Production process of dry-pressed ceramic tile body

A technology of ceramic brick adobe and production process, which is applied in the field of ceramic tile production, can solve the problems of reduced fluidity, overall cost increase instead of decrease, and lack of system technology, so as to improve sphericity and fluidity, reduce operators, and reduce system investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

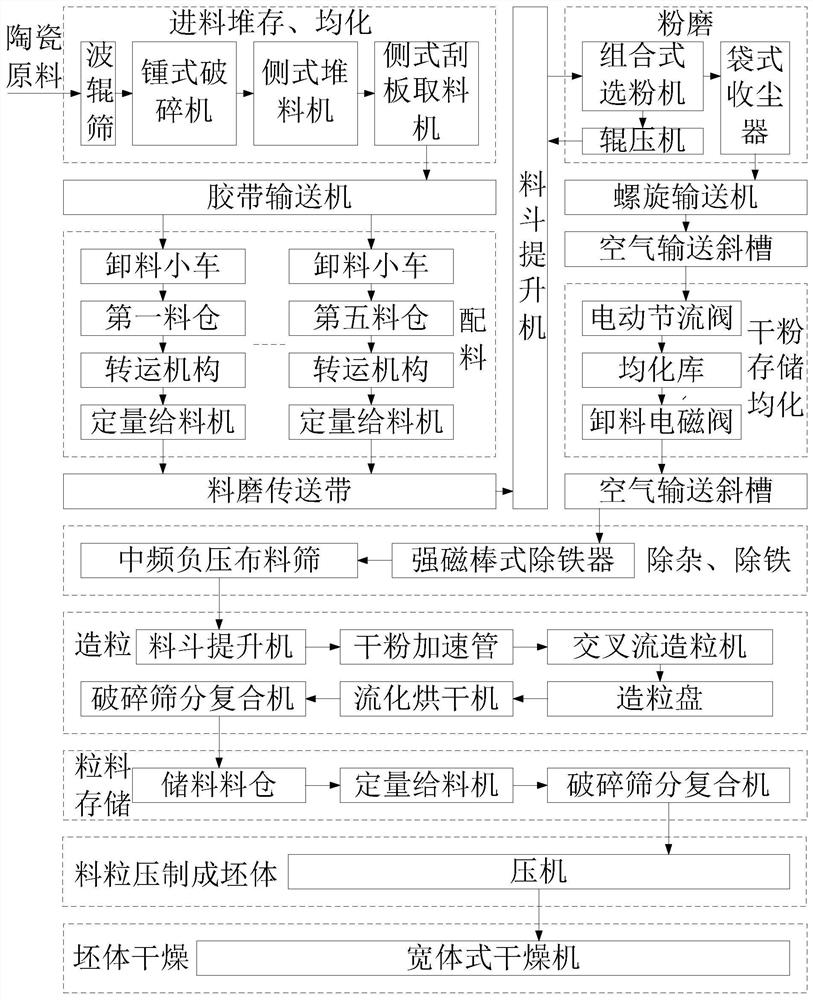

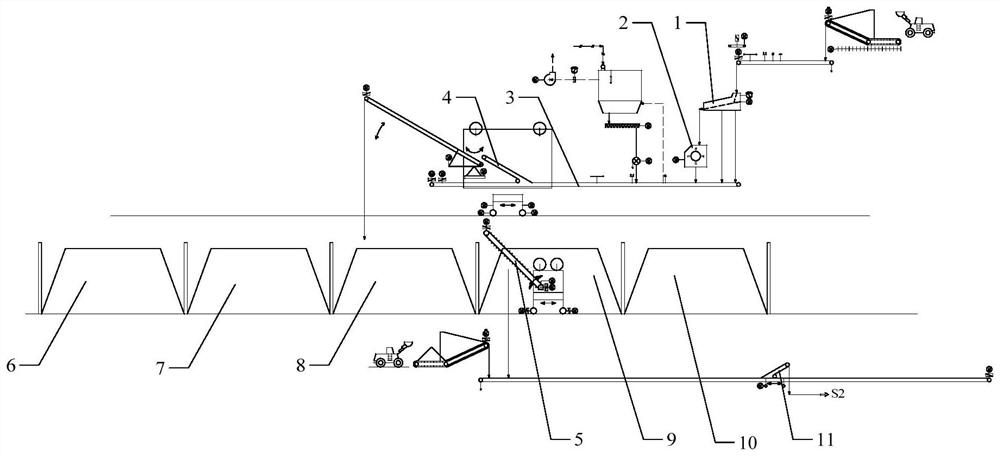

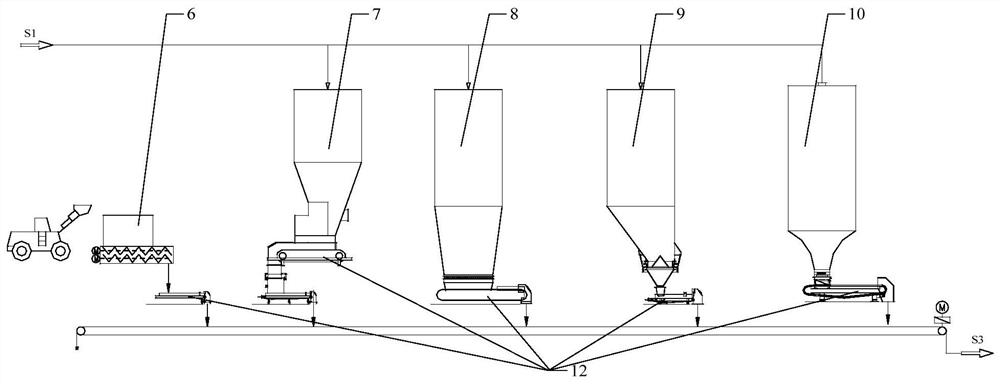

[0059] figure 1 It is a flow chart of a dry-pressed ceramic tile body production process according to an embodiment of the present invention, figure 2 It is a process layout diagram of S1 of a dry-pressed ceramic tile body production process in an embodiment of the present invention, image 3 It is a process layout diagram of S2 of a dry-pressed ceramic tile body production process according to an embodiment of the present invention, Figure 4 It is a process layout diagram of S3 of a dry-pressed ceramic tile body production process according to an embodiment of the present invention, Figure 5 It is a process layout diagram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com