Tobacco stalk pretreatment process

A tobacco stem pretreatment and tobacco stem technology, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as unfavorable pressing and cutting treatment, and achieve the effects of uniform internal and external moisture, simple process flow, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

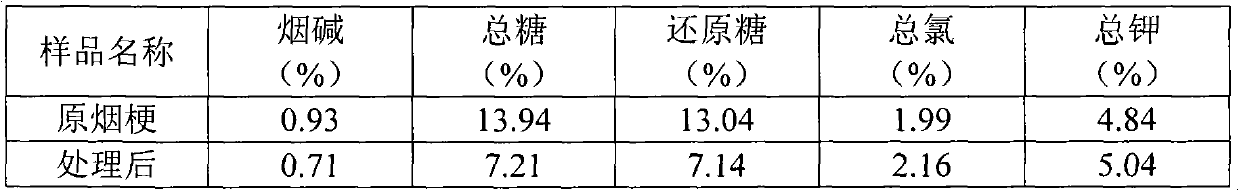

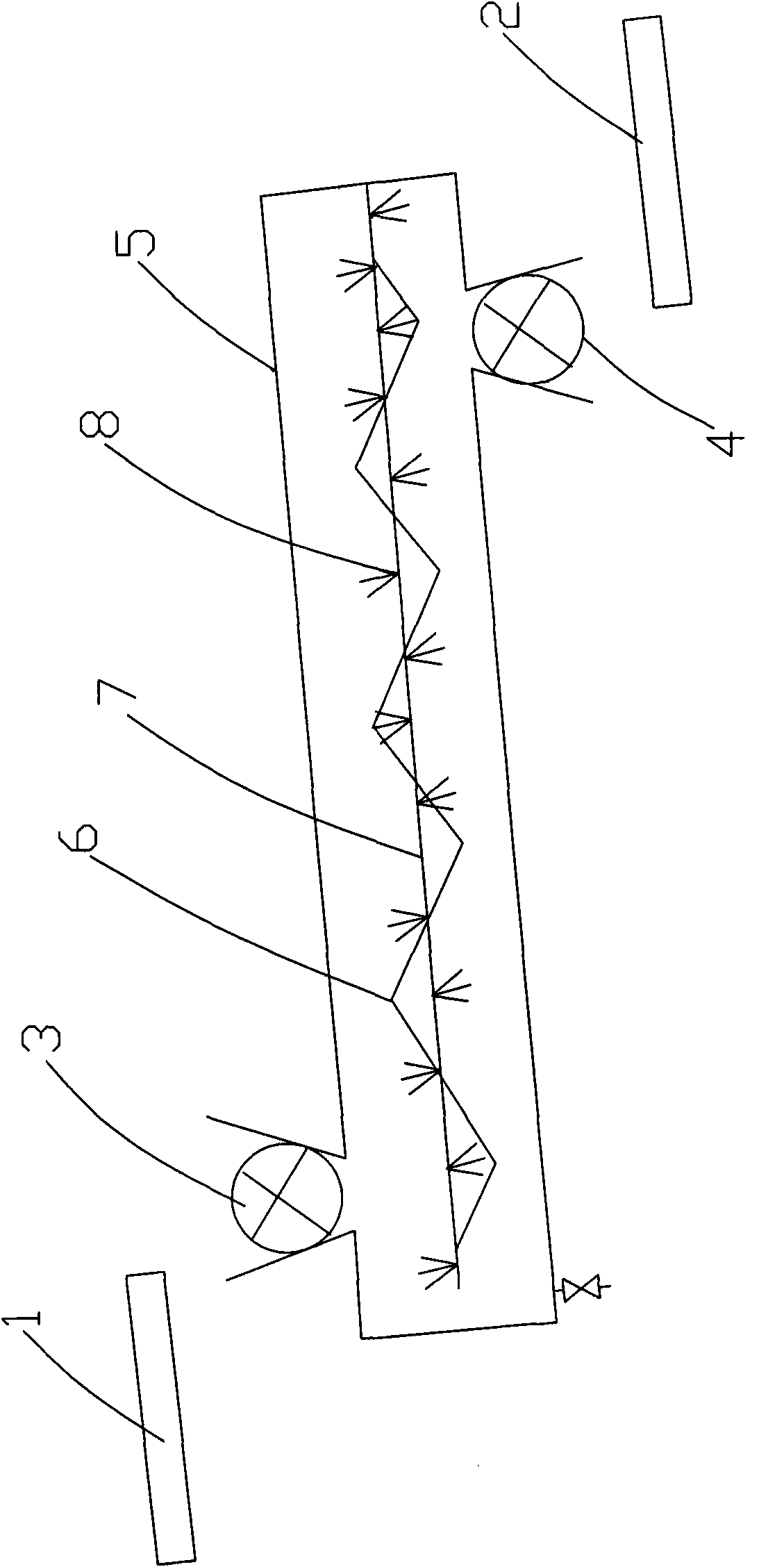

[0025] Embodiment: the tobacco stem pretreatment process of the present embodiment is carried out as follows:

