Patents

Literature

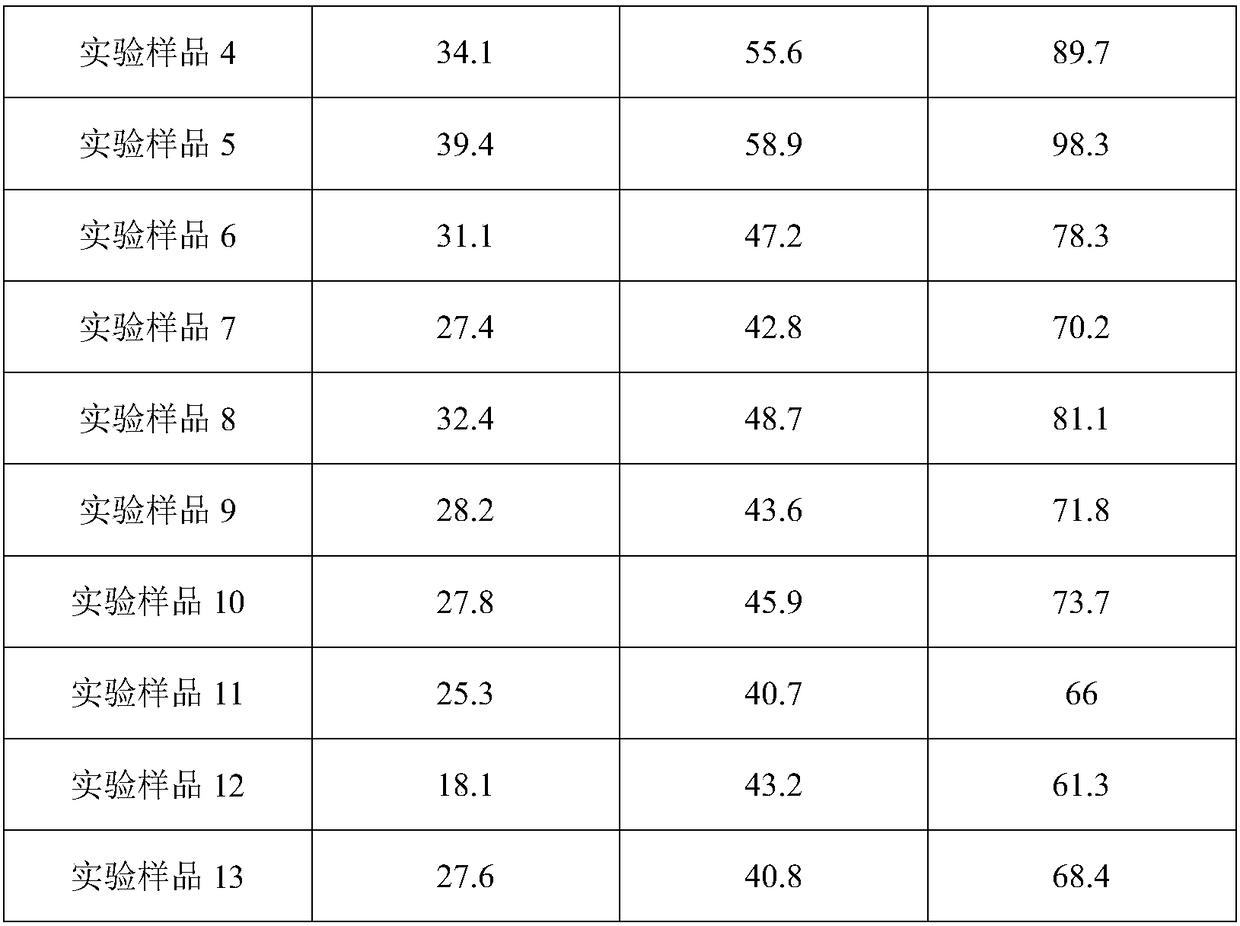

60results about How to "High amino acid nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bacillus subtilis strain and its application in fermentation and flavor enhancement of soy sauce

ActiveCN106754508AHigh amino acid nitrogen contentIncreased content of volatile flavor componentsBacteriaMicroorganism based processesSaline waterChemistry

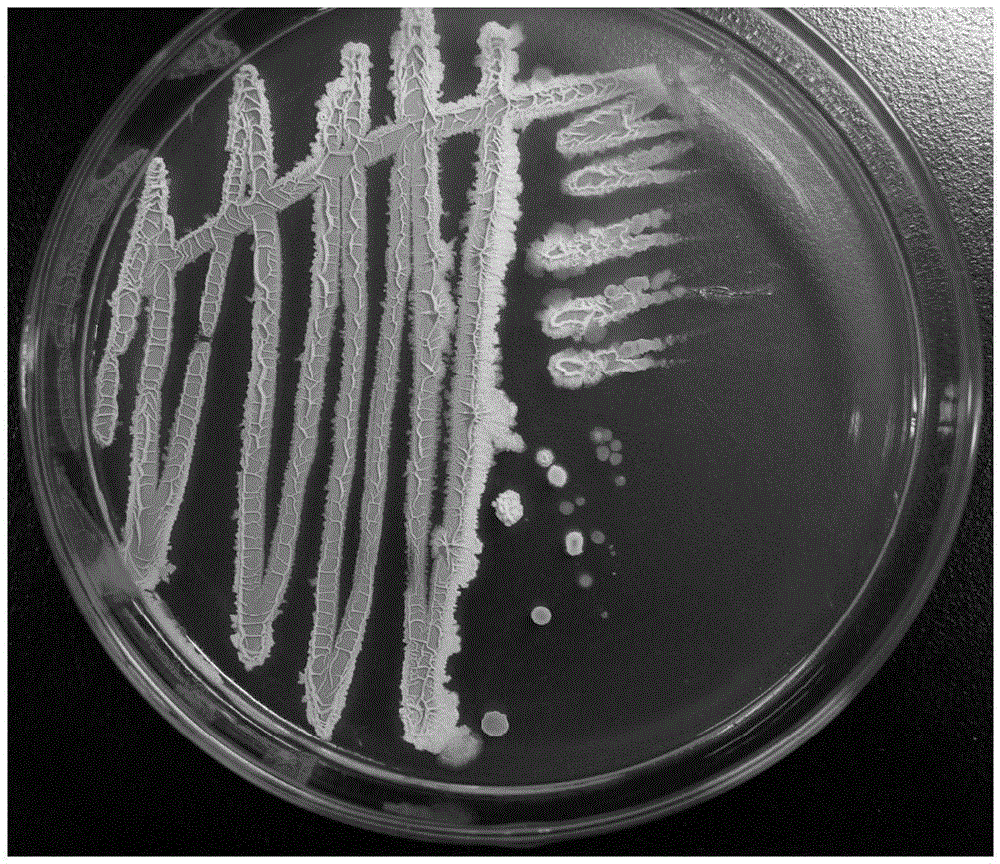

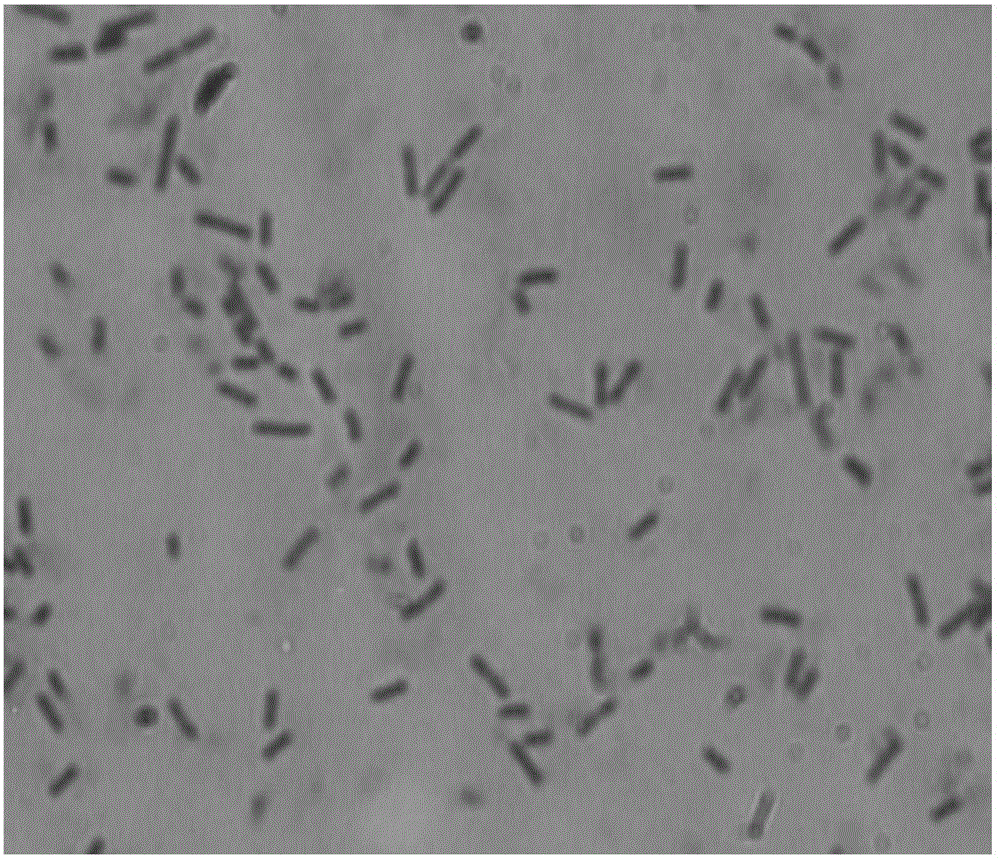

A bacillus subtilis strain, named as CS1.03 in the CCTCC NO: M 2015791, is collected in the China Center for Type Culture Collection. The bacillus subtilis strain is applied to fermentation and flavor enhancement of soy sauce by the steps of uniformly mixing finished starter for making soy sauce with saline water according to the mass ratio and fermenting at a constant temperature to obtain sauce mash; spraying solution of bacillus subtilis strain CS1.03 to the sauce mash and then carrying out first-stage fermentation at a normal temperature; after the fist-stage fermentation, carrying out sprinkling fermentation with saline water to obtain raw soy sauce finally. By application of the bacillus subtilis strain in fermentation and flavor enhancement of soy sauce, content of amino acid nitrogen and volatile flavor components of soy sauce can be increased greatly, and thus, the soy sauce has rich flavor and high quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for three-stage type fast fermentation of fish gravy

