Patents

Literature

108 results about "Pleasant Feeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for driving and killing mosquitoes and preparation method thereof

The invention relates to a composition for driving and killing mosquitoes. The composition is characterized by comprising the following substances by portions: 20 to 50 portions of natural essential oil, 10 to 35 portions of pyrethroid, 25 to 50 portions of solvent oil, 3 to 20 portions of surface active agent and 5 to 15 portions of antioxidant. The composition has the advantages of: (1) having no toxic side effect to body, having multiple action of driving mosquitoes, sterilizing and essence, being capable of reducing the cost of the product and bringing pleasant feeling to a user; (2) having different effective components with different action mechanism for target insects and also being capable of effectively retarding the drug resistance thereof; (3) having higher safety than chemosynthetic insecticide due to easy decomposition and low residue of the natural essential oil in natural environment; (4) having obvious control effect to mosquitoes, flies and cockroaches and being capable of effectively reducing the using amount of pyrethroid due to adding of the natural essential oil; and (5) having a certain action of restraining and killing various harmful bacterium such as golden staphylococcus aureus, shigella shigae and Pseudomonas aeruginosa due to adding of natural vegetable garlic oil.

Owner:江西山峰日化有限公司

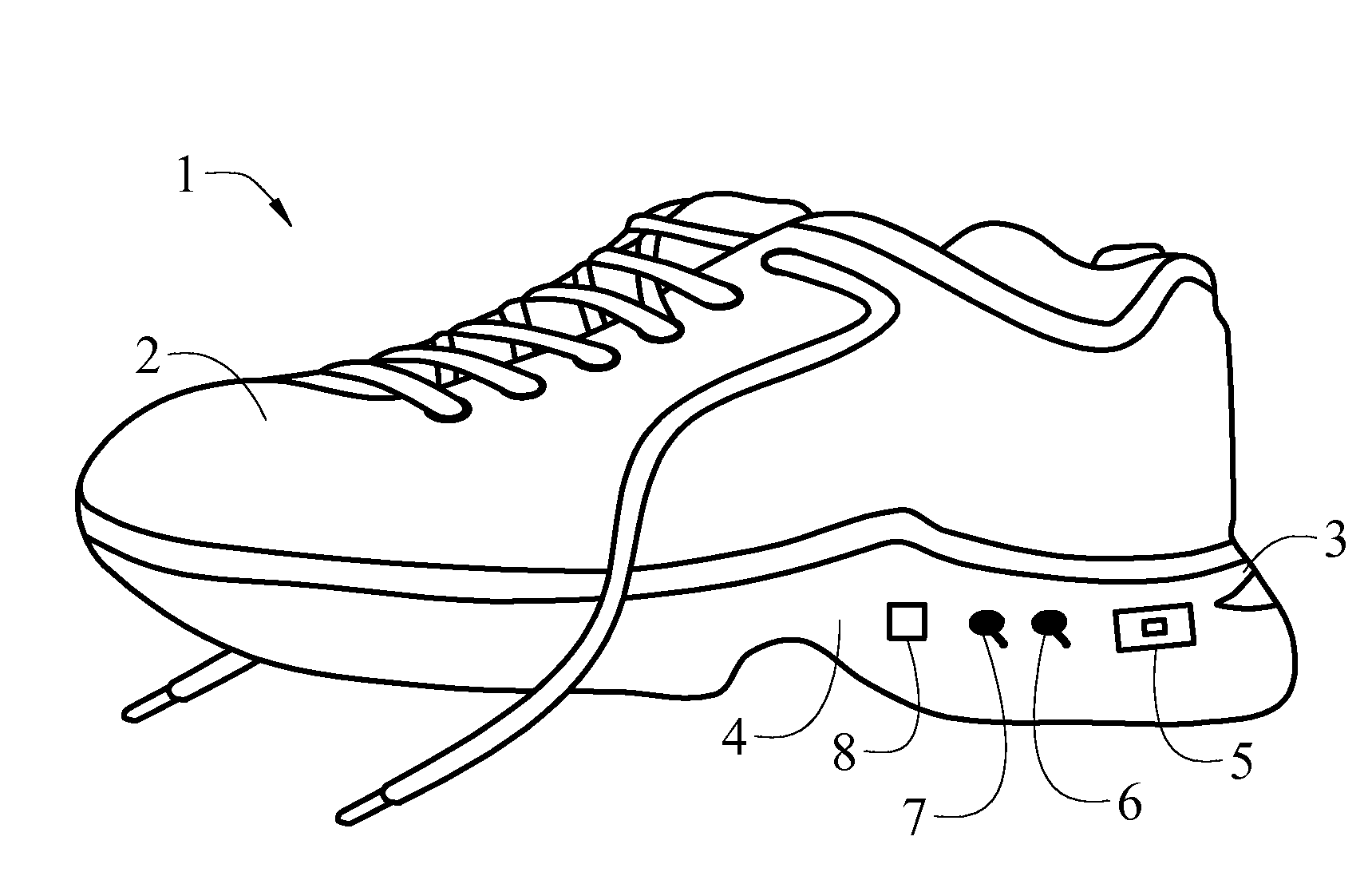

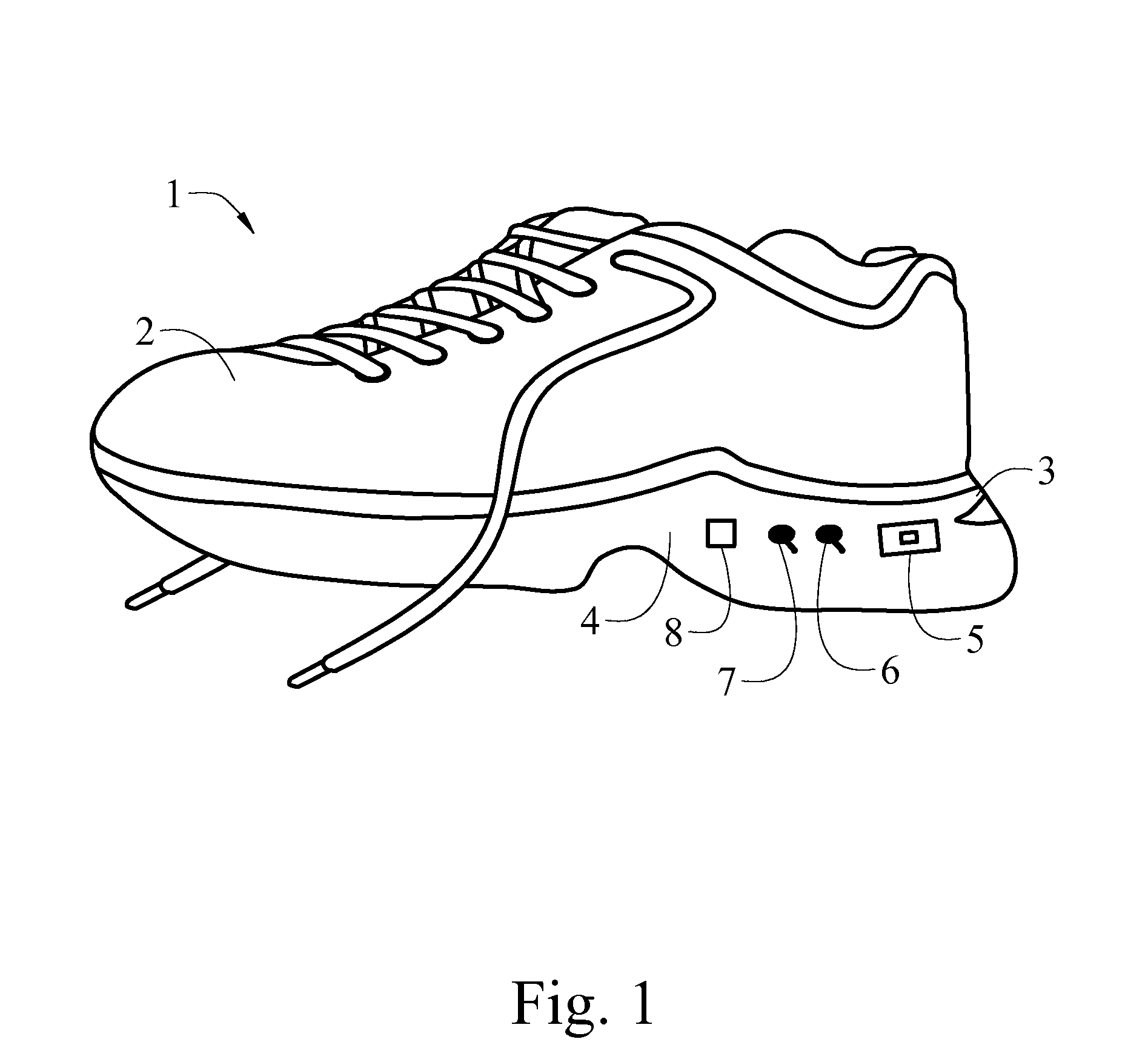

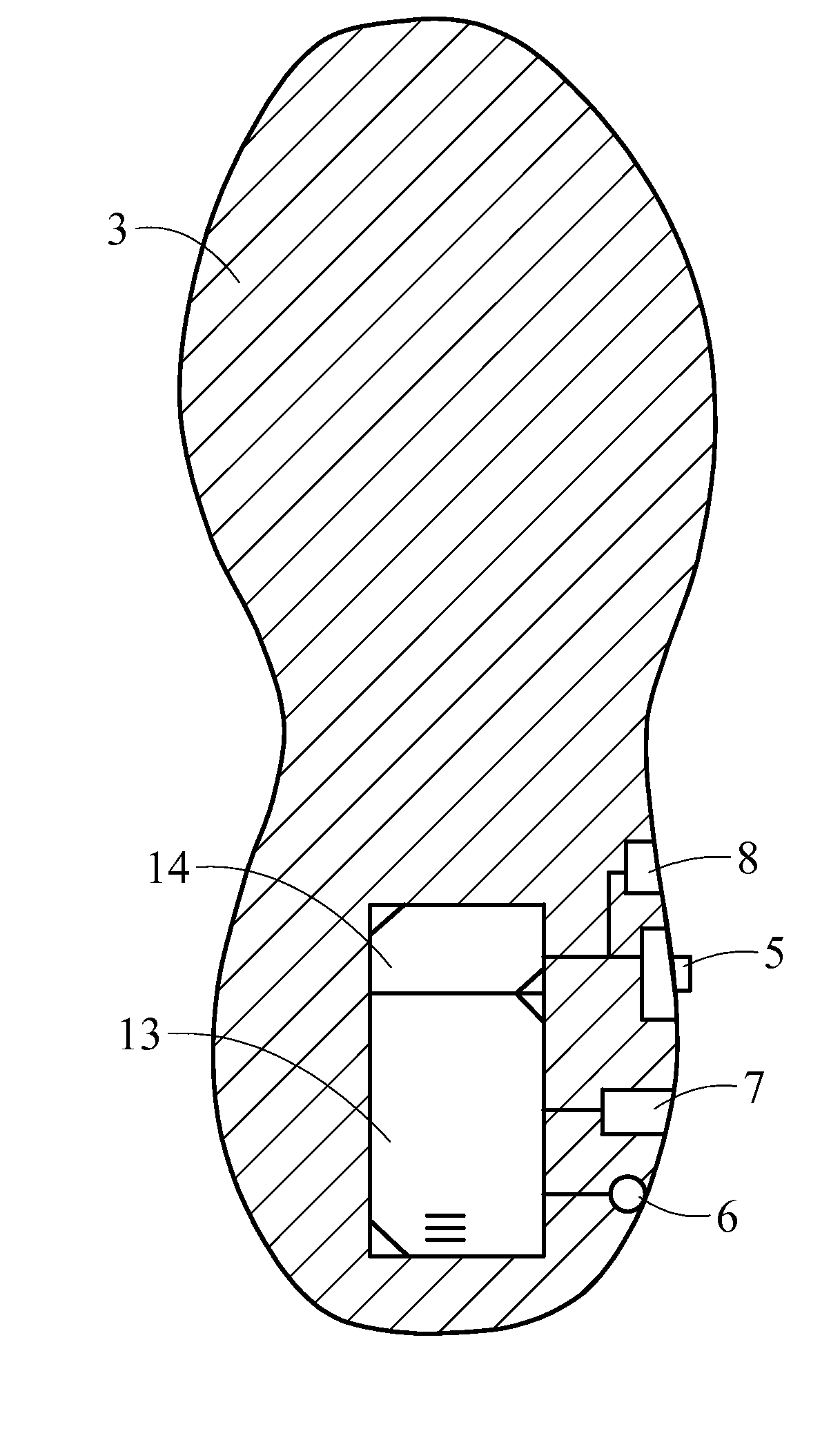

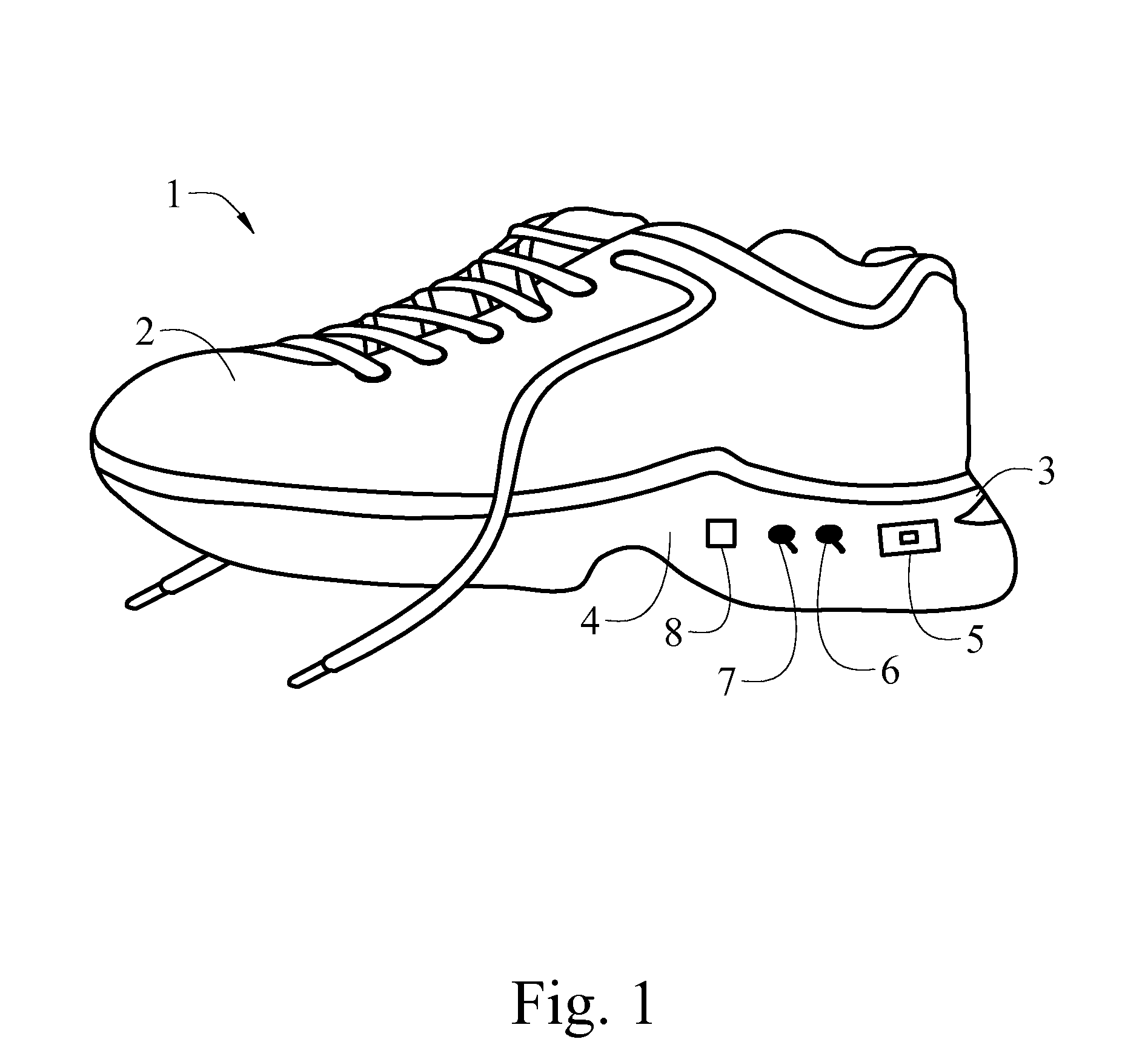

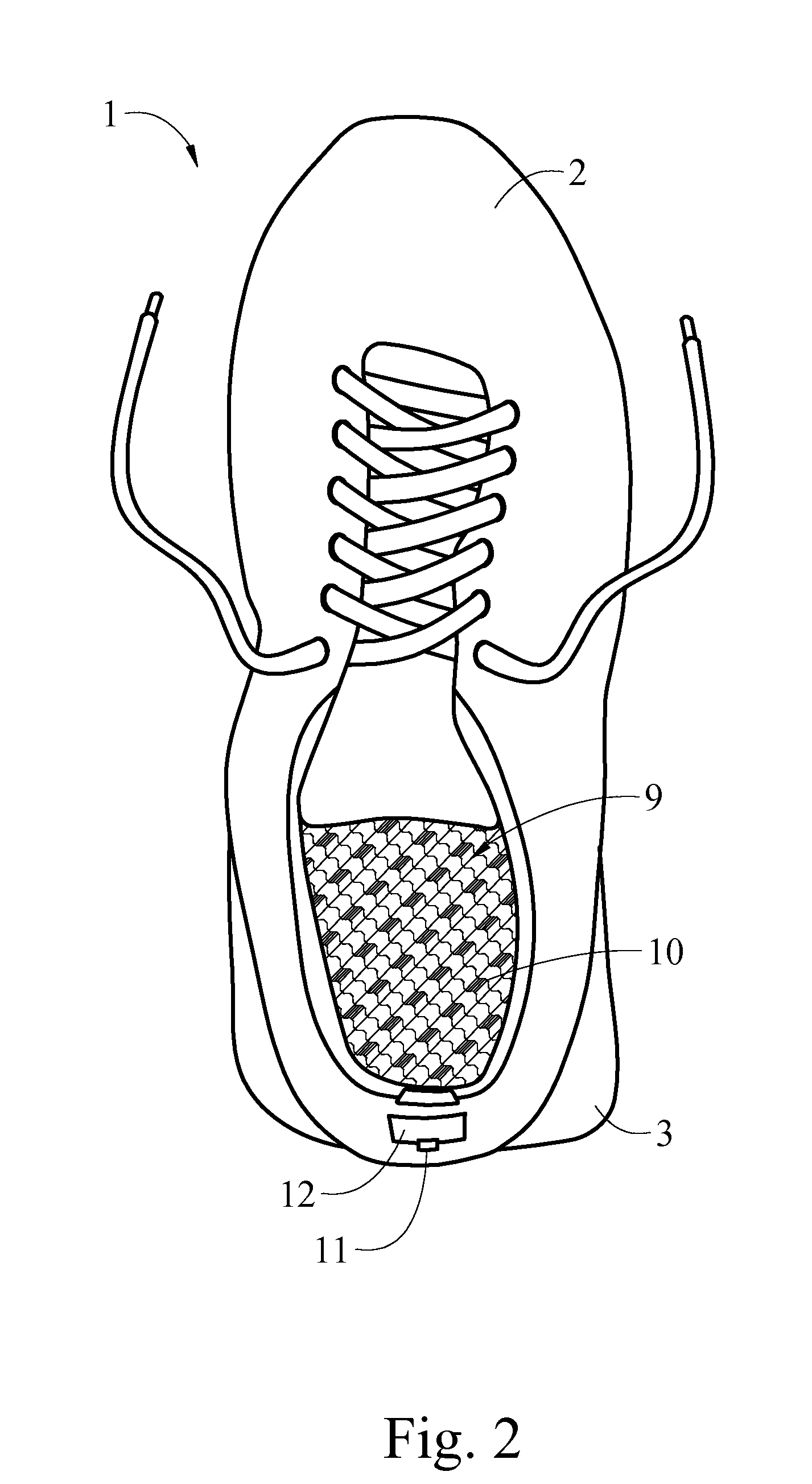

Vibratory shoe for feet

InactiveUS20080161734A1Avoid pollutionPleasant feelChiropractic devicesVibration massageAcupressurePleasant Feeling

A shoe incorporates reflexology and acupressure as applied to a foot when wearing the shoe. The shoe has a sole with a battery powered vibration unit that mechanically vibrates a spiked gel insole located near the underside of a foot. The rounded spikes of the insole stimulate the acupressure points of the foot for its relaxation and pleasant feelings in a person. The sole of the shoe has a port for battery charging, a switch to control the vibration, and a charge indicator light at the sole's edge. The sole has a latch to remove the battery from a compartment in the heel area. The vibrating shoe operates while bearing the weight of a person or not. A transmitter remotely activates the vibration unit as a person is standing.

Owner:BLOCKTON DEBORAH

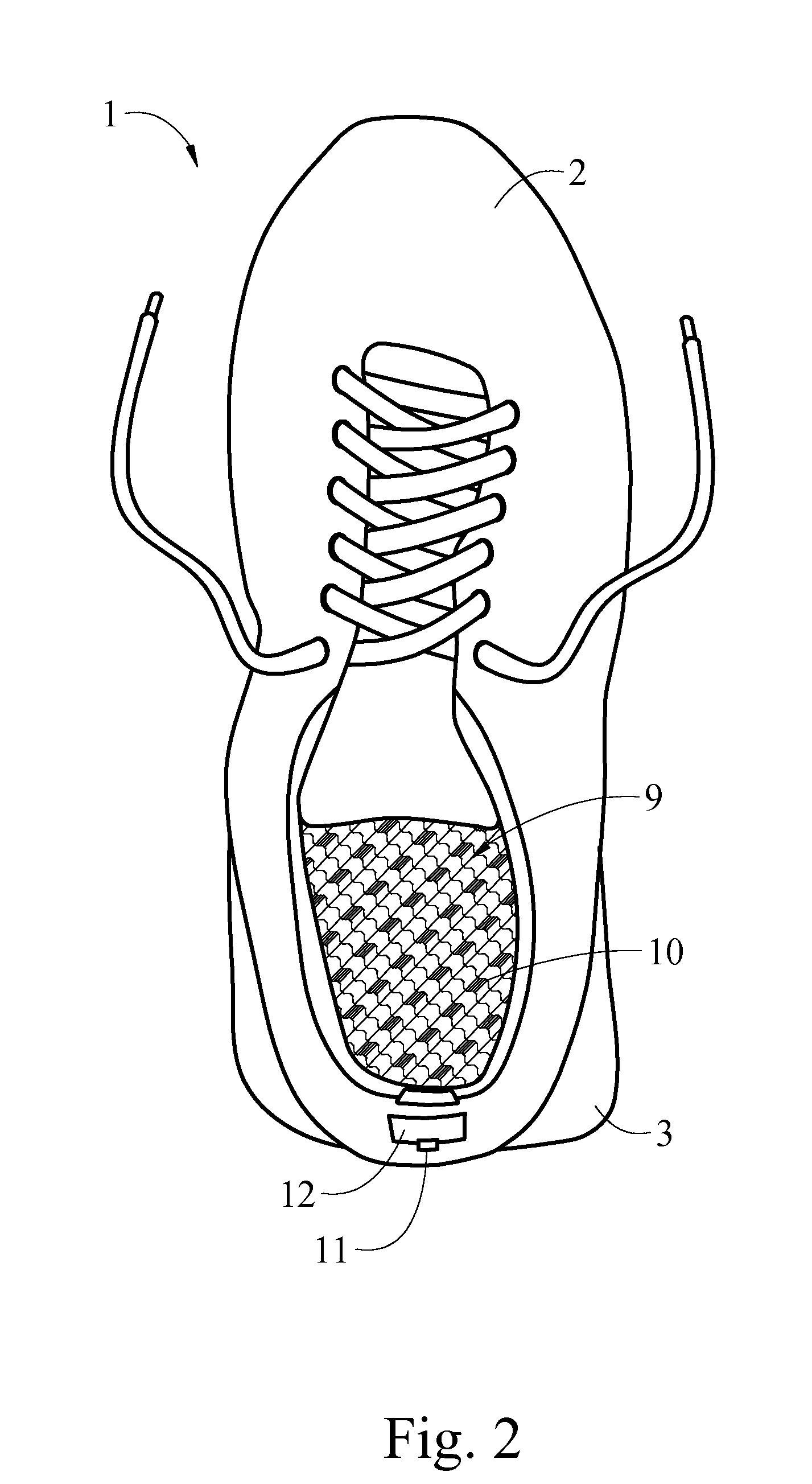

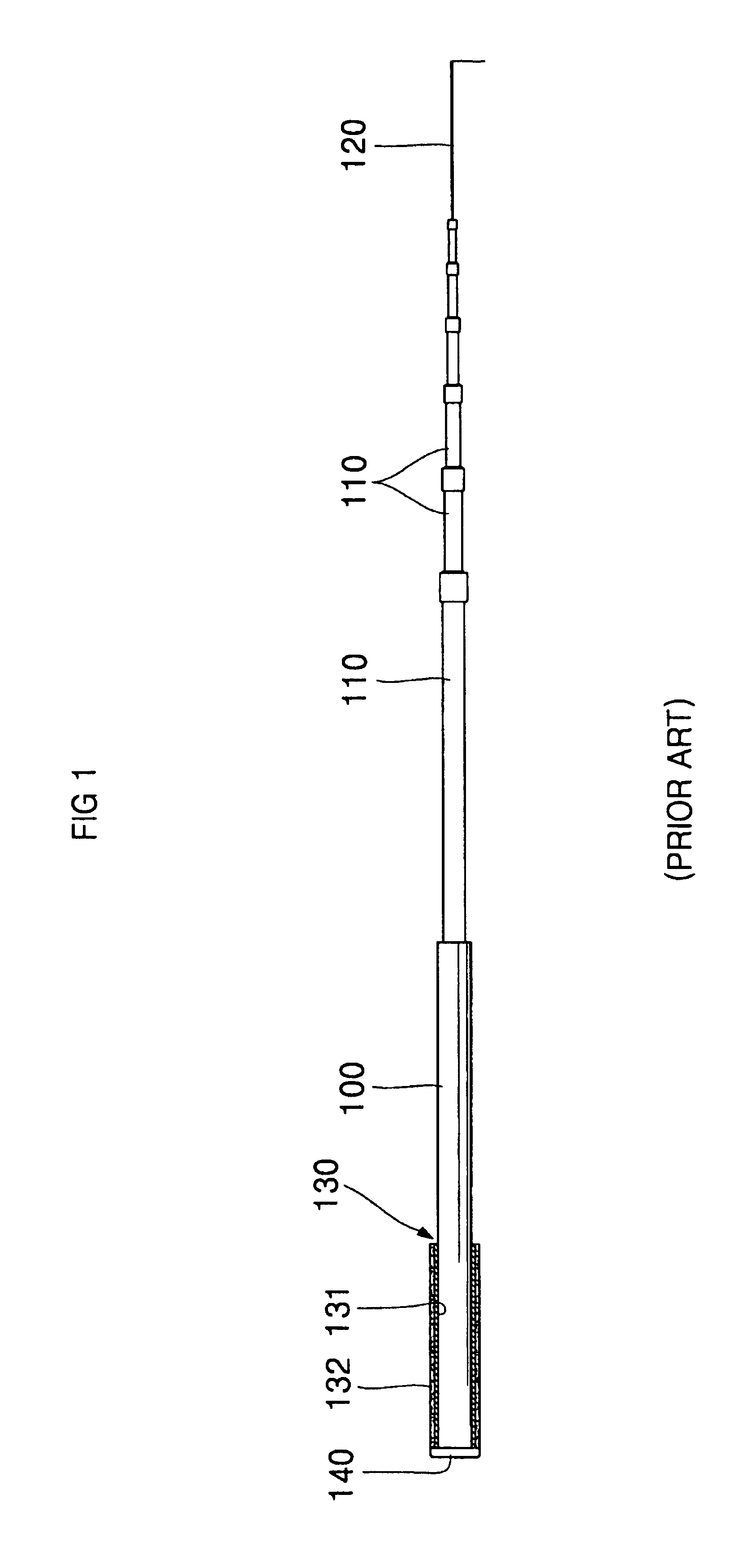

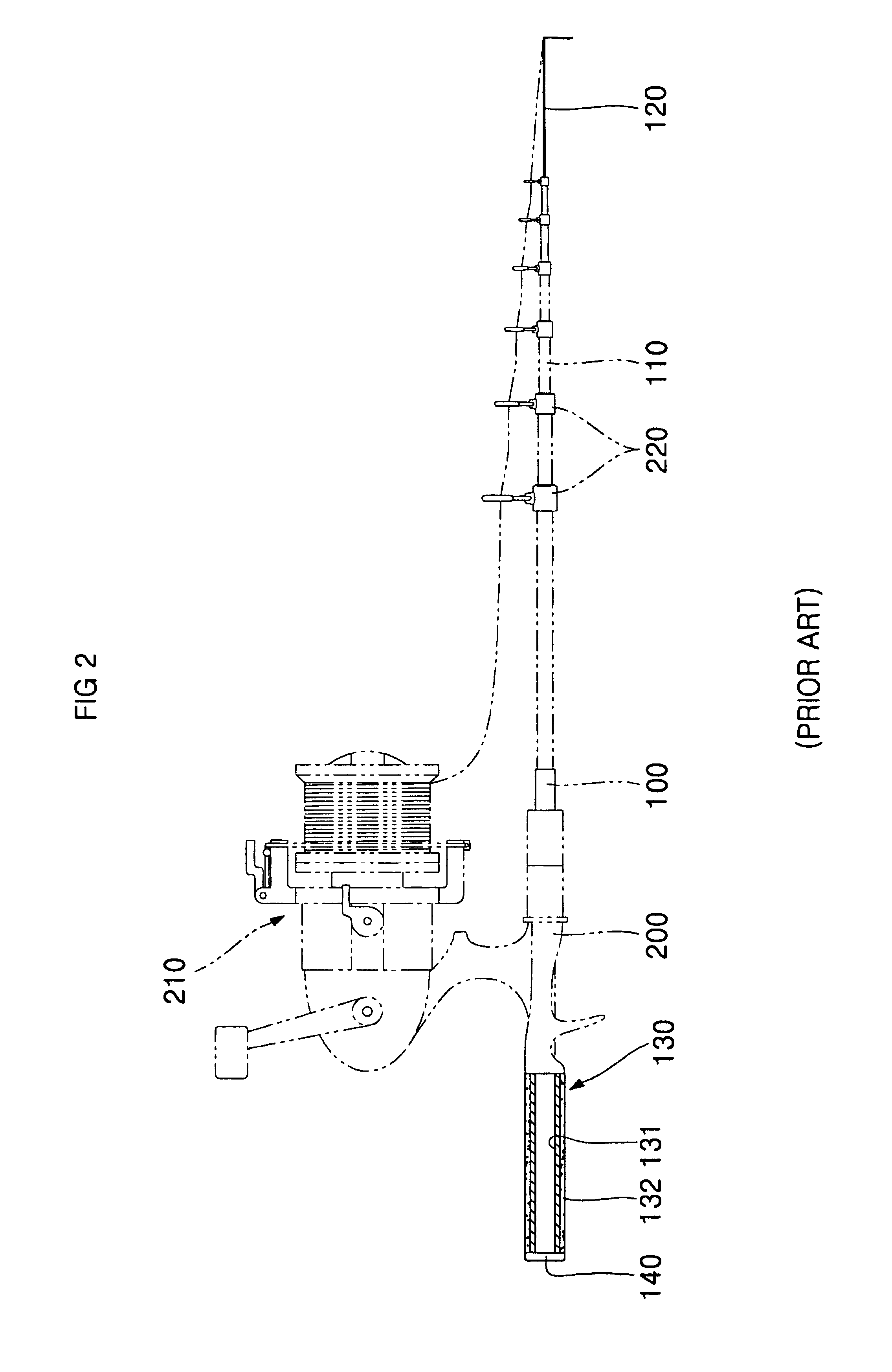

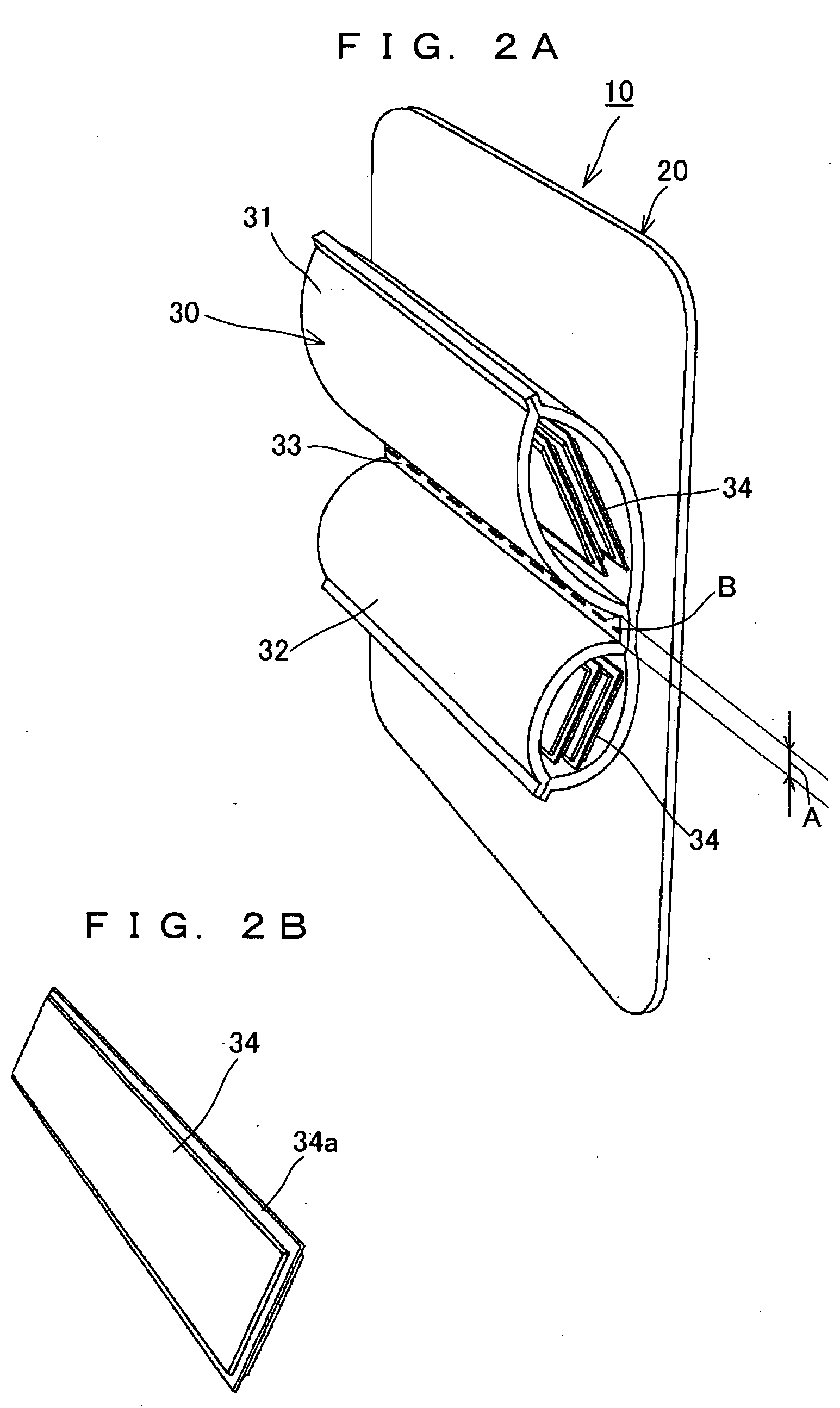

Fishing rod and butt grip for such rods

InactiveUS6973750B1Thrilling and agreeable feelingDoubling a user's interest in fishingRodsPleasant FeelingEngineering

The fishing rod of this invention includes a hollow cylindrical butt pipe, and a plurality of hollow cylindrical sections sequentially jointed together to form a telescopically retractable structure jointed to the butt pipe such that the sections are sequentially retracted into the butt pipe. A tip rod is mounted to the end of the outermost one of the sections remote from the butt pipe. A butt grip is fitted over the butt pipe, and consists of a hollow cylindrical tube opened at both ends thereof. A plurality of radial support ribs are formed on the inner surface of the tube while being directed in radial directions and spaced apart from each other at regular intervals. When the butt grip is fitted over the butt pipe, the external surface of the butt pipe is brought into close contact with the inside edges of the radial support ribs. The butt grip directly transmits vital vibrations of a fish taking a bait or caught by the hook to the hand of a user holding it, thus allowing the user to have a thrilling and agreeable feeling while fishing, and doubling a user's interest in fishing.

