Impregnating technology for the condom production and impregnating equipment thereof

A dipping process and condom technology are applied in the innovative field of dipping process method and dipping equipment for condom production, can solve problems such as reducing production cost, and achieve the effects of reducing production cost, saving consumption and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

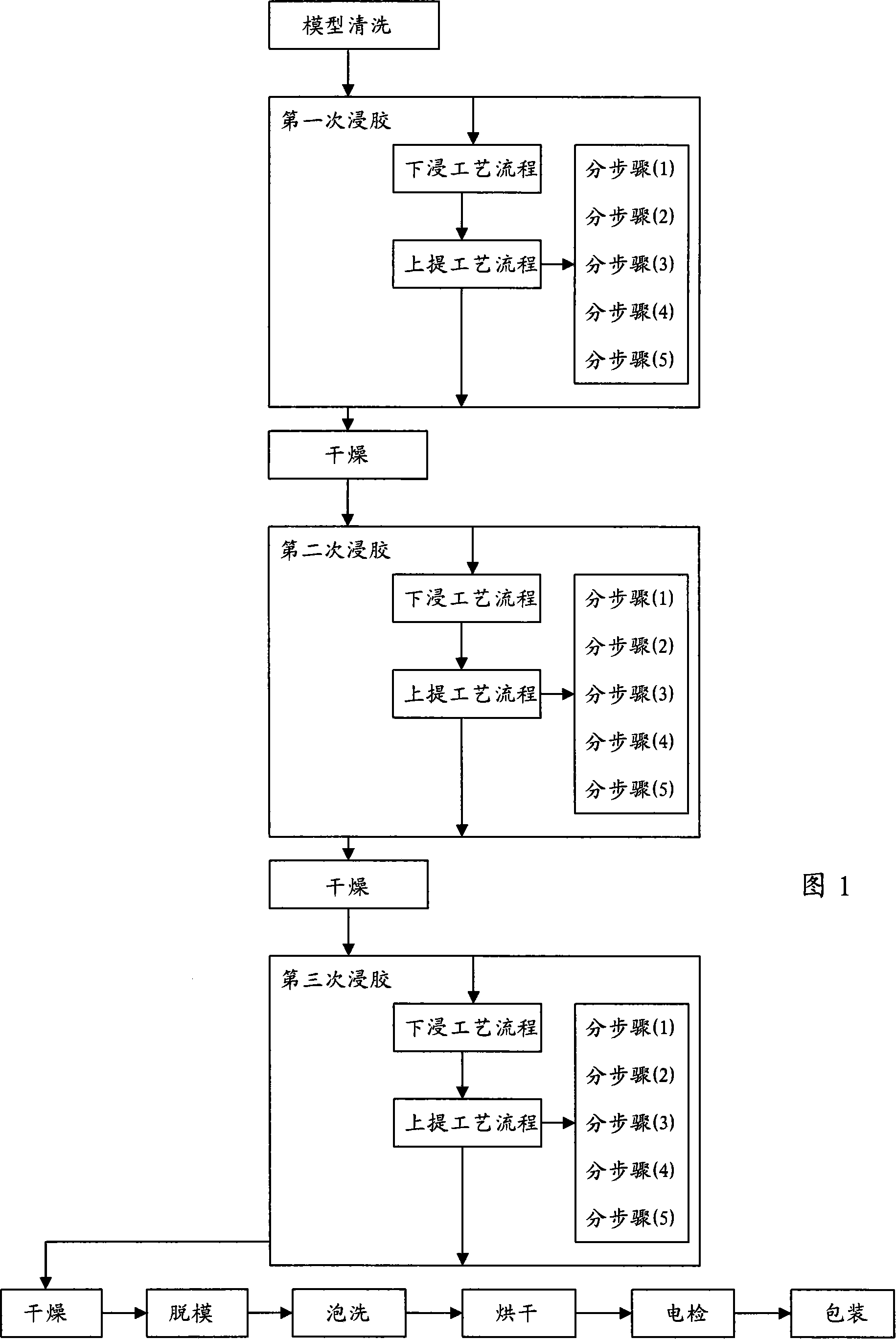

[0044] Example 1. A kind of dipping process method for condom production, as shown in Figure 1. This embodiment includes the steps of model cleaning, first dipping, drying, second dipping, drying, third dipping, drying, mold removal, soaking, drying, electrical inspection and packaging. The dipping step includes the dipping and lifting process of the model, and the lifting process includes the corresponding 5 sub-steps of lifting according to 5 sections of straight lines or curves with different inclinations and different lifting heights to improve the uniformity of the condom. sex. At the same time, the consumption of raw materials can be saved, and the production cost can be greatly reduced.

[0045] The 5 sub-steps of the lifting process are:

[0046] (1) After the model is turned from dipping to lifting, use a short straight line with a large inclination to lift to a small height to speed up the lifting speed so that the latex and thickness of the weak part of the condo...

Embodiment 2

[0052] Example 2. A dipping process method for condom production. Wherein, the lifting process includes three corresponding sub-steps of lifting according to three sections of straight lines or curves with different bevel angles and different lifting heights, so as to improve the uniformity of the condom.

[0053] The 3 sub-steps of the lifting process are:

[0054] (1) After the model is turned from dipping to lifting, use a short straight line with a large inclination to lift to a small height to speed up the lifting speed so that the latex and thickness of the weak part of the condom will increase significantly;

[0055] (2) Raise the model to a relatively high height with a small oblique angle and a long straight line, and keep a slow lifting speed to make the latex at the weaker part near the middle part of the condom more uniform and correspondingly increase, and the thickness is correspondingly increased;

[0056] (3) Raise the model to a middle height with a curve wi...

Embodiment 3

[0058] Example 3. A dipping process method for condom production. Wherein, the lifting process includes 6 corresponding sub-steps of lifting according to 6 sections of straight lines or curves with different bevel angles and different lifting heights, so as to improve the uniformity of the condom.

[0059] The 6 sub-steps of the lifting process are:

[0060] (1) After the model is turned from dipping to lifting, use a short straight line with a large inclination to lift to a small height to speed up the lifting speed so that the latex and thickness of the weak part of the condom will increase significantly;

[0061] (2) Raise the model to a relatively high height with a small oblique angle and a long straight line, and maintain a slow lifting speed so that the latex in the middle part of the condom near the opening is appropriately increased, and the thickness is appropriately increased;

[0062] (3) Raise the model to a smaller height with a curve with a smaller slope and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com