InactiveCN101564141APromote degradationIncrease the content of free amino acidsFood preparationIntermediate stageFlavor

The invention discloses a method for three-stage type fast fermentation of fish gravy. The method carries out fermentation of fish gravy by three stages of insulating fermentation with low salt in early stage at the temperature of 40 to 60 DEG C according to the weight ratio of 20:1 to 4:1 of fish and salt, natural fermentation in middle stage and insulating fermentation with high salt in late stage at the temperature of 40 to 60 DEG C according to the weight ratio of 3:1 to 2:1 of fish and salt; not only the increase of the content of total soluble nitrogen, amino acid nitrogen and free aminoacid thereof is faster, the content thereof exceeds national first-class fish gravy standard when carrying out fermentation for 15 days, and the flavor, body state and color thereof are better afterhigh-salt insulation in the late stage; and compared with the traditional method, the method can shorten the fermentation time of the fish gravy from 2 to 3 years to 1 to 1.5 years.

Owner:SOUTH CHINA UNIV OF TECH

Protease generating strain amplification method and method for increasing content of amino-acid-state nitrogen in vinegar

ActiveCN103756918AHigh amino acid nitrogen contentImprove germination rateFungiMicroorganism based processesBiotechnologyMicrobiology

The invention relates to the field of vinegar production and particularly relates to a method for increasing the content of amino-acid-state nitrogen in vinegar. The method comprises the steps of amplifying protease generating strains by using vinegar residue, and applying the amplified protease generating strains to alcoholic fermentation, thereby increasing the content of the amino-acid-state nitrogen in the vinegar. According to the method, the protease generating strains are amplified by the vinegar residue and then are applied to vinegar brewing, so that the vinegar residue can supply a carbon source and a nitrogen source, which are required for the growth of the strains, to the strains, can loosen a culture medium as a packing medium, plays a role in ventilating and promotes the propagation and metabolism of aerobes, partial vinegar residue resources can be recycled, the waste is changed into the valuable, and the production cost of vinegar enterprises is reduced.

Owner:山西金龙鱼梁汾醋业有限公司

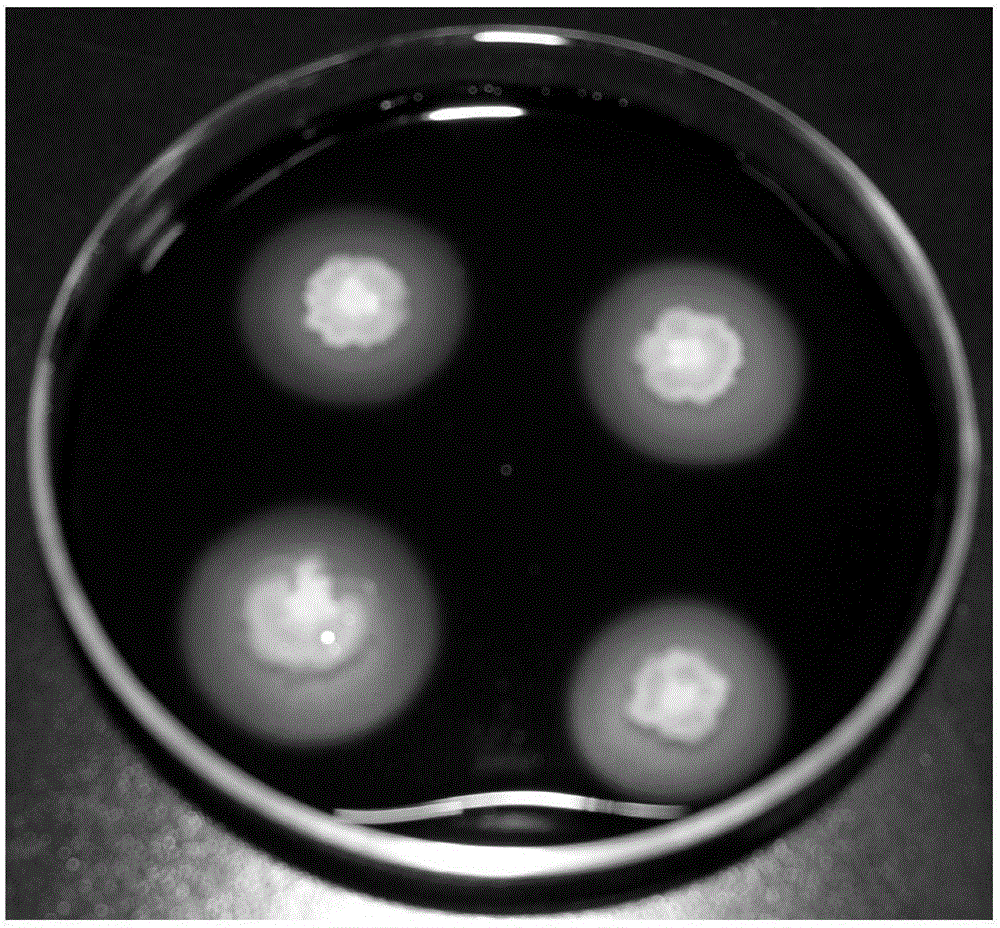

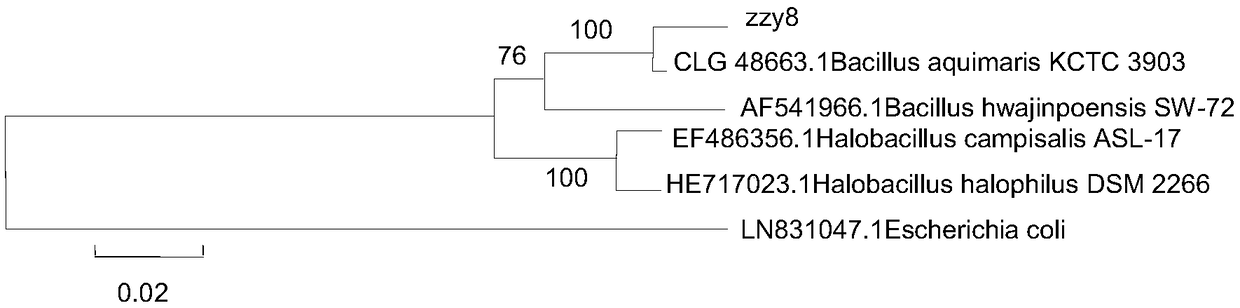

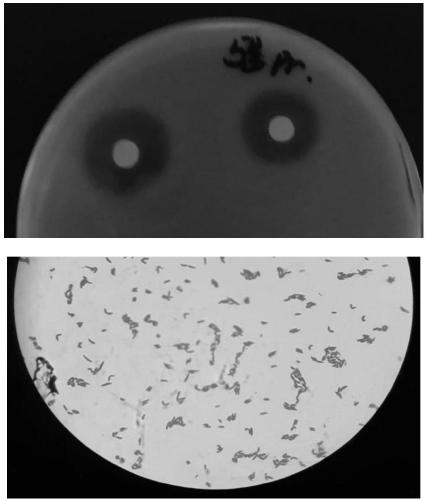

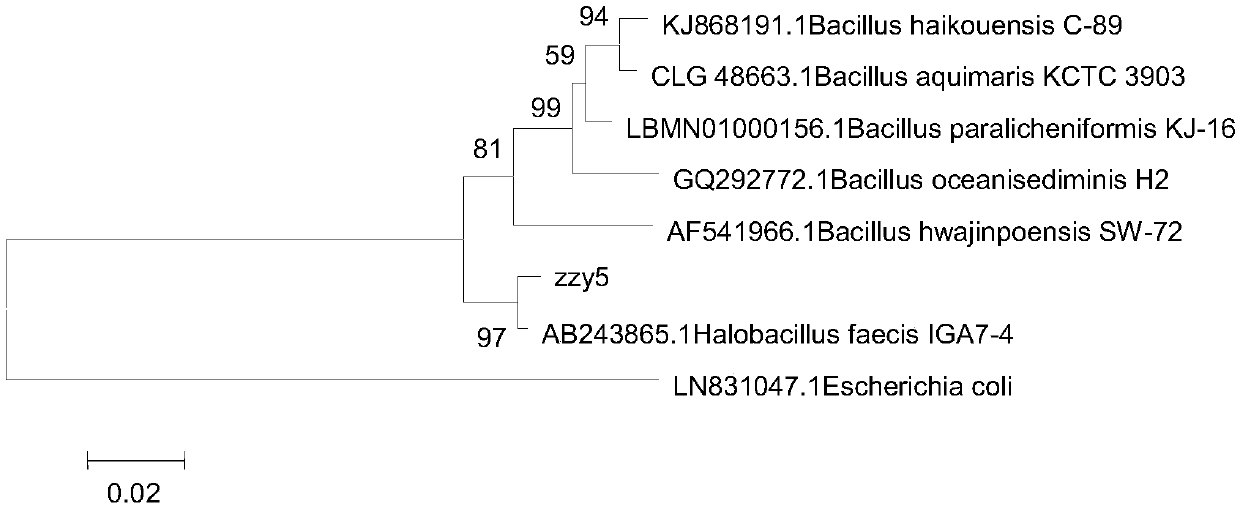

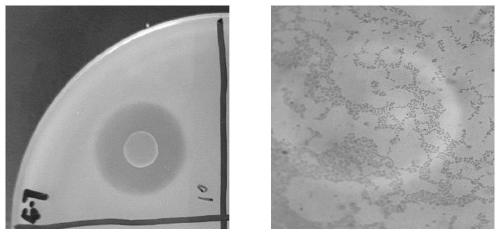

Moderately halophilic bacterial strain bacillus aquimaris for improving fermentation quality of fish sauce