Owner:KIM MYUNG KWON

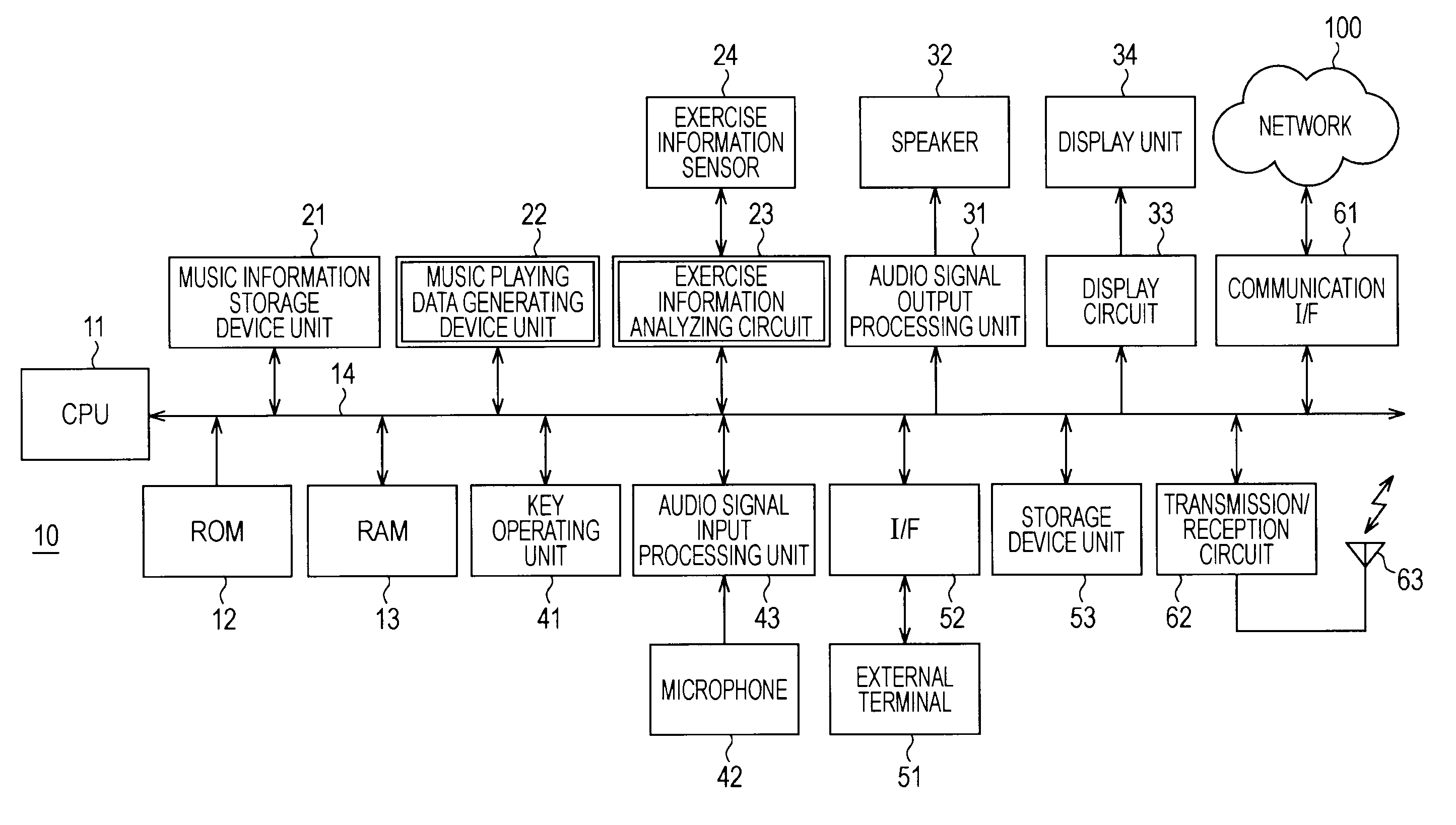

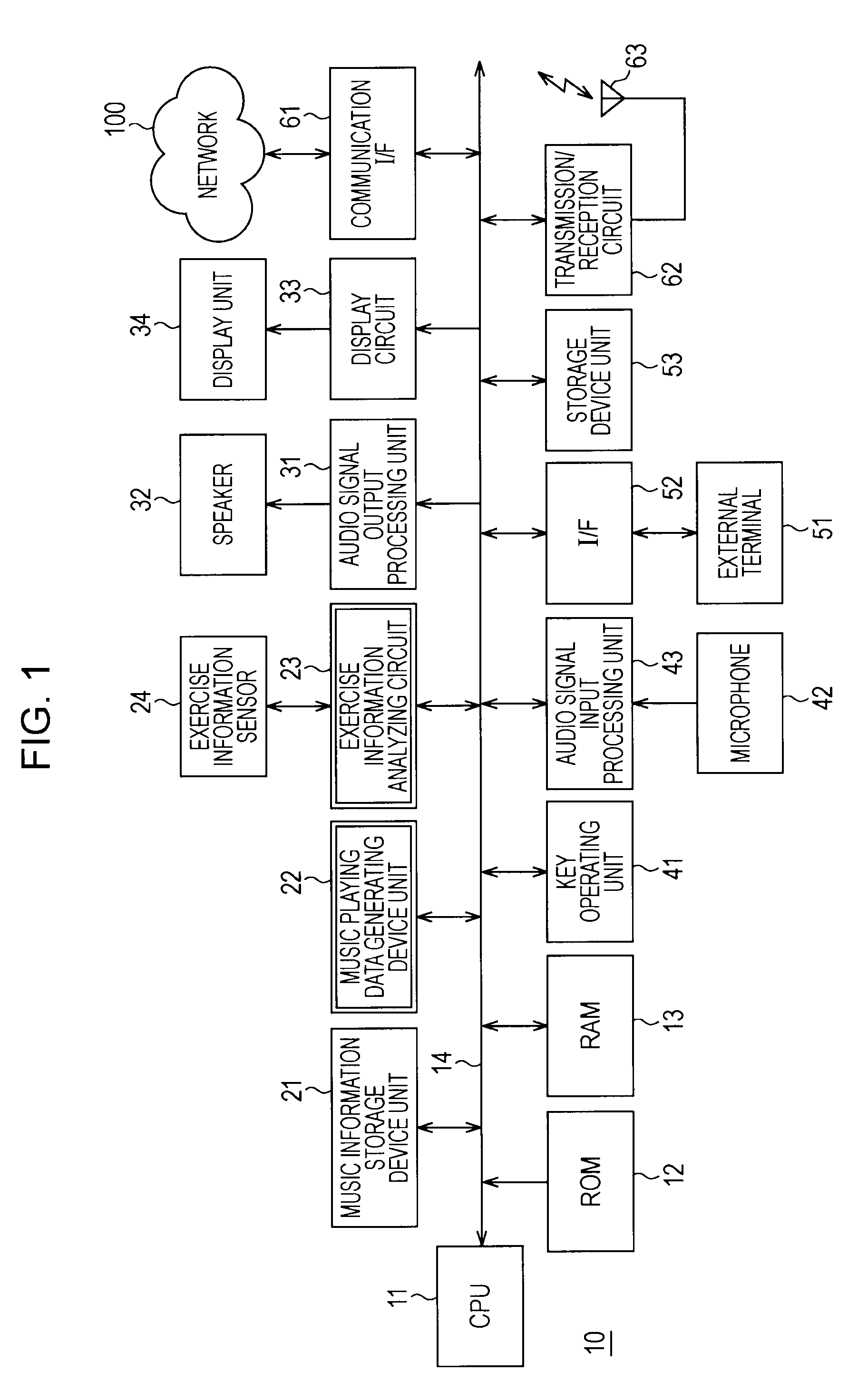

Audio reproducing device, audio reproducing method, and audio reproducing program

ActiveUS20090205482A1ContinuationProvide motivationElectrophonic musical instrumentsRecord information storageUnpleasant sensationPleasant Feeling

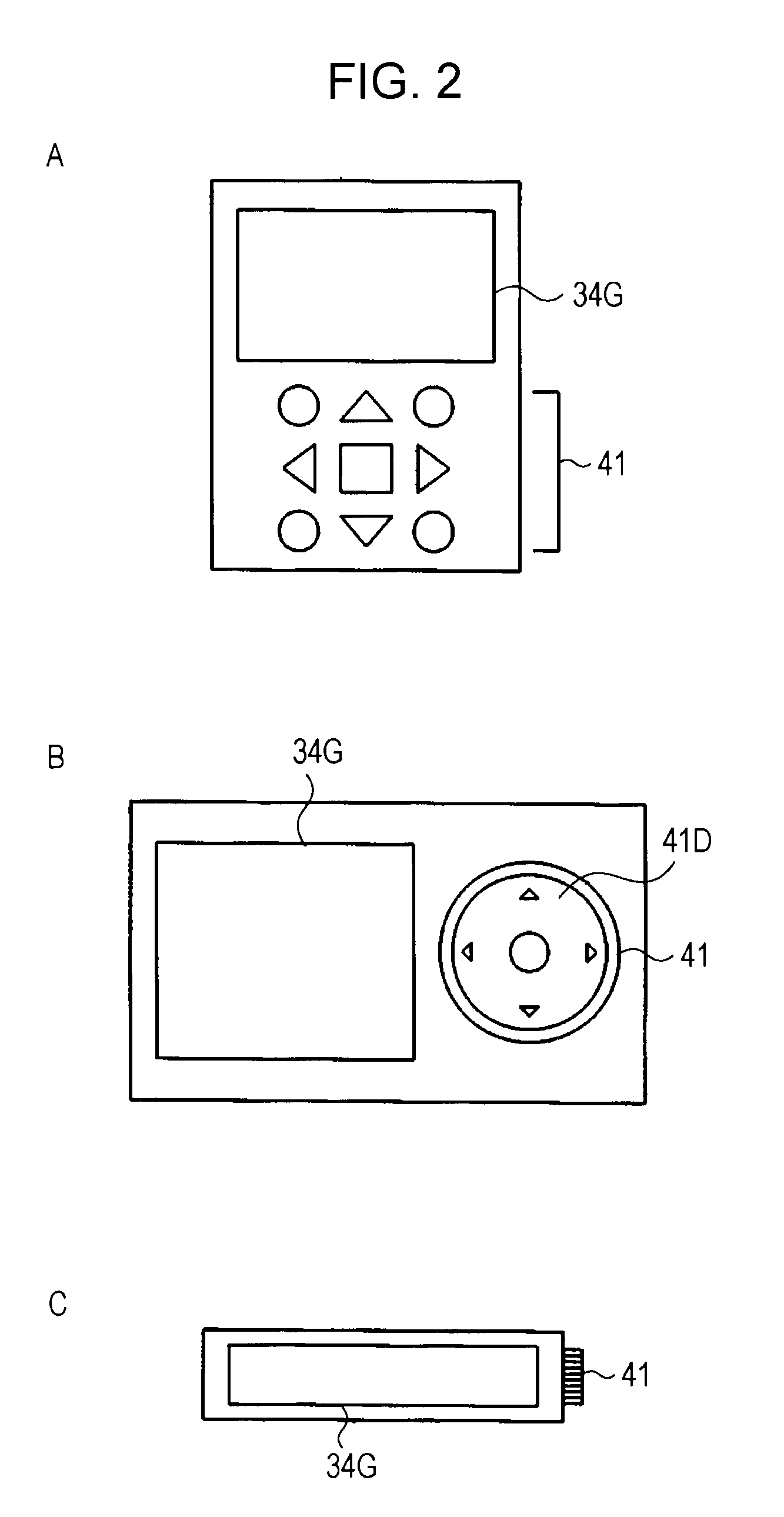

Provided is a device for playing audio with improved convenience, wherein music can be played such that oneness with the actions of the user can be obtained at all times, without giving the user any unnaturalness whatsoever such as unpleasant sensations. After starting playing of music data through such as an audio signal output processing unit 31, action tempo of the user is detected by an exercise information analyzing circuit 23, based on detection output from an exercise information sensor 24, and in the event that the difference between the detected action tempo of the user and the tempo of the music data being played is not a predetermined range, music data with a tempo of which the difference as to the action tempo of the user is within the predetermined range is searched by searching means such as a music playing data generating device unit 22, and a control unit 10 changes the music data to be played so as to play this searched music data.

Owner:SONY CORP

Blood pressure monitor and pulse wave detection apparatus

InactiveUS6432060B1Measurement of the blood pressure more accuratelyAccurate measurementEvaluation of blood vesselsCatheterBlood Pressure DeterminationsMedicine

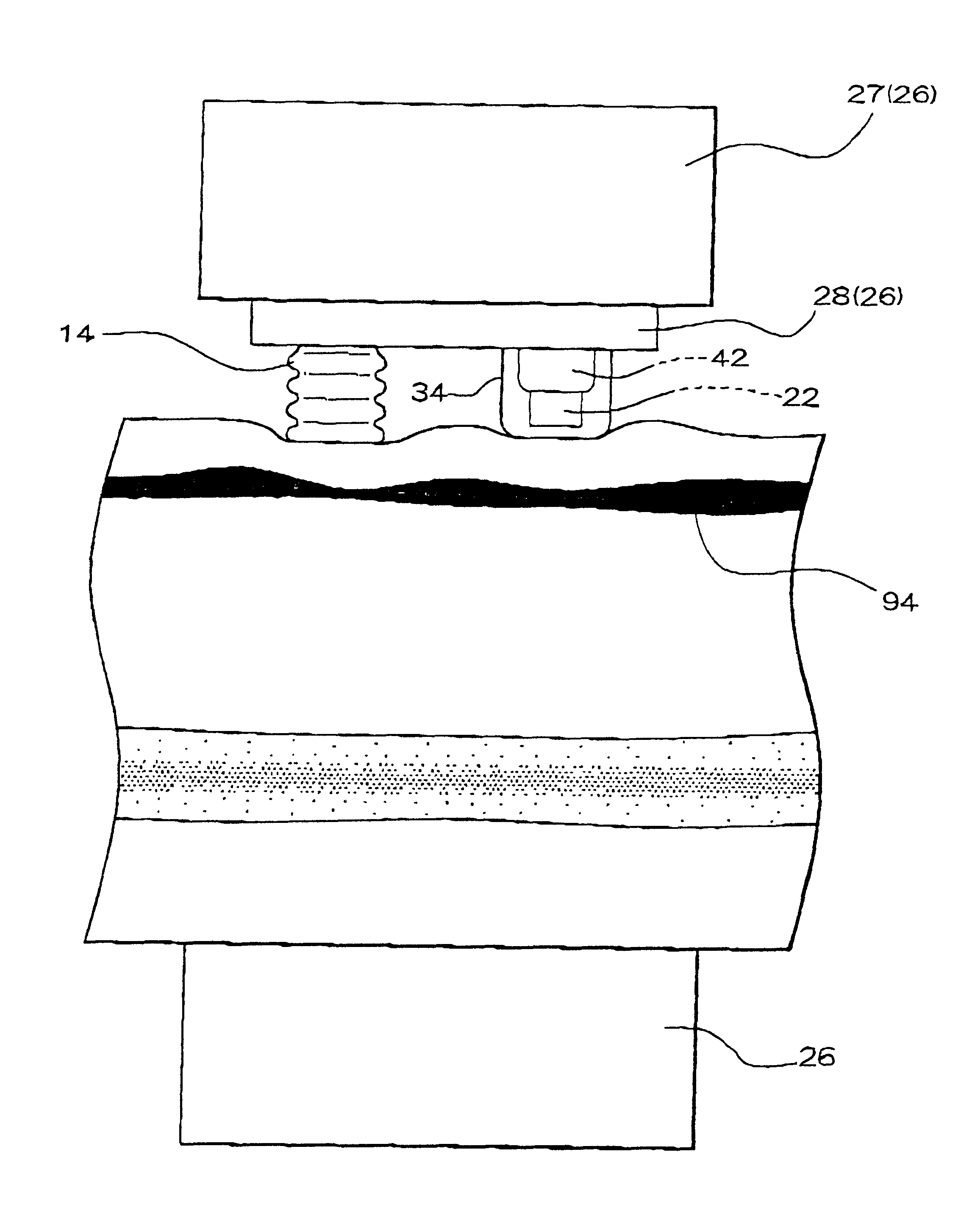

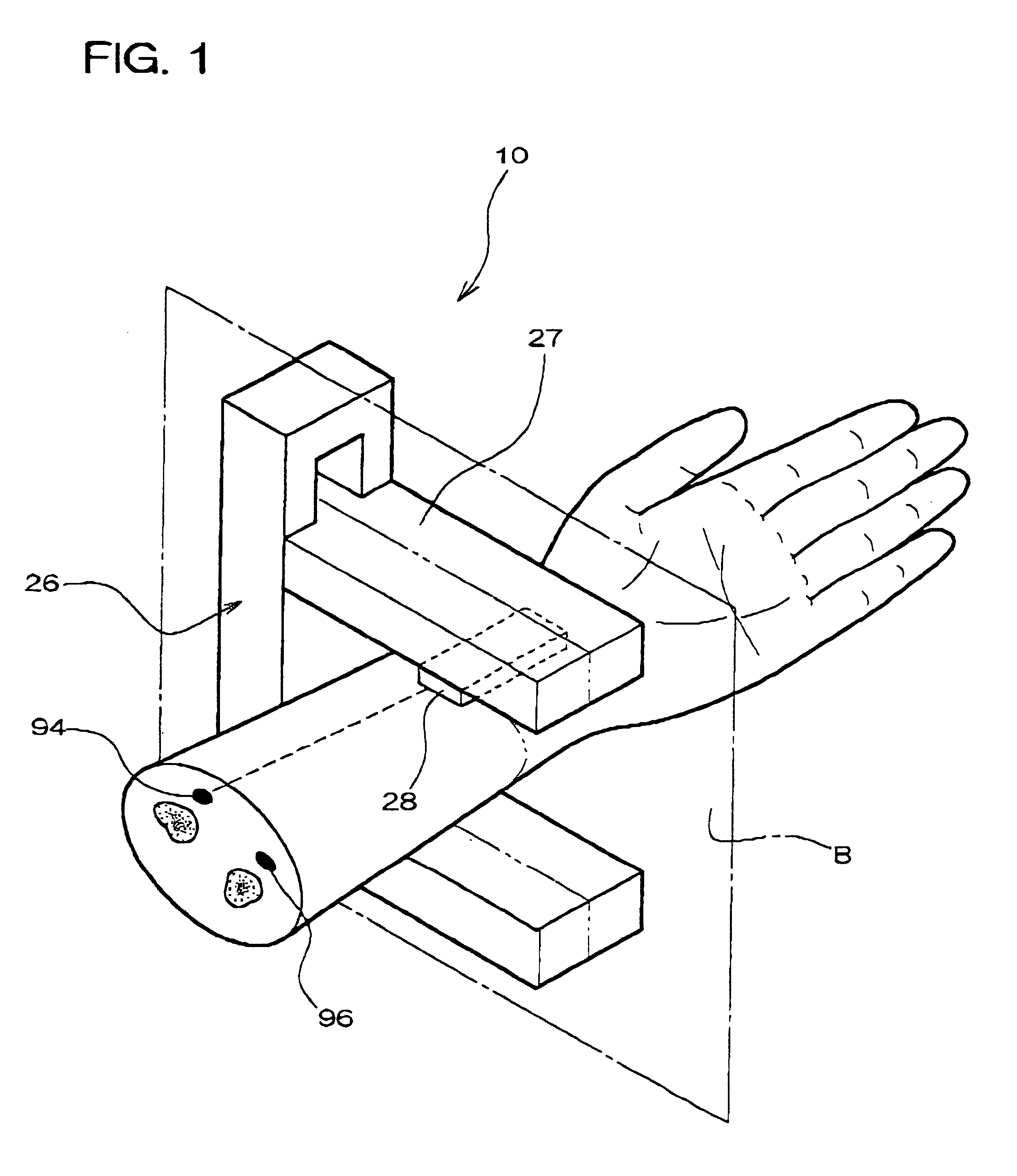

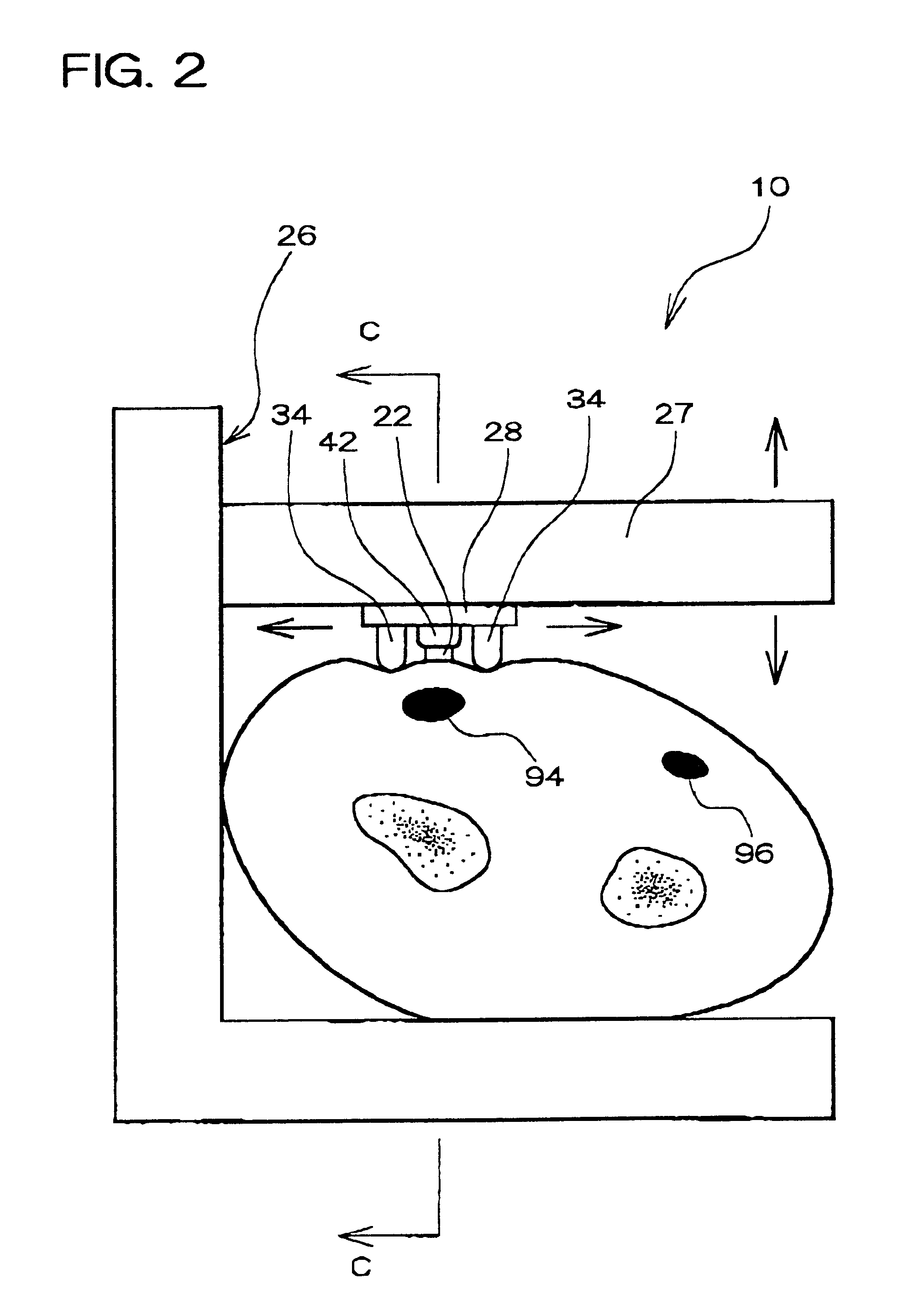

The blood pressure monitor (10) comprises an artery pressing section which locally presses an artery of the extremities or fingers at an arbitrarily variable pressing force, a vibration sensor (22) detecting a vibration of the artery at the pressed point or points on a peripheral side thereof, a mounting mechanism (26) which positions the artery pressing section and the vibration sensor (22) on the artery, a blood pressure determination section which determines the maximum and minimum pressures based on various pressing force values applied by the above-mentioned artery pressing section and signals detected by the vibration sensor (22) at these various pressing force values, guides (34) which are provided on each side of the vibration sensor (22) and guide the vibration sensor (22) to the artery by being located on the both sides of the artery, and a peripheral side pressing section which presses the artery on the peripheral side from the vibration sensor (22).The blood pressure monitor (10) does not impart an unpleasant or disagreeable feeling to the subject.

Owner:SEIKO EPSON CORP

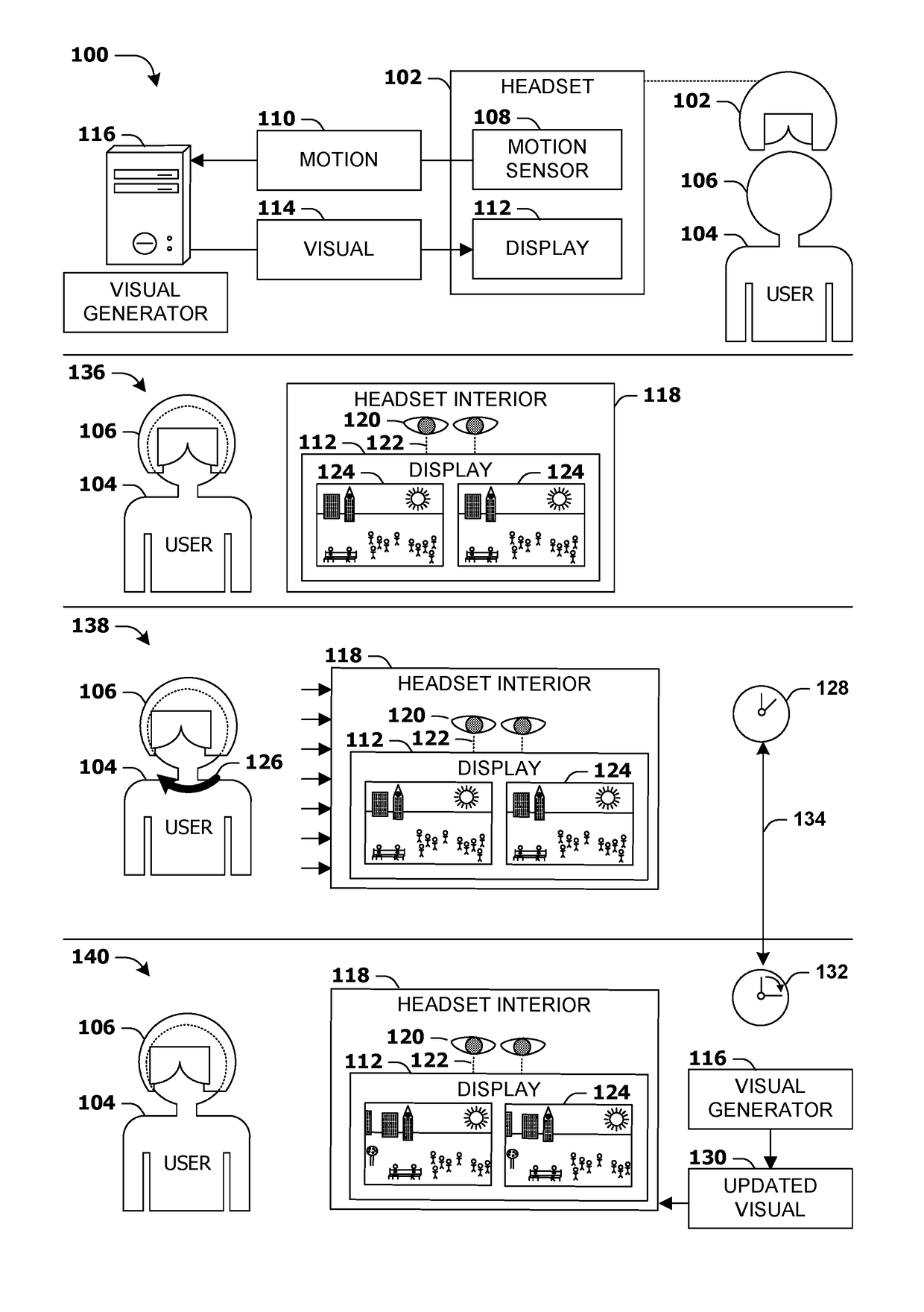

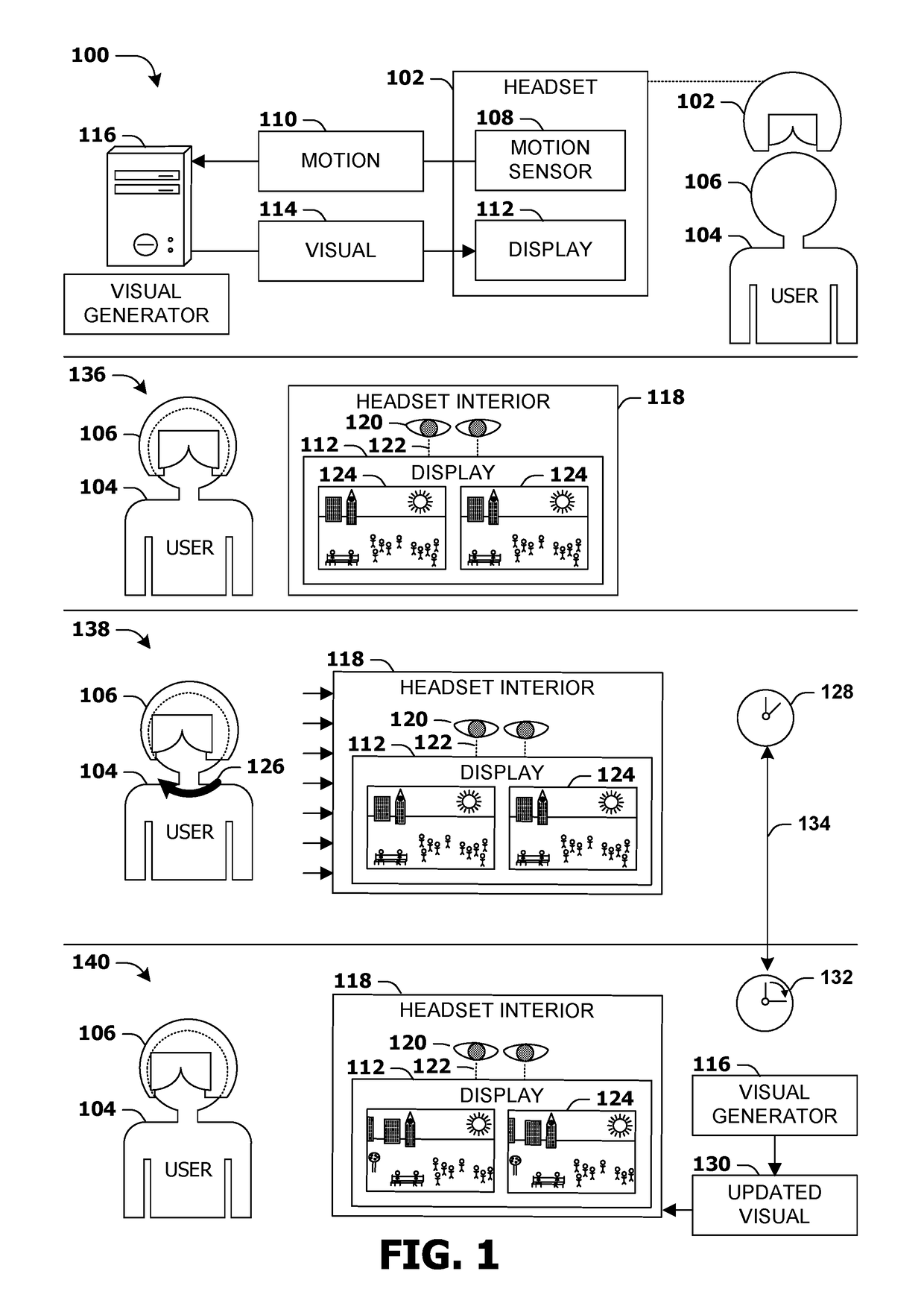

Headset visual displacement for motion correction

ActiveUS20180075653A1Accurate translationReduce and even eliminate sourceInput/output for user-computer interactionElectrophonic musical instrumentsDisplay devicePleasant Feeling

Many headset devices, such as virtual reality helmets, present visuals that respond to the user's motion, such that a rotation of the user's head causes the visual to be re-rendered from a correspondingly rotated perspective. The lag between the user's motion and the updated rendering from the new perspective may be perceivable even at high framerates, and may induce unpleasant feelings such as vertigo. Instead, headset devices may respond to detected motion by identifying a displacement of the physical location of the visual that causes it to maintain a physical position relative to a stationary reference point. The display is operatively coupled with a displacer, such as actuators or a projection adjustment, that are engaged to displace the display according to the identified displacement and maintain a physical location of the visual relative to the stationary reference point (e.g., until the visual is re-rendered from the updated perspective).

