Colorless highly-transparent polyimide film as well as preparation method and application thereof

A technology of aromatic polyimide and aromatic polyimide resin, which is applied in the fields of colorless and highly transparent polyimide film and its preparation and application, and can solve the problem that the light transmittance is only 78%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

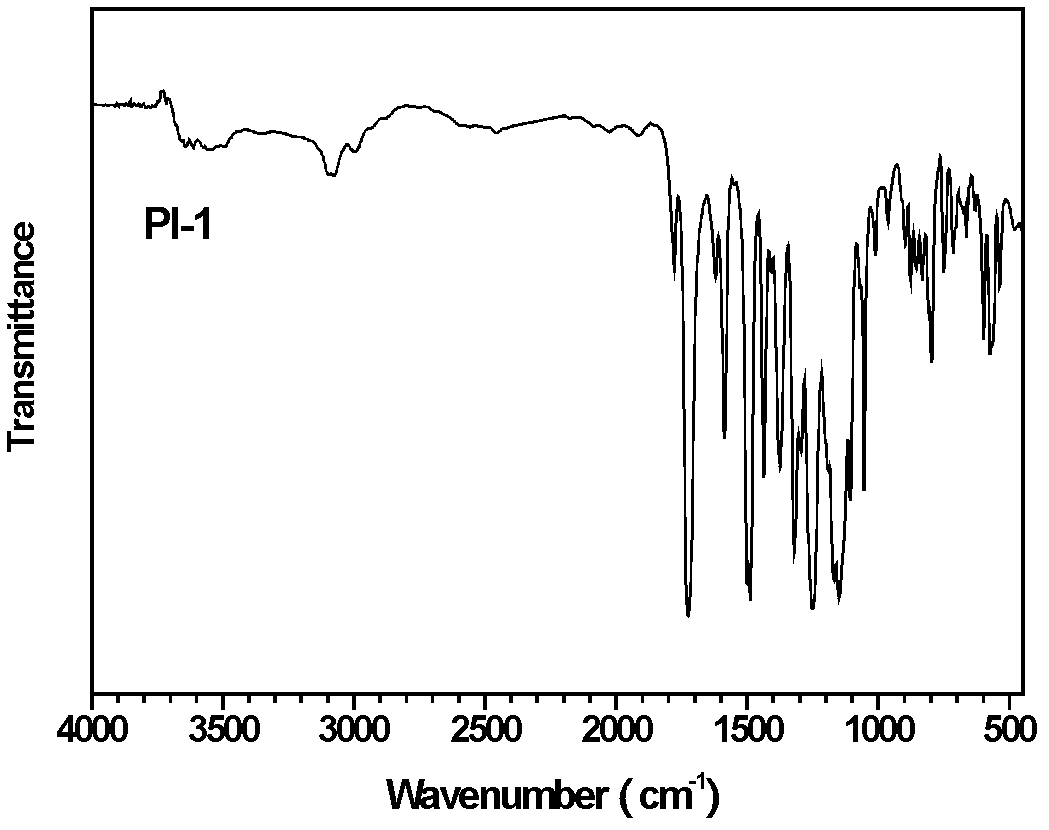

[0056] Embodiment 1, the preparation of homopolymer polyimide film

[0057] In a three-neck flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 56.85 grams (0.1 moles) of 4,4'-bis(3-trifluoromethyl-5-aminophenoxy)diphenylsulfone and 143 milliliters of N-methylpyrrolidone (NMP), stirred under nitrogen protection until completely dissolved, then added 22.42 grams (0.1 mole) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (CHDA), Stir until completely dissolved to obtain a homogeneous solution with a solid content of 35 wt.%. 0.65 g (0.005 mole) of isoquinoline and 24 ml of toluene were added to the above homogeneous solution, the temperature of the reaction system was raised to 180° C. and reacted for 24 hours, the toluene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into ethanol to obtain a fibrous crude product. Collect the precipitated crude product, wash it r...