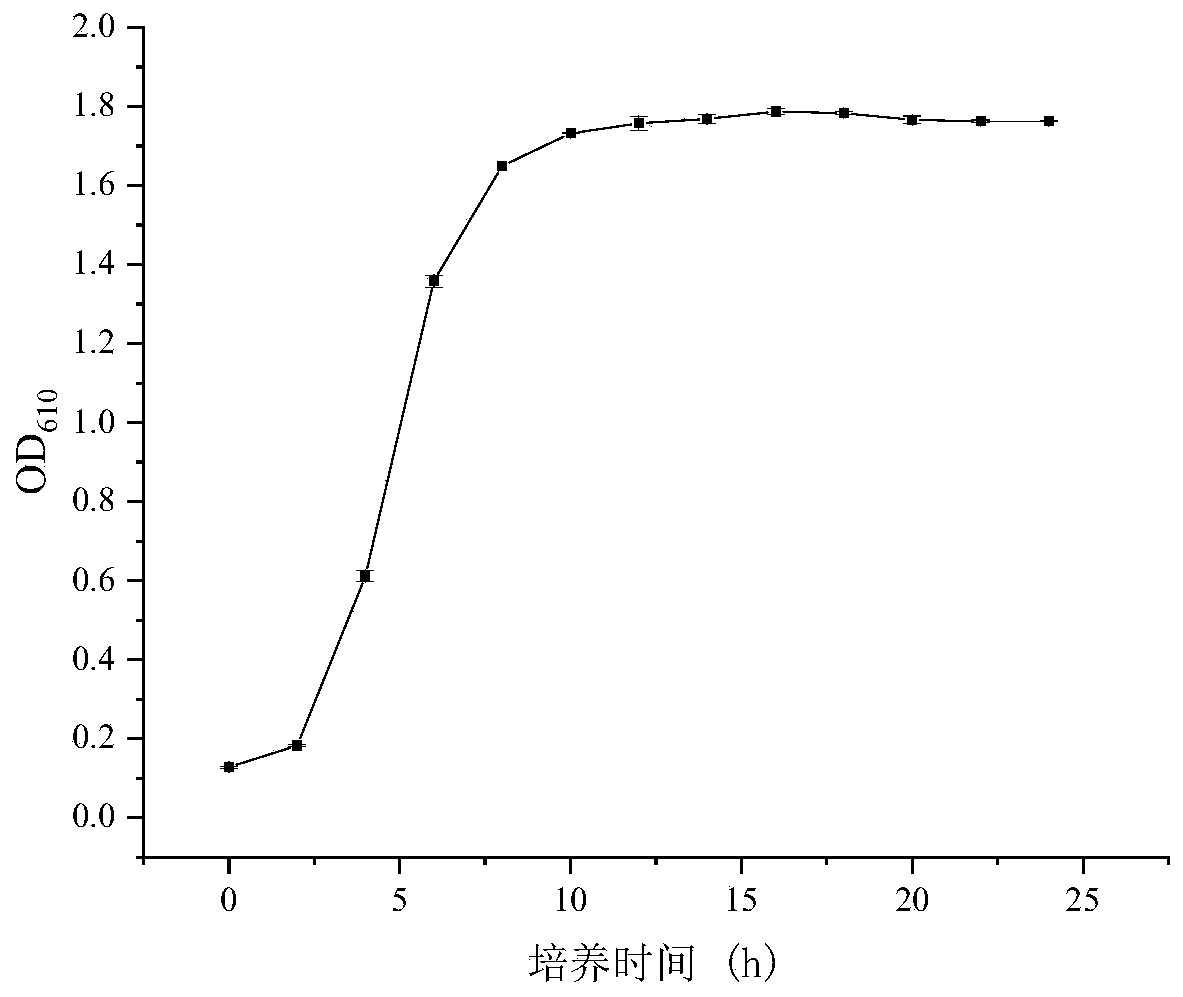

ActiveCN109456920AShort fermentation timeReduce salinityBacteriaMicroorganism based processesFood flavorBacterial strain

The invention discloses a moderately halophilic bacterial strain bacillus aquimaris for improving fermentation quality of fish sauce, and relates to the field of food microbial technology application. The bacterial strain has been collected in China General Microbiological Culture Collection Center on September 27, 2018 with the collection number being CGMCC NO. 16541 and can be called Bacillus aquimaris CGMCC16541. The bacterial strain is screened from traditional fermented shrimp sauce through a Gibbons culture medium. The bacterial strain has strong protease-producing ability, can be applied to animal aquatic product fermentation, and can accelerate the fermentation and flavor improvement of animal aquatic products.

Owner:JIANGSU UNIV

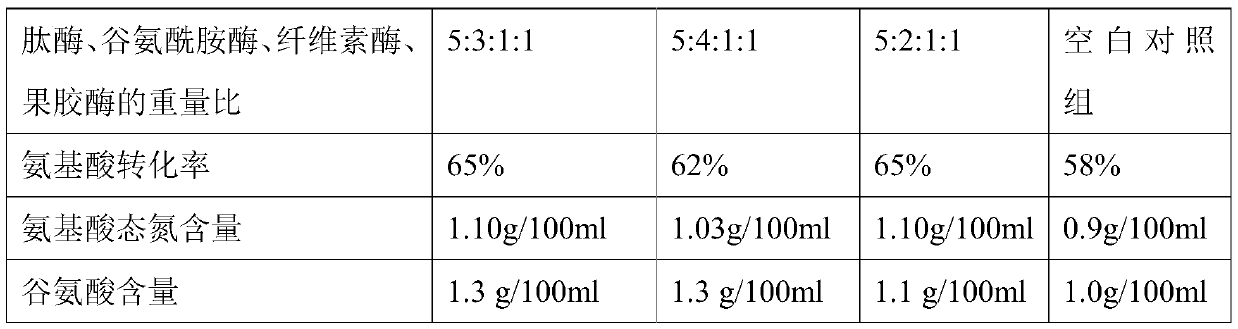

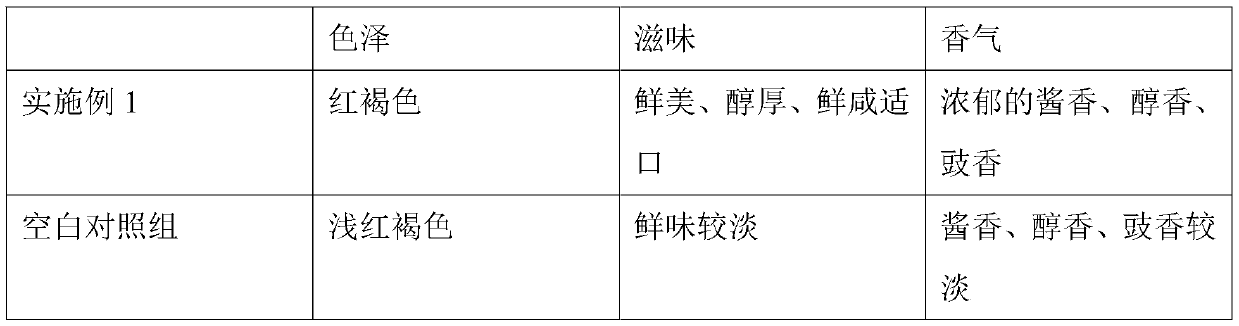

Production method for re-fermenting soy sauce by using mixed enzyme preparation

PendingCN111296819AEnhance aroma and tasteReduce a precipitationFood ingredient as taste affecting agentFood ingredient as flavour affecting agentPectinaseEngineering

The invention discloses a production method for re-fermenting soy sauce by using a mixed enzyme preparation. The production method comprises the following steps: raw material treatment, material steaming, mixed starter propagation, soy sauce mash preparation, tank fermentation, squeezing, re-fermentation and sterilization, wherein the weight ratio of peptidase to glutaminase to cellulase to pectinase is 5:3:1:1, the concentration of light salt brine is 8-12 g / 100 ml, the weight ratio of mixed enzyme to the light salt brine in the mixed enzyme preparation is 1: (4-6), and the addition weight ofthe mixed enzyme preparation is 0.1% of that of raw soy sauce. The mixed enzyme preparation is added to the raw soy sauce obtained after soy sauce fermentation and squeezing, and re-fermentation of the soy sauce is performed, so that the freshness of the soy sauce is improved, and primary precipitation of the soy sauce is effectively reduced.