Owner:VERIZON PATENT & LICENSING INC

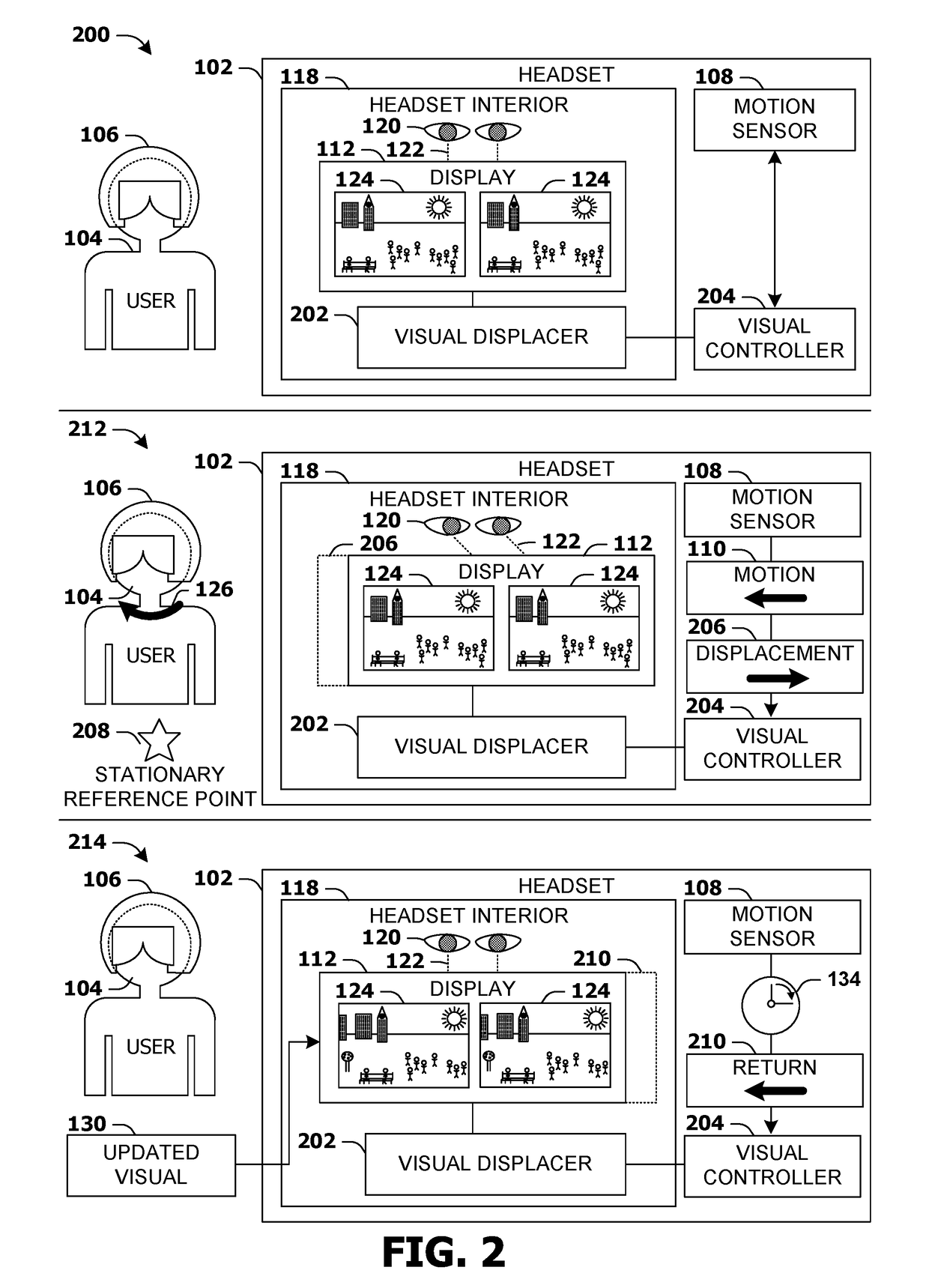

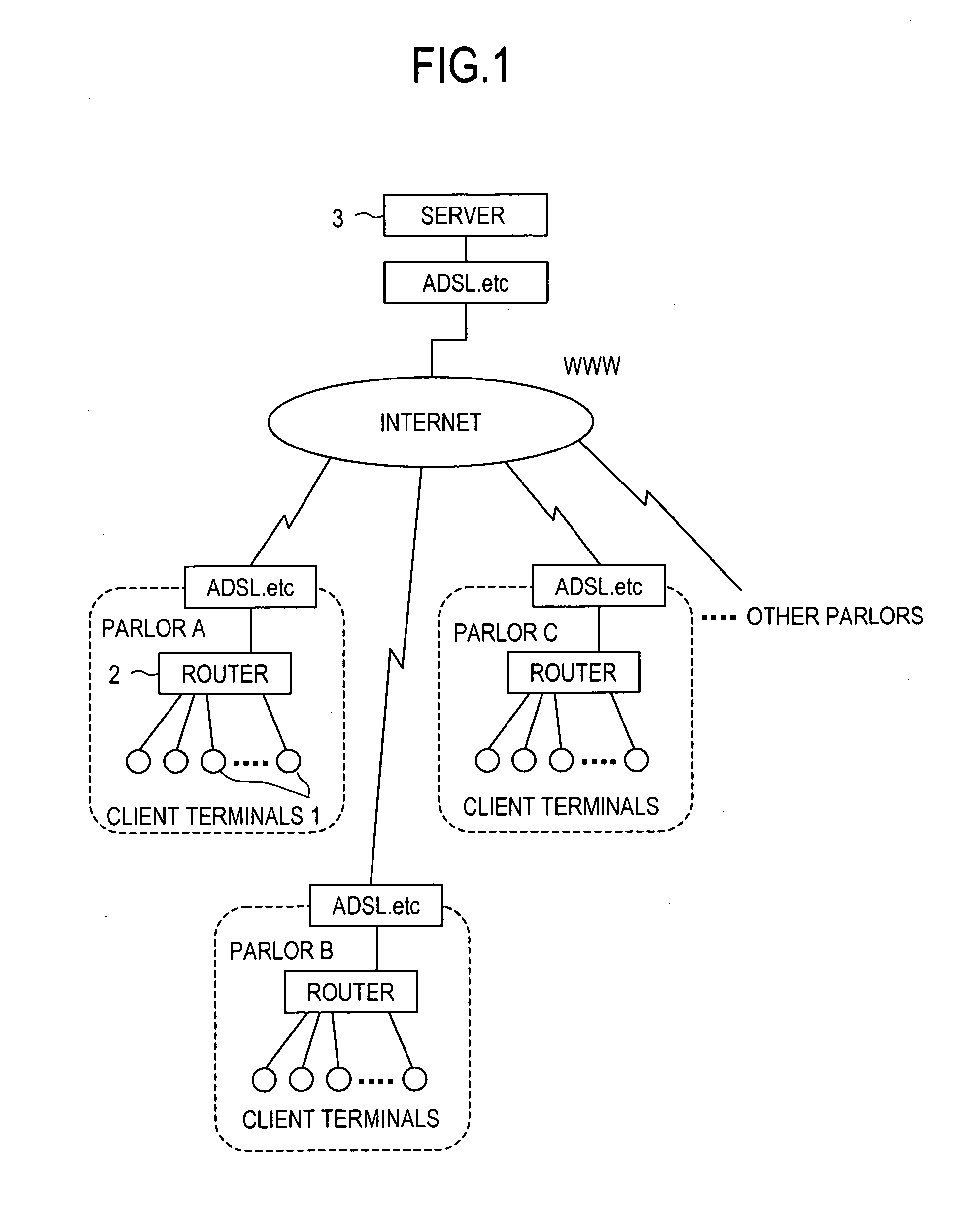

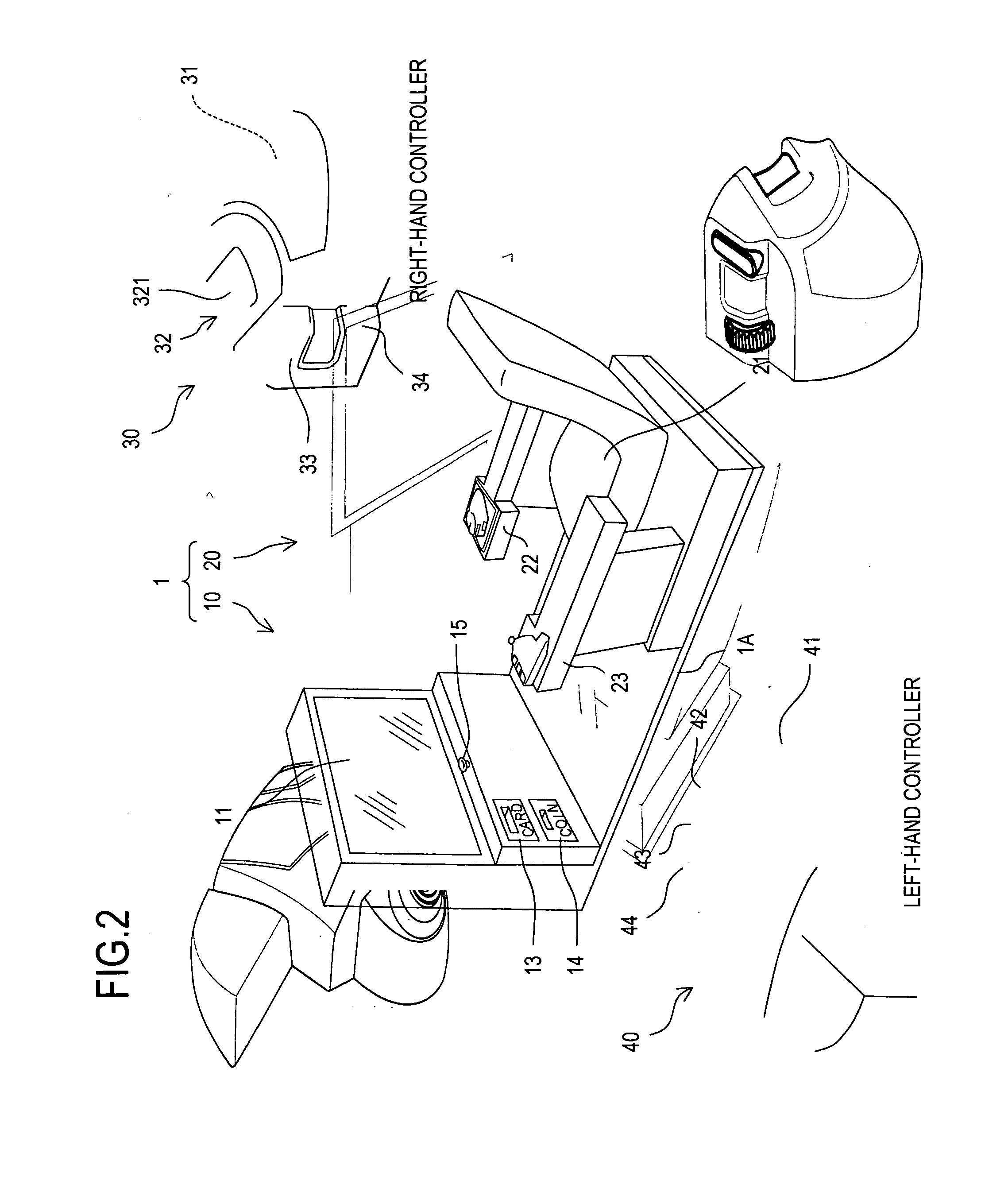

Video game machine, gaming image display method, gaming image dispaly program and network game system

InactiveUS20110018867A1Reduced D processing burdenReduce processing burdenCathode-ray tube indicatorsVideo gamesPleasant FeelingVirtual camera

A video game machine includes a monitor that permits three-dimensional viewing, a virtual camera controller for moving first and second virtual cameras while maintaining a positional relationship in which the two virtual cameras are separated from each other, an image display controller for synthesizing first and second image data acquired by the two virtual cameras upon leading the image data to a display memory, and reading out data content thereof, a game-related image storage block for storing panel images including objects and textures, and a specifier which issues a command for presenting a panel image. The image display controller maps a texture corresponding to an object read out in accordance with the command given from the specifier twice in two storage locations of the display memory that are offset from each other. A player is provided with a gaming image generated with a reduced 3D processing burden, yet creating compelling reality and enjoyable sensation in game playing.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

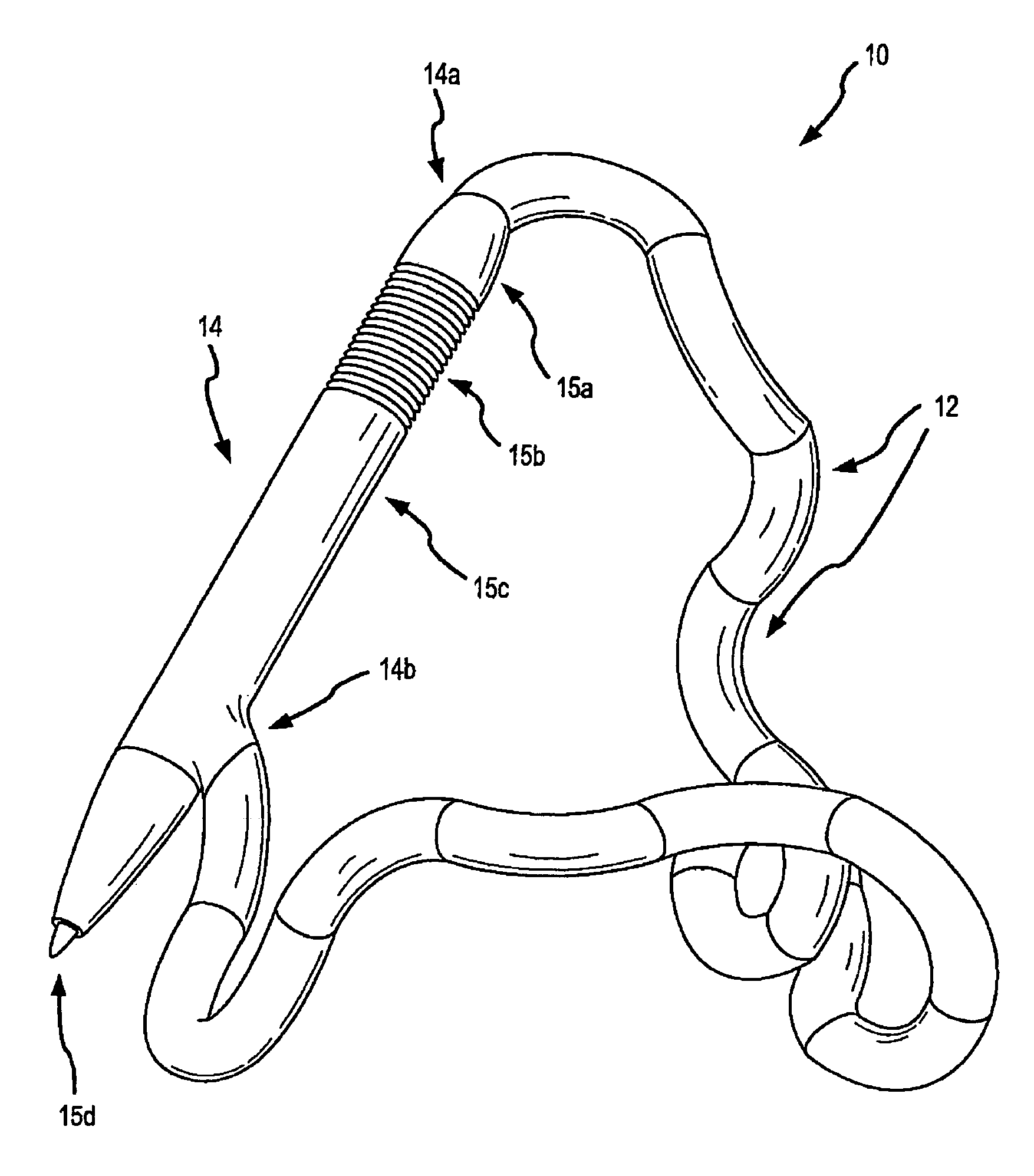

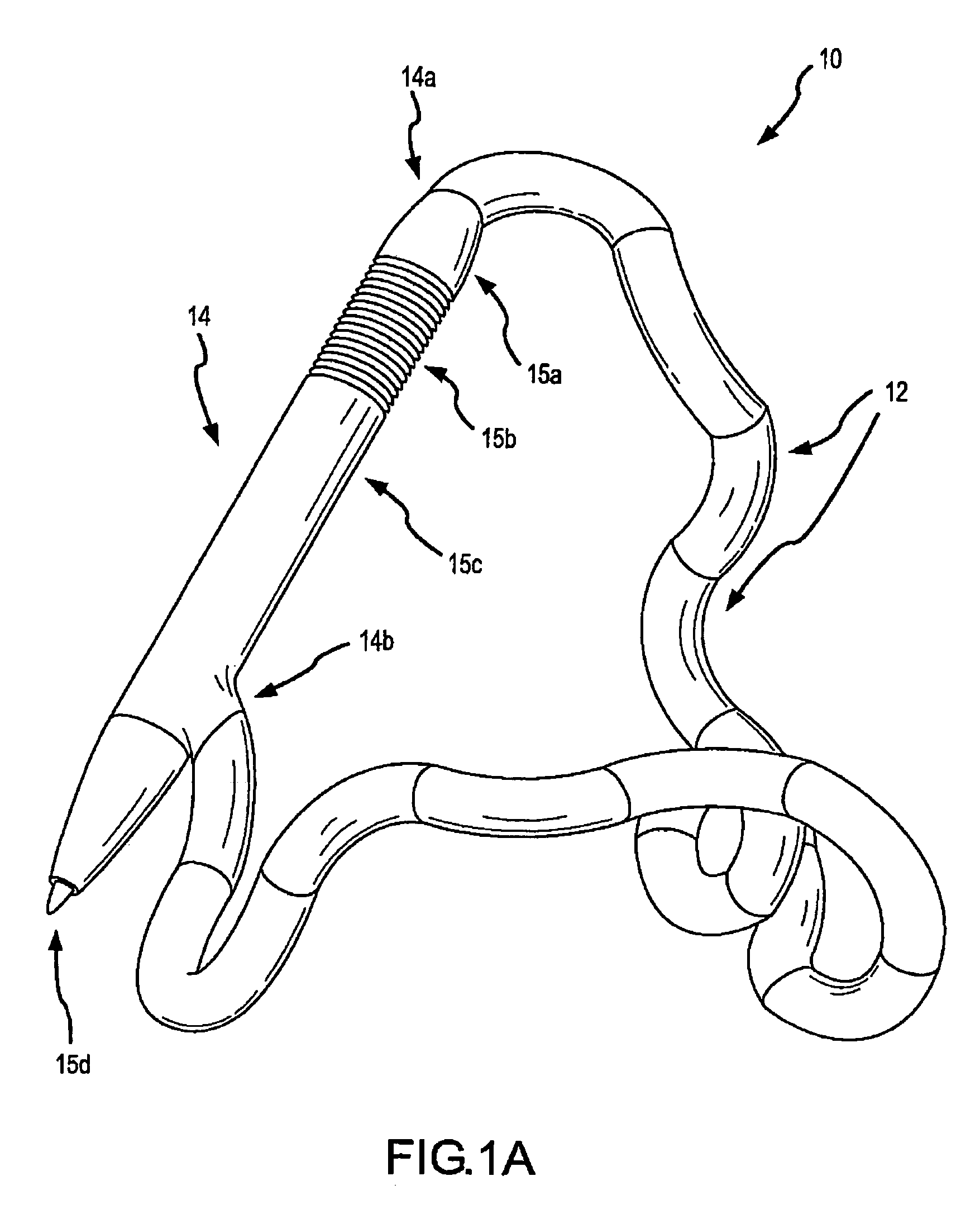

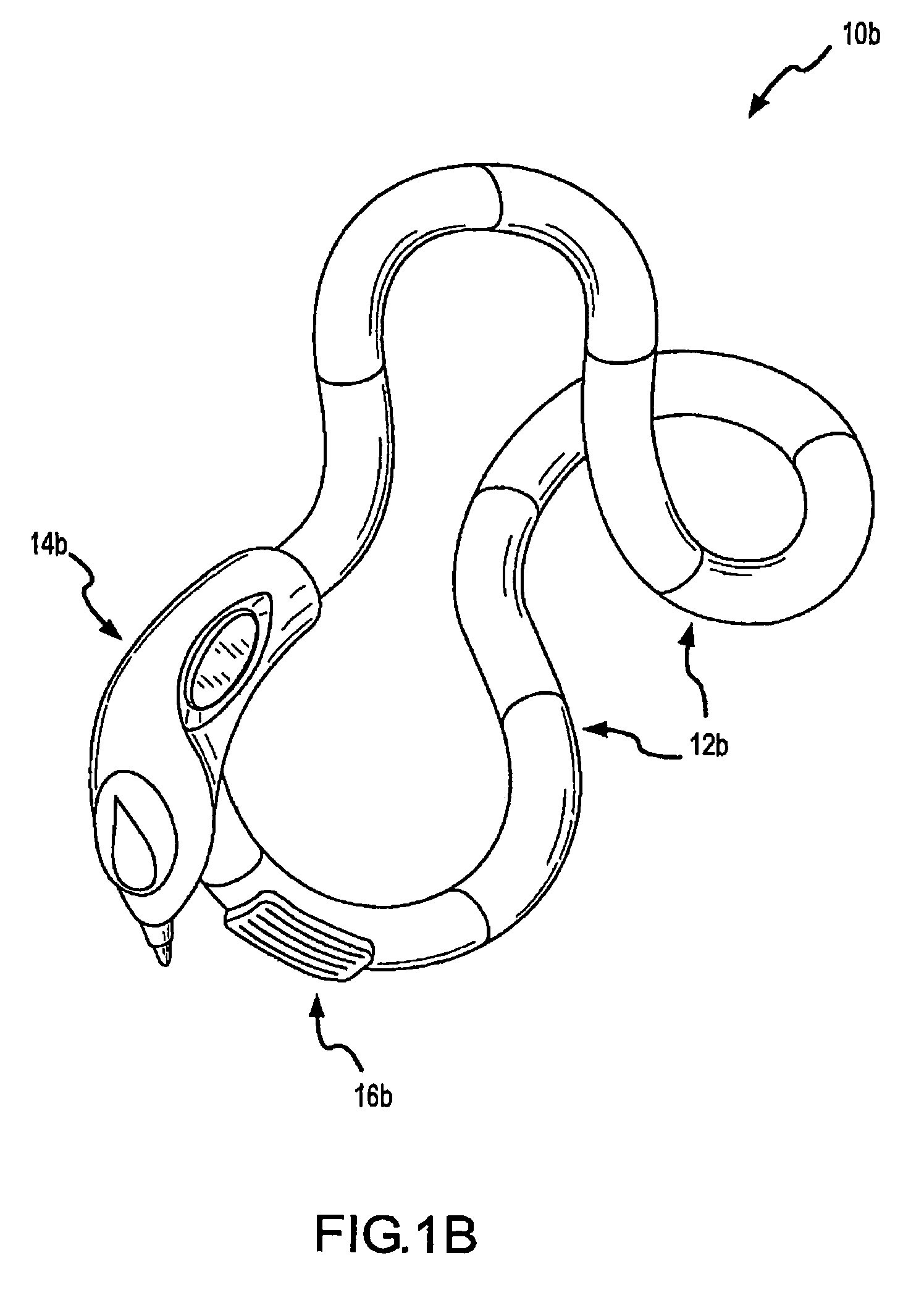

Therapeutic writing instrument devices and methods

InactiveUS7661896B2Efficiently and ergonomically grip and handleStrengthen or rehabilitate the fingers, hands, or forearmsWriting connectorsBrush bodiesEngineeringPleasant Feeling

The invention provides systems and methods for a writing instrument that can be manipulated into an infinite number of shapes and configurations. The invention can be applied to relieve minor stress as well as strengthen hand muscles, rehabilitate finger and joint movement, and improve overall range of hand motion. A textured coating can be applied to the surface of each segment that gives the writing instrument a unique feel, thereby creating a pleasant sensation and feel to the hands and fingers. Segments can operate as a holder for a writing instrument body, and similarly can be arranged to provide a creative sculpture. Segments can be removed as desired by the user.

Owner:KOPIITERU +1

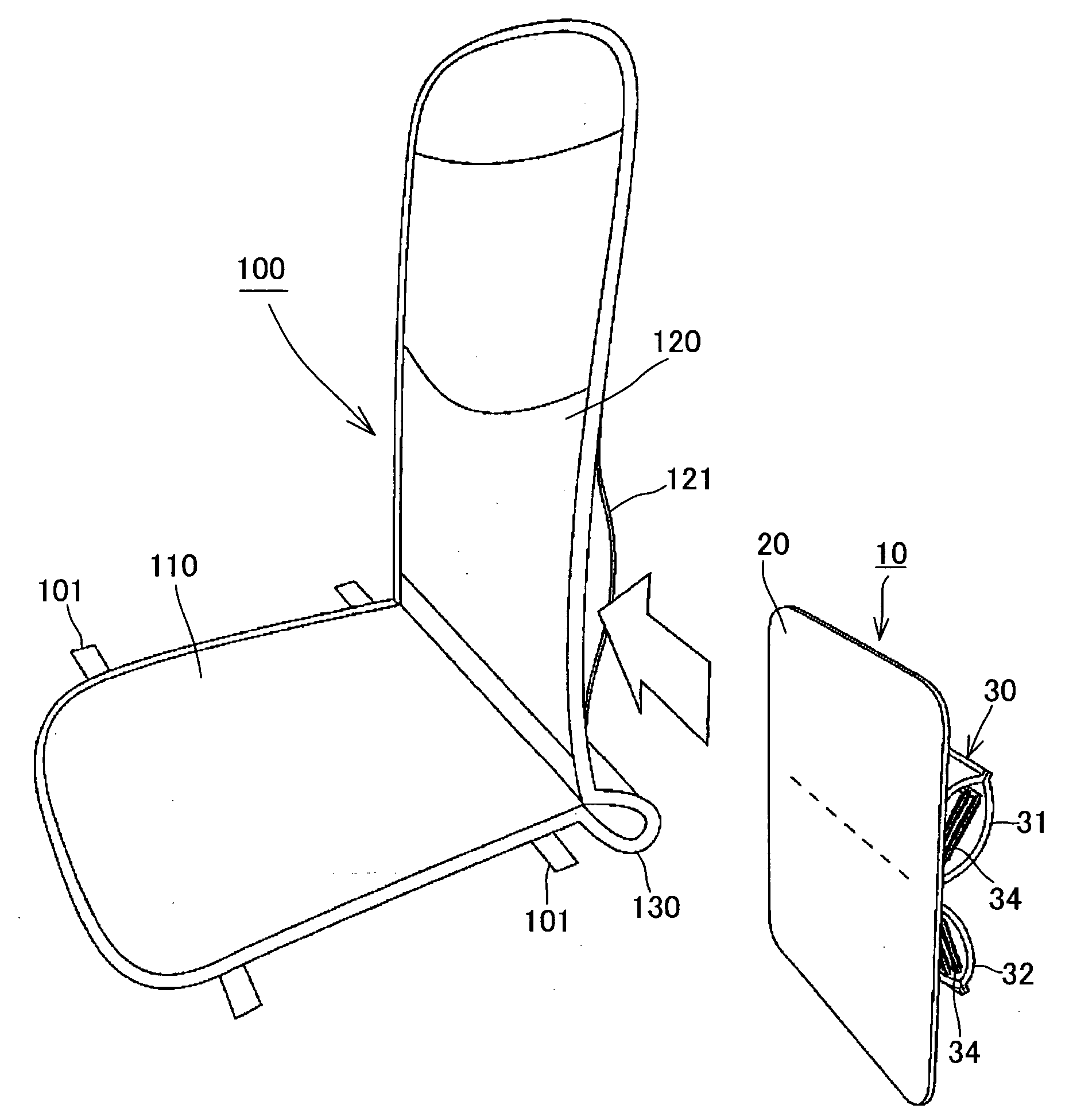

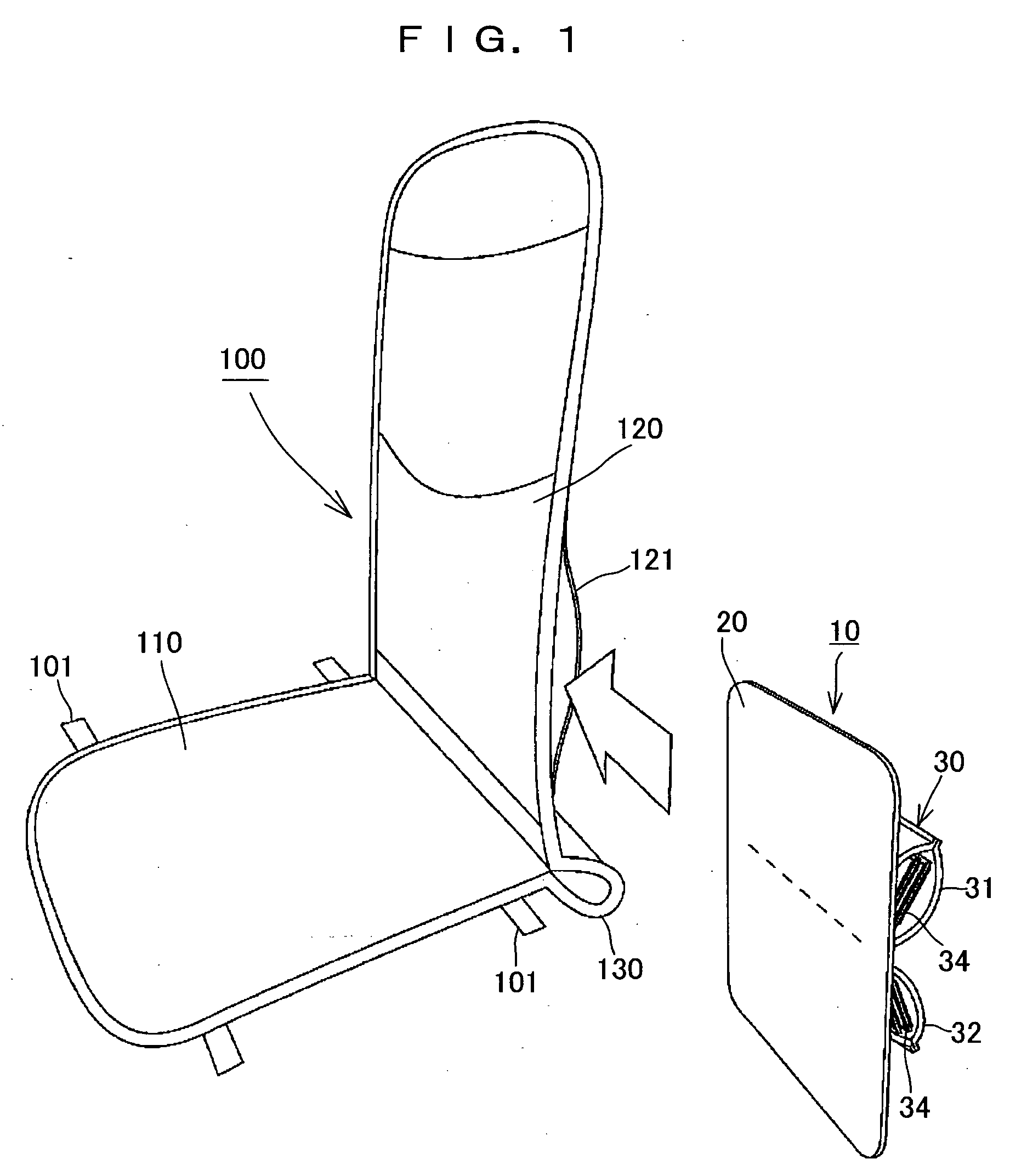

Lumbar support, cushion for seat, and seat structure

Owner:DELTA TOOLING CO LTD

Vibratory shoe for feet

InactiveUS7832124B2Avoid pollutionReduces instanceChiropractic devicesVibration massageAcupressureEngineering

