Glass fiber reinforced plastic filler-type catalytic desulfurization tower

A technology of catalytic desulfurization and glass fiber reinforced plastics, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as uneven gas distribution in the tower, and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

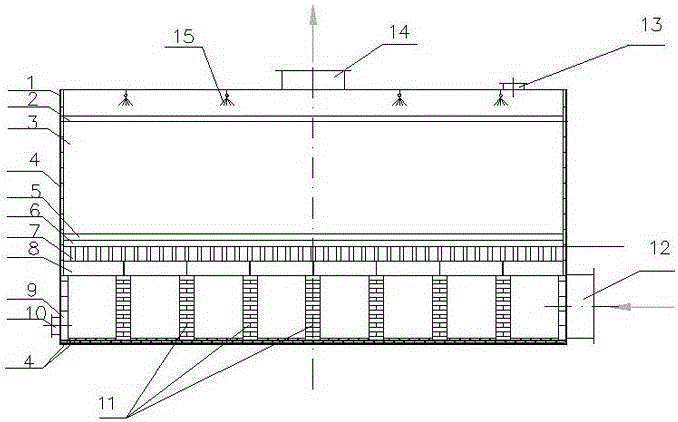

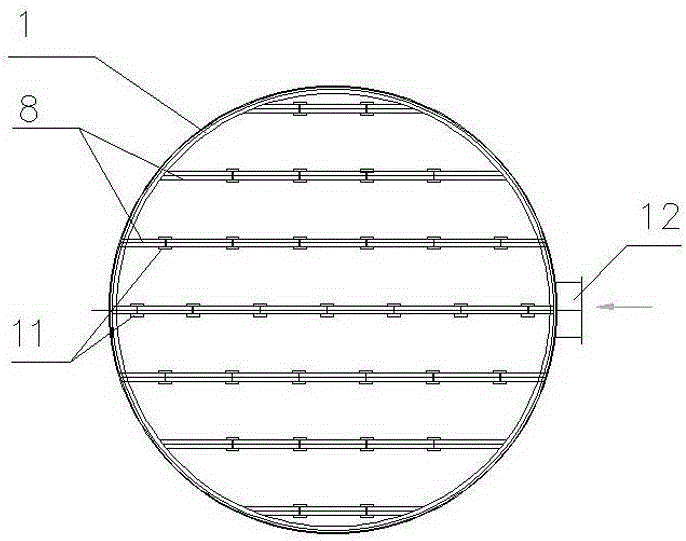

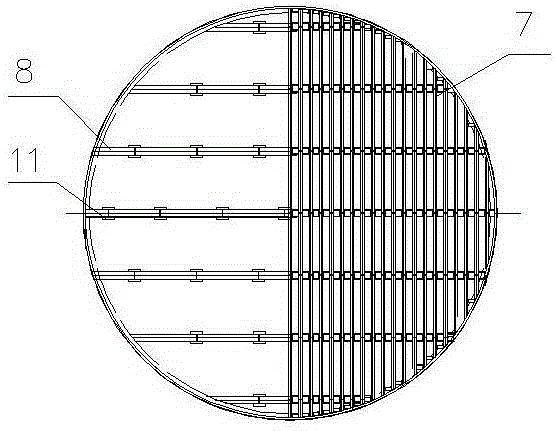

[0017] refer to figure 1 , the present invention provides a fiberglass packed catalytic desulfurization tower, which is composed of several tower body units 1 (or 1 group of tower body units). Shower nozzle 15, flue gas outlet 14, packing layer 3, structured packing layer 5, grid 6, bar beam 7, main beam 8, column 11, circulating liquid outlet 10 and flue gas inlet 12. The FRP tower body is composed of an inner layer of FRP and an outer layer of carbon steel, and the outer layer acts as a reinforcement. The inner wall of the FRP tower is provided with a layer of conjoined lining bricks 4 and the bottom of the tower is tiled with conjoined lining bricks 4 (patent number ZL20113014294.4). The flue gas outlet 14 is set at the center of the top of the tower. There are 30 nozzles 15, which are evenly distributed between the top of the tower and the packing. There is one flue gas inlet 12, which is arranged on the lower side of the tower, and the direction is perpendicular to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com