Owner:LAIZHOU SENSIR BREWING FOOD

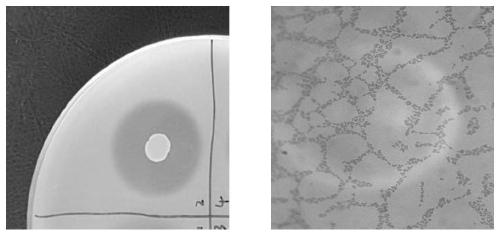

Halobacillus faecis capable of improving fermentation quality of fish paste

ActiveCN109593669AShort fermentation timeReduce salinityBacteriaMicroorganism based processesLaboratory cultureFood flavor

The invention discloses halobacillus faecis capable of improving the fermentation quality of a fish paste, relates to the application field of food microbiology technologies. The halobacillus faecis is collected in China General Microbiological Culture Collection Center (CGMCC) on September 27, 2018, with the collection number of CGMCC NO.16543, and can be named as Halobacillus faecis CGMCC16543.The halobacillus faecis is screened from a conventional fermented shrimp paste by using a Gibbons medium; the halobacillus faecis has relatively strong protease-producing ability, can be applied to fermentation of animal aquatic products, and can accelerate the fermentation and flavor improvement of the animal aquatic products.

Owner:JIANGSU UNIV

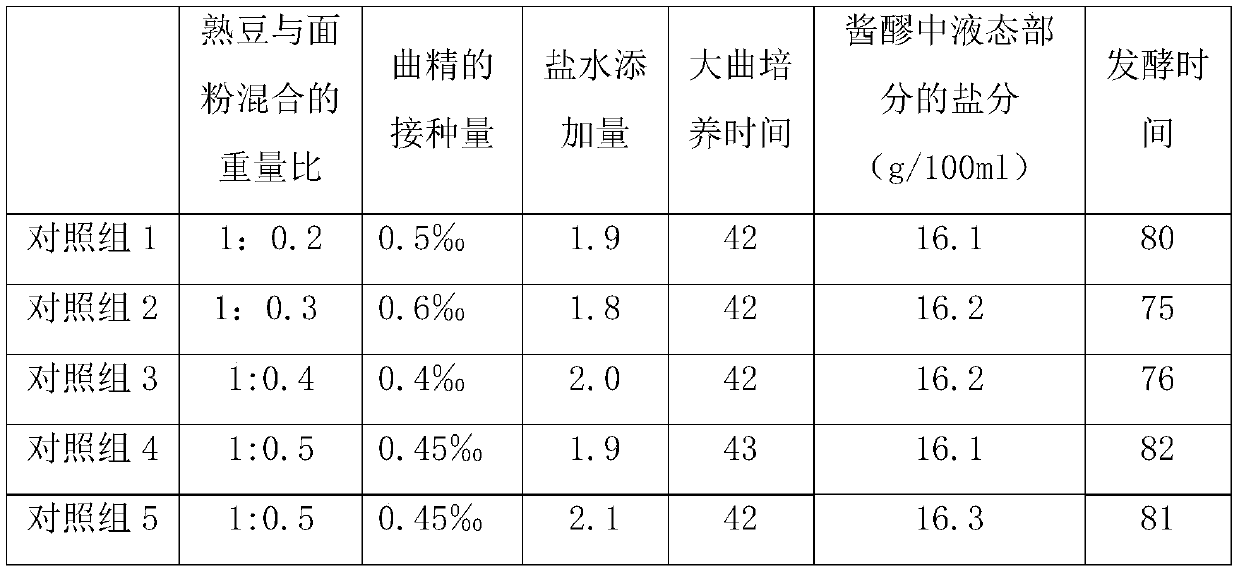

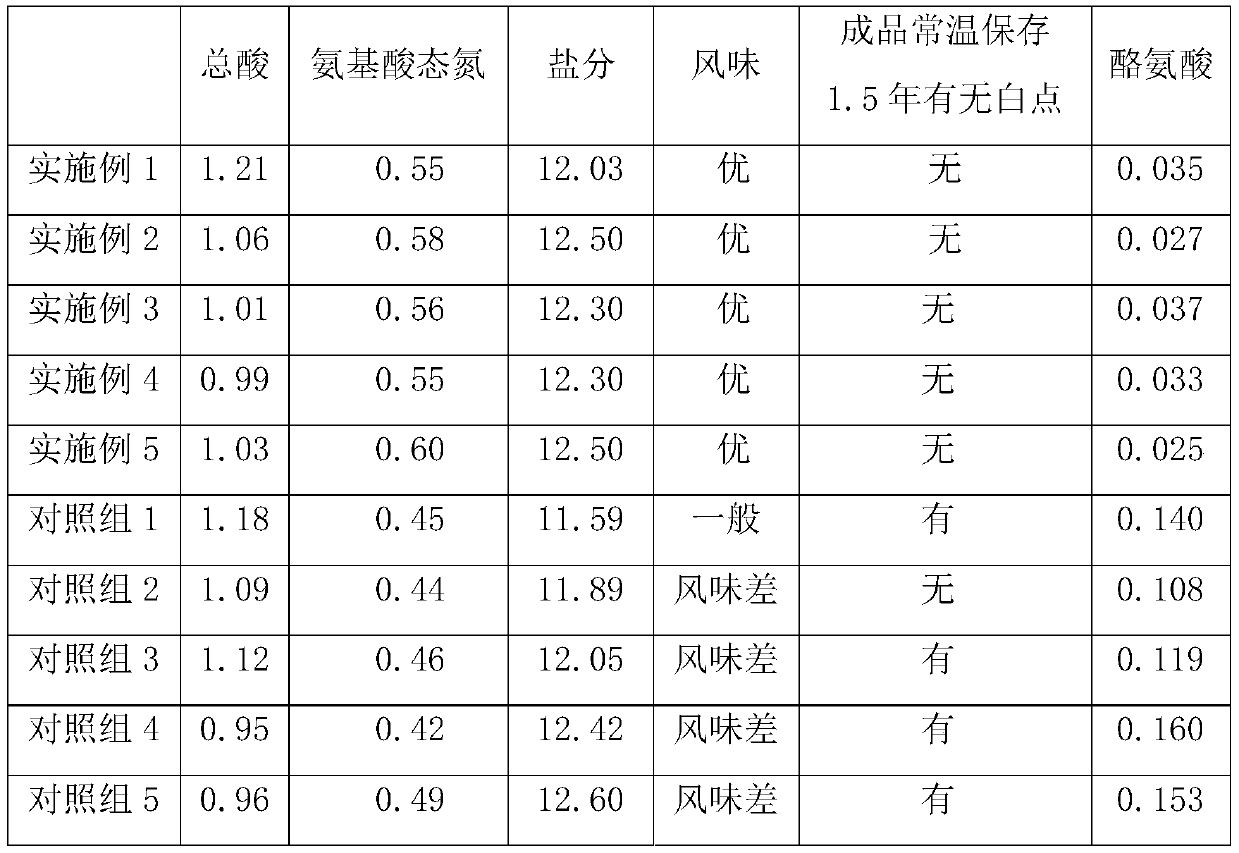

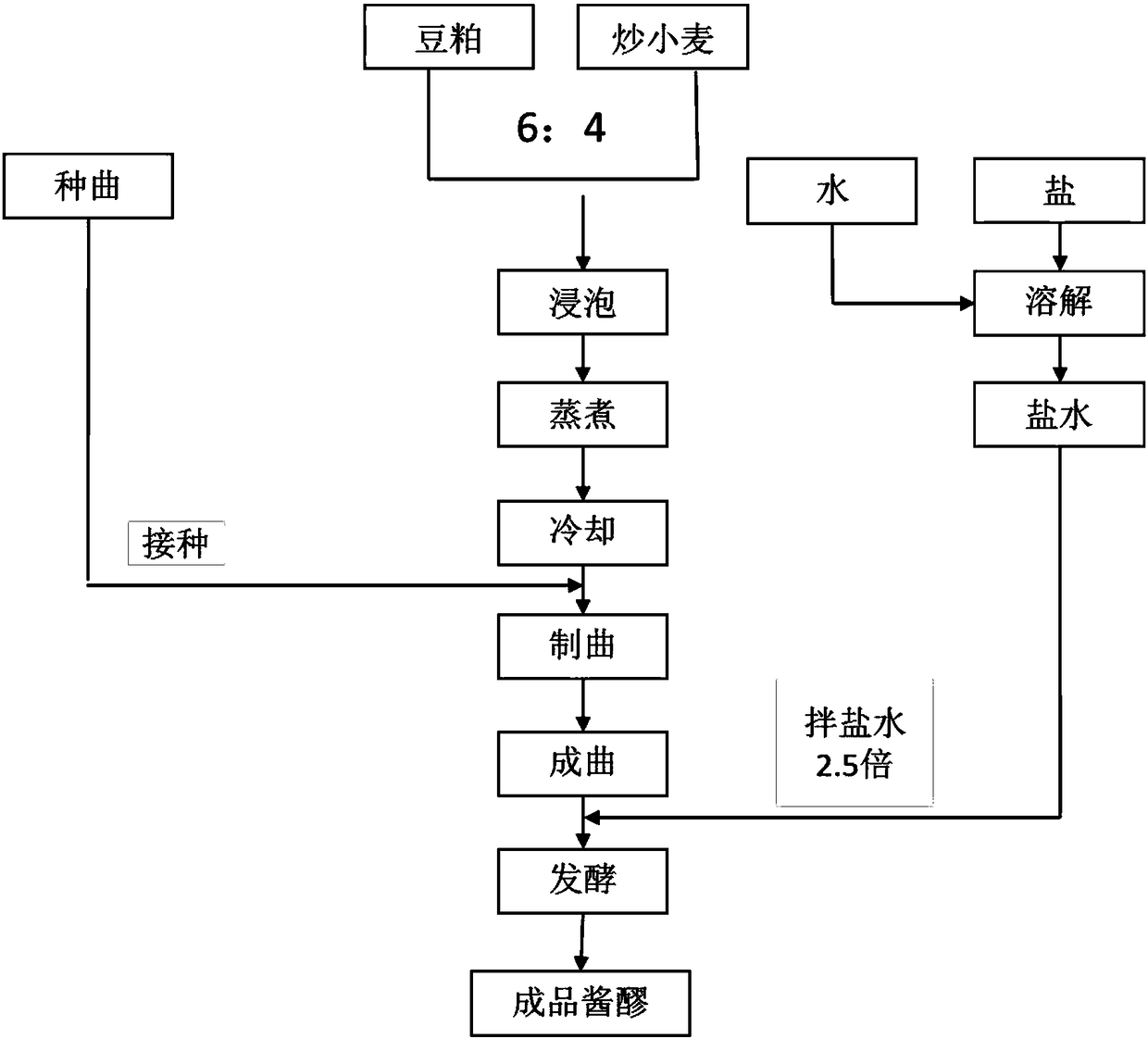

Brewing process of bean sauce mash for soybean sauce

PendingCN110101015AReduce protease activityInhibitionFood ingredient as flavour affecting agentHigh concentrationMaterials preparation