[0026] A, the tobacco stems are screened to remove impurities, and the impurity removal process includes using screening and impurity removal equipment to screen out broken stems and dust in the tobacco stems and remove impurities such as hemp in the tobacco stems;

[0027] B. Place the tobacco stems after sieving and removing impurities in saturated steam with a pressure of 1.5-4.0 bar and a temperature of 110-143°C for 1-10 minutes;

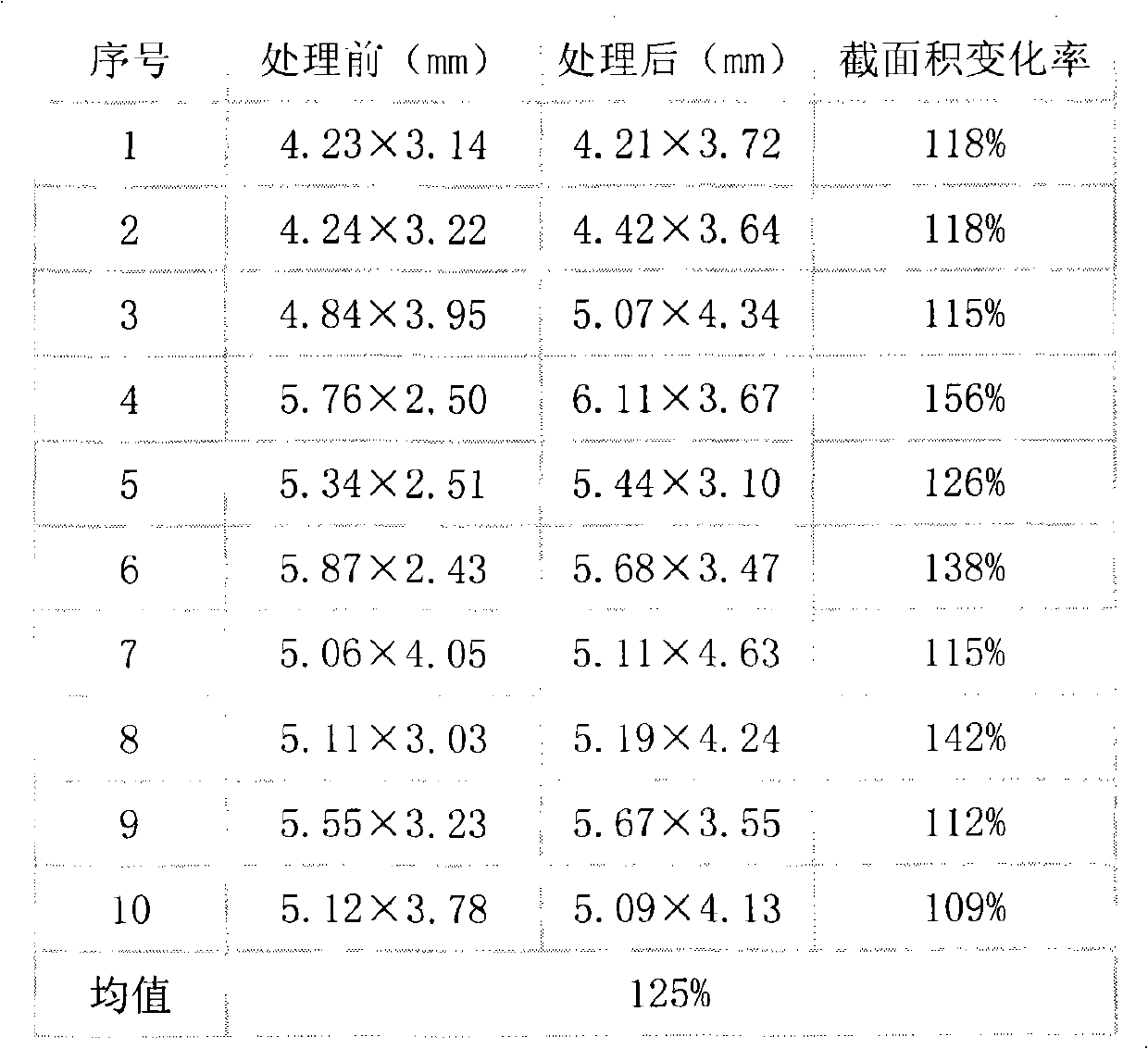

[0028] C. After the moisture content of the tobacco stems treated with saturated steam reaches 18-30%, the stems are pressed and cut.

[0029] In specific implementation, the pressure of the saturated steam is preferably 2.0-3.0 bar, and the processing time of the tobacco stems in the saturated steam is preferably 3-5 minutes; after the moisture content of the tobacco stems is preferably 20-25%, it is Squeeze and cut stems.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com