Brewing method of olive fruit fermented wine

A technology for fermenting wine and olives, which is applied in microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc. The coexistence of aroma, the taste of glycol, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

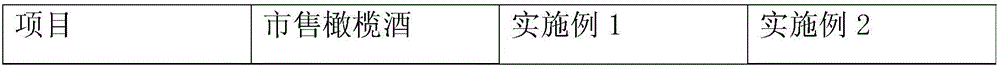

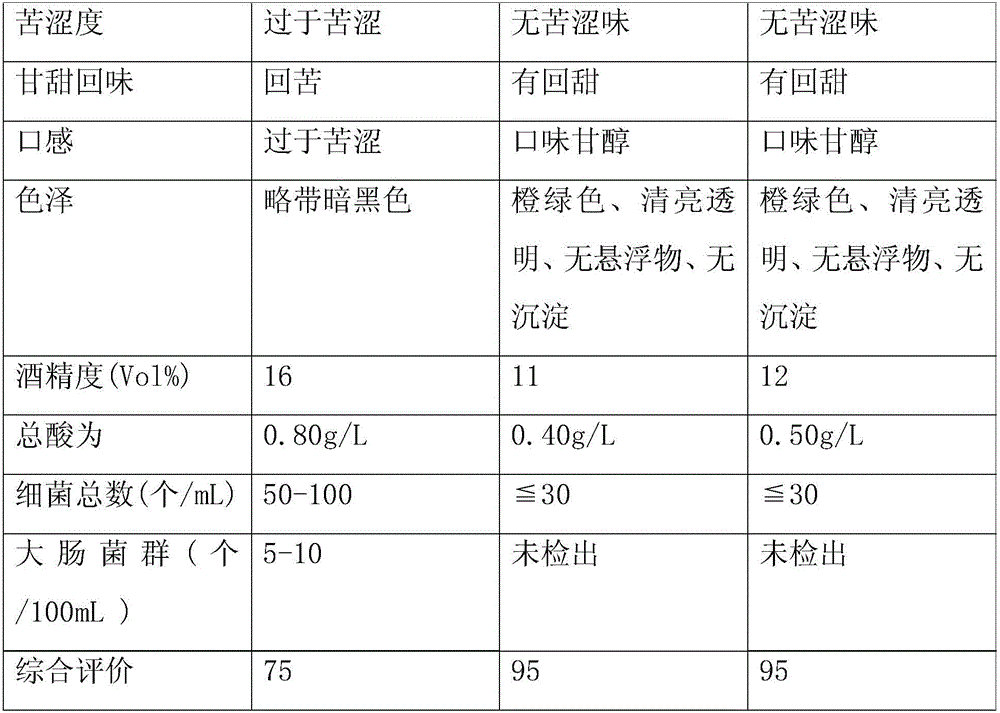

Examples

Embodiment 1

[0029] A brewing method of olive fruit fermented wine, comprising the steps of:

[0030] (1) Fresh olives are selected, cleaned, sterilized, broken, and the pulp is taken after depitting by a depitting machine;

[0031] (2) The pulp is crushed with food crushing equipment to obtain olive pulp, and the olive pulp is subjected to enzyme inactivation treatment under 680W microwave conditions for 5 minutes, and the sample load of each microwave treatment is 40g;

[0032] (3) Adding 0.10% tannase and 0.01% sucralose by mass fraction to the olive pulp obtained in step (2) for debittering treatment, the debittering process is maintained at 60°C for 10 minutes, and then cooled to room temperature, and add 0.3% citric acid to prevent the oxidation of the olive pulp according to the mass of the slurry, and add 0.0025% nisin to carry out antibacterial; the total weight of the tannase and sucralose accounts for 0.8wt% of the olive pulp;

[0033] (4) Move the olive slurry obtained in the ...

Embodiment 2

[0038] A brewing method of olive fruit fermented wine, comprising the steps of:

[0039] (1) Fresh olives are selected, cleaned, sterilized, broken, and the pulp is taken after depitting by a depitting machine;

[0040] (2) The pulp is crushed with food crushing equipment to obtain olive pulp, and the olive pulp is subjected to enzyme inactivation treatment under 800W microwave conditions for 3 minutes, and the sample load of each microwave treatment is 60g;

[0041] (3) Adding mass fraction 0.12% tannase and mass fraction 0.015% sucralose to the olive pulp obtained in step (2) for debittering treatment, the debittering process is maintained at 65°C for 15 minutes, then cooled to room temperature, and add 0.6% citric acid to prevent the oxidation of the olive pulp according to the mass of the slurry, and add 0.003% nisin to carry out antibacterial; the total weight of the tannase and sucralose accounts for 1.5wt% of the olive pulp;

[0042] (4) Move the olive slurry obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com