The invention provides a brewing process of a bean sauce mash for soybean sauce. The process comprises the following steps of (1) material preparation, wherein soybeans are cleaned, soaked and then cooked into cooked beans, and the cooked beans are cooled and uniformly mixed with flour and a culture to obtain a mixed material; (2) starter making, wherein the mixed material is put into a starter pool for culture to obtain a starter for making hard liquor, and the temperature of the starter material needs to be controlled to be 23-26 DEG C 2 hours before the starter is taken out; (3) fermentation, wherein brine is added to the starter for making hard liquor after being cooled, uniform stirring is carried out to prepare a bean sauce mash blank, the temperature of the cooled brine is 3-5 DEG C, and according to the concentration of the brine, it is ensured that the salt content of the liquid part of the bean sauce mash blank is 17.5-18.5 g / 100ml; the bean sauce mash blank is put into a fermentation tank for fermentation to prepare the bean sauce mash. The brewing process of the bean sauce mash for the soybean sauce has the advantages that by controlling the temperature of the starter material before the starter is taken out and adding the high-concentration low-temperature cooled brine to the starter for making hard liquor in the fermentation stage, the activity of protease in thebean sauce mash blank is reduced, and therefore the generation of white spots of the soybean sauce is inhibited.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

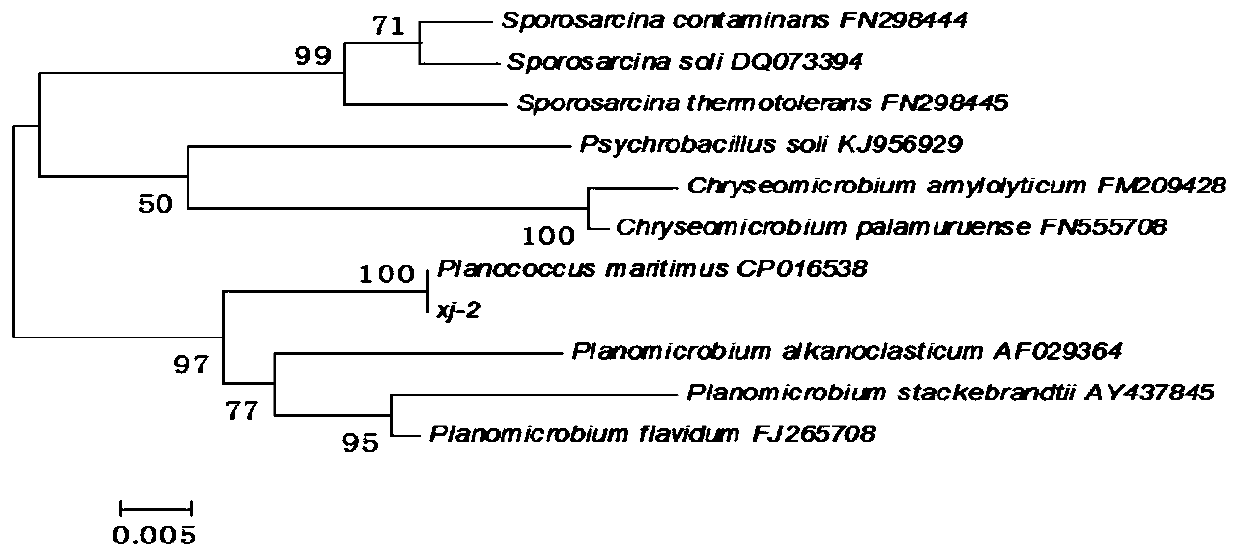

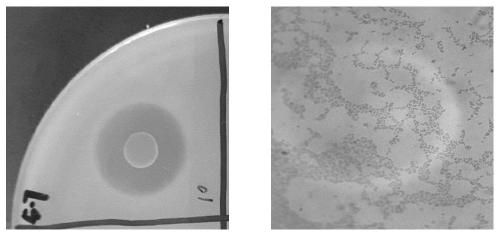

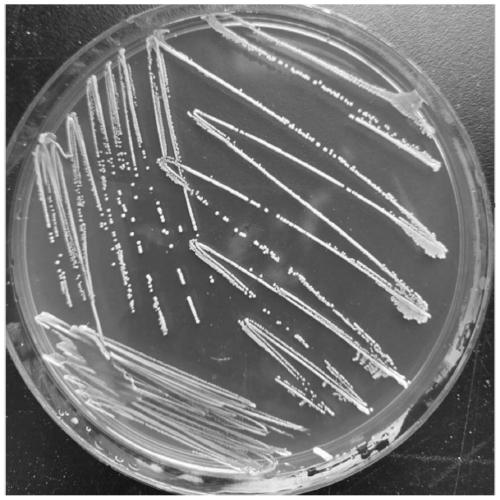

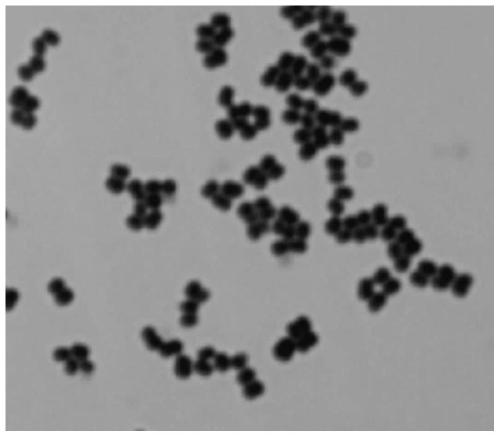

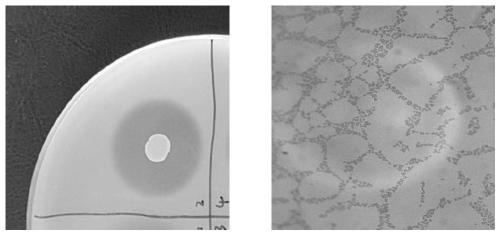

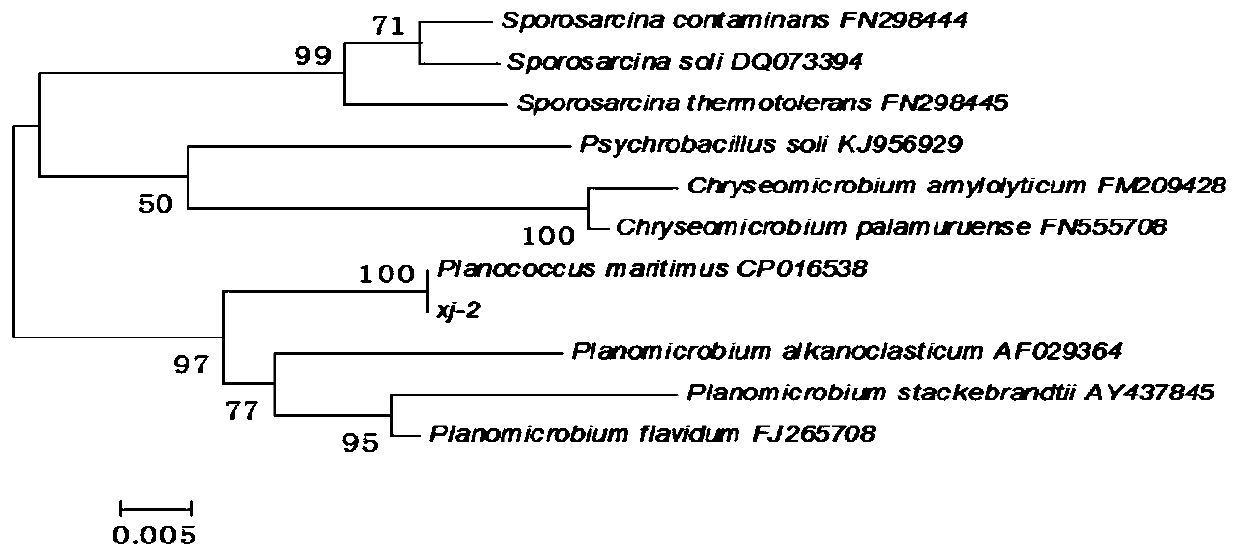

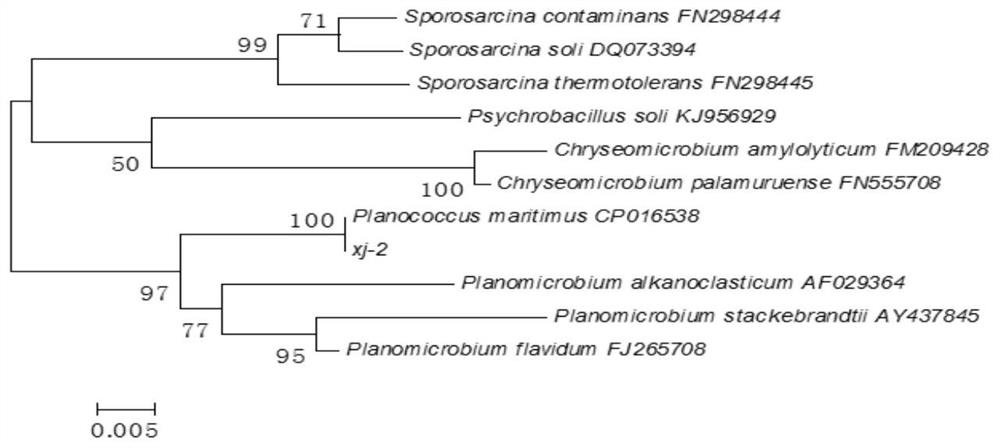

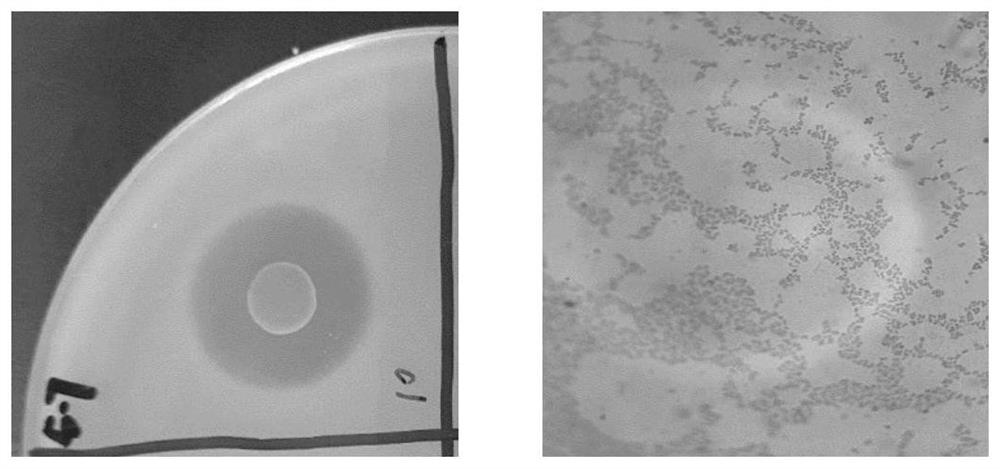

Planococcus ferment for improving low-salt fish sauce fermentation quality

ActiveCN111534451ADeliciousRich in nutritional valueBacteriaClimate change adaptationBiotechnologyFermentation starter

