A stator iron core structure of a hydrogenerator and a molding method thereof

A hydroelectric generator, stator core technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the difficulty and disadvantage of increasing the processing and assembly technology of hydroelectric generator stator core structure Problems such as long-term safe and stable operation of the hydroelectric generator set, broken teeth, etc., have achieved the effect of meeting the operating conditions and technical requirements, increasing the difficulty of processing technology, and increasing the difficulty of assembly technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

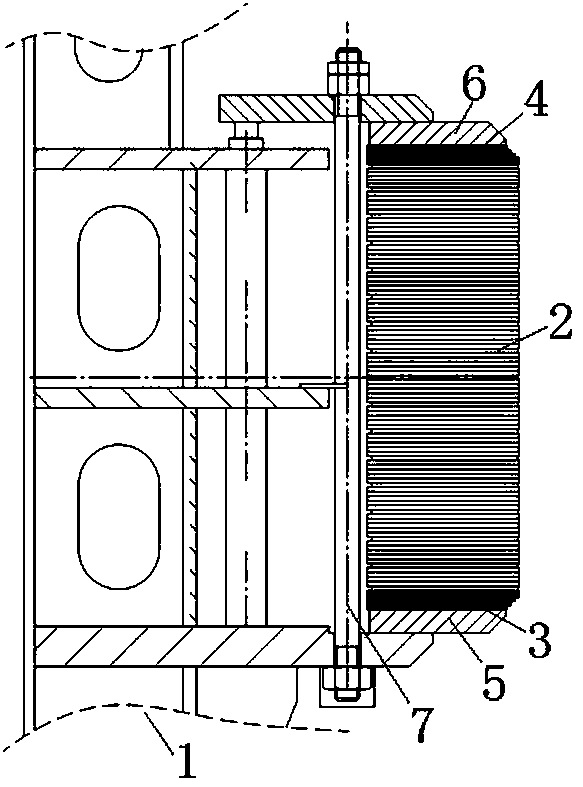

[0025] see figure 1 As shown, the stator core structure of the present invention includes several silicon steel sheets, each silicon steel sheet is a fan-shaped non-circular structure, and the thickness of each silicon steel sheet is about 0.5mm. These silicon steel sheets are divided into excitation end iron core assembly 4, middle iron core assembly 2, water machine end iron core assembly 3, excitation end iron core assembly 4 and water machine end iron according to the arrangement position on the stator frame 1. The core assembly 3 is located at both axial ends of the middle iron core assembly 2 .

[0026] Among them, the excitation end iron core assembly 4 assembled in the excitation end area of the stator frame 1 is composed of silicon steel sheets arranged in order according to the conventional design requirements, and arranged and bonded to form an overall ring structure. The thickness of the iron core assembly 4 at the excitation end is determined by bonding and com...

Embodiment 2

[0041] The stator core structure of the present invention includes several silicon steel sheets, each silicon steel sheet is fan-shaped and non-circular in structure, and the thickness of each silicon steel sheet is about 0.5 mm. These silicon steel sheets are divided into excitation end iron core assembly, middle iron core assembly and water machine end iron core assembly according to the arrangement position on the stator frame. The excitation end iron core assembly and water machine end iron core assembly are located in The axial ends of the middle iron core assembly.

[0042] Among them, the excitation end iron core assembly assembled in the excitation end area of the stator frame is composed of silicon steel sheets arranged in order according to the conventional design requirements, and arranged and bonded into an overall ring structure. The thickness of the iron core assembly at the excitation end is determined by bonding and combining about 150 layers of the above-men...

Embodiment 3

[0057]The stator core structure of the present invention includes several silicon steel sheets, each silicon steel sheet is a full circle structure, and the thickness of each silicon steel sheet is about 0.5 mm. These silicon steel sheets are divided into excitation end iron core assembly, middle iron core assembly and water machine end iron core assembly according to the arrangement position on the stator frame. The excitation end iron core assembly and water machine end iron core assembly are located in The axial ends of the middle iron core assembly.

[0058] Among them, the excitation core assembly assembled in the excitation end area of the stator frame is made of silicon steel sheets with a thickness of 0.5 mm arranged in accordance with the conventional design requirements, and the arrangement and bonding combination is an overall ring shape with a thickness of about 25 mm. structure. The thickness of the iron core assembly at the excitation end is determined by bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com