Sticky-rice-flavor-type liqueur brewing method

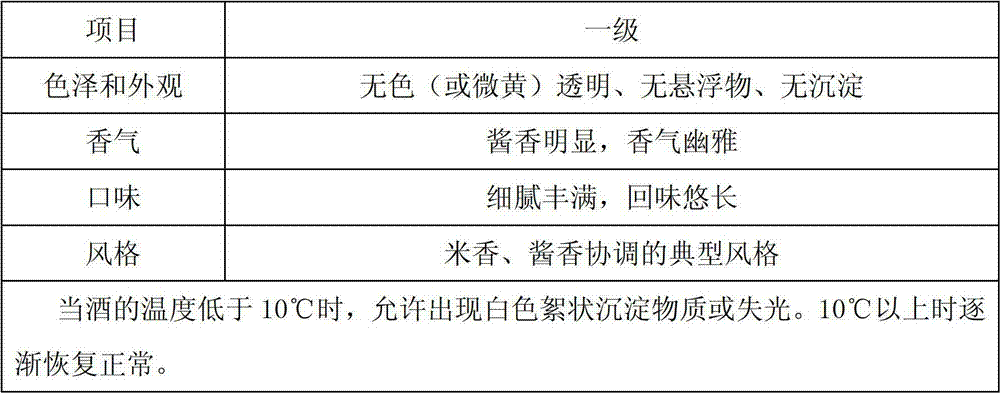

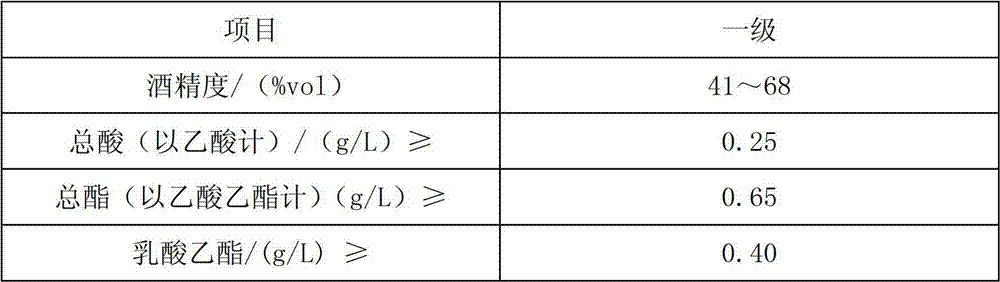

A sauce-flavored liquor and glutinous rice technology, applied in the field of liquor brewing, can solve the problems of rice wine with monotonous aroma, short fermentation cycle, and inconspicuous cellar aroma, and achieve the effect of elegant aroma, obvious sauce aroma, and long aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

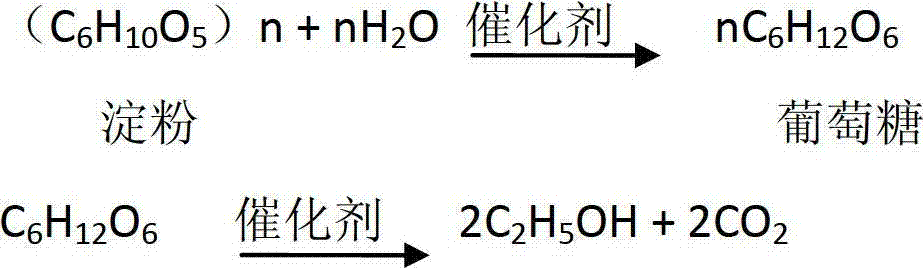

Method used

Image

Examples

Embodiment 1

[0034] Take by weighing 1500kg of high-quality glutinous rice, take by weighing 30kg of bran koji, and activate and rejuvenate 45kg of high-temperature koji.

[0035] The measured 1500kg of high-quality glutinous rice is transported to the rice steamer by the air conveyor, and the operator of the rice steamer needs to steam the rice evenly for 35 minutes, so that the rice is cooked but not sticky, hard on the outside and soft on the inside, and has no heart. until. When the cooked rice is air-dried to 20°C, turn on the koji mixer, sprinkle the weighed koji evenly on the cooked rice grains, and mix well. Then put the rice grains that have been mixed well into the special feeding bucket, and use the electric hoist crane to transport them to the 5m U-shaped stainless steel saccharification tank for solid-state cultivation and saccharification.

[0036] When the rice grains are fed into the saccharification tank for 12 hours, it is the vigorous stage of aerobic respiration of the...

Embodiment 2

[0051] Take by weighing 1500kg of high-quality glutinous rice, take by weighing 40kg of bran koji, and activate and rejuvenate 55kg of high-temperature koji.

[0052] The measured 1500kg of high-quality glutinous rice is transported to the rice steamer by the air conveyor, and the operator of the rice steamer needs to steam the rice evenly for 35 minutes, so that the rice is cooked but not sticky, hard on the outside and soft on the inside, and has no heart. until. When the cooked rice is air-dried to 25°C, turn on the koji mixer, sprinkle the weighed koji evenly on the cooked rice grains, and mix well. Then put the rice grains that have been mixed well into the special feeding bucket, and use the electric hoist crane to transport them to the 5mU stainless steel saccharification tank for solid-state cultivation and saccharification.

[0053] When the rice grains are fed into the saccharification tank for 11 hours, it is the vigorous stage of aerobic respiration of the benefic...

Embodiment 3

[0066] Take by weighing 1500kg of high-quality glutinous rice, take by weighing 45kg of bran koji, and activate and rejuvenate 60kg of high-temperature koji.

[0067] The measured 1500kg of high-quality glutinous rice is transported to the rice steamer by the air conveyor, and the operator of the rice steamer needs to steam the rice evenly for 35 minutes, so that the rice is cooked but not sticky, hard on the outside and soft on the inside, and has no heart. until. When the cooked rice is blown to 30°C, turn on the koji mixer, sprinkle the weighed koji evenly on the cooked rice grains, and mix well. Then put the rice grains that have been mixed well into the special feeding bucket, and use the electric hoist crane to transport them to the 5mU stainless steel saccharification tank for solid-state cultivation and saccharification.

[0068] When the rice grains are fed into the saccharification tank for 14 hours, it is the vigorous stage of aerobic respiration of the beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com