The invention discloses a planococcus ferment for improving the low-salt fish sauce fermentation quality, and relates to the application field of food microbiological technologies. Four strains of planococcus have been preserved in the China general microbiological culture collection centre (CGMCC); the numbers are respectively as follows: CGMCC NO.17057, CGMCC NO.17058, CGMCC NO.17059, and CGMCCNO.17060; and suggested classified names are respectively as follows: planococcus maritimus, planococcus plakortidis, planococcus dechangensis, and planococcus rifietoensis. The production period of the fish sauce fermented by utilization of planococcus is greatly reduced; the fermentation temperature is reduced; the fish sauce obtained by the method is transparent brownish red; and the fish saucehas the unique aroma of aquatic products, and is free from impurities, such as suspension or flocculation.

Owner:JIANGSU UNIV

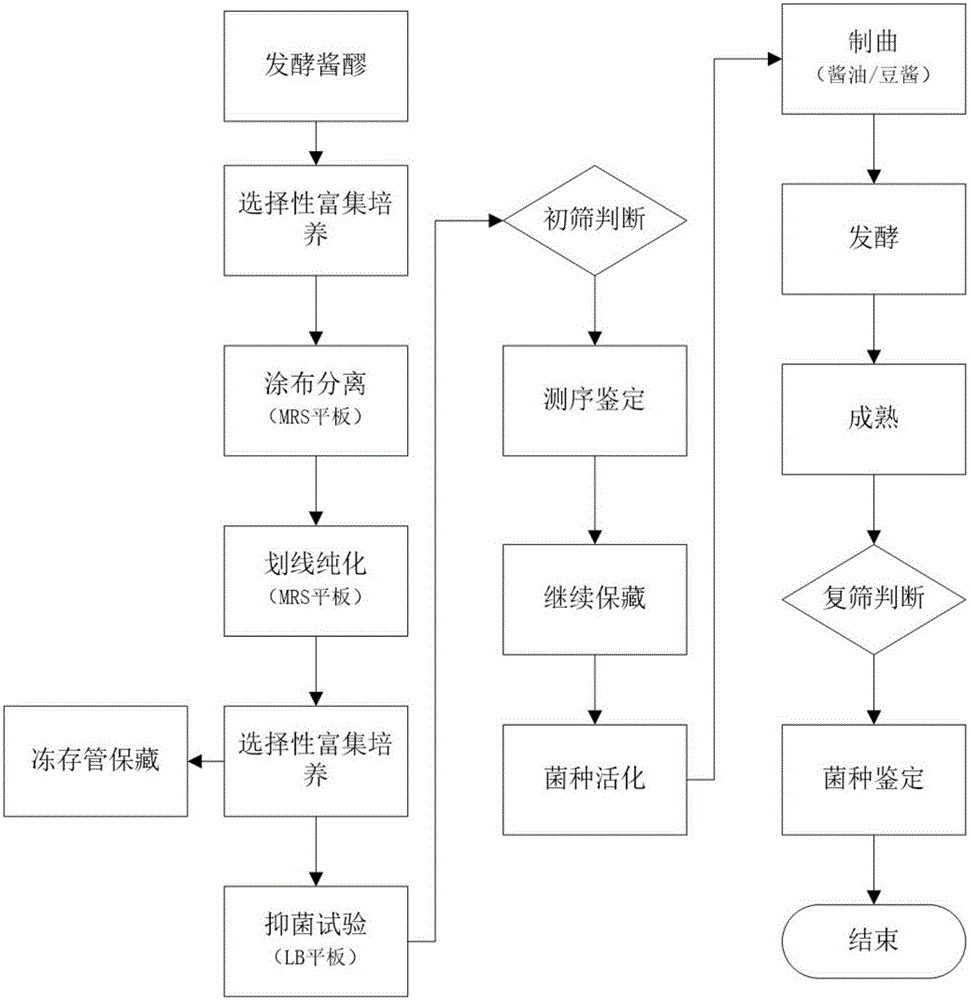

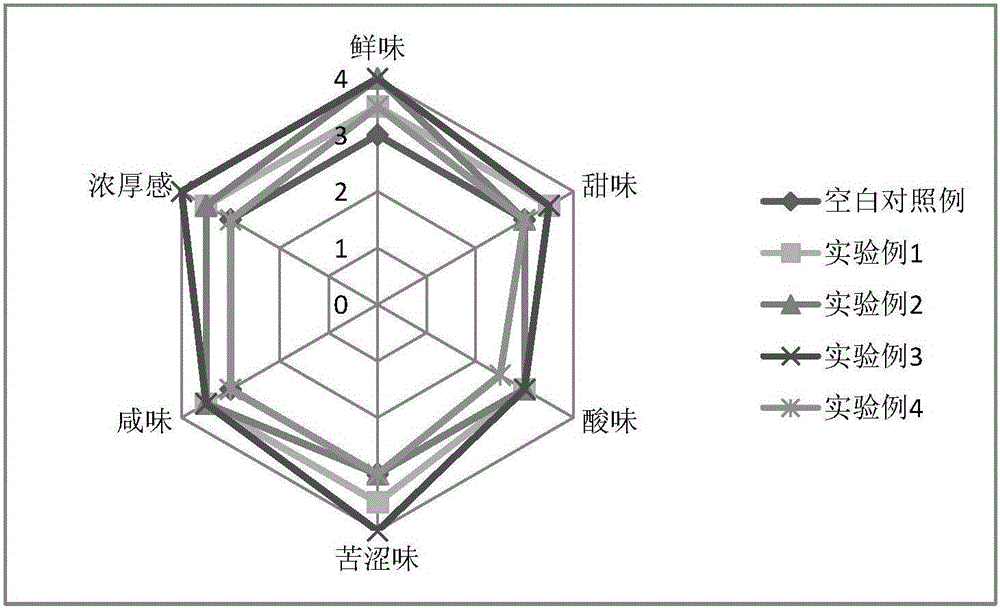

Pediococcus acidilactici for enhancing flavour of fermented soy sauce

ActiveCN110343635AAdd flavorImprove qualityBacteriaMicroorganism based processesMicroorganismSynechococcus

The invention belongs to the technical field of microorganisms, and specifically relates to a strain of pediococcus acidilactici for enhancing flavour of fermented soy sauce. The pediococcus acidilactici Pi Niang R036 has been deposited in Guangdong Culture Collection Center on March 21, 2019, with the deposit number of GDMCC NO: 60617. The strain of pediococcus acidilactici Pi Niang R036 can growup well at 4 DEG C - 50 DEG C, and be boosted to grow at a high temperature, reaching the fastest growth at 37 DEG C - 45 DEG C. The pediococcus acidilactici Pi Niang R036 can be tolerant to 12% salt, and normally grow up in 0%-8% salt concentration, and grow up in an acidic condition of pH 3.5-6. The pediococcus acidilactici of the invention can be made into a microbial agent that can be appliedin traditional fermented food industries such as thick broad-bean sauce, soy sauce, vinegar, soybean paste, fermented flour sauce and fermented soya beans as a functional inoculants for optimizing production process, improving flavour of the products and enhancing quality of the products.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