Owner:BLOCKTON DEBORAH

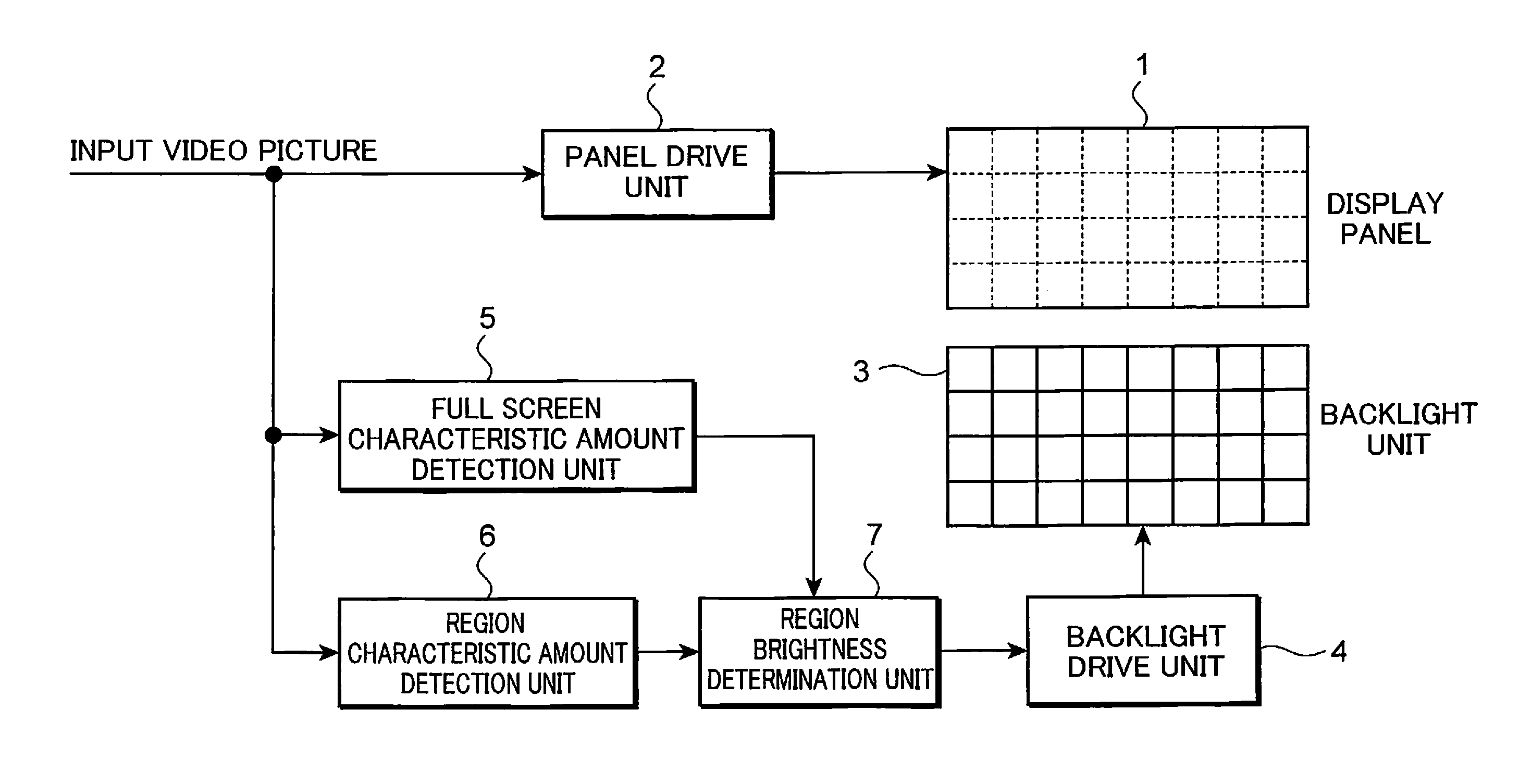

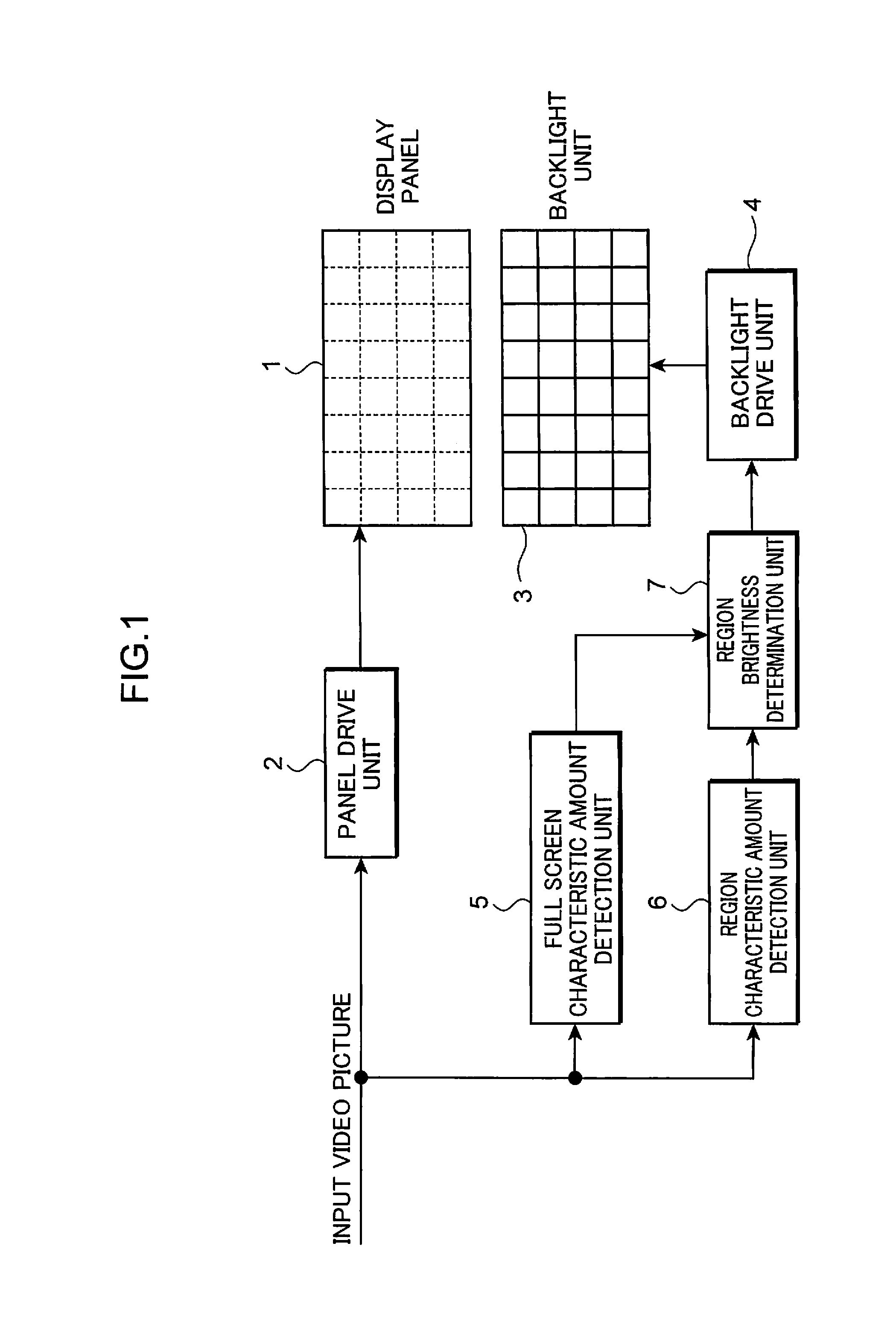

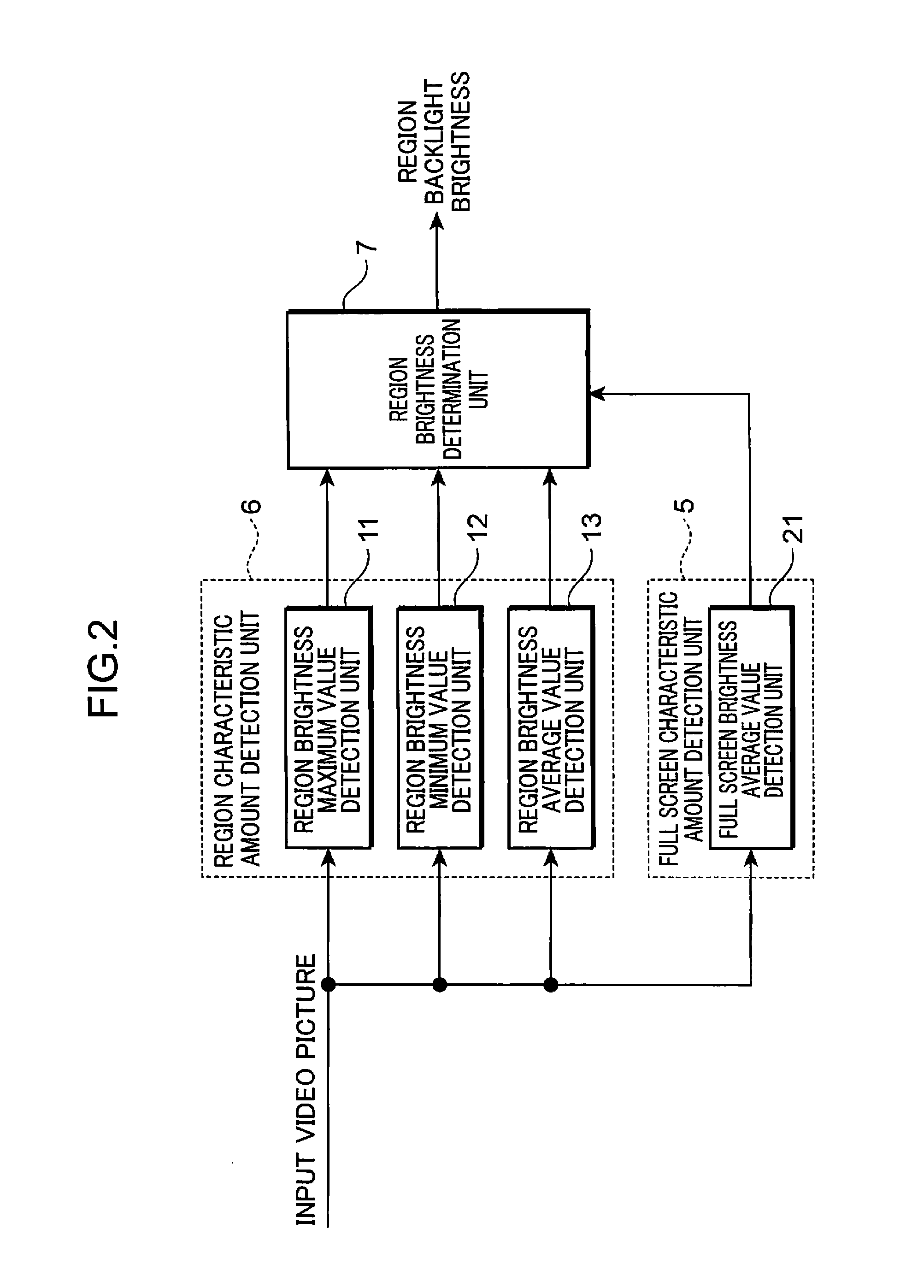

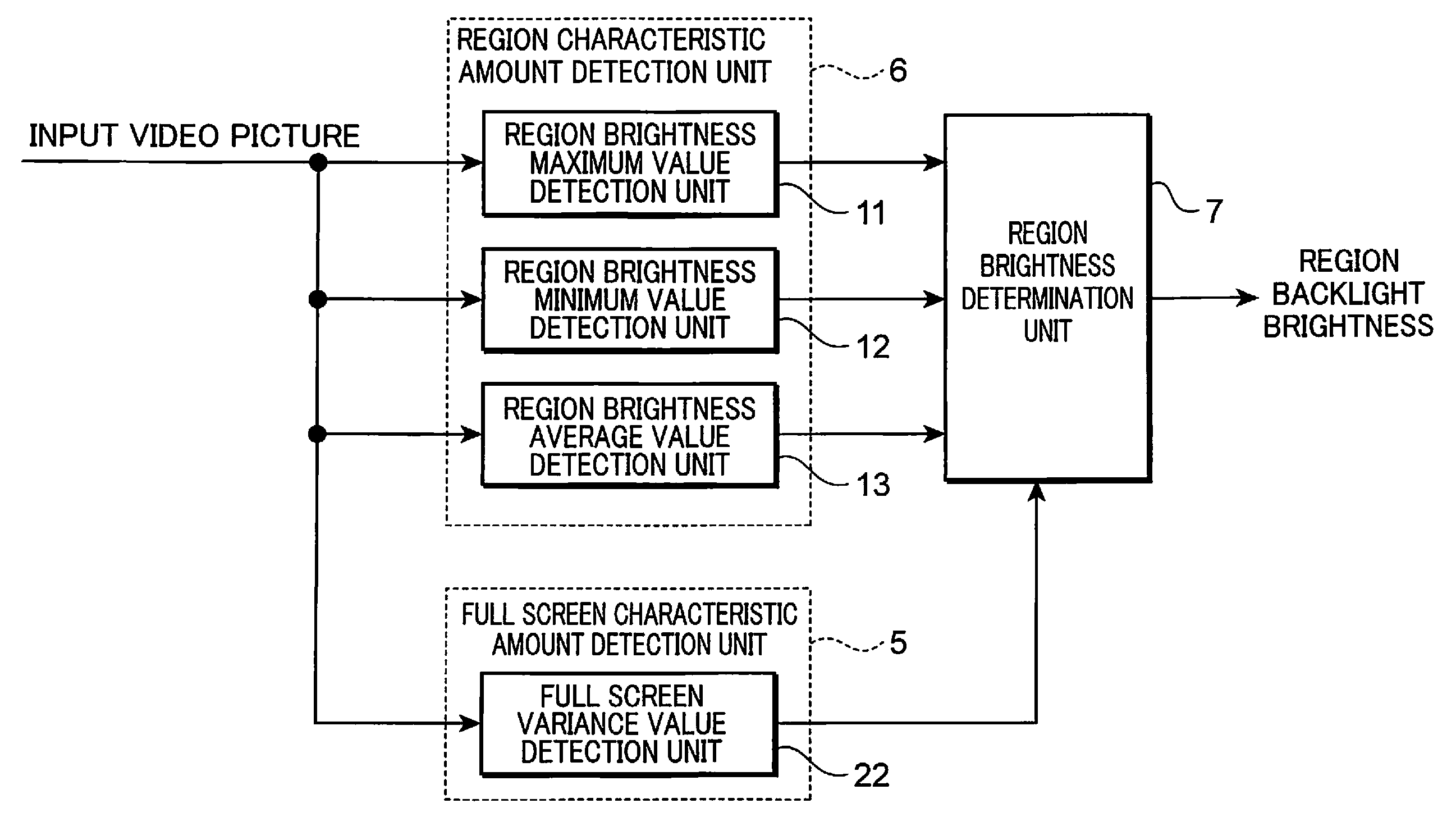

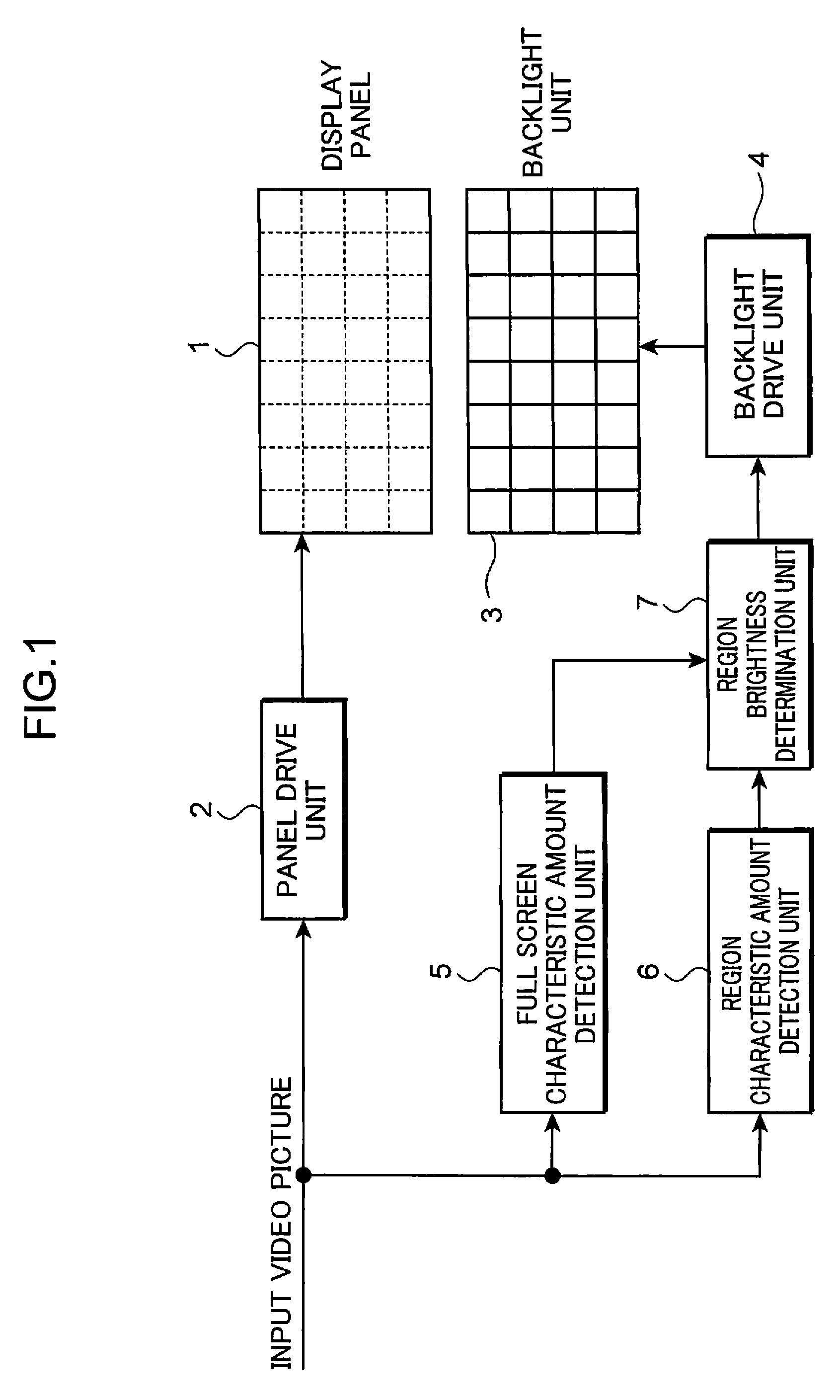

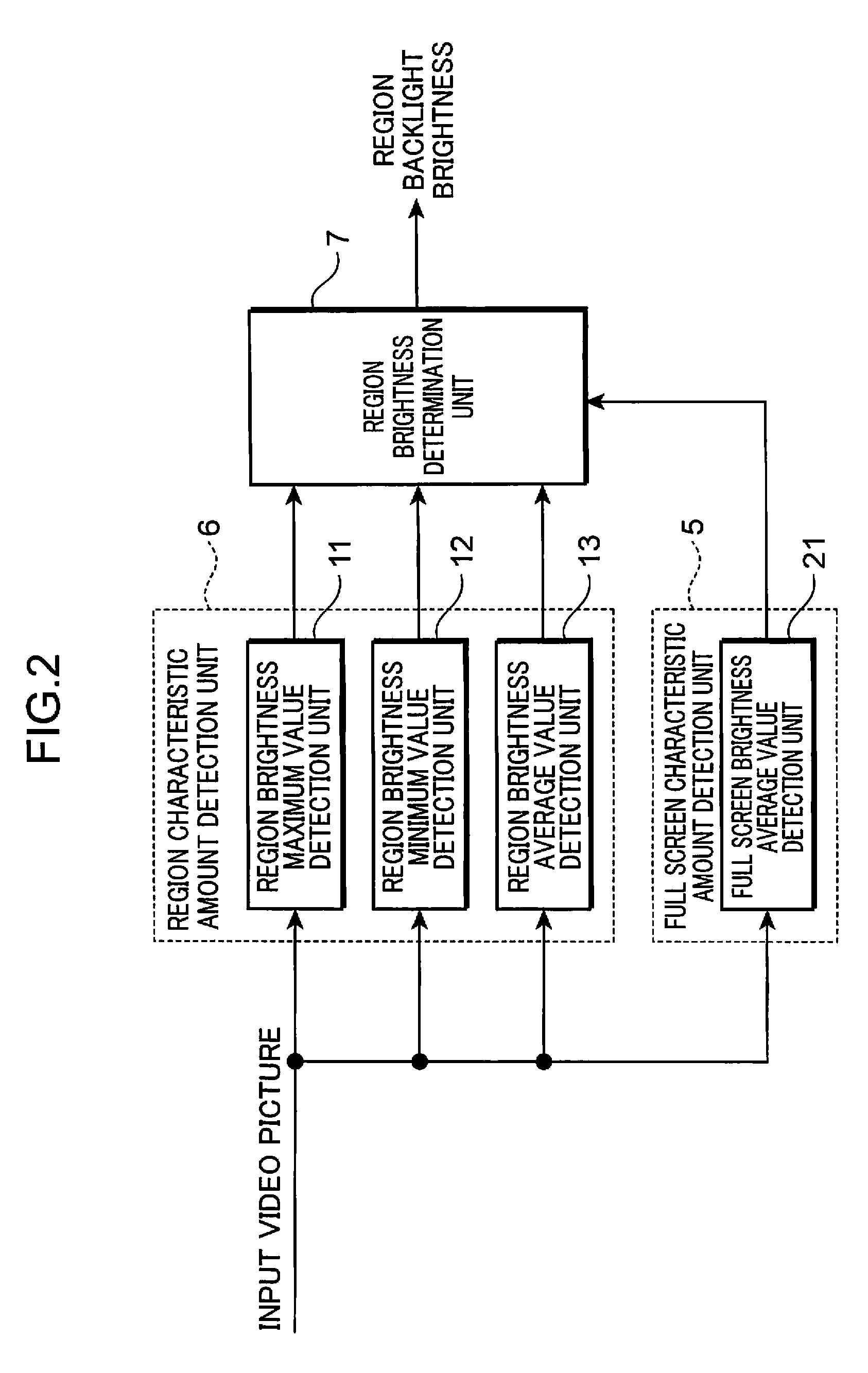

Display device and display control method

ActiveUS20120038694A1Reducing unpleasant sensationInsufficient brightnessCathode-ray tube indicatorsInput/output processes for data processingComputer graphics (images)Display device

Provided are a display device and a display control method capable of reducing a visually unpleasant sensation that is experienced by a user. This display device includes a display panel (1) which displays a video picture, a backlight unit (3) which is disposed on a back surface of the display panel (1), and which includes a plurality of light sources for each region obtained by dividing the display panel (1) into a plurality of regions, a region characteristic amount detection unit (6) which detects a characteristic amount of an image of each of the divided regions, a full screen characteristic amount detection unit (5) which detects a characteristic amount of an image of the overall display panel, a region brightness determination unit (7) which determines an emission brightness of the respective light sources corresponding to each of the regions based on the detected characteristic amount of the image of each region, and the detected characteristic amount of the image of the overall display panel, and a backlight drive unit (4) which drives the respective light sources to emit light at the determined emission brightness.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

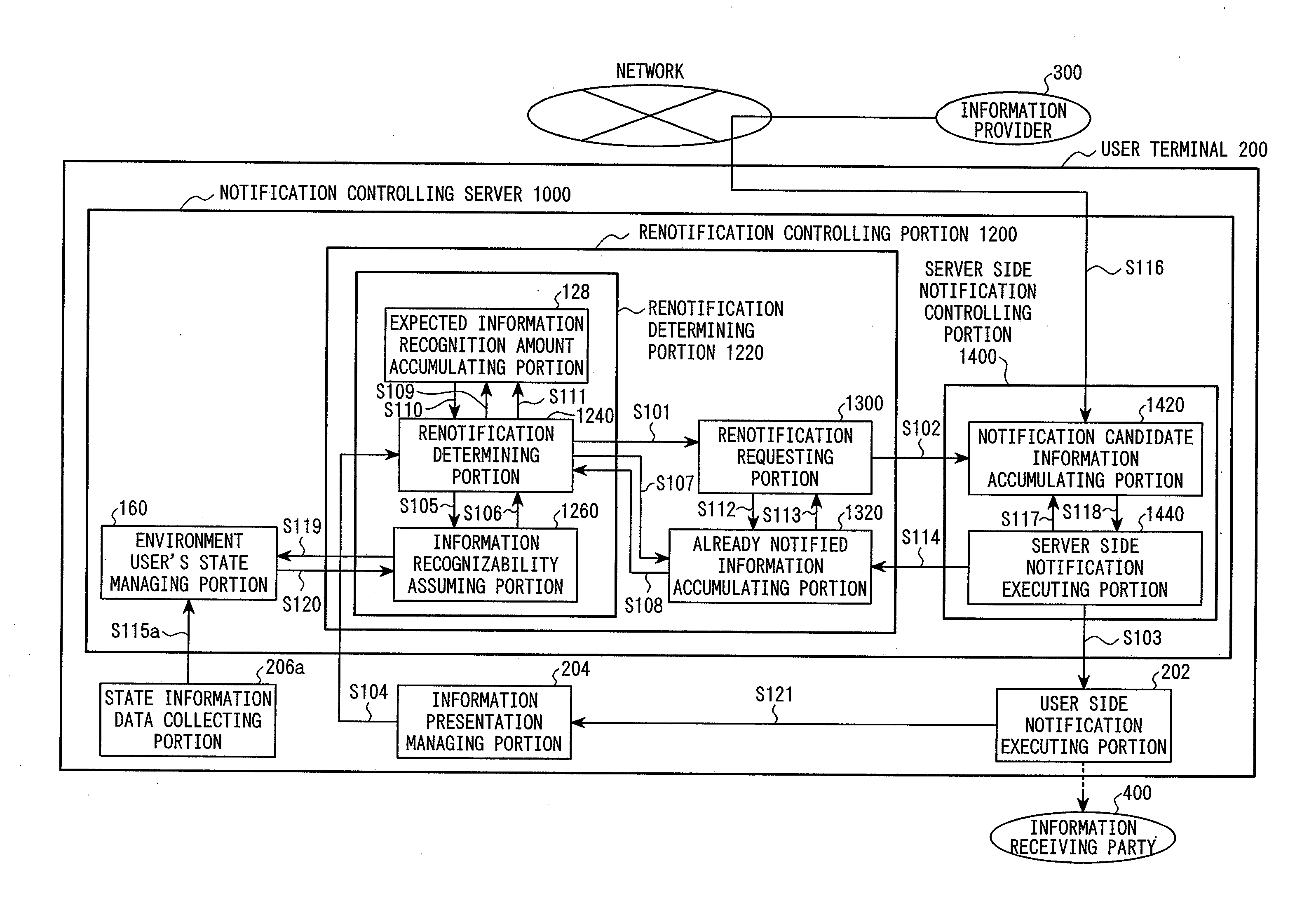

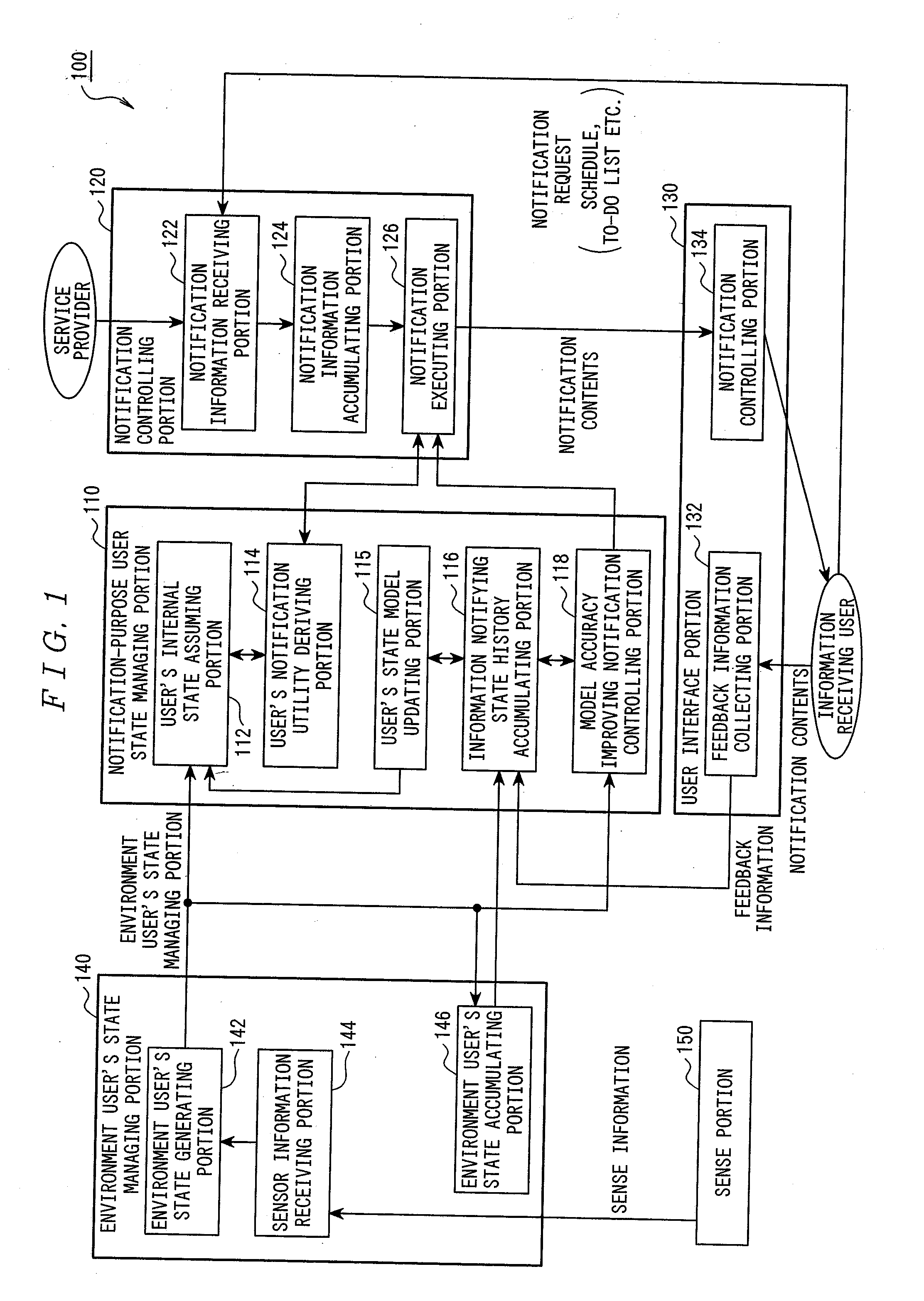

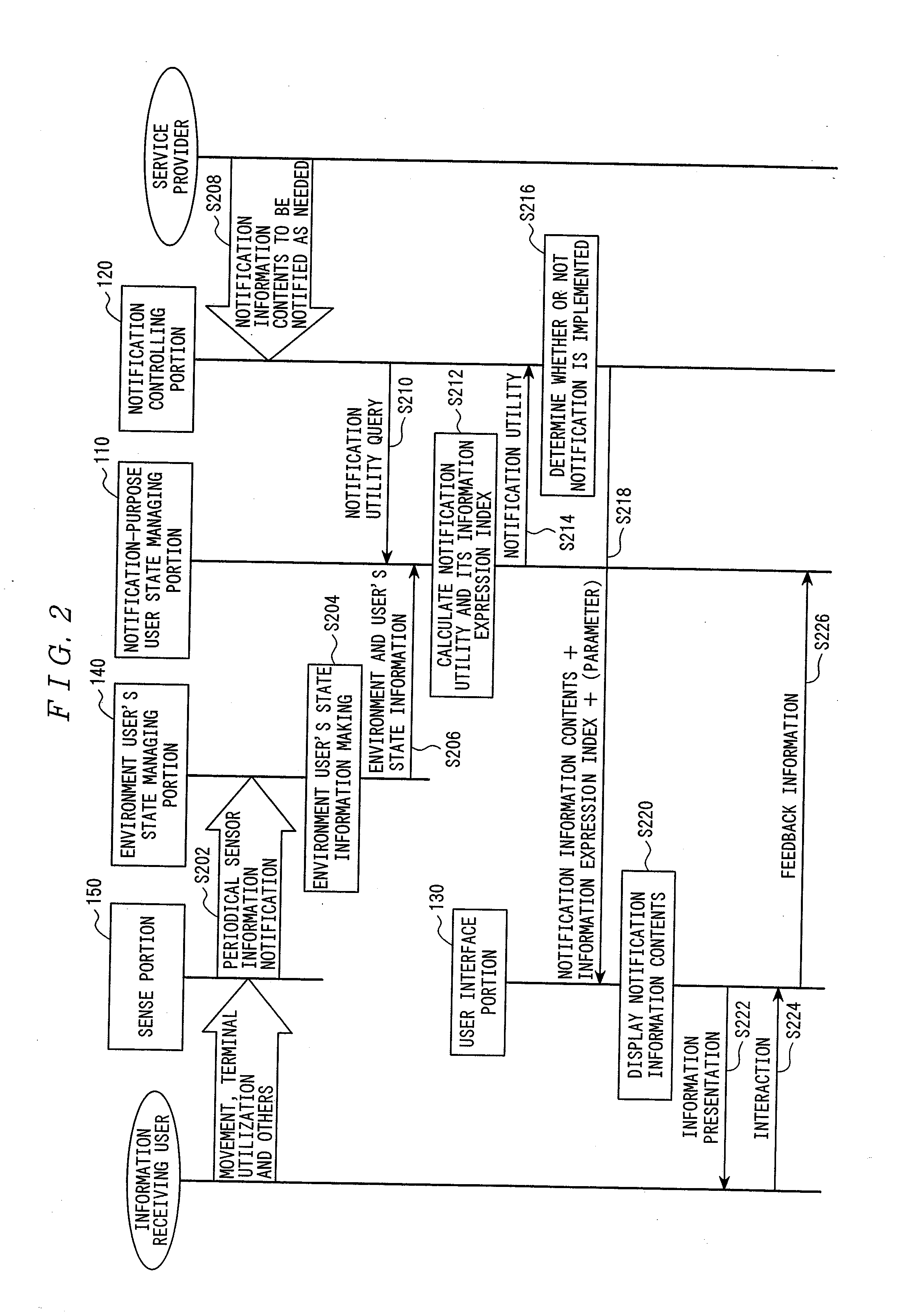

Information Notification System and Information Notification Method

InactiveUS20080288606A1Efficiently notifiedReduce the burden onMetadata multimedia retrievalMultiple digital computer combinationsPleasant FeelingComputer science

A notification-purpose user state managing apparatus, a notification controlling apparatus, an information notification apparatus, an information notification system and an information notification method capable of reducing an unpleasant feeling and a burden and encouraging a user to recognize information are provided. The information notification system includes a notification-purpose user state managing apparatus including user's internal state assuming means for assuming a user's internal state based on an observable state element and user's notification utility assuming means for assuming utility to a user receiving information when information is notified based on the user's internal state; and a notification controlling apparatus including notification executing means for determining whether or not information is notified based on the utility and notifying information based on the determination. Whether notified information is renotified is determined based on the result of assumption of user's information recognizability, whereby it is not necessarily required to use a specified user's reaction indicating that information has been received, and whether information has been received is assumed, and if it is determined that information has not been received, notified information is renotified, whereby a possibility that the user recognizes information can be increased.

Owner:NTT DOCOMO INC

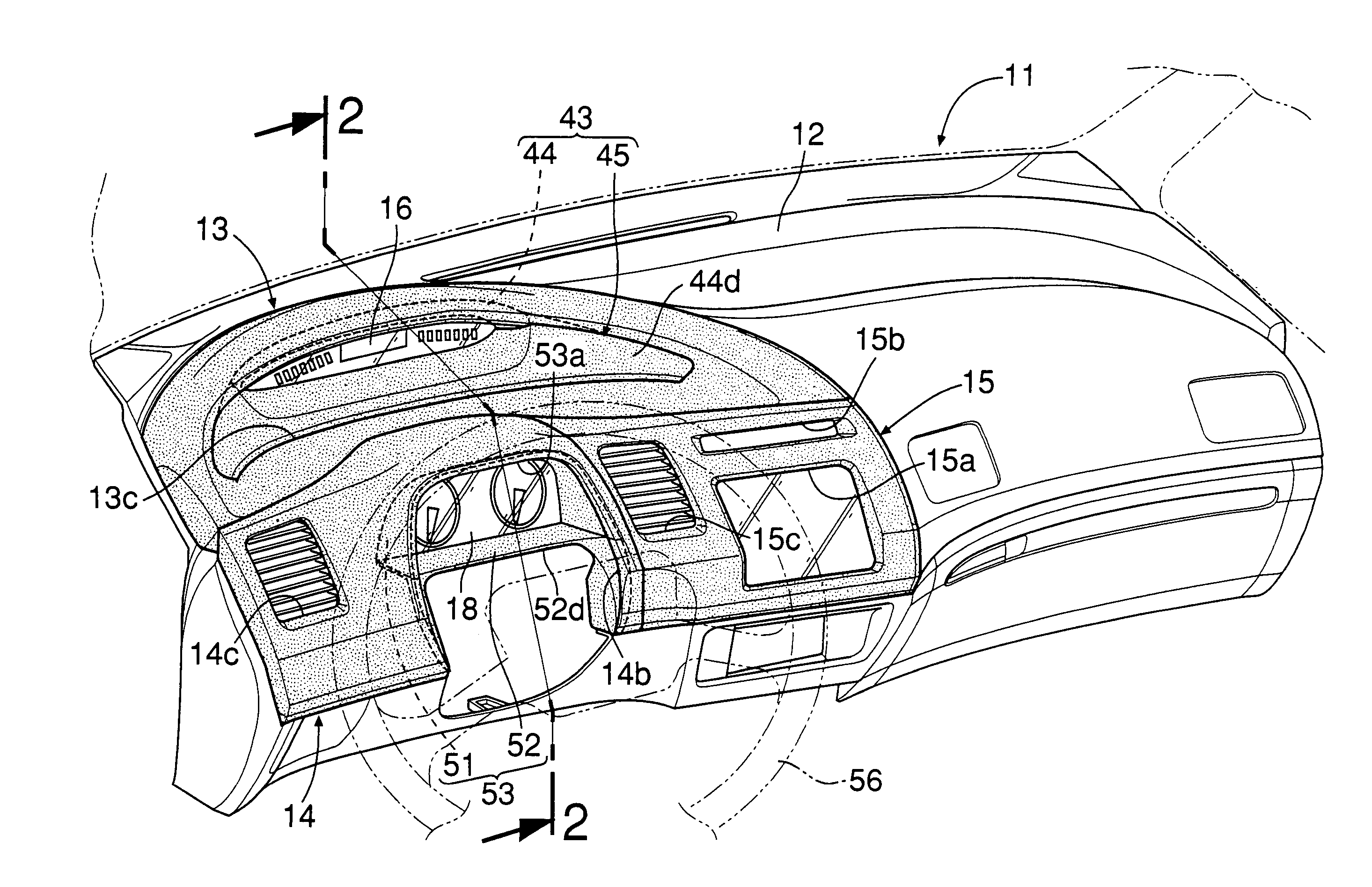

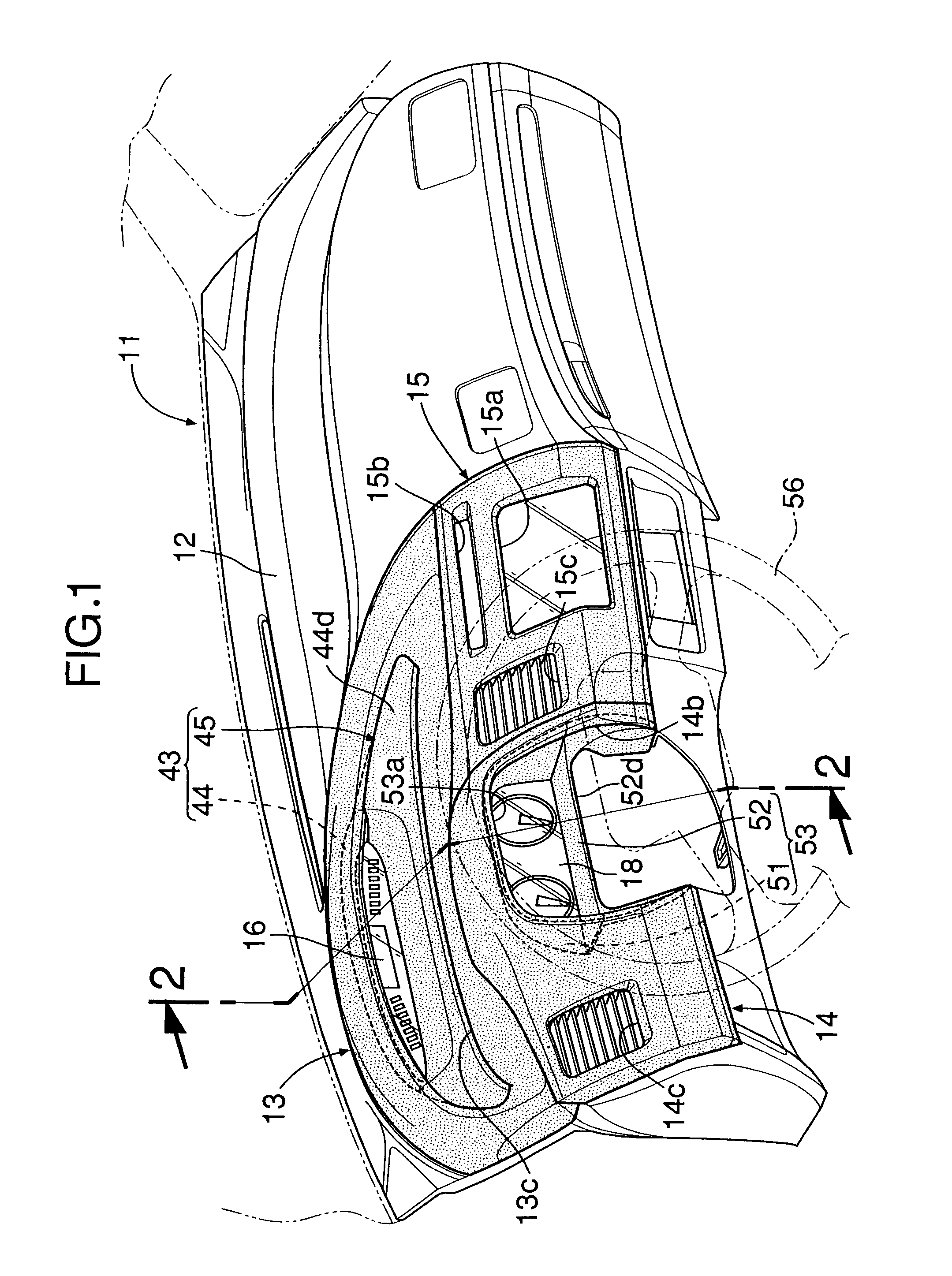

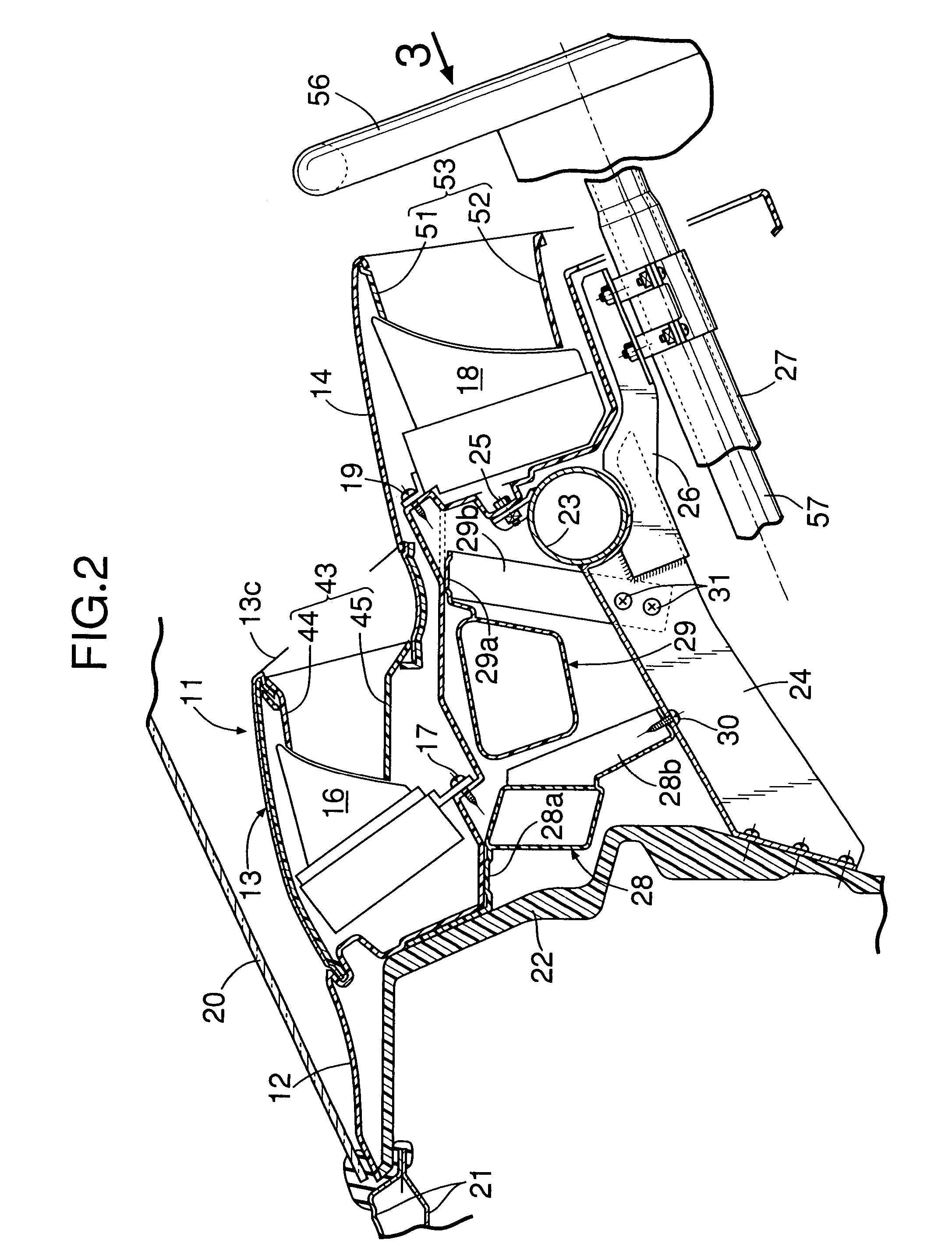

Automobile instrument panel structure

InactiveUS7036865B2Increase awarenessPedestrian/occupant safety arrangementInstrument arrangements/adaptationsDashboardDriver/operator

