Refrigerating machine oil composition

A technology for refrigerating machine oil and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as damage to the integrity and efficiency of the refrigeration system, influence on the air tightness of the compressor, and acceleration of oil deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

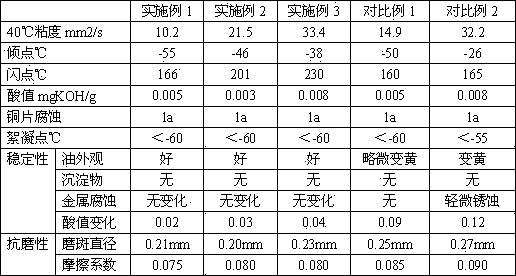

Embodiment 1

[0026] The components and contents of the refrigerating machine oil composition described in Example 1 are as follows: an alkylnaphthalene mixture containing C6~C7 substituted alkyl is selected, wherein the viscosity of the alkylnaphthalene mixture at 40°C is 5.0~9.0mm 2 / s, the addition amount is 59.0wt%, and then add the alkylnaphthalene mixture of C8~C9 substituted alkyl, wherein the viscosity of the alkylnaphthalene mixture at 40°C is 22~26mm 2 / s, the addition amount is 38.44wt%, antiwear agent tricresyl phosphate 4wt%, antioxidant 2,6-di-tert-butyl p-cresol 0.5wt%, oily agent oleic acid amide 0.05wt%, corrosion inhibitor ( 2~mercaptobenzothiadiazole) 0.01wt%, antifoaming agent (simethicone) 10PPM, the viscosity of the refrigerating machine oil composition at 40°C is 10.2mm 2 / s.

Embodiment 2

[0027] The components and contents of the refrigerating machine oil composition described in Example 2 are as follows: an alkylnaphthalene mixture containing a C8-C9 substituted alkyl group is selected, wherein the viscosity of the alkylnaphthalene mixture at 40°C is 22-26 mm 2 / s, the addition amount is 99.5wt%, anti-wear agent triphenyl phosphate 0.25wt%, antioxidant 2,6-di-tert-butyl-p-cresol 0.1wt%, butyl-octyldiphenylamine 0.1wt%, Oily agent butyl stearate 0.05wt%, the viscosity of the refrigerating machine oil composition at 40°C is 21.5mm 2 / s.

Embodiment 3

[0028] The components and contents of the refrigerating machine oil composition described in Example 3 are as follows: an alkylnaphthalene mixture containing C10-C12 substituted alkyl is selected, wherein the viscosity of the alkylnaphthalene mixture at 40°C is 28-35mm 2 / s, the addition amount is 80wt%, anti-wear agent tricresyl phosphate 8wt%, triphenyl thiophosphate 2wt%, antioxidant 2,6-di-tert-butyl p-cresol 1.5wt%, oily agent methyl oleate 7.95wt% ester, 0.05wt% oleic acid amide, 0.05wt% corrosion inhibitor (2-mercaptobenzothiadiazole), 100PPM antifoaming agent (simethicone), and the viscosity of the refrigerating machine oil composition at 40°C is 33.4mm 2 / s.

[0029] Each refrigerating machine oil combination in the embodiment also added 0.01% corrosion inhibitor (2-mercaptobenzothiadiazole) and 10PPM antifoaming agent (simethicone).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com