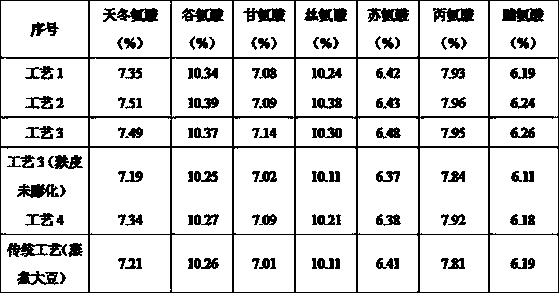

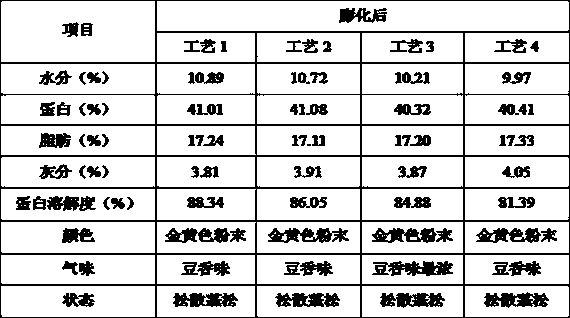

Method for brewing soy sauce through puffing soybeans

The invention provides a method for brewing a soy sauce through puffing soybeans. The method comprises the steps of pretreating raw materials: performing dust removal and impurity removal on soybeans,cleaning the soybeans after dust removal and impurity removal, crushing the cleaned soybeans to obtain bean granules, performing dust removal and impurity removal on bran, and cleaning the bran afterdust removal and impurity removal; puffing the raw materials: puffing the bean granules and the bran; preparing mother culture: weighing the puffed bran, flour and water, uniformly mixing the weighedbran with the weighed flour and the weighed water in the mass ratio of the weighed bran to the weighed flour to the weighed water being 4 to 1 to 4, performing sterilization, performing inoculation with aspergillus oryzae spores, and performing culturing until the mother culture is mature; preparing finished culture: weighing the puffed bean granules, the flour, the puffed bran and distilled water, uniformly mixing the weighed puffed bean granules with the weighed flour, the weighed puffed bran and the weighed distilled water in the mass ratio of the weighed puffed bean granules to the weighed flour, to the weighed puffed bran to the weighed distilled water being 20 to 16 to 1 to 16, performing sterilization, performing scattering, performing inoculation with mature mother culture havingthe same mass, and performing culturing until materials are covered with peak green spores so that finished culture is obtained; and preparing undecanted wine and performing fermentation: uniformly mixing the finished culture with salt water in the volume ratio of the finished culture to the salt water being 1 to 1.7, performing loading into a jar, and performing fermentation. Compared with a traditional technology, the method for brewing a soy sauce through puffing soybeans provided by the invention has the advantages that the time for brewing the soy sauce is shortened, the utilization rateof protein and the yield rate of the soy sauce can be increased, and the soy sauce is outstanding in palatable taste and unique in flavor and has scorch aroma compared with finished products in the prior art.

Owner:HENAN SHENNONG FEED TECH CO LTD

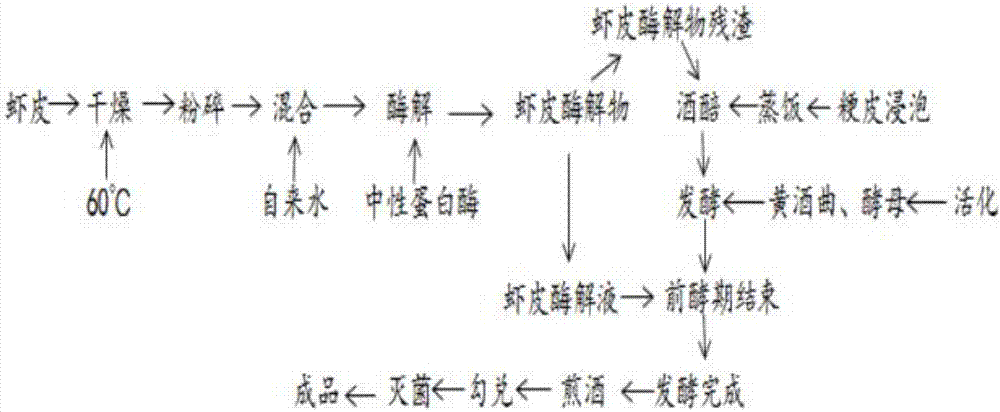

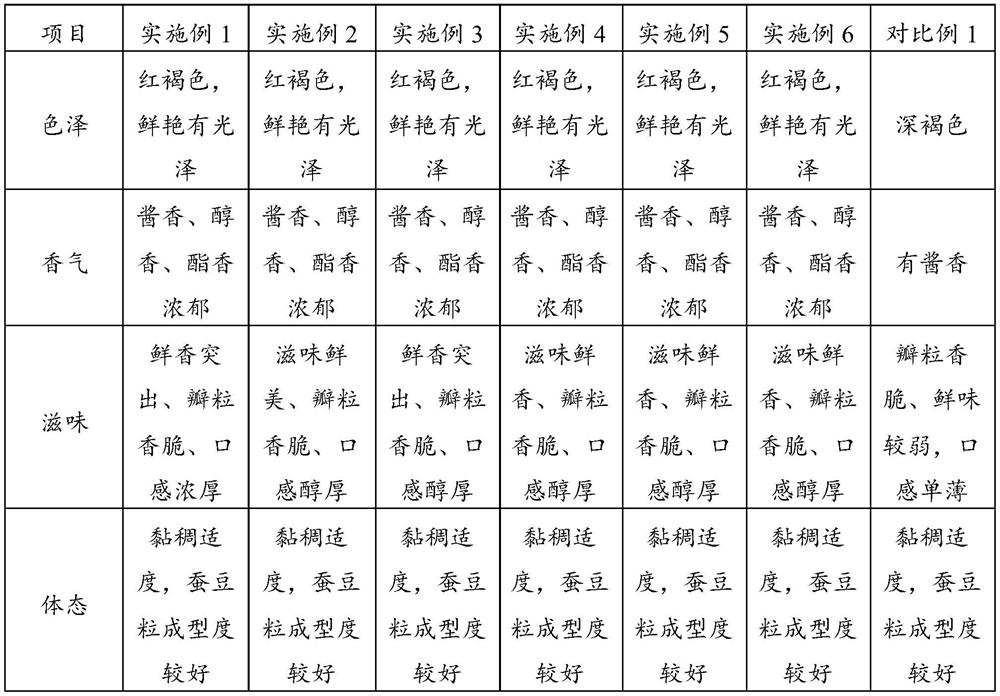

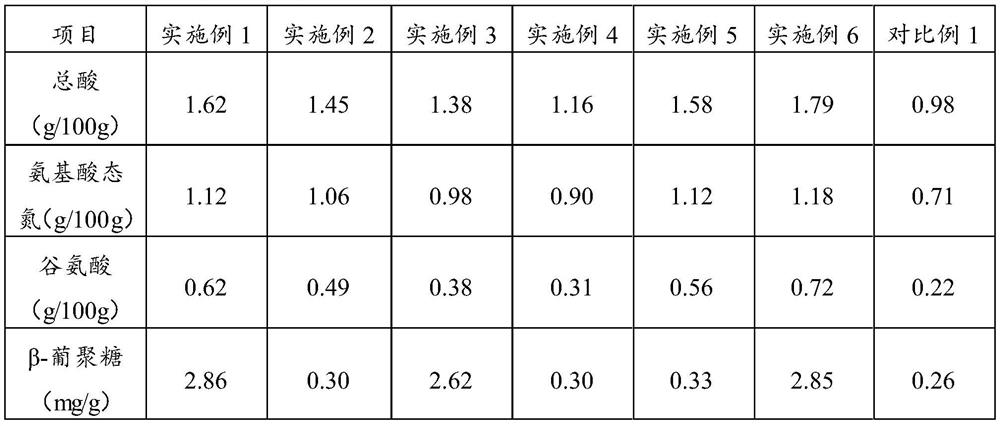

Shrimp-taste cooking wine and preparation method thereof

The invention discloses shrimp-taste cooking wine and a preparation method thereof. The cooking wine is prepared through fermentation of a main material of polished round-grained rice and an auxiliary material of dried small shrimps. The method at least comprises the following steps of mixing pretreated dried small shrimps with neutral protease, and performing enzymolysis so as to obtain dried small shrimp zymolyte; performing centrifuging to obtain enzymatic hydrolysate and zymolyte residues; then adding the dried small shrimp zymolyte residues into boiled milled rice which is steamed, adding distiller's yeast and active dry yeast, and performing fermentation; and after a primary fermentation period is completed, adding the dried small shrimp enzymatic hydrolysate, performing after fermentation, and after the fermentation is completed, performing filtration so as to obtain wine fluid. According to the cooking wine and the preparation method thereof disclosed by the invention, the dried small shrimps are subjected to baking, crushing and proteolysis treatment, so that the dried small shrimp zymolyte is obtained; the dried small shrimp zymolyte is added to alcoholic fermentative materials, and co-fermentation is performed so that the cooking wine is produced; and the content of amino-acid nitrogen in the shrimp-taste cooking wine is high, so that the shrimp-taste cooking wine not only has rich specific fragrance and palatable taste of cooking wine, but also has the efficacy of enriching the calcium, resisting ageing and protecting the heart.