Owner:HONDA MOTOR CO LTD

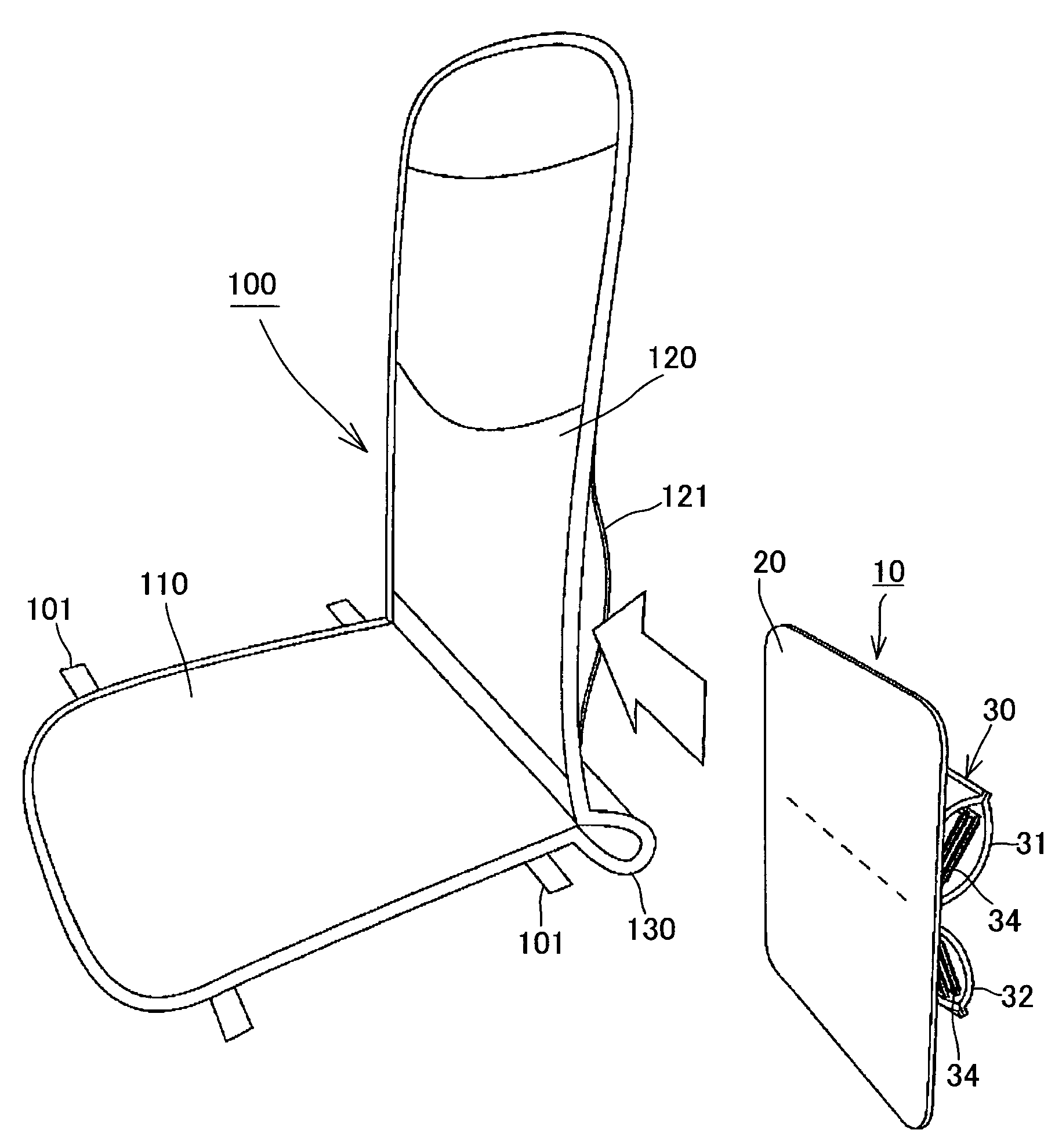

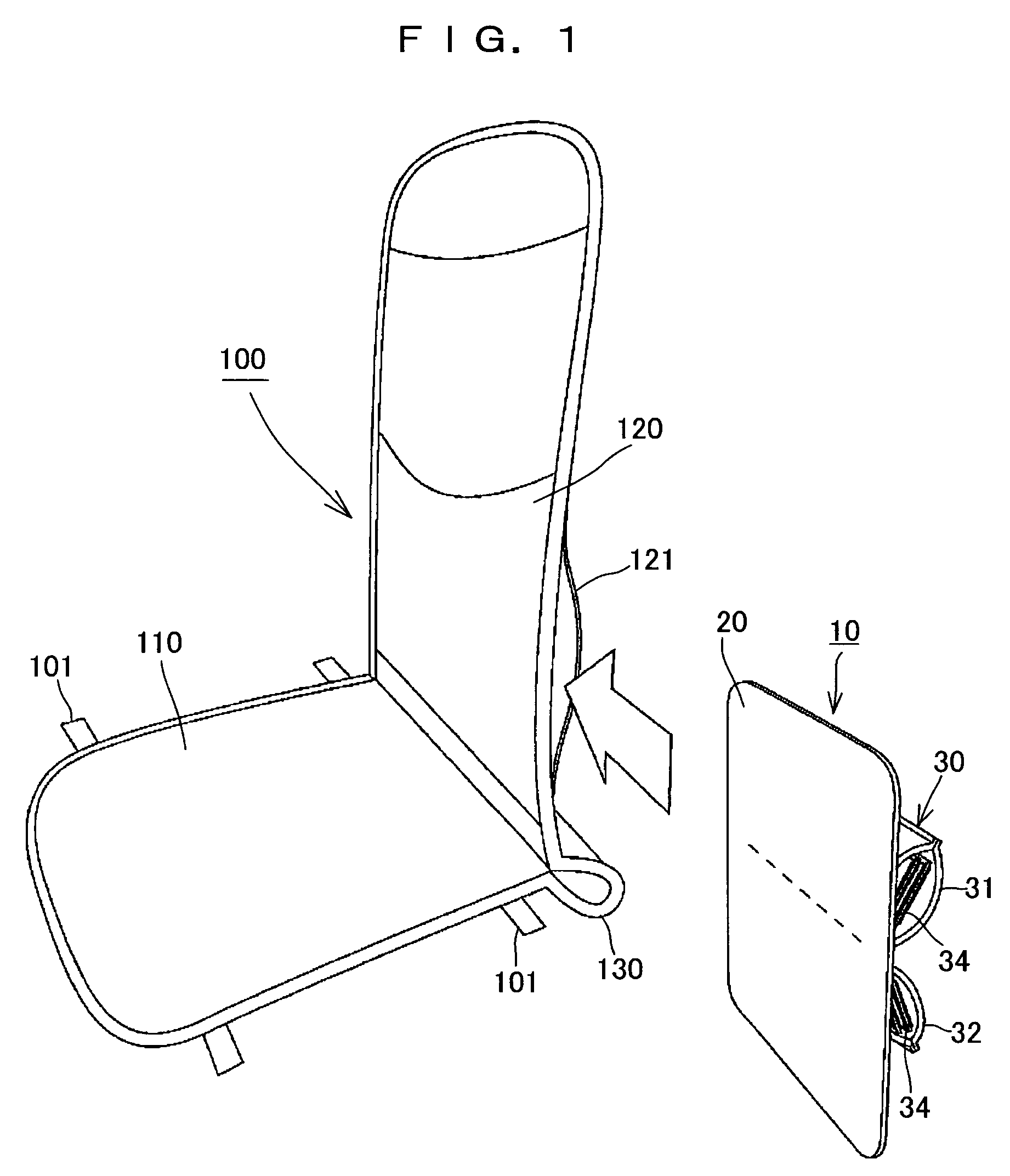

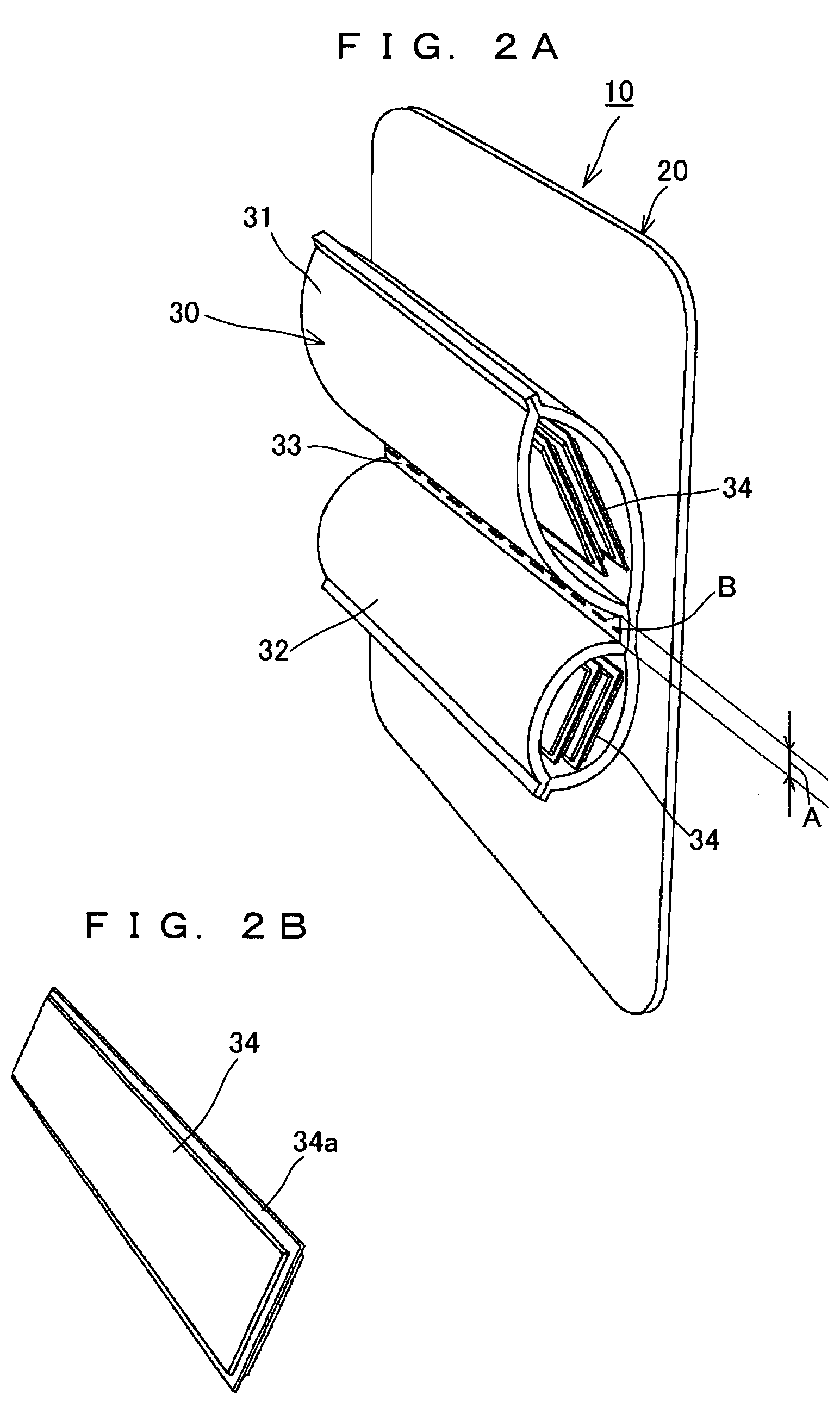

Lumbar support, cushion for seat, and seat structure

In order to provide a lumbar support which conforms to the curve of the spinal column so as not to give a feeling of incompatibility or other unpleasant feeling, and is easily adjusted to meet a user's preference, a lumbar support 10 of the present invention is structured such that a bulging member 30 provided with two housing parts 31 and 32 to house a cushioning material for adjustment 34 is fixed on the back surface of a flexible plate 20, which is incorporated so that the front surface of the flexible plate 20 is positioned to the front surface side of a back cushion 120. Accordingly, the curvature of the two housing parts 31 and 32 does not affect a feeling of contact with the waist as it is, but works as a feeling of contact with larger curvature owing to the flexible plate 20, which results in suppression of pressure on the nervous system between the third and fourth lumbar vertebrae. Furthermore, by setting the width of a border region 33 between the two housing parts 31 and 32 in an appropriate range, it is possible to suppress a feeling of pressure on such a nervous system, and at the same time, to suppress any feeling of incompatibility or other unpleasant feeling caused by too large a curvature.

Owner:DELTA TOOLING CO LTD

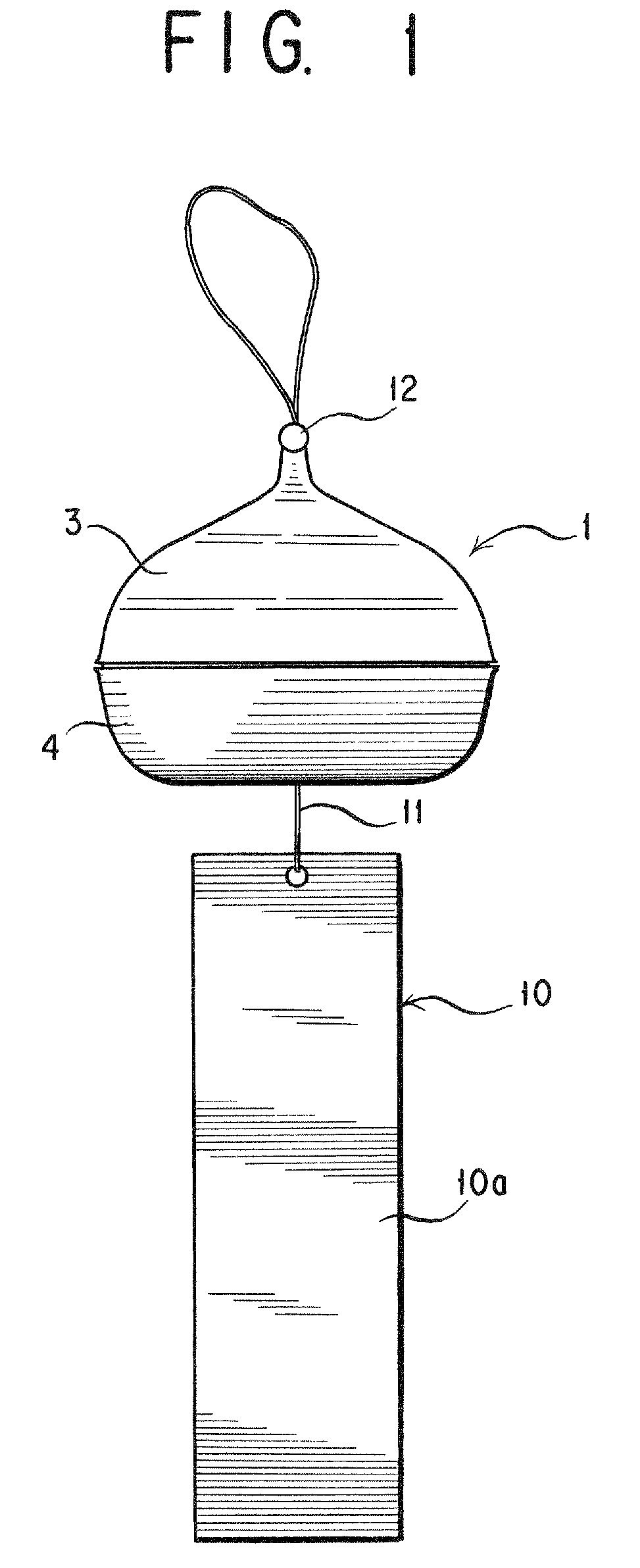

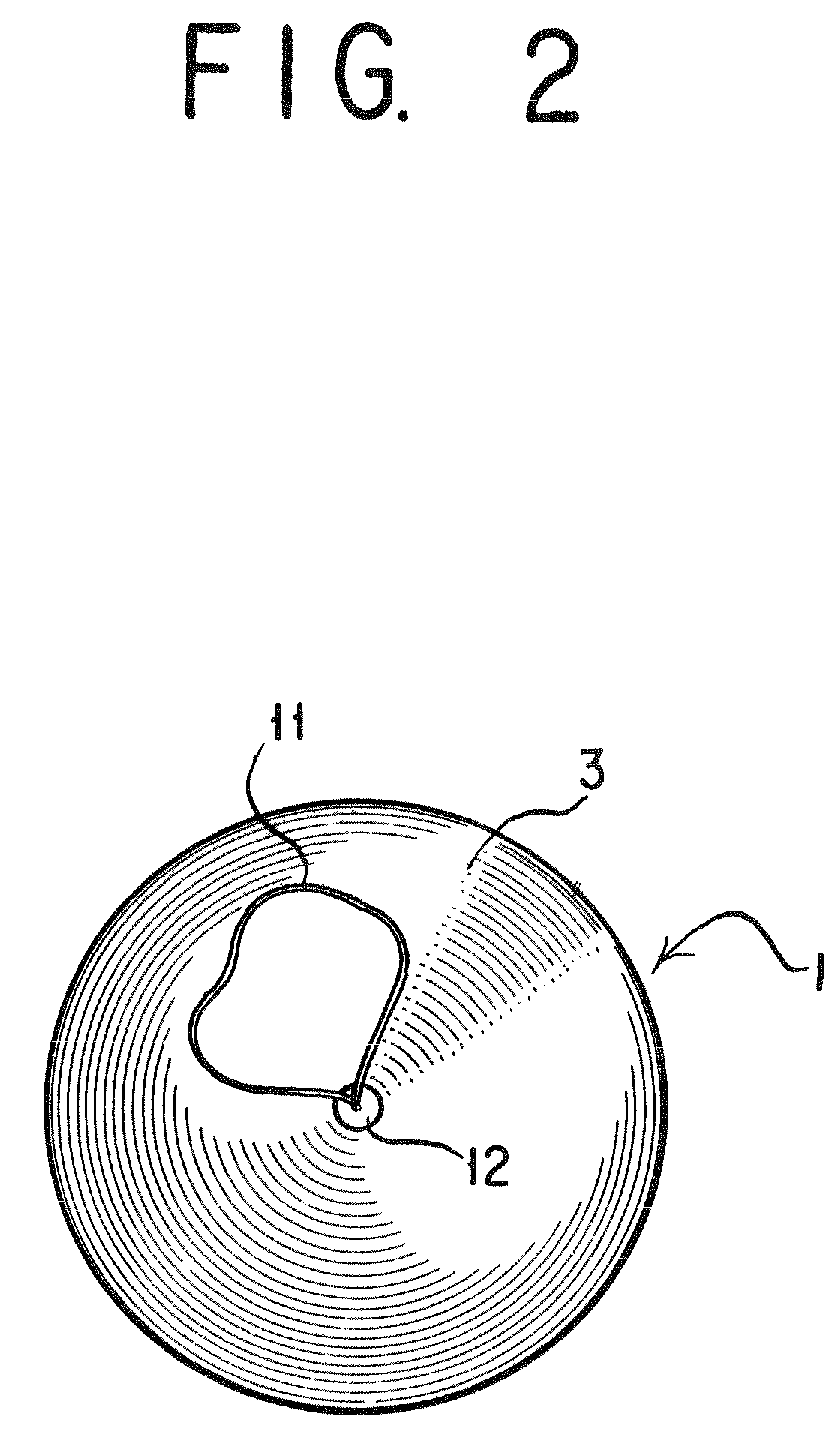

Flying insect trapping apparatus

A flying insect trapping apparatus is provided that is capable of attracting and trapping flying insects such as flies or wasps very well and moreover without giving a user an unpleasant feeling. The flying insect trapping apparatus comprises an attractive and inductive member having a vertical surface portion, an entry port surrounding an upper part of the attractive and inductive member and a trap chamber communicating with the entry port, whereby a flying insect is attracted by the member and to land on the surface portion thereof and then is induced to move along the surface portion and to pass through said entry port so as to be trapped in the inside of the trap chamber.

Owner:FUMAKILLA LTD

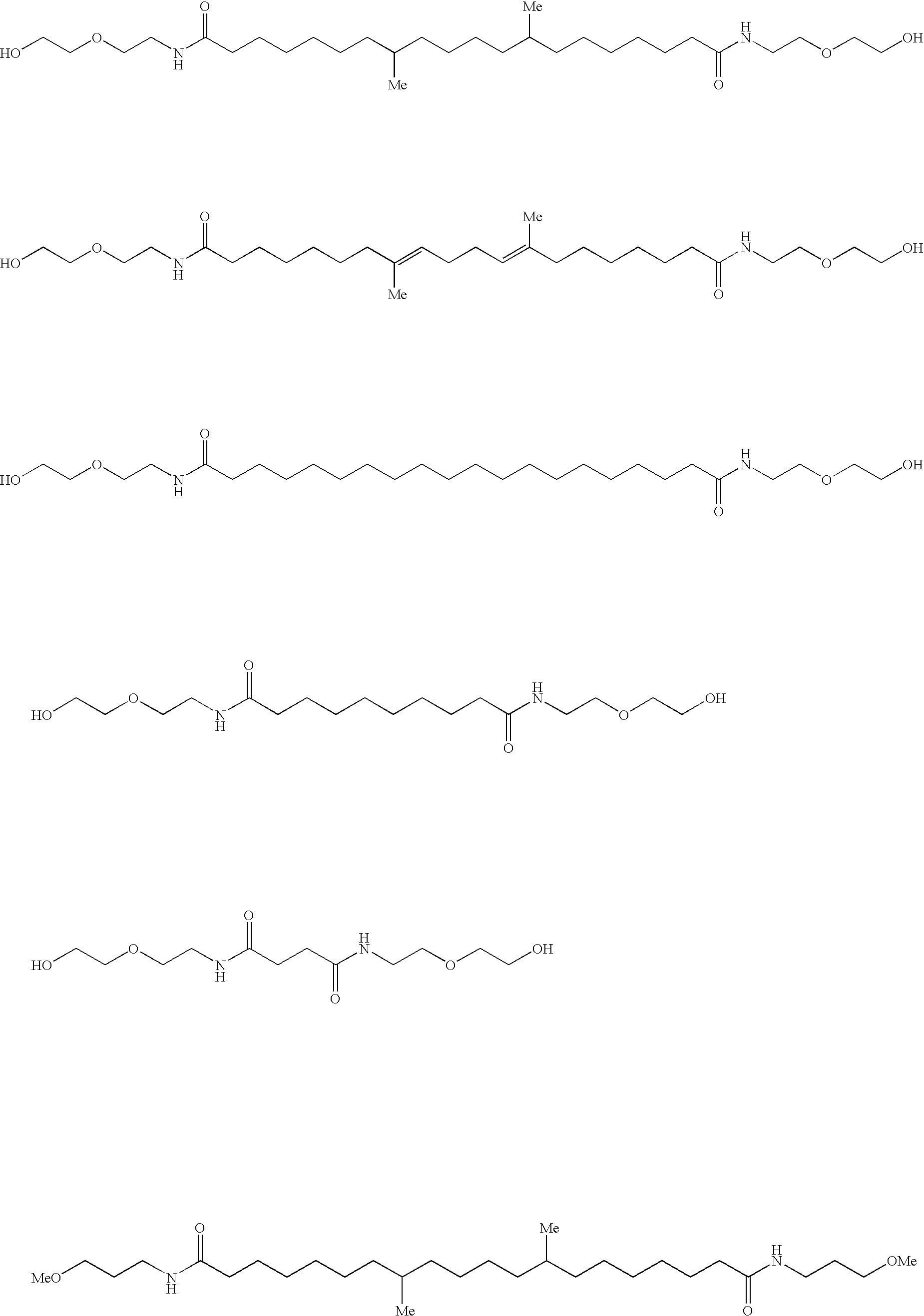

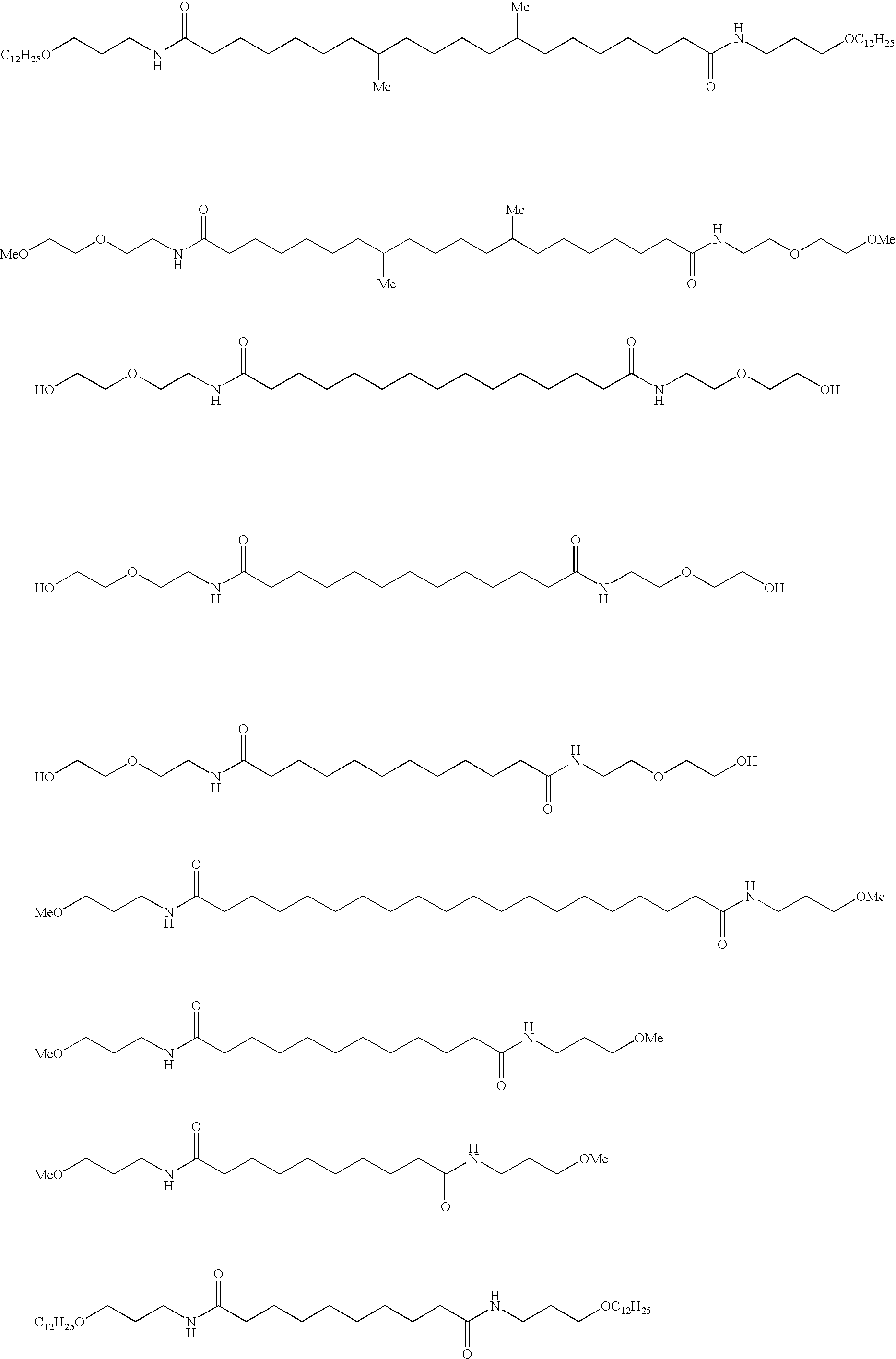

Hair cleansing composition

InactiveUS20040157984A1Excellent effect for preventing and repairingPreventing spilt end and breakage of hairCosmetic preparationsHair cosmeticsPolymer scienceActive agent

Provided is a hair cleansing composition containing (A) an amphipathic amide lipid, (B) an anionic surfactant and (C) a silicone. The hair cleansing composition of the present invention has advantages such as protecting hair from physical or chemical stimulation and preventing split ends or hair breakage~without impairing its cleansing ability and,feeling upon use, and moreover, gives to hair after shampooing a pleasant feeling to the touch and moisture retention properties such as natural smoothness, moist feeling, and suppleness which healthy hair inherently possesses, and has excellent stability.

Owner:KAO CORP

Therapeutic hand toys

ActiveUS7601045B2Strengthen or rehabilitate the fingers, hands, or forearmsRelieve pressureElectrotherapyGymnastic exercisingEngineeringPleasant Feeling

Owner:TANGLE

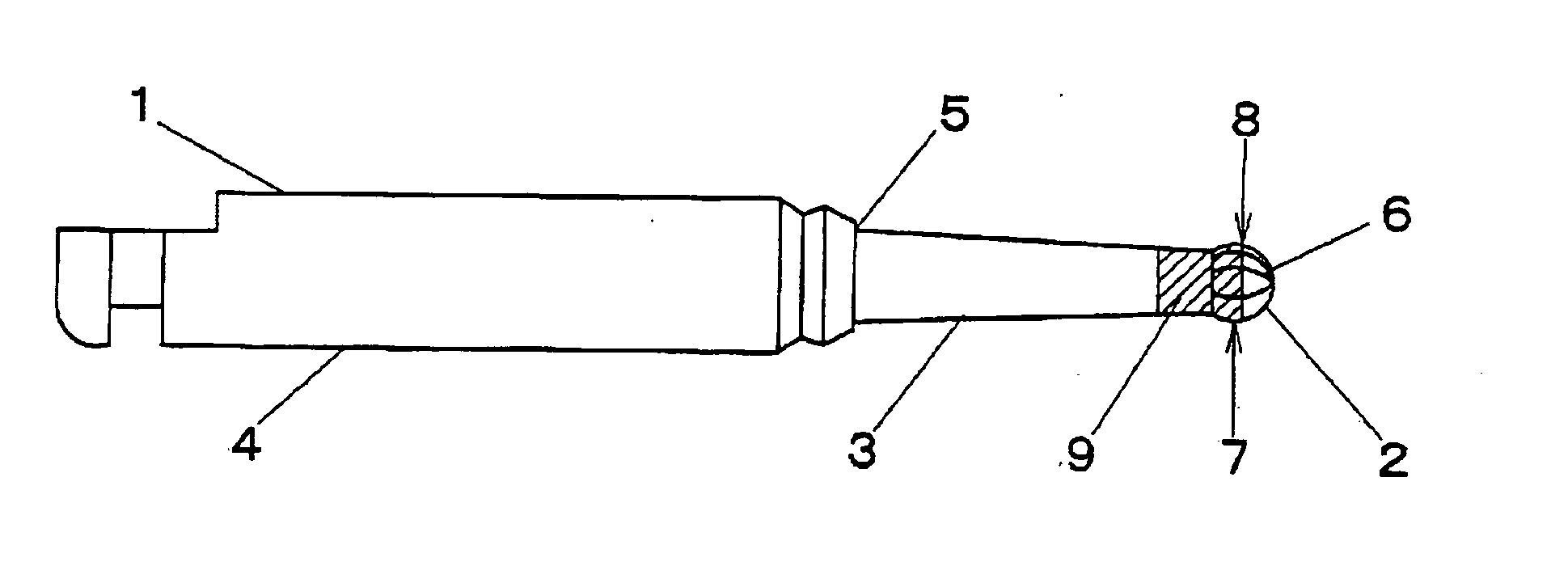

Electronic cigarette tar and preparation method thereof

ActiveCN107125803ARich aromaComfortable tasteTobacco treatmentEssential-oils/perfumesCinnamyl acetateLemon oil

The invention provides electronic cigarette tar which comprises the following components by mass percentage: 90-99% of atomized liquid and 1-10% of coca cola essence, wherein the coca cola essence comprises the following components in parts by weight: 0.1-2 parts of alpha pinene, 0.1-2 parts of beta pinene, 1-30 parts of limonene, 1-10 parts of sweet orange oil, 1-20 parts of lemon oil, 0.1-0.5 parts of myrcene, 0.1-2 parts of cinnamic aldehyde, 0.1-5 parts of cinnamon oil, 0.1-10 parts of citral, 0.1-5 parts of geranial, 1-10 parts of geranyl acetate, 0.1-5 parts of sinensal, 1-10 parts of citronellol, 1-10 parts of geranyl propionate, 0.1-5 parts of eugenol allylguajacol, 0.1-2 parts of ethyl maltol, 0.1-3 parts of furanone, 0.1-5 parts of raspberry ketone, 1-25 parts of cinnamyl alcohol, 1-10 parts of cinnamyl acetate, 1-15 parts of vanillin, 1-15 parts of ethyl vanillin and 0.1-2 parts of coffee extract. The electronic cigarette tar with a coca cola taste is rich and plump in fragrance, and can achieve an effect similar to a pleasant feeling brought by drinking coca cola. The invention further provides a preparation method of the electronic cigarette tar. The method is simple and easy to operate, and is suitable for industrial production.

Owner:SHENZHEN HANGSEN STAR TECH

Cutting Bar for Dental Use

Provided is a cutting bar for dental use that can cut both dentin and enamel with a single bar unanesthetically and efficiently without causing any pain or unpleasant sensation in a patient, in particular, a cutting bar for dental use that can fundamentally solve the problem in that a cutting blade of a cutting bar rotating at low speed comes into contact with hard enamel present in a surface layer of a tooth during cutting of carious dentin to cause unpleasant sensation in a patient. A cutting bar for dental use includes a head in which a cutting blade is formed; a neck leading to the head; and a handle joined to the neck through an intermediation of a joint portion, wherein diamond abrasive grains are electrodeposited in a predetermined range extending from a substantially maximum diameter portion of the head to the neck.

