemical reactor, analytical testing instrument etc.

[0043] Main raw materials: nitric acid, TBP extractant, kerosene, cerium-rich rare earth nitrate solution.

[0044] The processing steps described in the present embodiment are as follows:

[0045] (1) Ultrasonic extraction: Add 500ml of cerium-rich rare earth nitrate solution, 1000ml of extract mixed with TBP and kerosene into the ultrasonic extraction equipment, REO=200g / L in the cerium-rich rare earth nitrate solution, CeO 2 / REO=47%, place the probe of the probe-type ultrasonic generator in the mixed material, control the operating temperature to 60°C, adjust the ultrasonic generator, adjust the frequency to 80kHz, and the ultrasonic intensity to 20.0W / cm 2 , under the action of an ultrasonic generator, the extraction and separation operation is carried out. After ultrasonic extraction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com