Embodiment 2

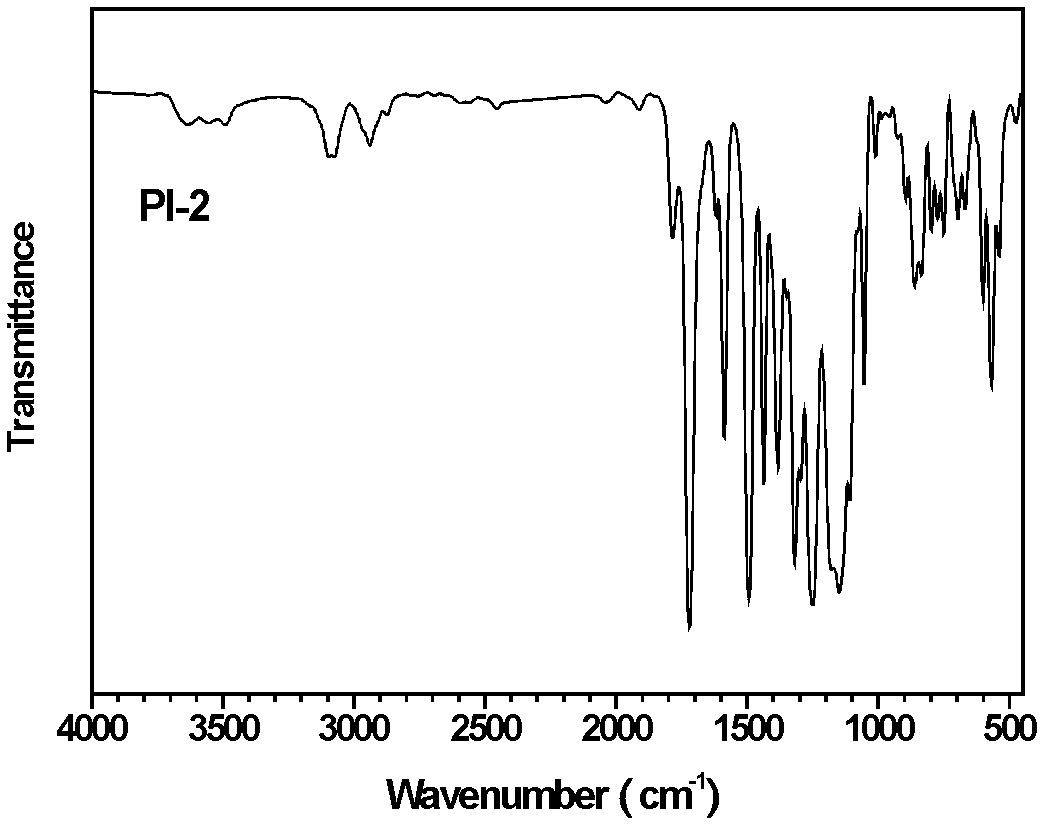

[0061] Embodiment 2, the preparation of homopolymeric polyimide film

[0062] In a three-neck flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 56.85 grams (0.1 moles) of 4,4'-bis(2-trifluoromethyl-4-aminophenoxy)diphenylsulfone and 173 milliliters of N-methylpyrrolidone (NMP), stirred under nitrogen protection until fully dissolved, added 19.61 grams (0.1 mole) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA), stirred Until it is completely dissolved, a homogeneous solution with a solid content of 30wt.% is obtained. 0.13 g (0.001 mole) of isoquinoline and 30 ml of toluene were added to the above homogeneous solution, the temperature of the reaction system was raised to 180° C. and reacted for 12 hours, the toluene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into ethanol to obtain a fibrous crude product. Collect the precipitated crude product, wash i...

Embodiment 3

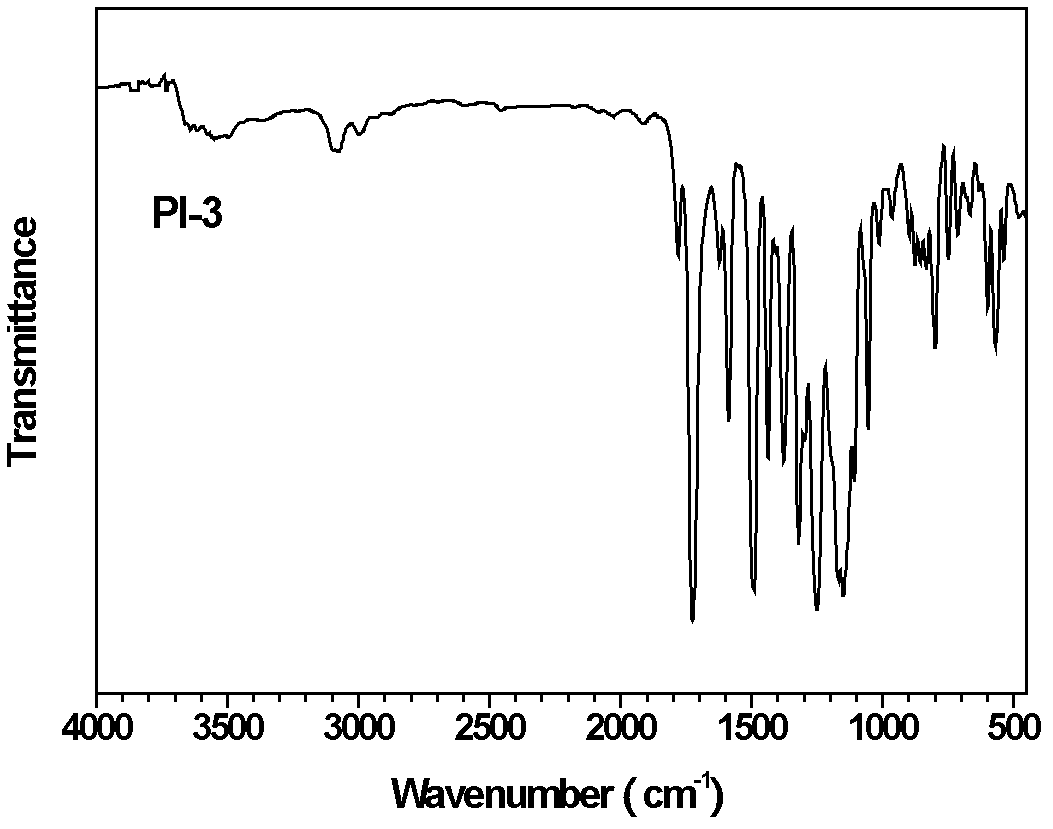

[0066] Embodiment 3, the preparation of homopolymer polyimide film

[0067] In a three-necked flask equipped with a mechanical stirrer, a water separator, a nitrogen inlet and outlet, and a thermometer, add 40.35 grams (0.105 moles) of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenylsulfone and In 228 milliliters of γ-butyrolactone, after stirring under nitrogen protection until completely dissolved, add 23.62 grams (0.1 moles) of bicyclo[2.2.1]heptane-2,3,5,6-tetracarboxylic dianhydride (BHDA) , and stirred until completely dissolved to obtain a homogeneous solution with a solid content of 20wt.%. 1.29 g (0.01 mole) of quinoline and 55 ml of toluene were added to the above homogeneous solution, the reaction system was heated to 180° C. and reacted for 12 hours, the toluene was distilled off, and the heating was stopped. Cool the reaction solution to 80-120°C and pour it into a propanol / water mixed solution (propanol / water volume ratio = 1:2) to obtain a fibrous crude product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com