Owner:NIHON UNIVERSITY

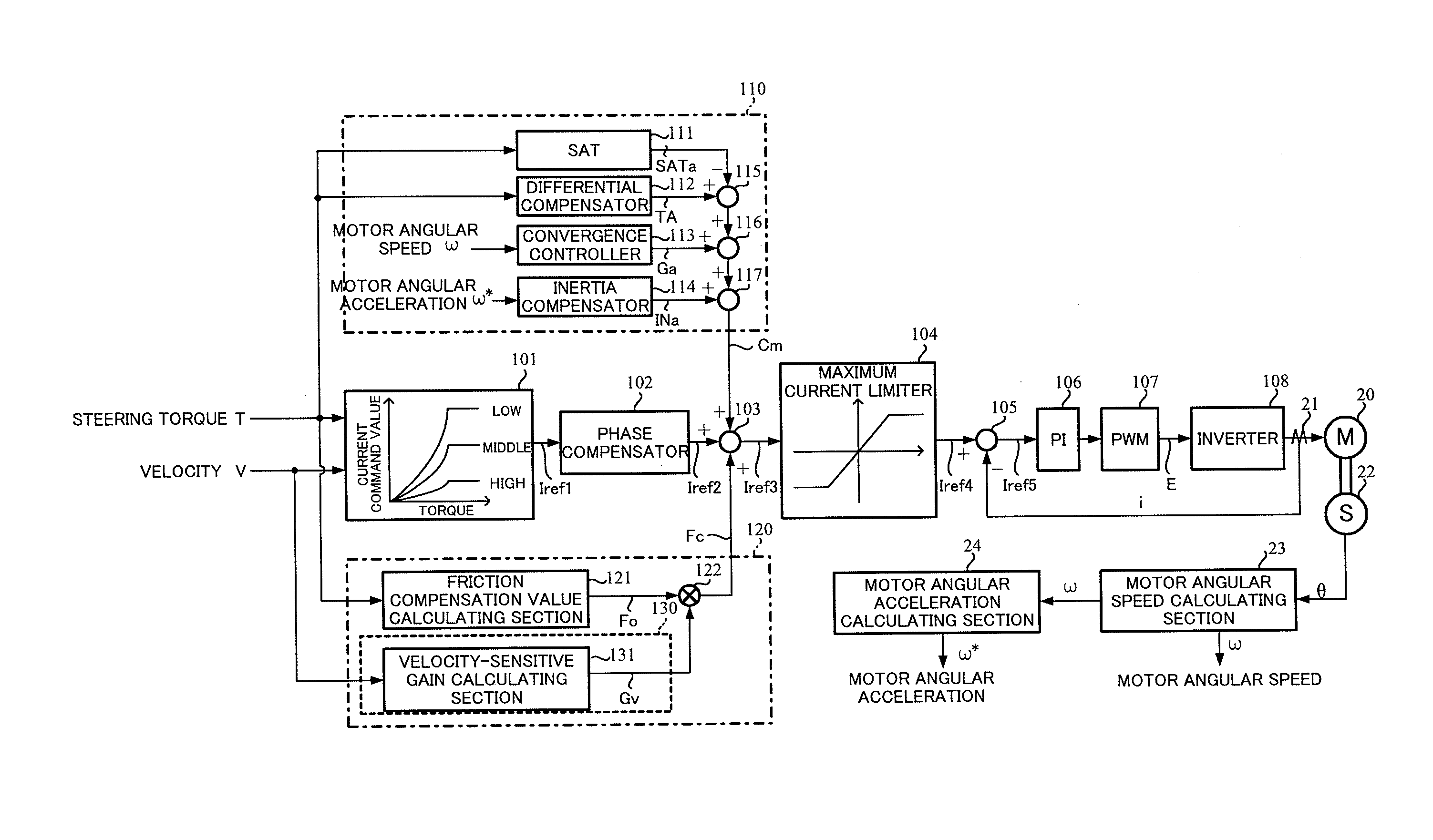

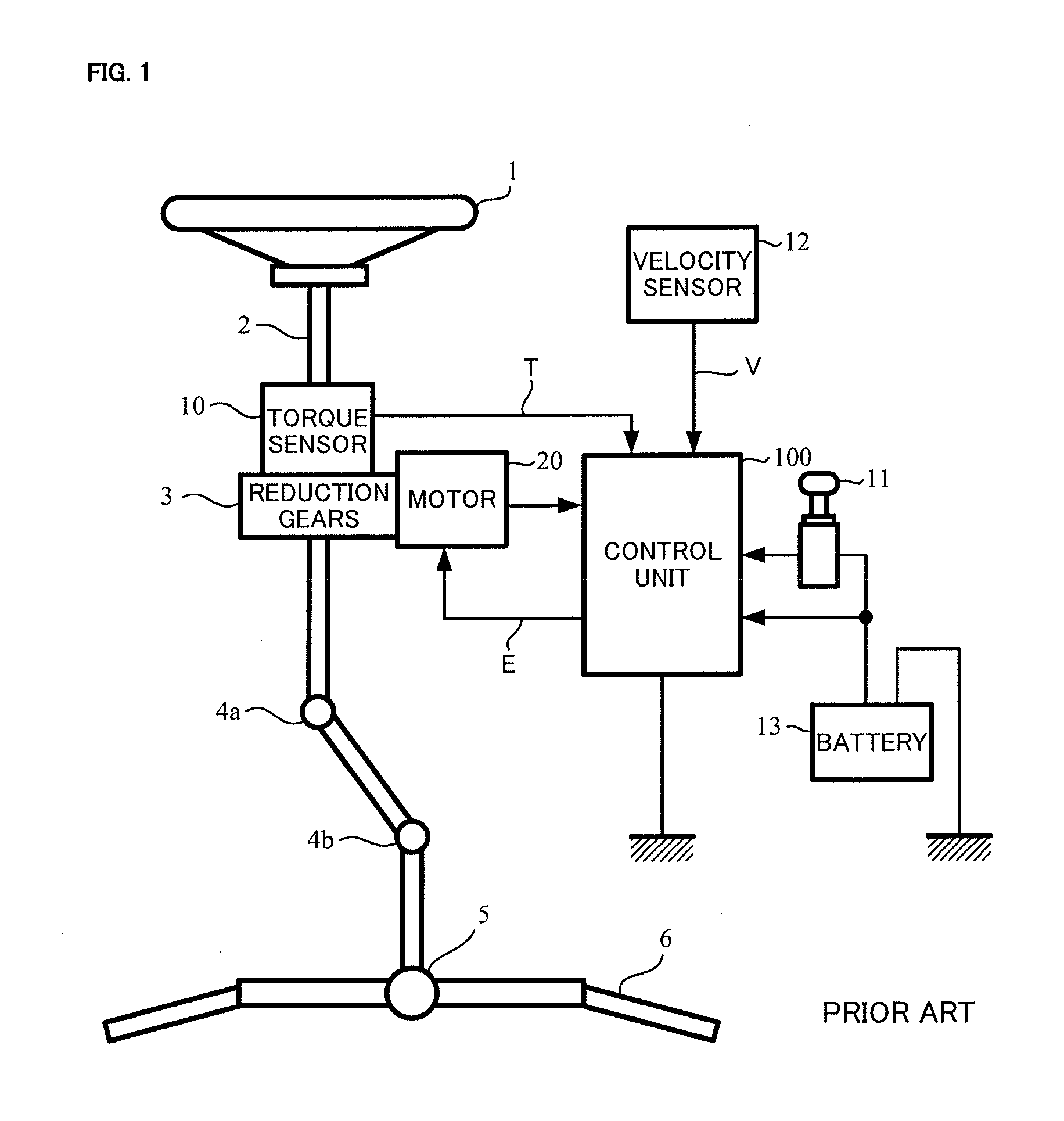

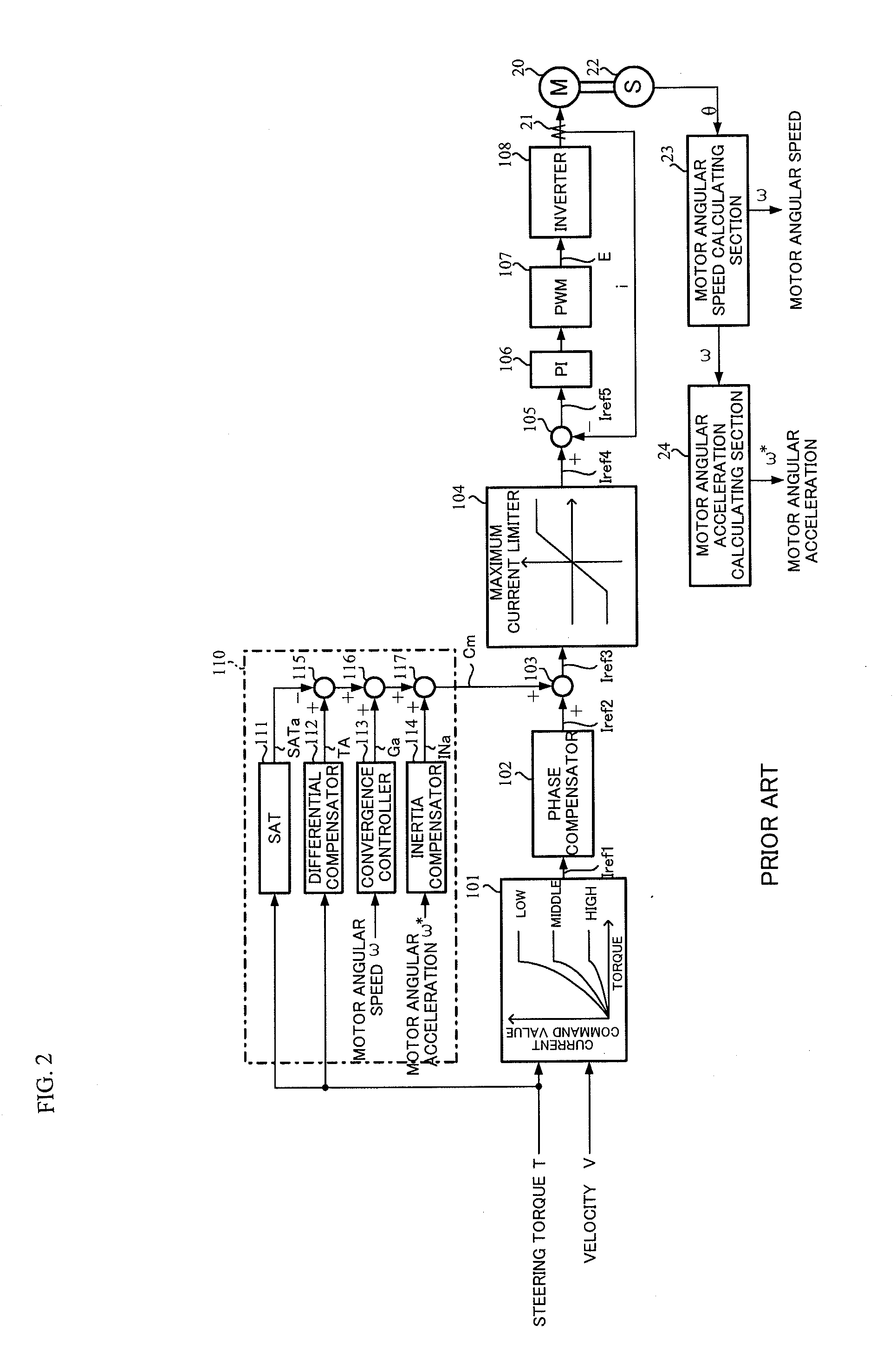

Electric power steering apparatus

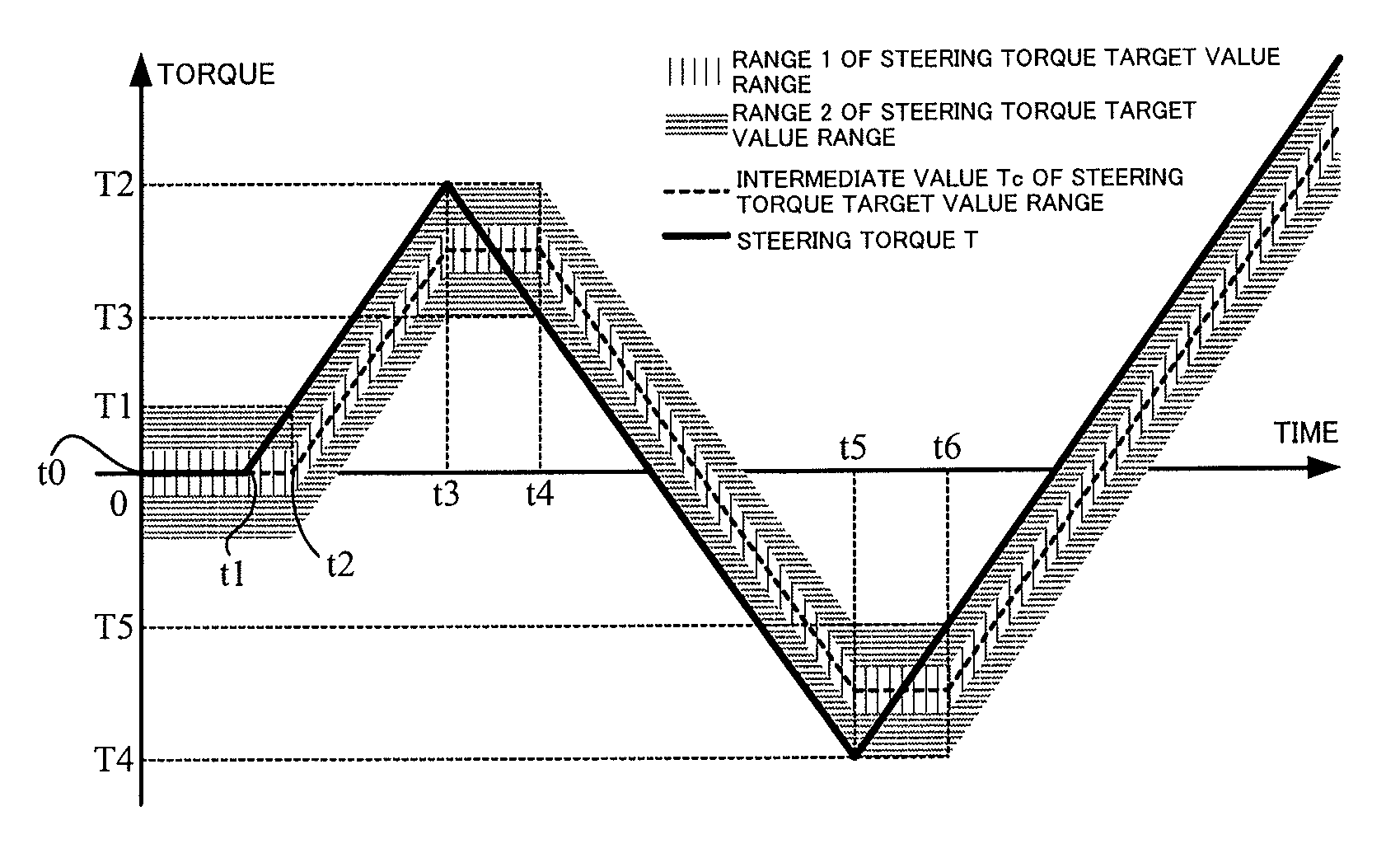

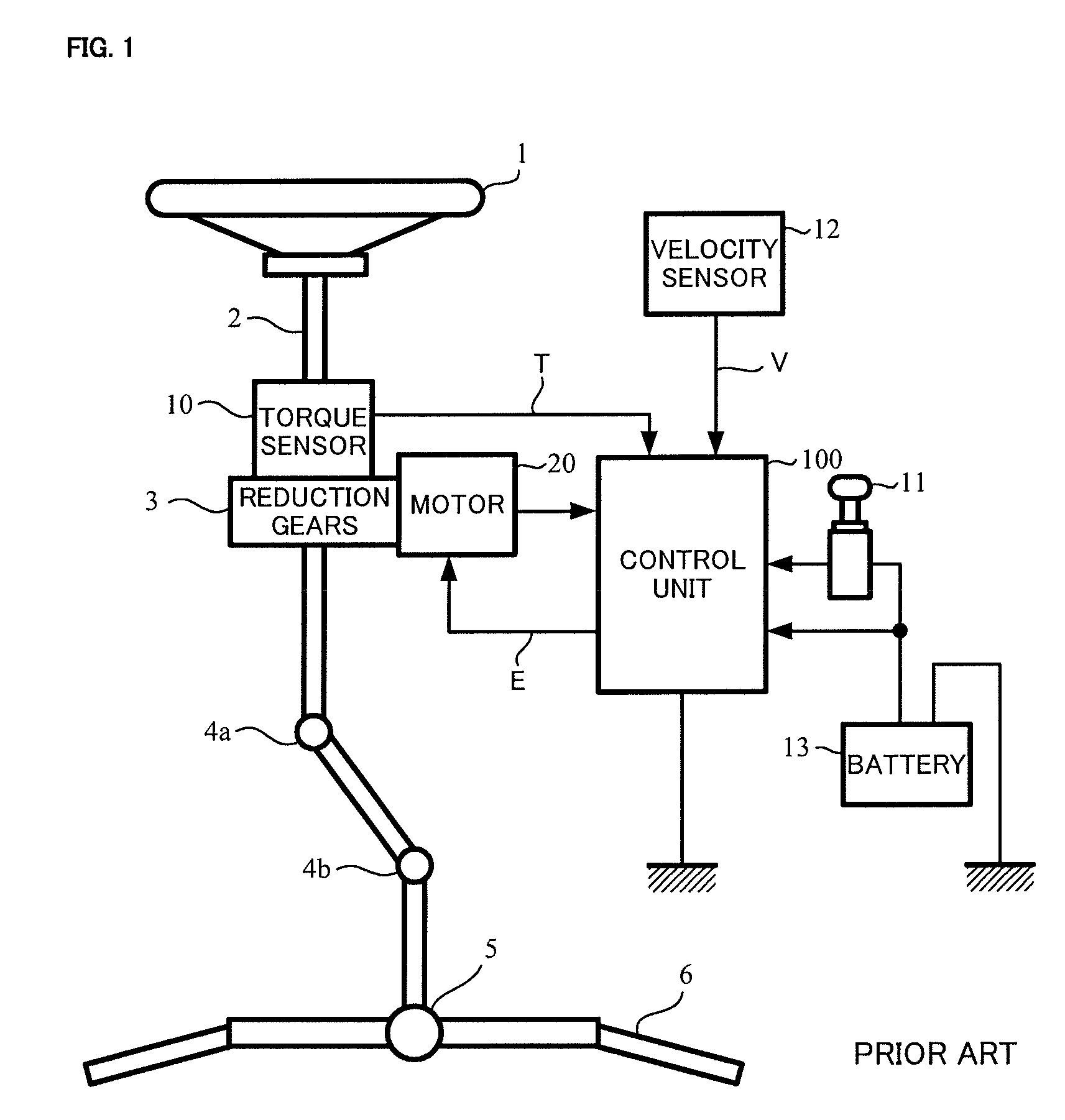

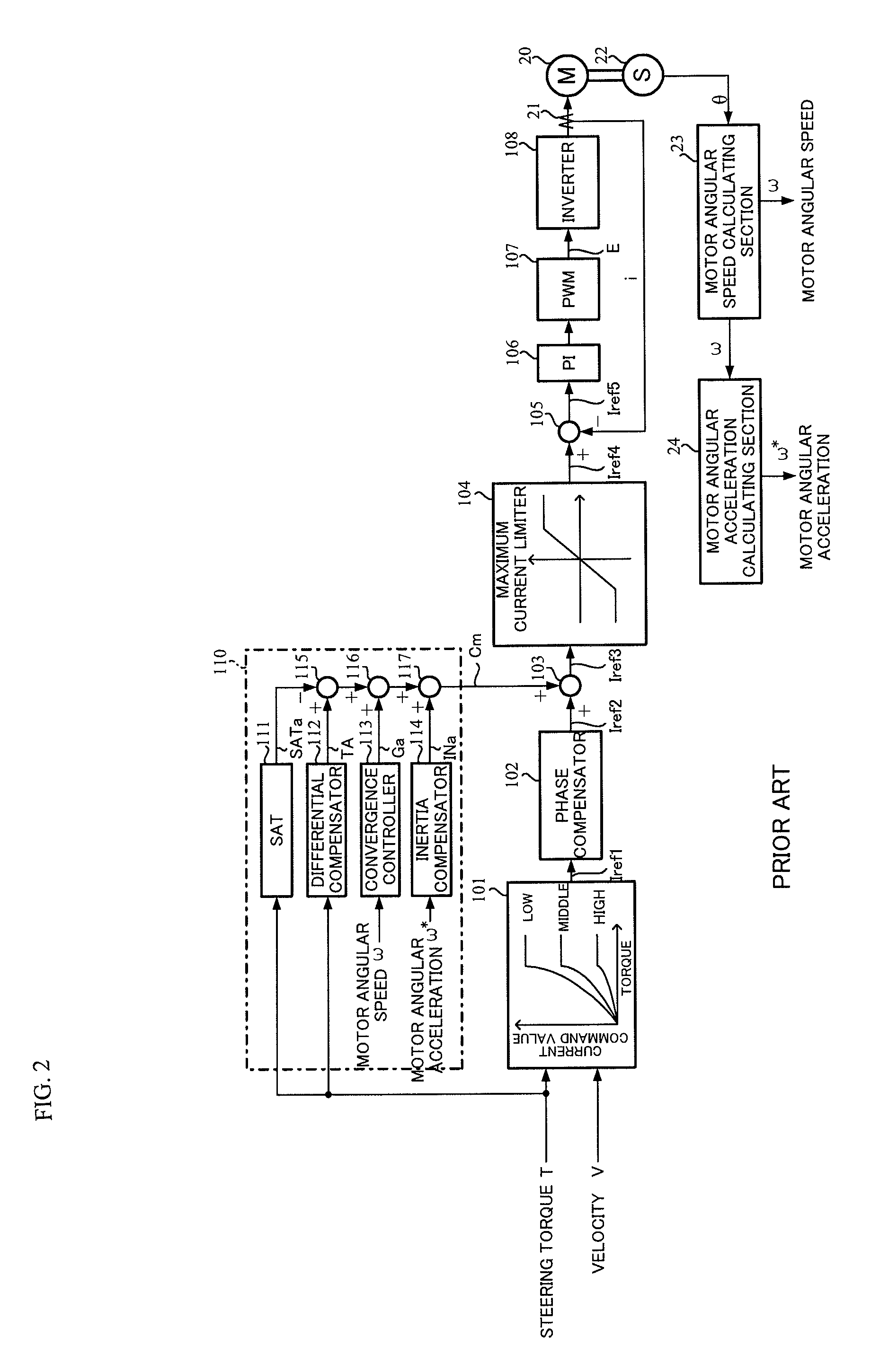

ActiveUS20110276229A1Without uncomfortable feelingFeel comfortableSteering initiationsDigital data processing detailsElectric power steeringStatic friction

[Problem]An object is to provide an electric power steering apparatus that compensates both a static friction and a dynamic friction, performs the switching between a static friction compensation and a dynamic friction compensation smoothly and without unpleasant sensation in order to achieve a natural comfortable steering feeling.[Means for Solving]In an electric power steering apparatus wherein a current command value is calculated based on at least a steering torque, and a motor is controlled by a current control value calculated based on said current command value to provide a steering assist force to a steering mechanism, wherein: there is provided a friction compensator calculating a friction compensation value for compensating friction to said steering mechanism on the basis of said steering torque, and said current command value is corrected by said friction compensation value.

Owner:NSK LTD

Electric power steering apparatus

ActiveUS8825301B2Without uncomfortable feelingFeel comfortableDigital data processing detailsSteering initiationsElectric power steeringStatic friction

An electric power steering apparatus that compensates both a static friction and a dynamic friction, performs the switching between a static friction compensation and a dynamic friction compensation smoothly and without unpleasant sensation in order to achieve a natural comfortable steering feeling. In an electric power steering apparatus wherein a current command value is calculated based on at least a steering torque, and a motor is controlled by a current control value calculated based on said current command value to provide a steering assist force to a steering mechanism, wherein: there is provided a friction compensator calculating a friction compensation value for compensating friction to said steering mechanism on the basis of said steering torque, and said current command value is corrected by said friction compensation value.

Owner:NSK LTD

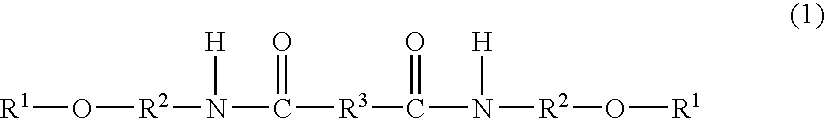

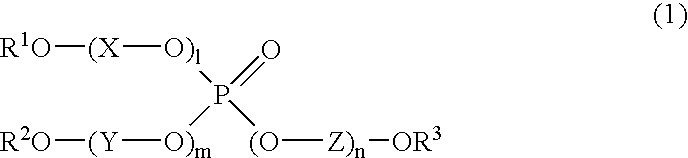

Method of treating skin with a composition comprising a phosphoric triester and a skin activating component

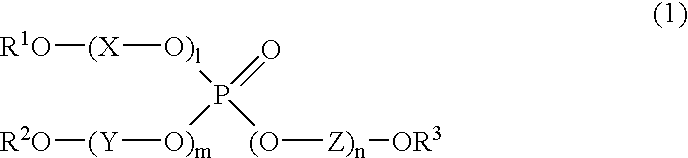

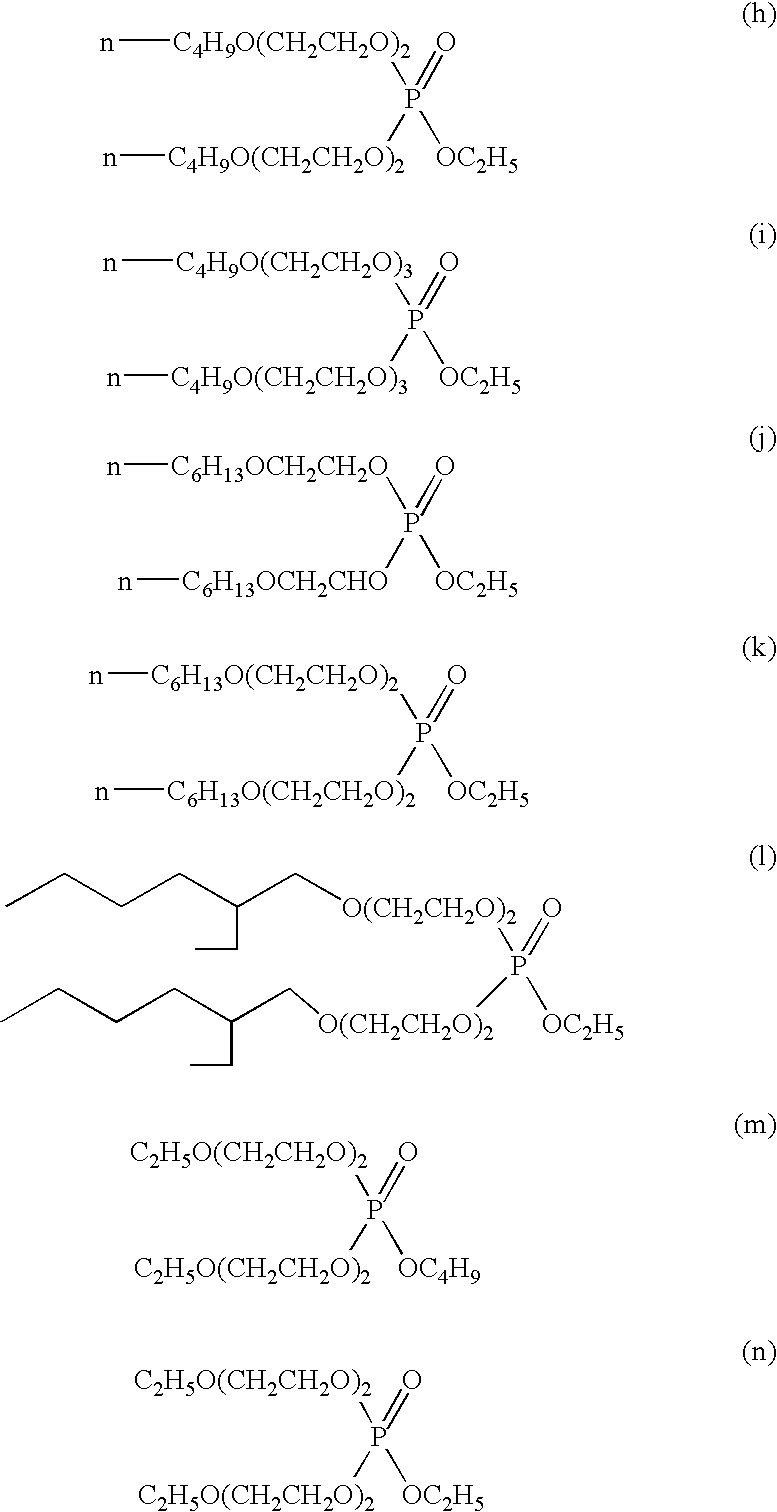

InactiveUS20050123578A1Improve permeabilityGood effectCosmetic preparationsToilet preparationsWrinkle skinSkin complexion

The invention relates to a cosmetic comprising (A) a phosphoric triester represented by the general formula (1): wherein R1 and R2 are independently an alkyl group having 1 to 8 carbon atoms, R3 is an alkyl group having 1 to 4 carbon atoms, X, Y and Z are independently an alkylene group having 2 or 3 carbon atoms, l and m are independently a number of 1 to 10, and n is a number of 0 to 10, and (B) a skin activating component. The cosmetic is excellent in moisturizing effect; the effects of preventing and remedying skin roughness; the effects of preventing the firm and resilient skin from declining and remedying the declined skin; the effects of preventing a complexion from dulling and remedying a dull looking face; the effects of preventing and remedying the conspicuousness of pores of the skin and pimples caused by excess sebum, microorganisms or keratonosis; the effects of preventing development of wrinkles and remedying the wrinkled skin; and the effects of preventing and remedying spots and freckles, and moreover gives users a pleasant feeling upon use.

Owner:KAO CORP

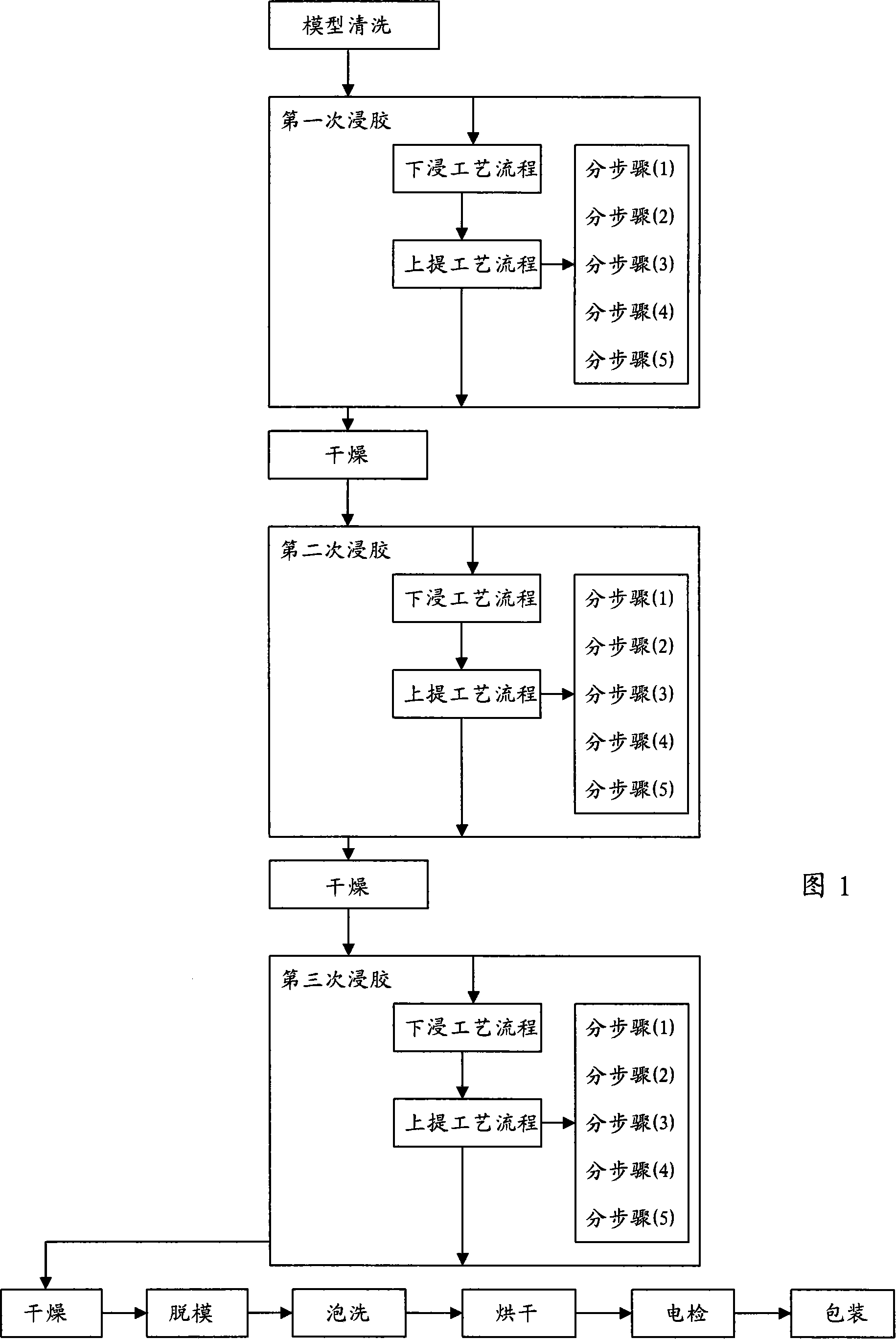

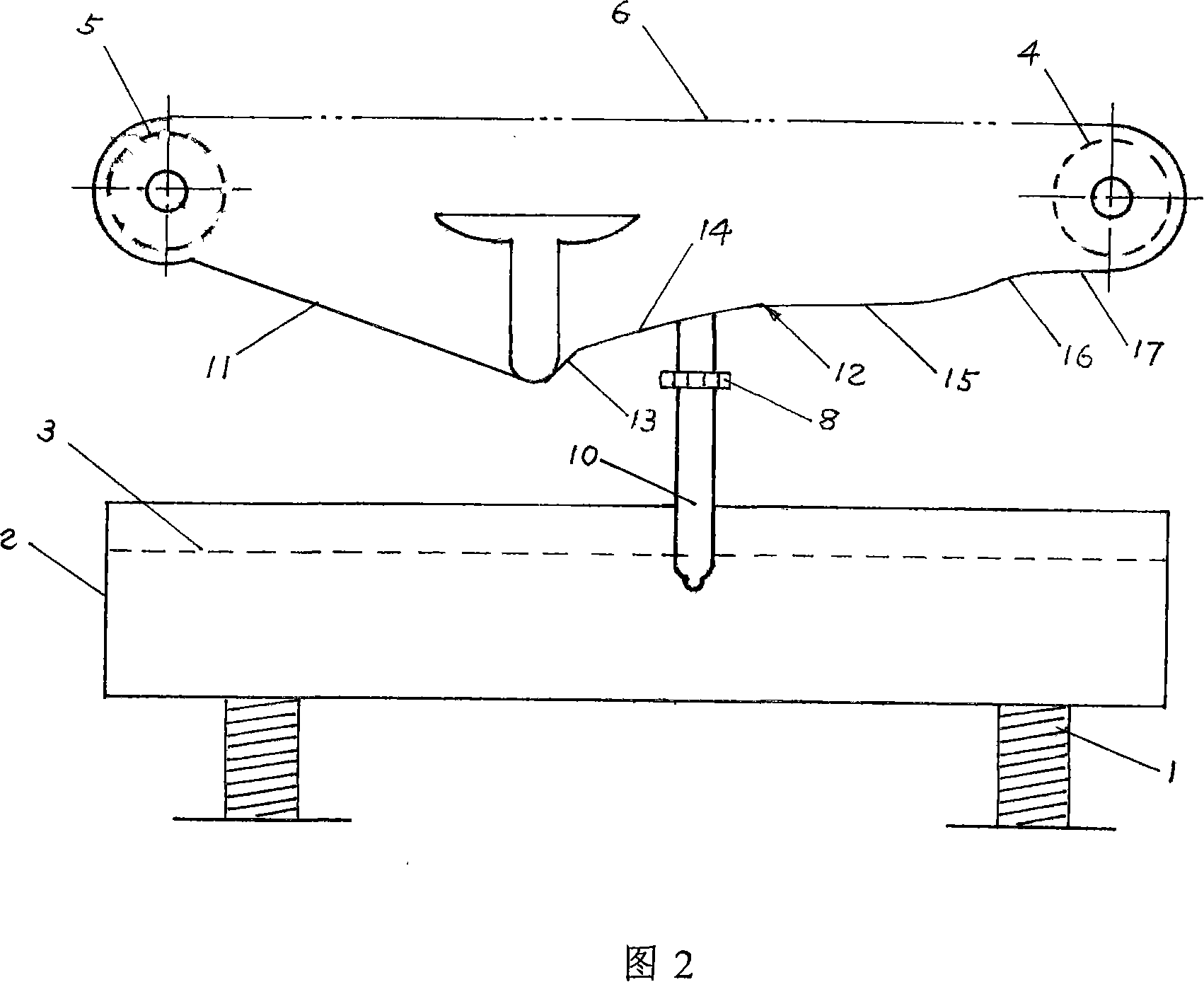

Impregnating technology for the condom production and impregnating equipment thereof

InactiveCN101138874ASolve the homogenization problemPromote homogenizationDomestic articlesCoatingsElectricityInternational standard

A dipping technological method and dipping equipments are used for producing condom. The method includes the steps of cleaning, gum dipping, exsiccating, demoulding, dunking and washing, drying, electric inspecting and packing of a model etc. The gum dipping includes the technological flows of dipping down and lifting up of the model, and the lifting up includes three to six sub-steps of three to six segments of liner or curvilinear lifting according to different oblique angle and different lifting heights. The equipments include a screw lifting rod, a dripping groove, latex, a machine frame, double up-turned and down-turned chain wheels, a motor, a double chain, a multi-chain plate, a model base, a model and a double-guideway. The double-guideway includes a dripping down segment and a lifting up segment. The lifting up segment includes three to six segments of liner or curvilinear segments according to different oblique angle and different lifting heights. The method and the equipments can solve the problem of the uniformity of the film and can produce the thin product to improve the sensitivity, comfort and pleasant feeling when using; at the same time the cost of the raw material is saved more than 10 percent, which greatly reduces the production cost; the method and the equipments can be widely applied to the production of a super-thin natural latex condom which achieves the international standard.

