Device heating method

A heating method and marking device technology, applied in the direction of temperature control using electric methods, can solve the problems of unpredictable and controllable heating effects, inability to adjust the heating mechanism by itself, and rapid instantaneous temperature changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

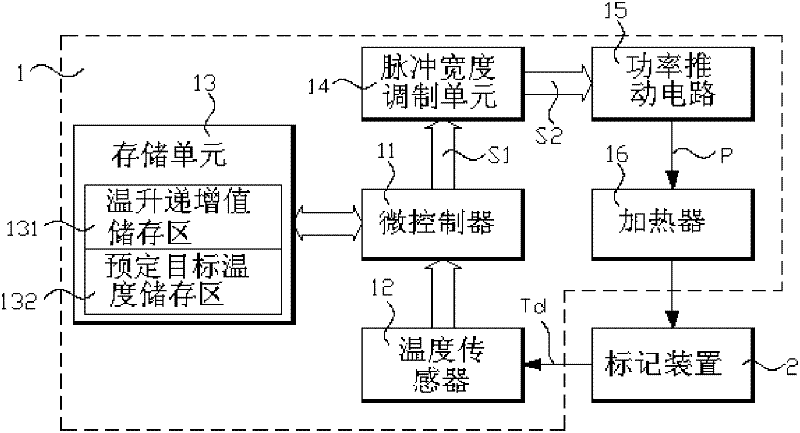

[0021] refer to image 3 As shown, it shows a circuit block diagram of a preferred embodiment of the present invention. As shown in the figure, the heating module 1 includes a microcontroller (microcontroller) 11, and the microcontroller 11 is respectively connected to a temperature sensor 12, a storage unit 13, and a pulse width modulation (Pulse Width Modulation, PWM) unit 14 and A power boost circuit 15 is connected to a heater 16 . One of the main applications of the heating module 1 and the marking device 2 of the present invention is a portable electronic device, such as a notebook computer. The microcontroller 11 can be an embedded controller equipped with a keyboard controller, and the marking device 2 can be a hard disk. In addition to the pulse width modulation unit 14 , a digital-to-analog circuit (digital-to-analog circuit) can also be used to drive the heater 16 .

[0022] The temperature sensor 12 is used to sense the device temperature Td of a marking device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com