Owner:QINGDAO DOUBLE BUTTERFLY GROUP

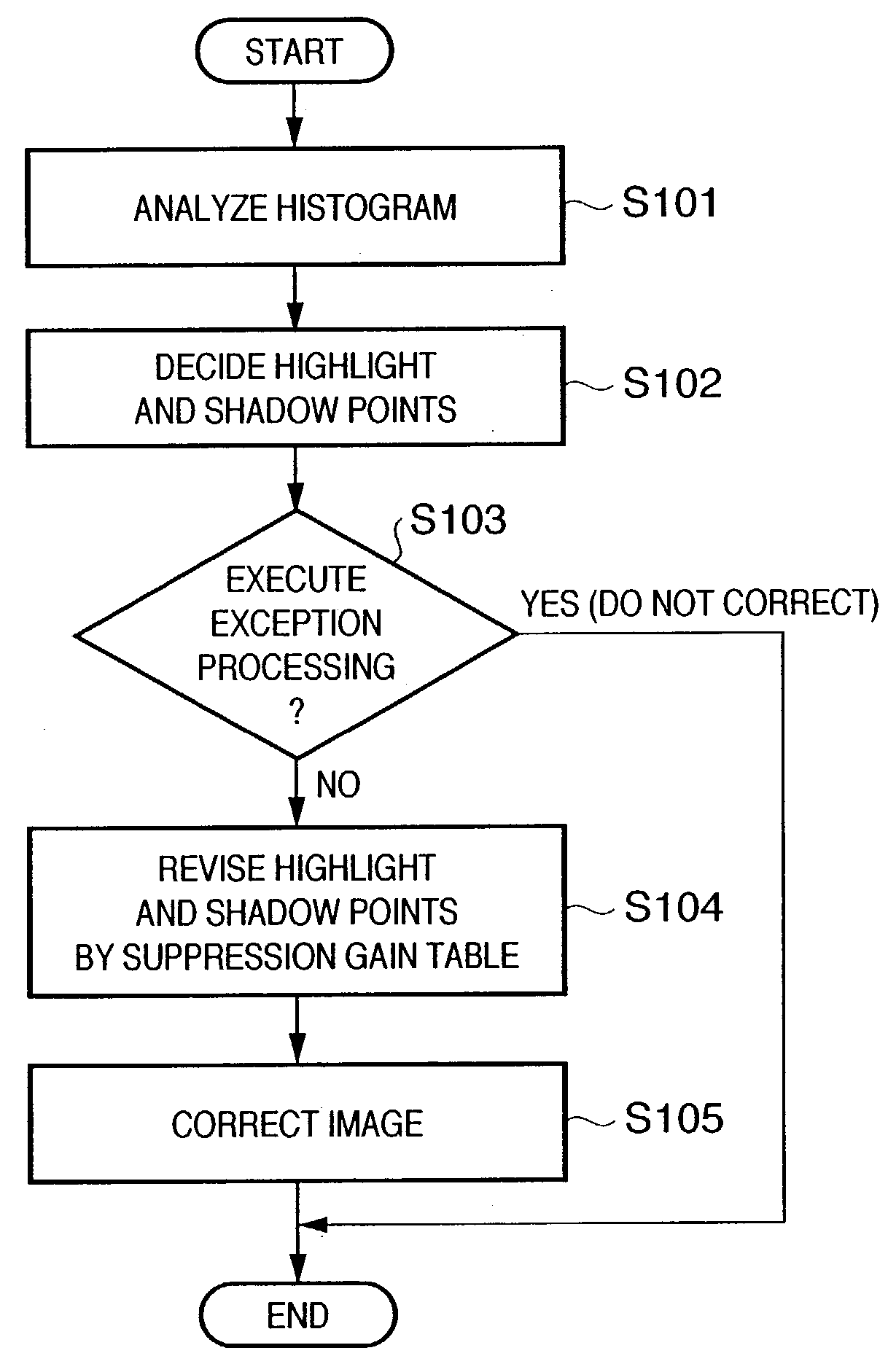

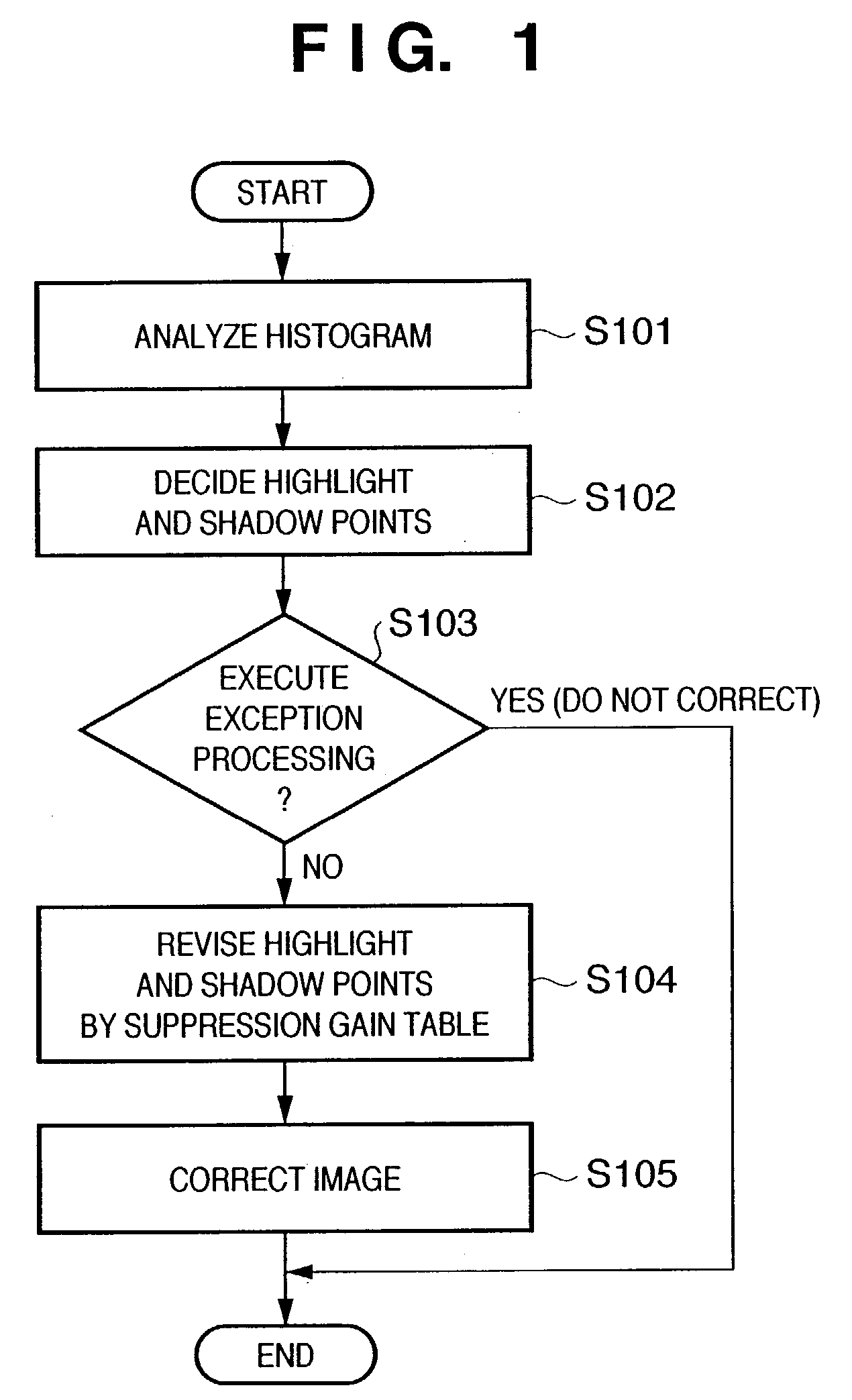

Image processing apparatus and method

The color reproduction performance of image input / output devices has been improved greatly and even very slight changes in color ascribable to a color balance correction are recognizable. As a consequence, there are cases where a specific color shift, such as a color shift in the yellow or blue direction, gives a disagreeable sensation when applied with regard to a slight color change in the color of the human skin, which is a memory color. Accordingly, highlight and shadow points are detected based upon the histogram of an image, color information of the highlight and shadow points is revised by adjusting average color difference information based upon a hue angle acquired from average color difference information of image data having luminance levels of the highlight and shadow points, and the image is corrected based upon the revised color information of the highlight and shadow points.

Owner:CANON KK

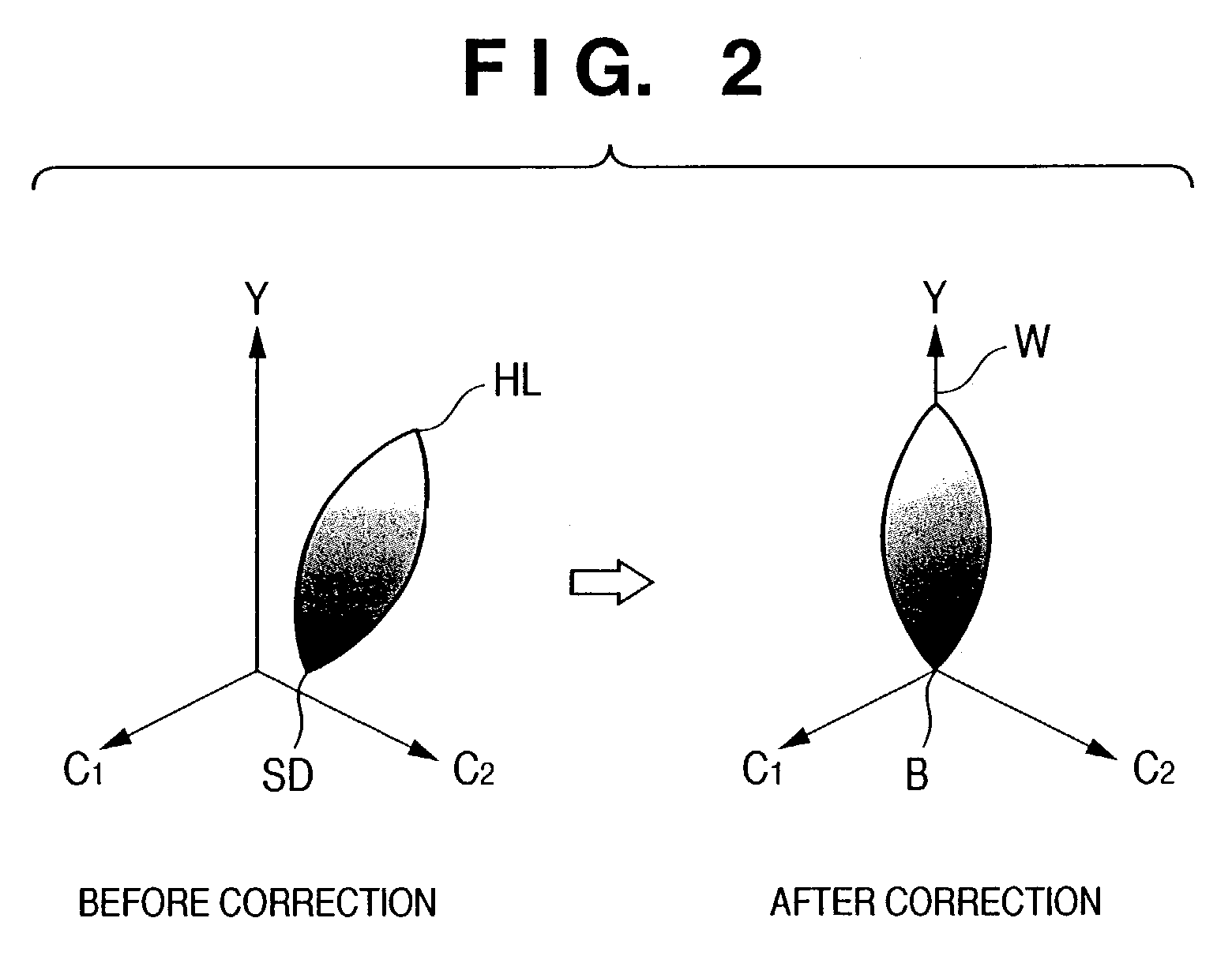

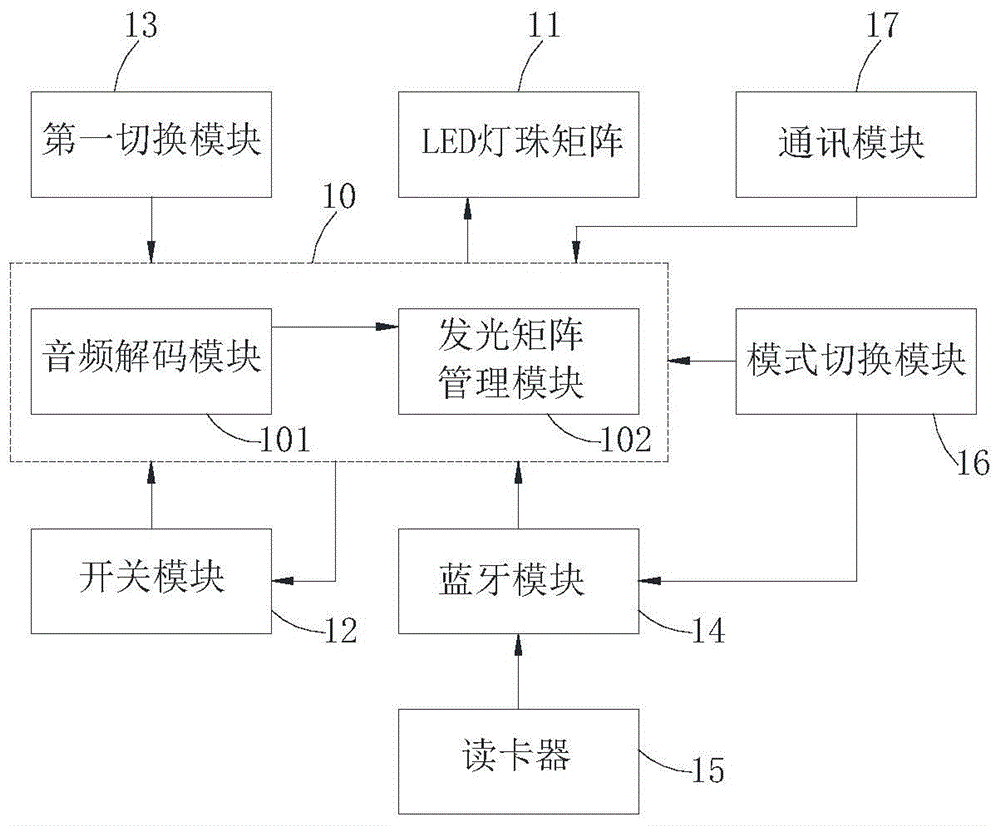

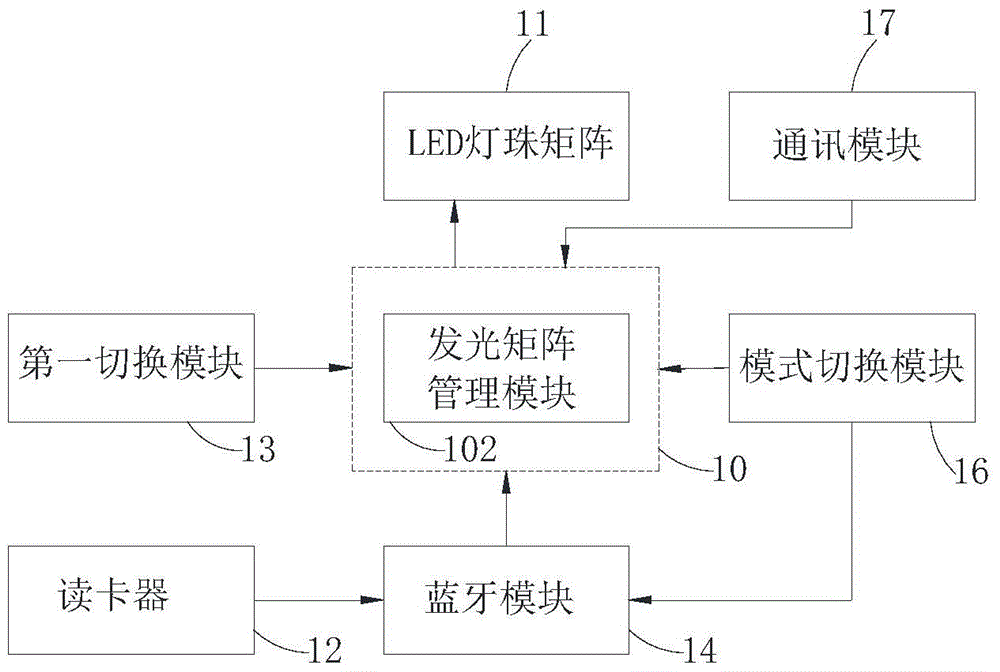

Acoustic-optical matching system and method

InactiveCN105744431AImprove depressed spiritIncrease pleasureElectroluminescent light sourcesFrequency/directions obtaining arrangementsFeature vectorPleasant Feeling

The invention discloses an acoustic-optical matching system which comprises a conversion module used for converting an audio signal to frequency components of different frequency points of a frequency domain, a sorting module used for sorting each frequency component, a value-taking module used for taking a value with the highest amplitude from a result after sorting as an audio feature value, a comparison module used for comparing the audio feature value and multiple groups of to-be-selected light-emitting feature vectors, a selection module used for selecting one group of light-emitting feature vectors which are the same as or are most similar to the audio feature value from the groups of to-be-selected light-emitting feature vectors, and a display module used for displaying the light-emitting feature vectors. According to the acoustic-optical matching system and method, the light and the audio frequency are matched, so that the pleasant feeling can be improved, or people can feel relaxed, and furthermore, when the people have high pressure, listening more to sounds at the specific frequency helps to relieve the pressure.

Owner:深圳市因为科技有限公司 +1

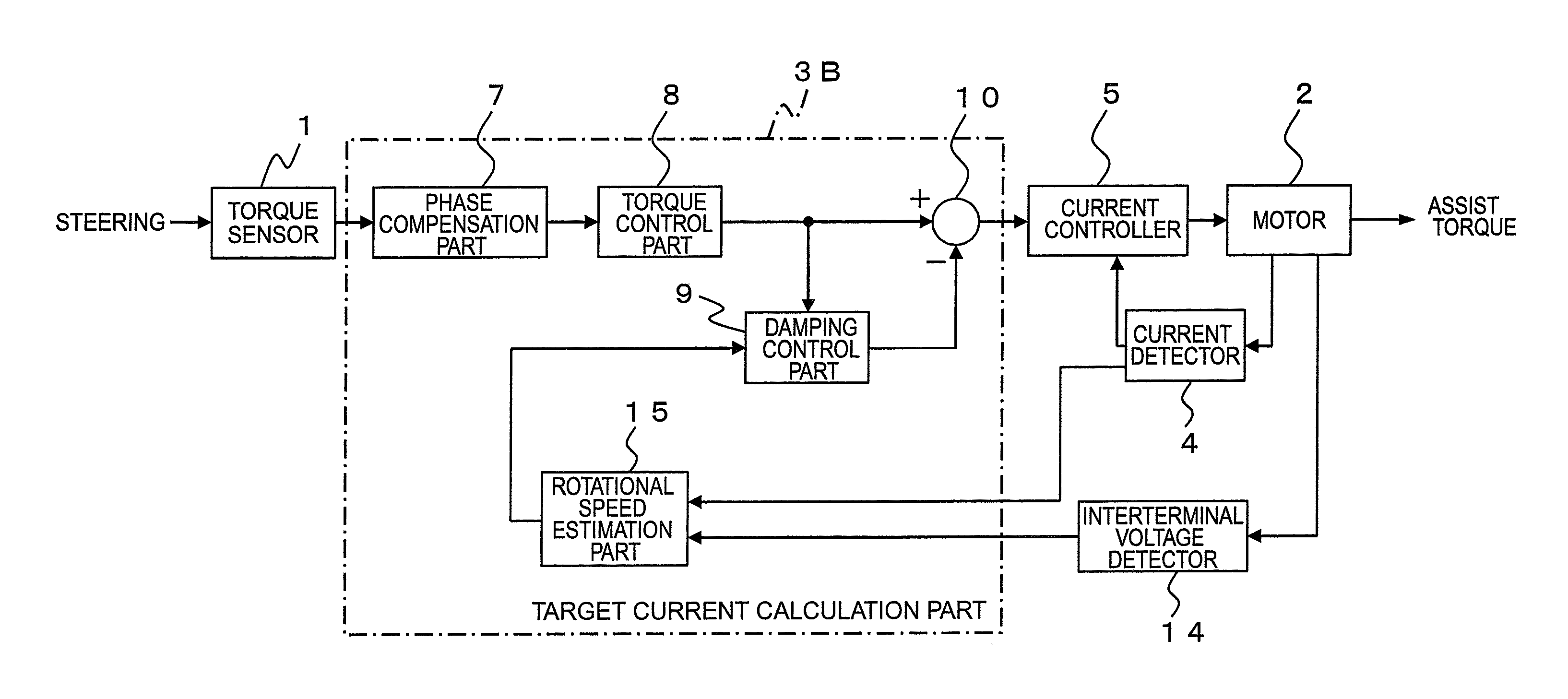

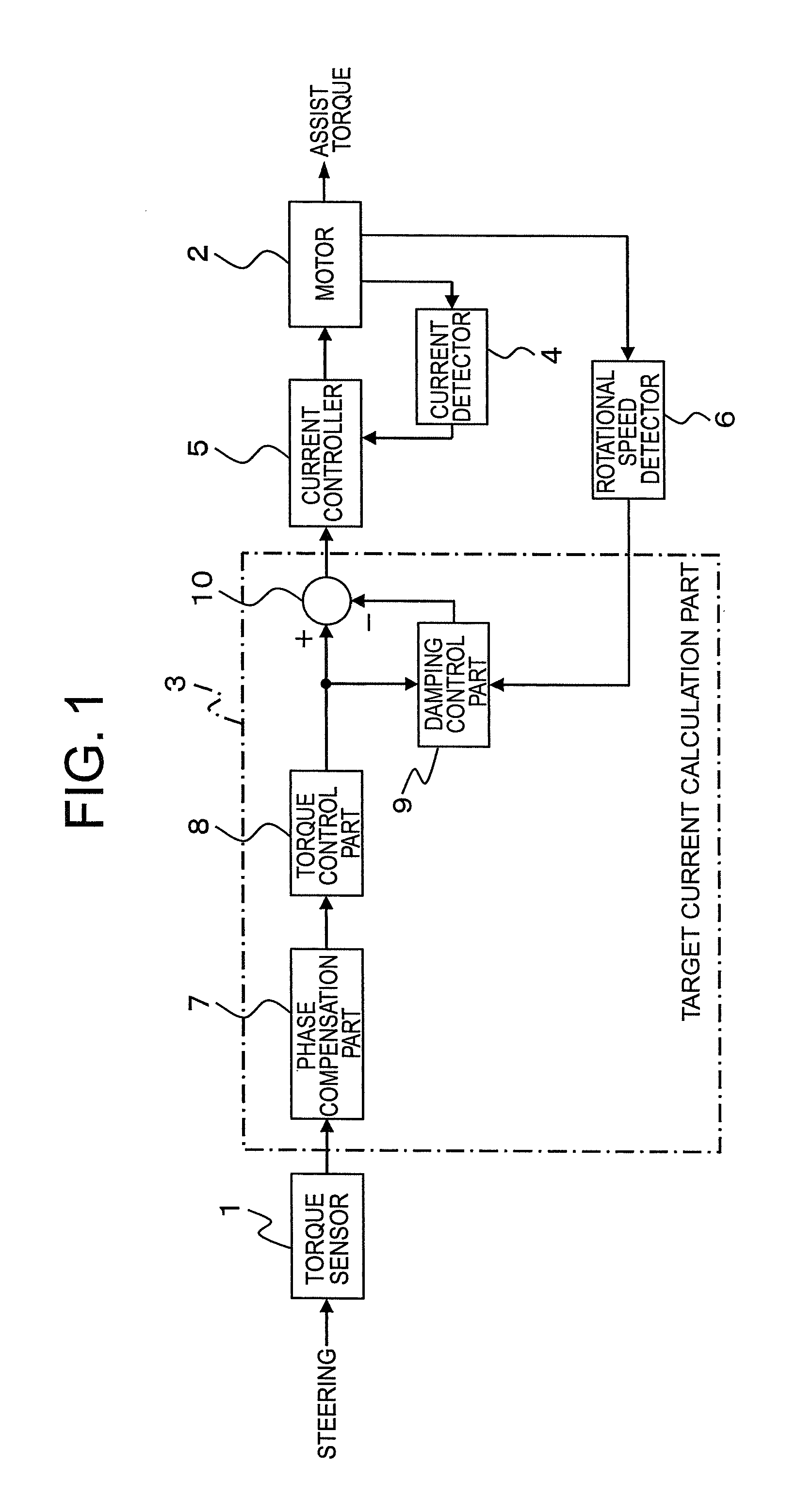

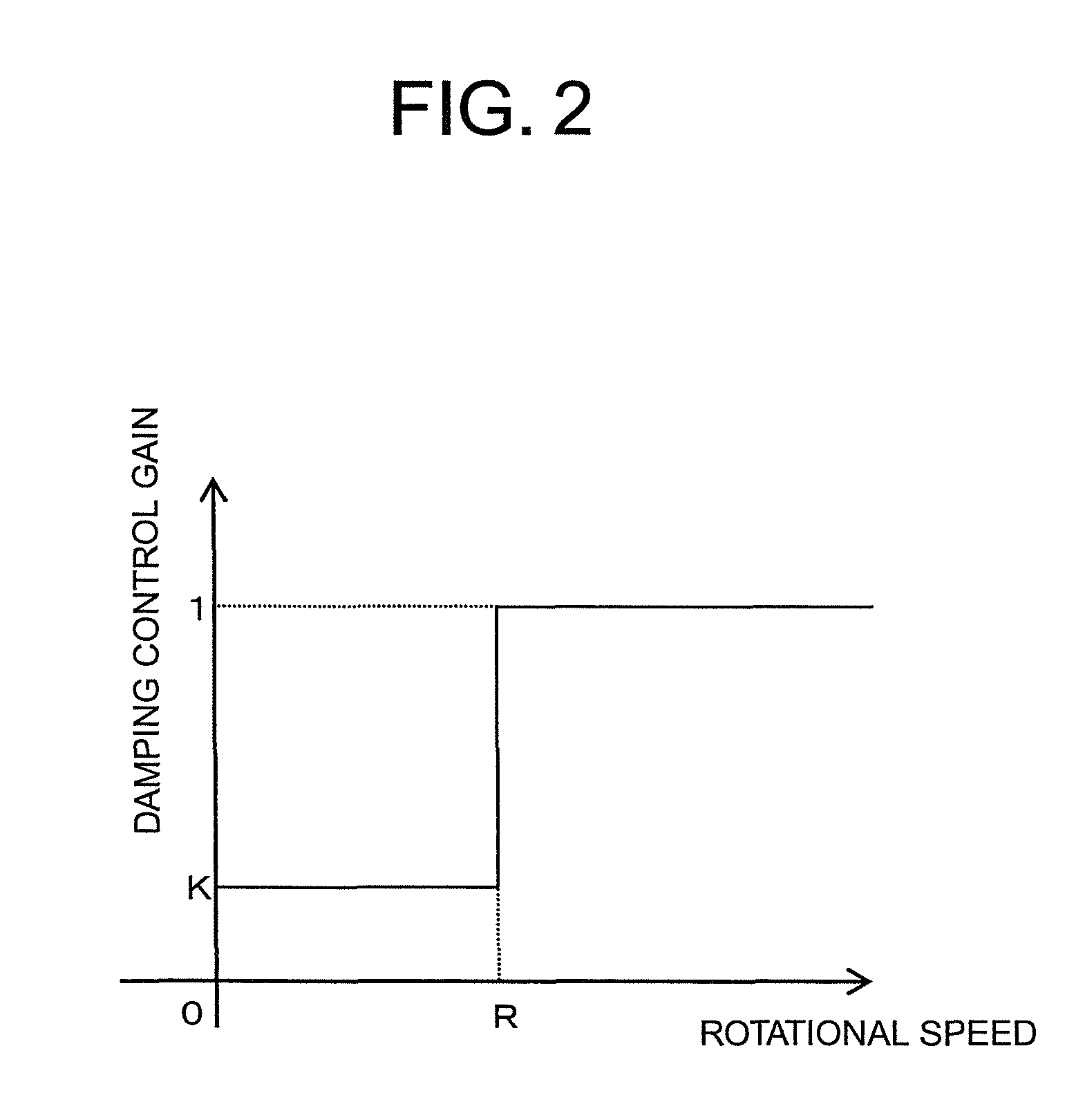

Electric power steering control apparatus

InactiveUS8423245B2Reducing steering torqueReduce vibrationSteering initiationsDigital data processing detailsElectric power steeringPleasant Feeling

An electric power steering control apparatus can reduce steering torque even in a steering holding state or a slight steering state without providing an unpleasant feeling to a driver. The apparatus includes a torque sensor for detecting steering torque generated by the driver for a vehicle, a motor for generating assist torque to assist the steering torque, a rotational speed detector for detecting the rotational speed of the motor, a torque controller for calculating an assist torque current corresponding to the assist torque based on the steering torque, and a damping control section for calculating a damping current to be added to the assist torque current to suppress vibrations generated in a steering system of the vehicle. The damping controller reduces a damping control gain to calculate the damping current when the rotational speed of the motor is equal to or less than a predetermined speed.

Owner:MITSUBISHI ELECTRIC CORP

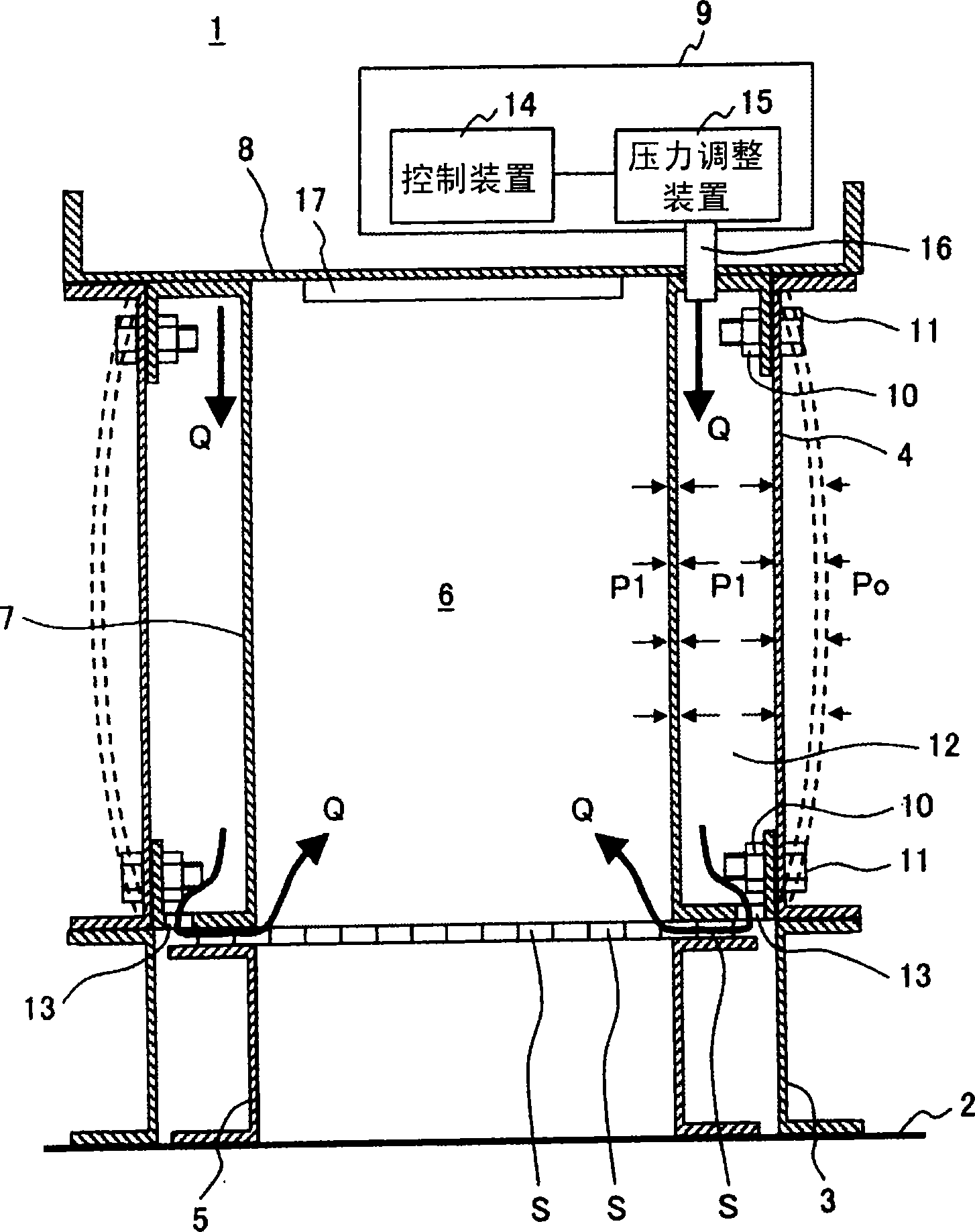

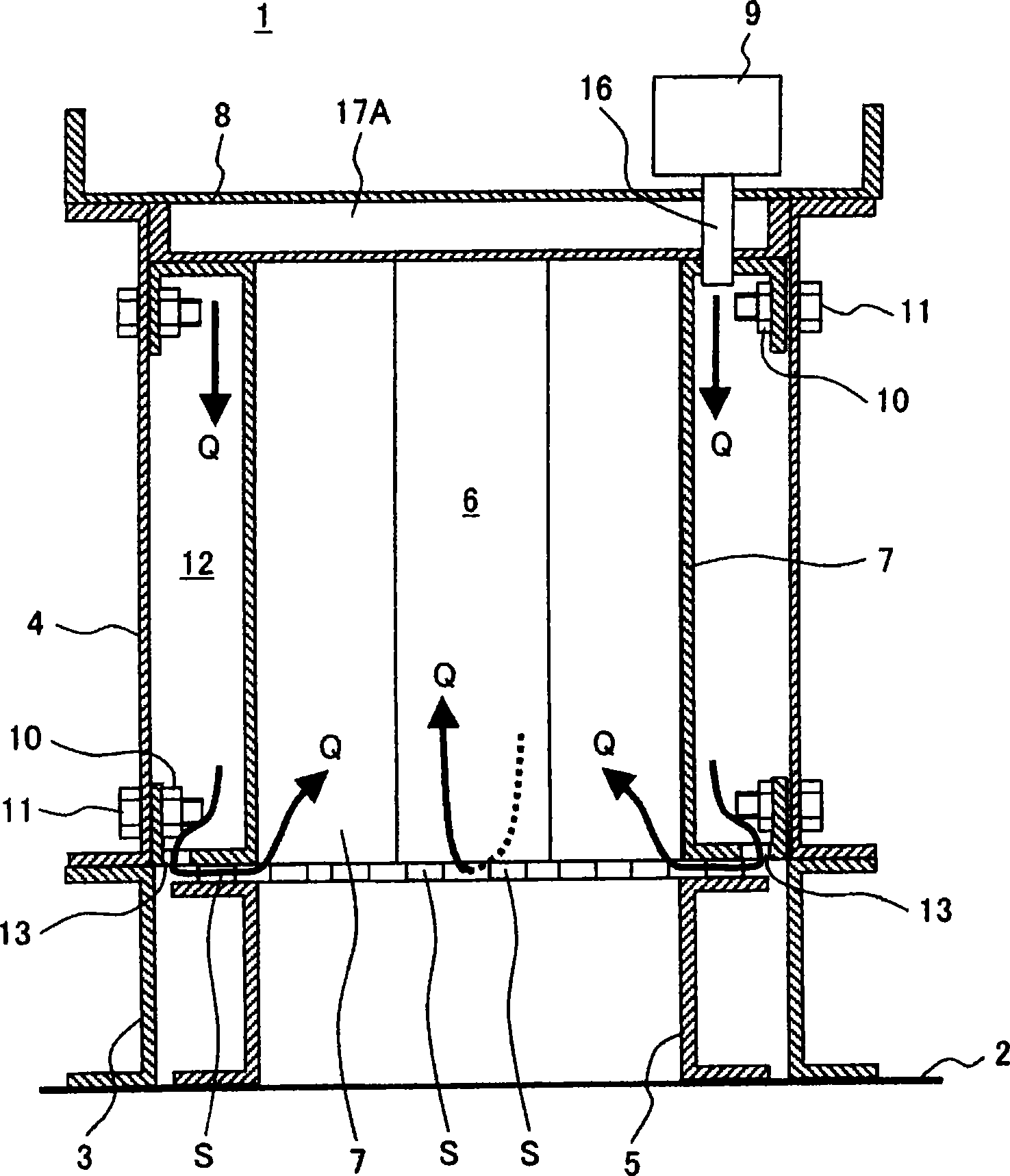

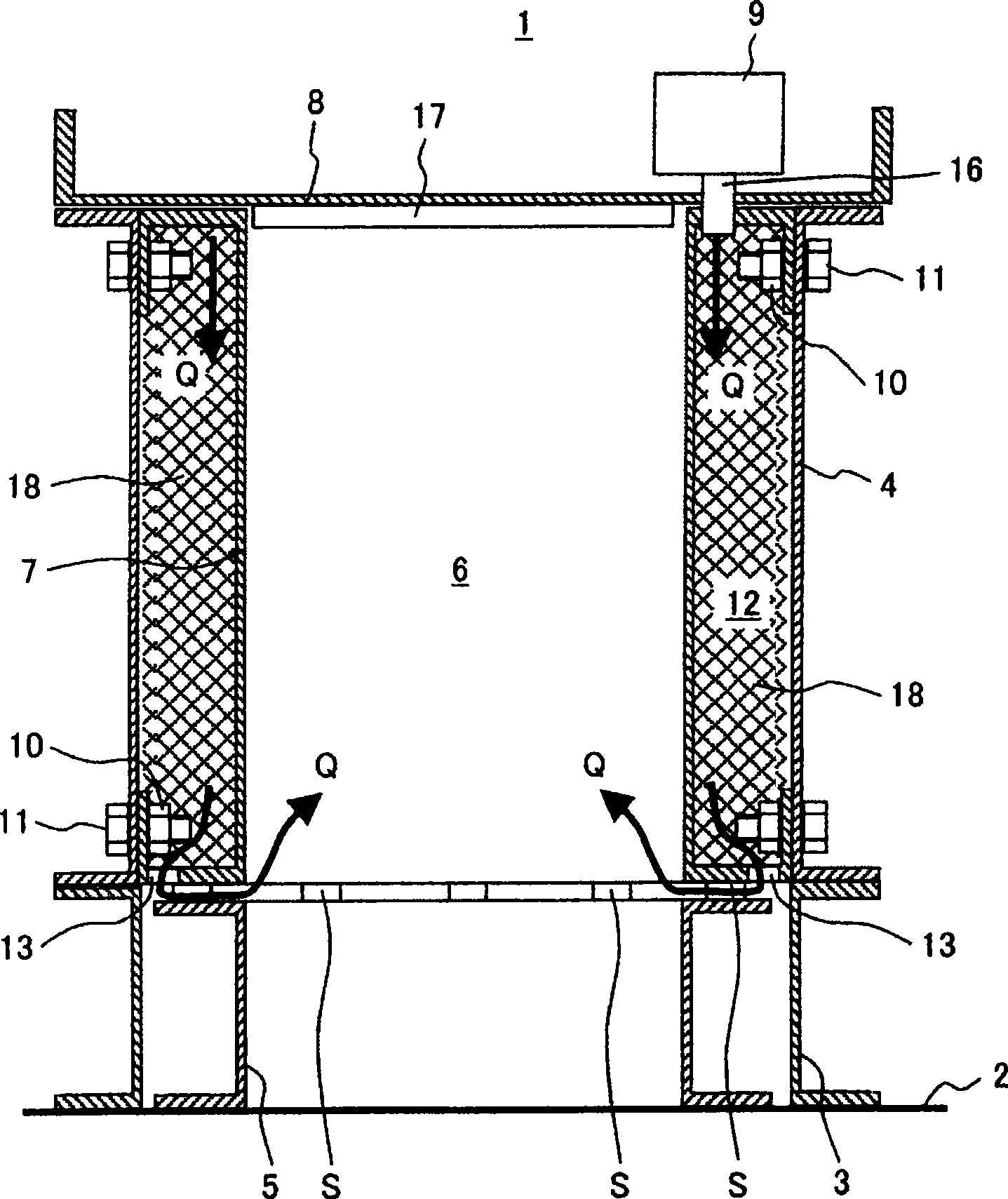

Elevator device

ActiveCN101428723ANo unpleasant feelingFix security issuesBuilding liftsPleasant FeelingAtmospheric pressure

The invention provides an elevator device which thoroughly solves the problems of the insecurity and unease to passengers caused by panel bending and the unease problem to the passengers caused by feeding and exhausting air for pressure governing. The elevator device of the invention is constructed by arranging an air channel which communicates the space between an outside panel and the inside panel of the elevator car chamber with the elevator car chamber at bottom of an inside panel, and supplying air to the space formed between the inside panel and the outside panel through an air pressure control unit or exhausting air from the space. The adoption of said method, the bending of the outside panel causes little affect on the inside panel, which solves the insecurity and unease problems to the passengers due to the bending panel. Moreover the air can not directly blow to the passengers in the elevator car, thereby not causing unhappy feelings to the passengers.

Owner:HITACHI LTD

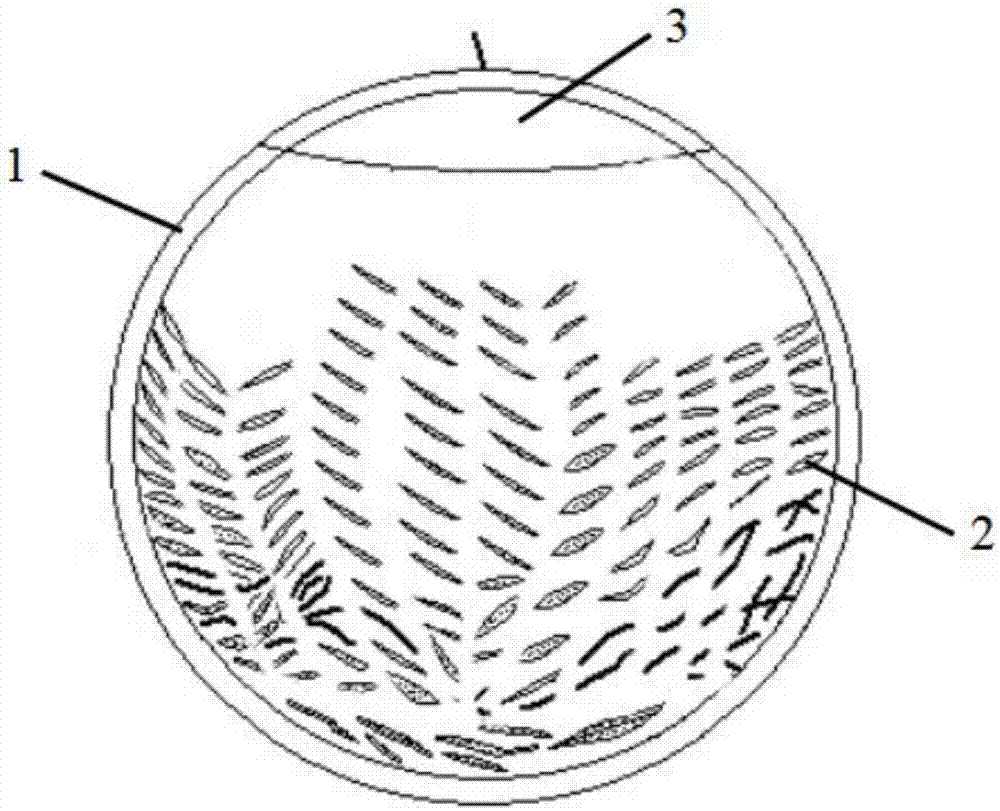

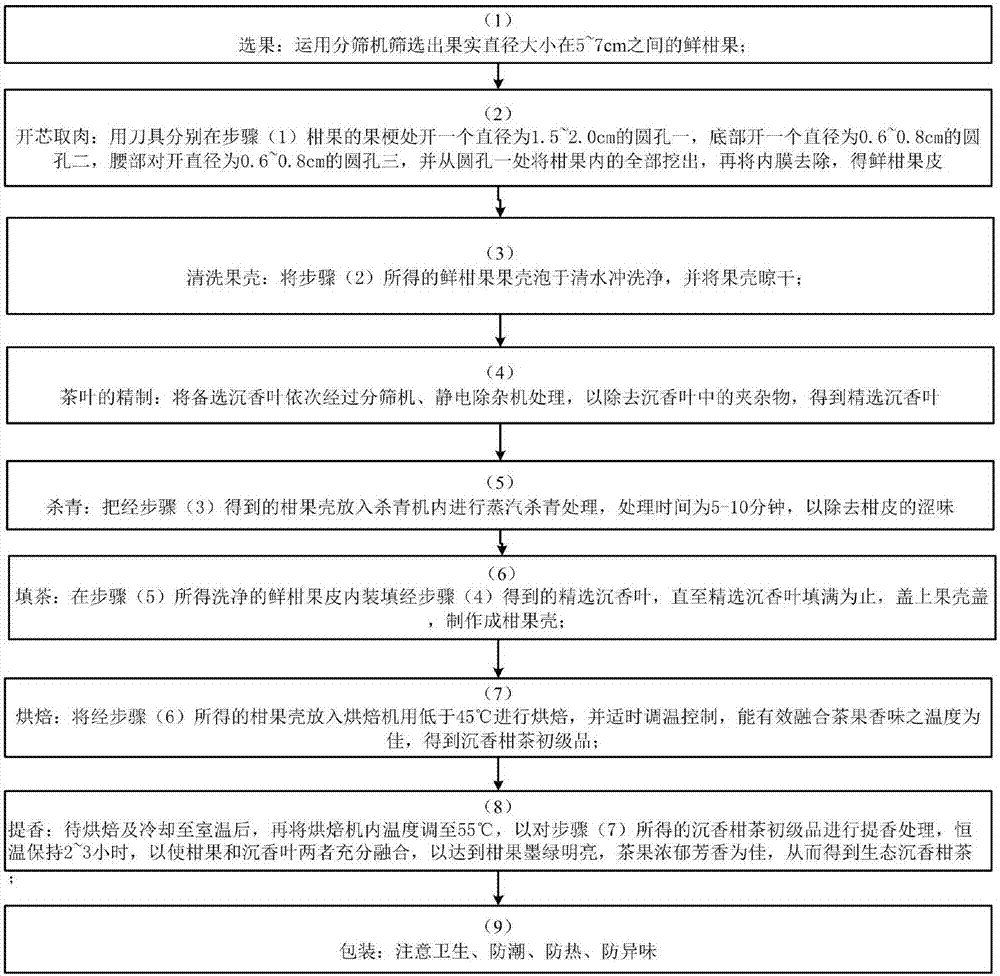

Ecological aloewood hesperidium tea and preparation method thereof

The invention discloses ecological aloewood hesperidium tea and a preparation method thereof. The preparation method comprises the following steps: selecting fruits, opening the fruit cores to select pulp, washing shells, refining tea leaves, carrying out fixation, filling tea, roasting, improving fragrance and packaging. The ecological aloewood hesperidium tea is prepared by using natural hesperidium and aloewood tea as raw materials by a special process without additive, the fruit fragrance of hesperidium and the mellow taste of tea are combined, and hesperidium and tea can mutually absorb essence to achieve unique flavor and excellent taste, and the health effect of hesperidium and tea can be achieved. According to the preparation method, the preparation process is simple and the production cost is low, a pleasant feeling is brought for people after being taken, and the hesperidium tea along with sweet aftertaste brings health life for human beings.

Owner:杨广汉

Display device and display control method

ActiveUS8933975B2Reducing unpleasant sensationInsufficient brightnessCathode-ray tube indicatorsInput/output processes for data processingComputer graphics (images)Display device

Provided is a display device capable of reducing a visually unpleasant sensation experienced by a user. This display device includes a display panel displaying a video picture, a backlight unit disposed on a back surface of the display panel and including a light sources for each region obtained by dividing the display panel into regions, a region characteristic amount detection unit detecting a characteristic amount of an image of each of the divided regions, a full screen characteristic amount detection unit detecting a characteristic amount of an image of the overall display panel, a region brightness determination unit determining an emission brightness of the respective light sources corresponding to each of the regions based on the detected characteristic amount, and the detected characteristic amount of the image of the overall display panel, and a backlight drive unit driving the respective light sources to emit light at the determined emission brightness.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

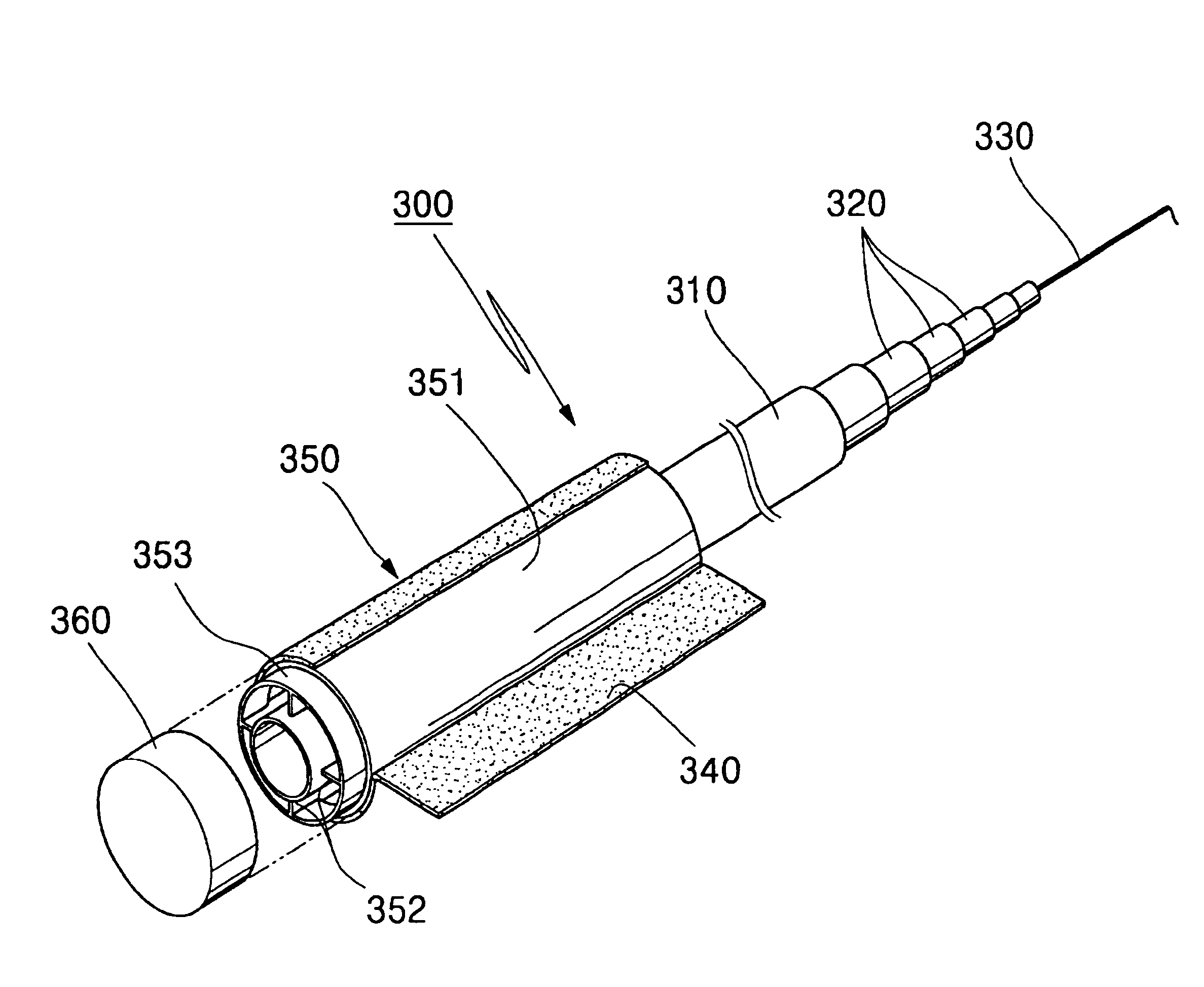

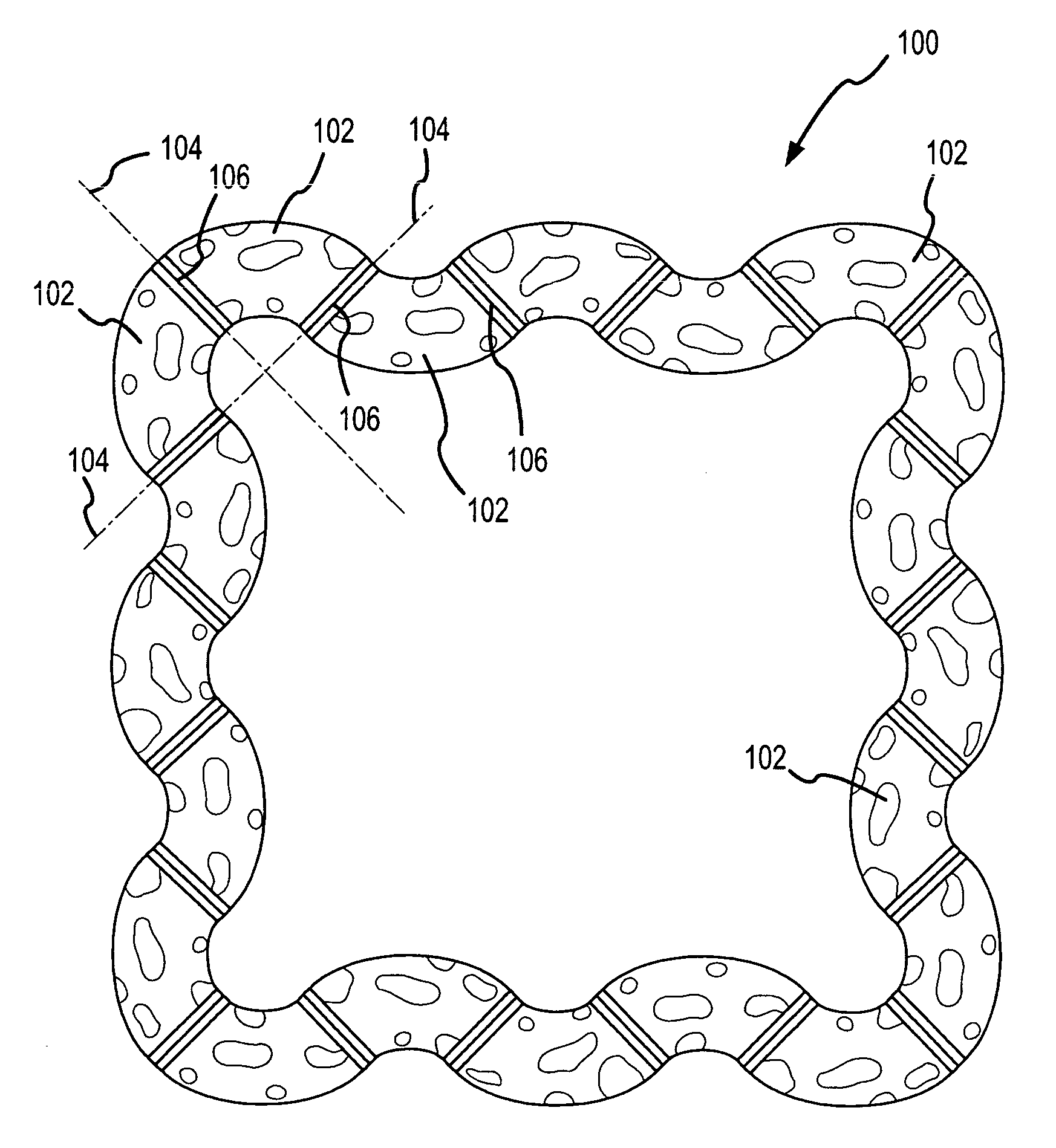

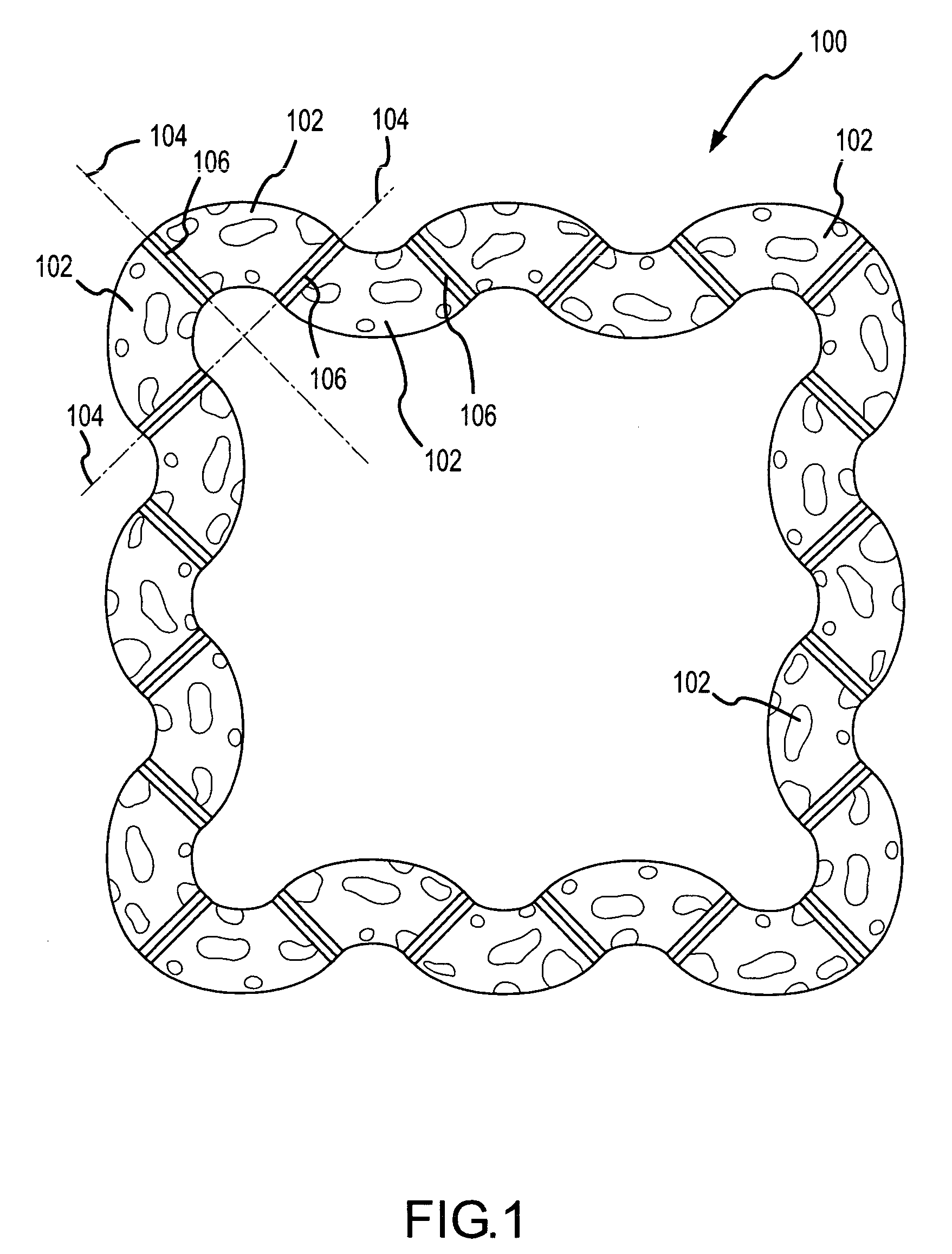

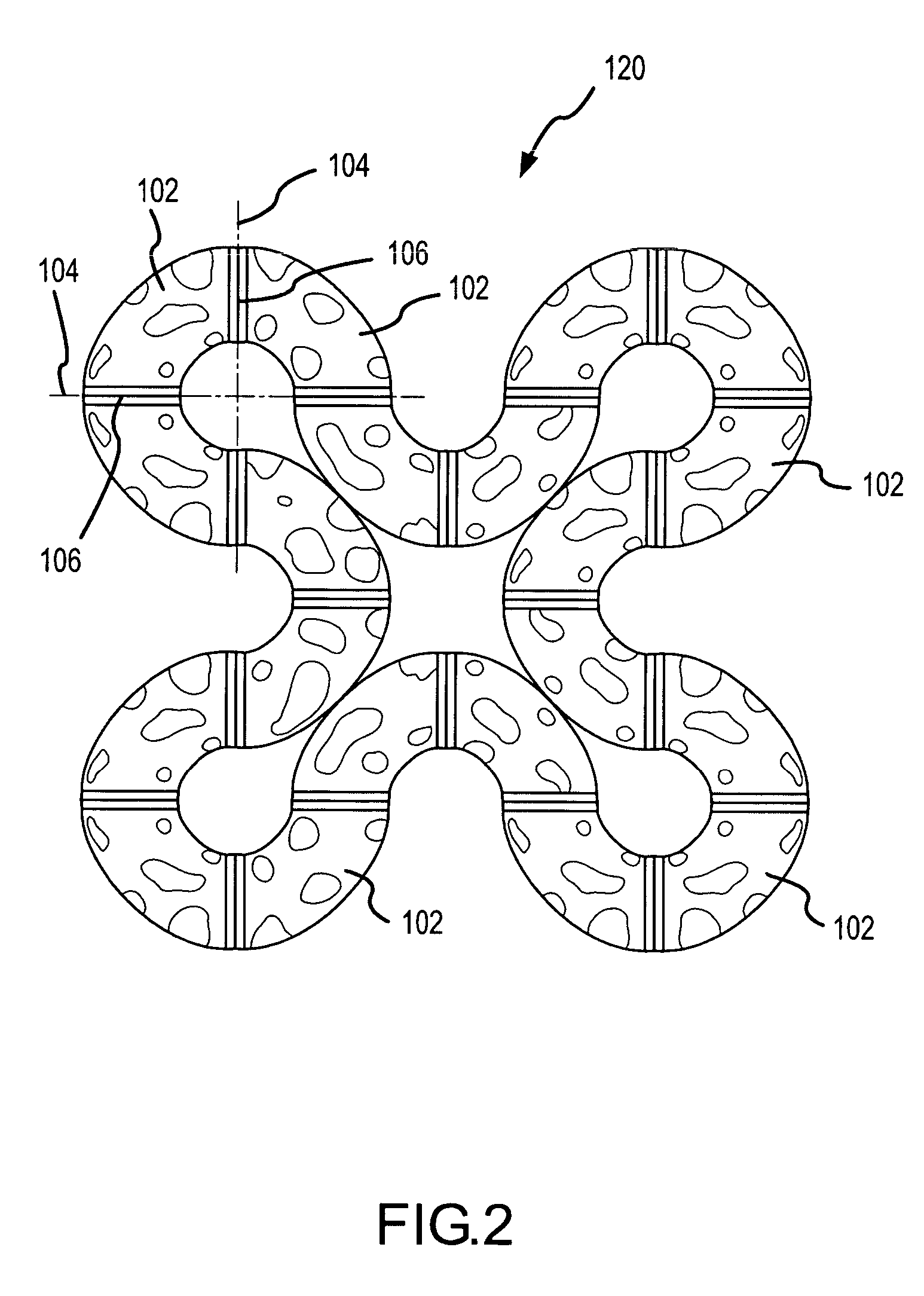

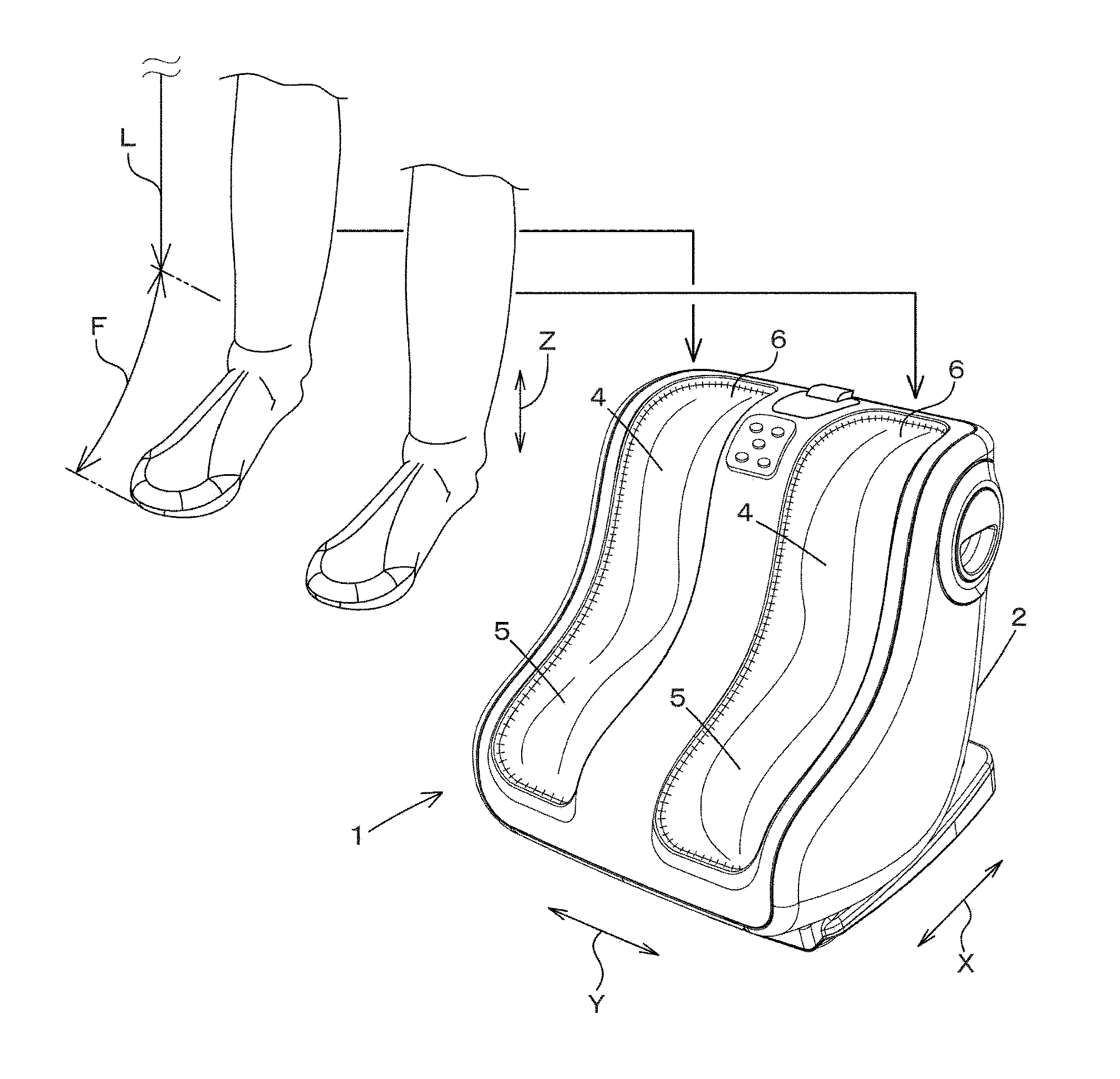

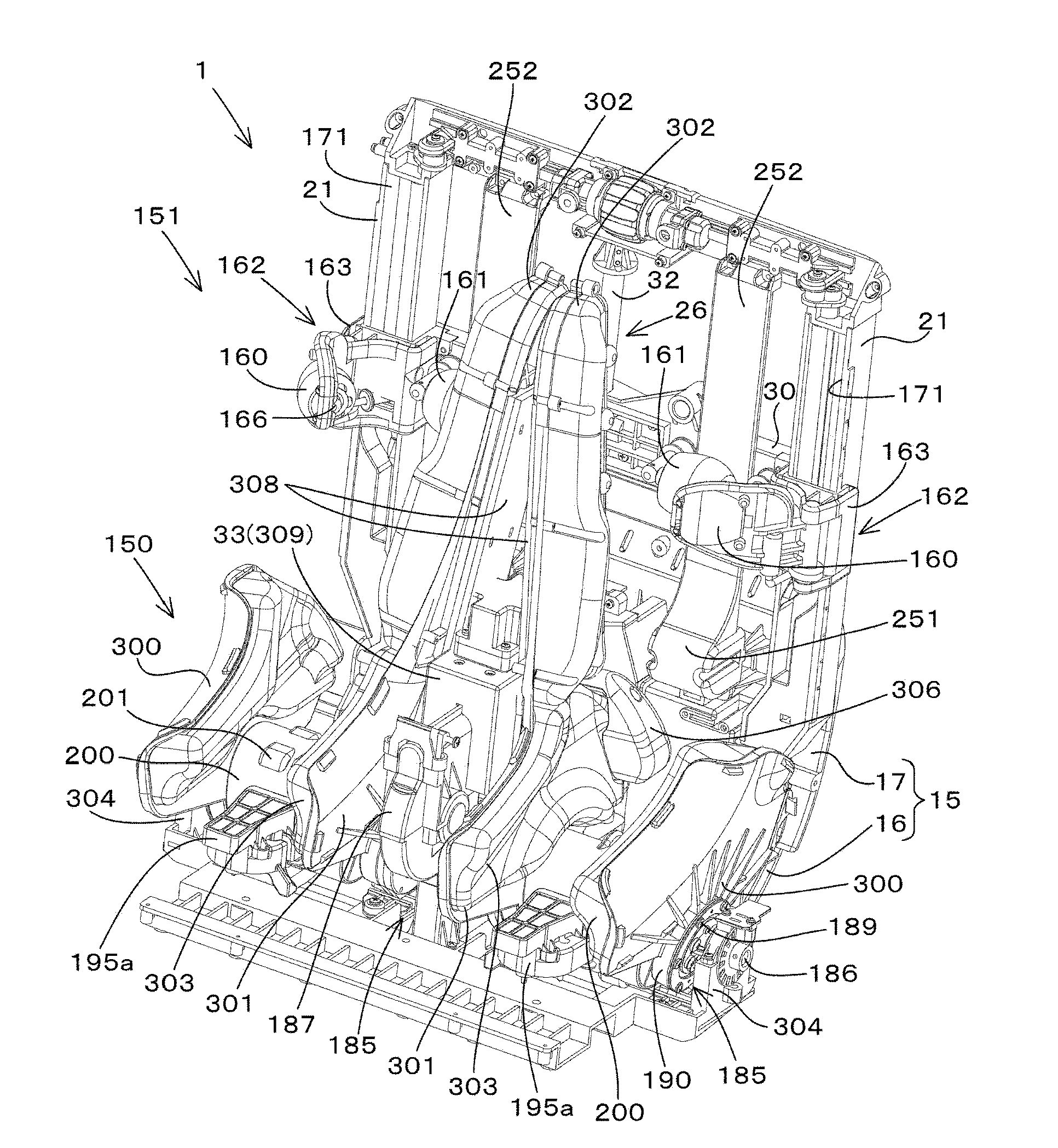

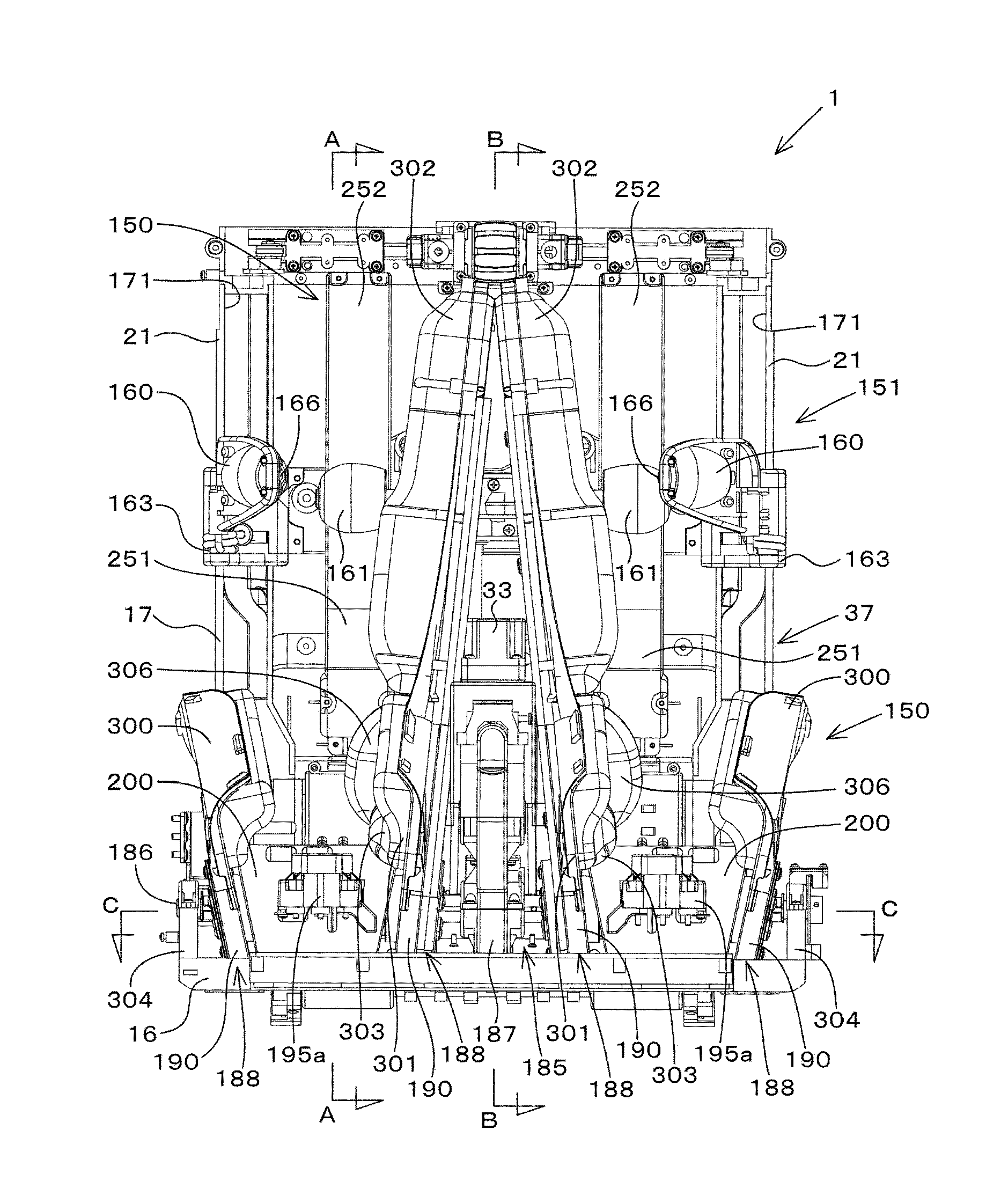

Leg-massaging machine

ActiveCN103565618ANew and comfortable massageLow number of componentsDevices for pressing relfex pointsRoller massagePleasant FeelingEngineering

The present invention makes it possible to obtain a novel and pleasant feeling of massage even while reducing the number of constituent parts by making the therapeutic members of the leg-massaging machine to have a long shape that extends from the calf to the foot. The leg-massaging machine is provided with: an outer therapeutic member (300) formed so as to cover the outside of the foot; a front-pressing therapeutic member (160) that is disposed above the outer therapeutic member (300) and presses the front surface of the calf while moving in the vertical direction; an inner therapeutic member (301) that is disposed so as to face the outer therapeutic member (300) and the front-pressing therapeutic member (160) in the left-right direction and is made to be long in the vertical direction so as to follow along the inside of the calf to the inside of the foot; a rotation axis (186) provided crossing in the left-right direction so as to pass through the base end side of the inner therapeutic member (301) and the outer therapeutic member (300); a driving unit (309) for rotating the rotation axis (186); and a converting unit (188) for converting the rotational driving force of the rotation axis (186) into a squeezing massage action of the inner therapeutic member (301) and the outer therapeutic member (300) on the leg.

Owner:DAITO ELECTRIC MACHINE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com