Owner:安徽海神黄酒集团有限公司

High amino acid nitrogen sweet bean half brewing technology

ActiveCN110037247AHigh amino acid nitrogen contentImprove rednessClimate change adaptationFood ingredient as taste affecting agentFlavorBiotechnology

The present invention discloses a high amino acid nitrogen sweet bean half brewing technology and belongs to the field of food fermentation technology. The brewing technology comprises the following steps: (1) aspergillus oryzae and rice residues are inoculated into cooked broad bean halves, and even stirring and koji-making are conducted to obtain a broad bean half koji material; and (2) the broad bean half koji material is subjected to a diluted state fermentation to obtain sweet bean halves. The technology uses the rice residues to improve amino acid nitrogen of the sweet bean halves, and the obtained sweet bean halves are red and bright in color and luster, and mellow in ester flavor and sauce fragrance.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Broad bean mash and preparation method thereof

PendingCN111869827AHigh amino acid nitrogen contentOutstanding fragranceFood scienceBiotechnologyAspergillus oryzae

The invention provides broad bean mash and a preparation method thereof. The broad bean mash is prepared from the following raw materials in parts by weight of 100 parts of dried broad beans, 15-25 parts of compound wheat flour, 100-140 parts of saline water and 0.02-0.05 part of aspergillus oryzae koji essence, wherein the compound wheat flour comprises wheat flour, highland barley flour and vital gluten in a mass ratio of (3-8): (0-7): (0-3); the saline water comprises edible salt, water and soy sauce; and the content of amino acid nitrogen in the saline water is 0.1-0.3 g / 100mL, and the concentration of the saline water is 27.0-30.0 g / 100mL. According to the broad bean mash provided by the invention, under the combined action of the components with the contents, the amino acid content of the broad bean mash is relatively high, and the broad bean mash is fresh and fragrant, ruddy in color and luster, rich in sauce ester fragrance and fragrant and crisp in petals.

Owner:成都市金福猴食品股份有限公司 +1

Method for improving flavor of high-salt liquid fermentation soy sauce with various salt-tolerant yeasts

InactiveCN108433085AIncrease profitImprove the situation of a single flavor substanceYeast food ingredientsYeastFlavor

The invention discloses a method for improving flavor of a high-salt liquid fermentation soy sauce with various salt-tolerant yeasts. According to the method, different salt-tolerant yeasts are addedto the high-salt liquid fermentation soy sauce in a combining manner at different time, so that the product quality of the obtained soy sauce is improved, and the flavor is improved, wherein the salt-tolerant yeasts are microzymes normally growing under the salinity of 16-18%. According to the method, various salt-tolerant yeasts are added, so that the condition that the soy sauce is single in flavor substances is improved. According to the method, a fermentation method of a conventional high-salt liquid fermentation soy sauce is improved, so that various flavor substances of alcohols, aldoketones, phenols, acids and the like in finished products of the soy sauce are increased, and the flavor and the product quality of the finished products of the soy sauce are improved.

Owner:TIANJIN UNIV OF SCI & TECH

Pediococcus acidilactici and application thereof

The invention relates to Pediococcus acidilactici and use thereof in preparation of seasonings and further relates to a method for preparing the seasonings from Pediococcus acidilactici. The strain is Pediococcus acidilactici ZF559 and has a preservation number of CCTCC M 2016690. By preparing the seasonings from the strain, the growth of bacillus can be remarkably inhibited, and the number of the bacillus in a product can be remarkably reduced.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +2

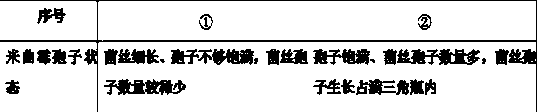

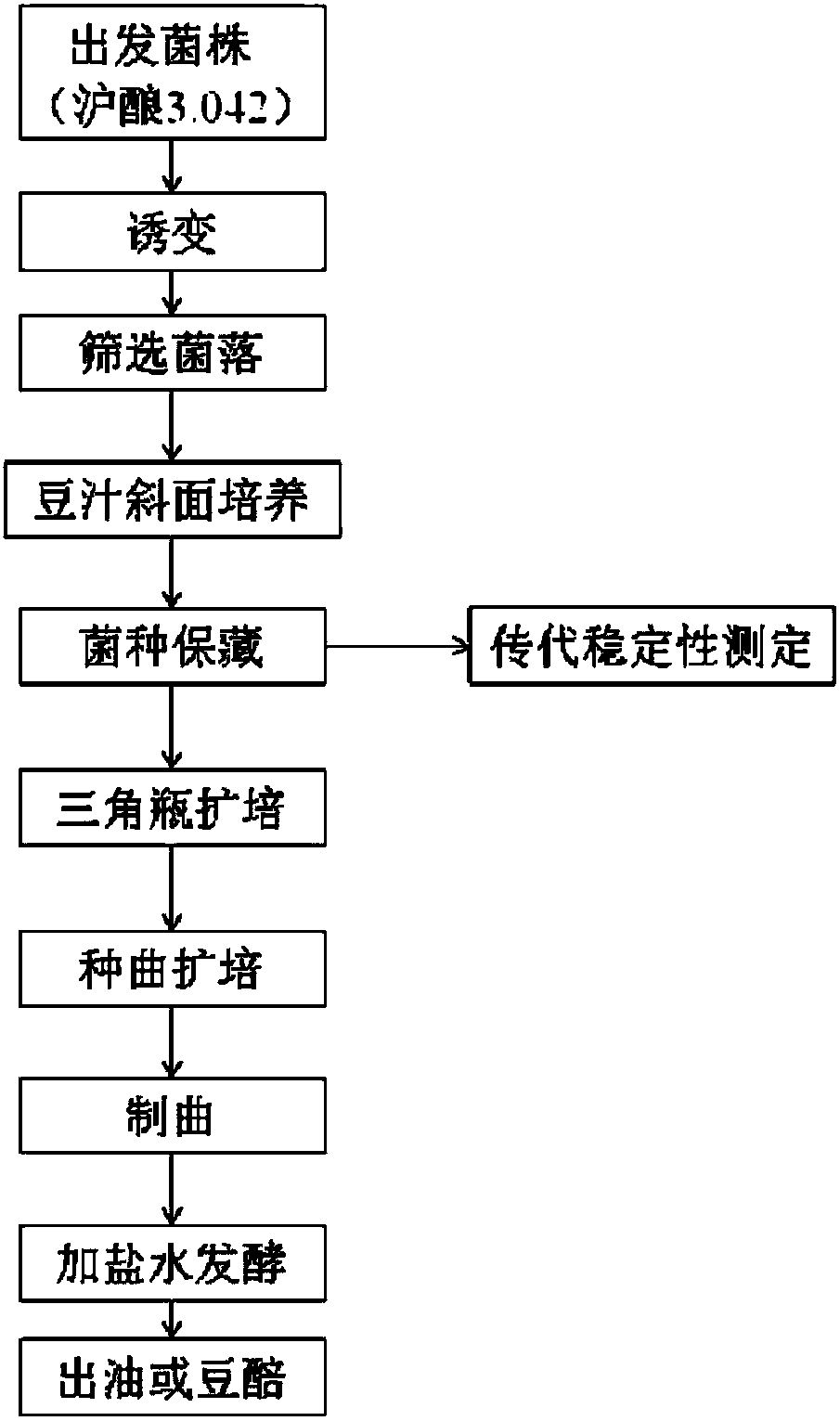

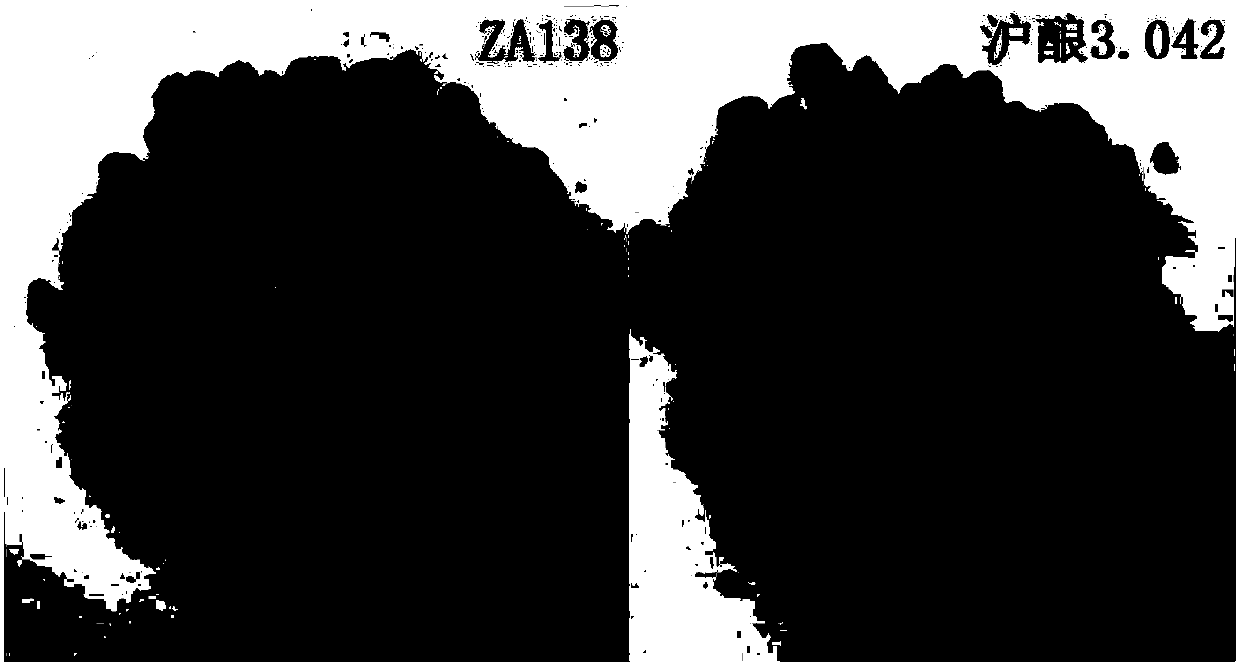

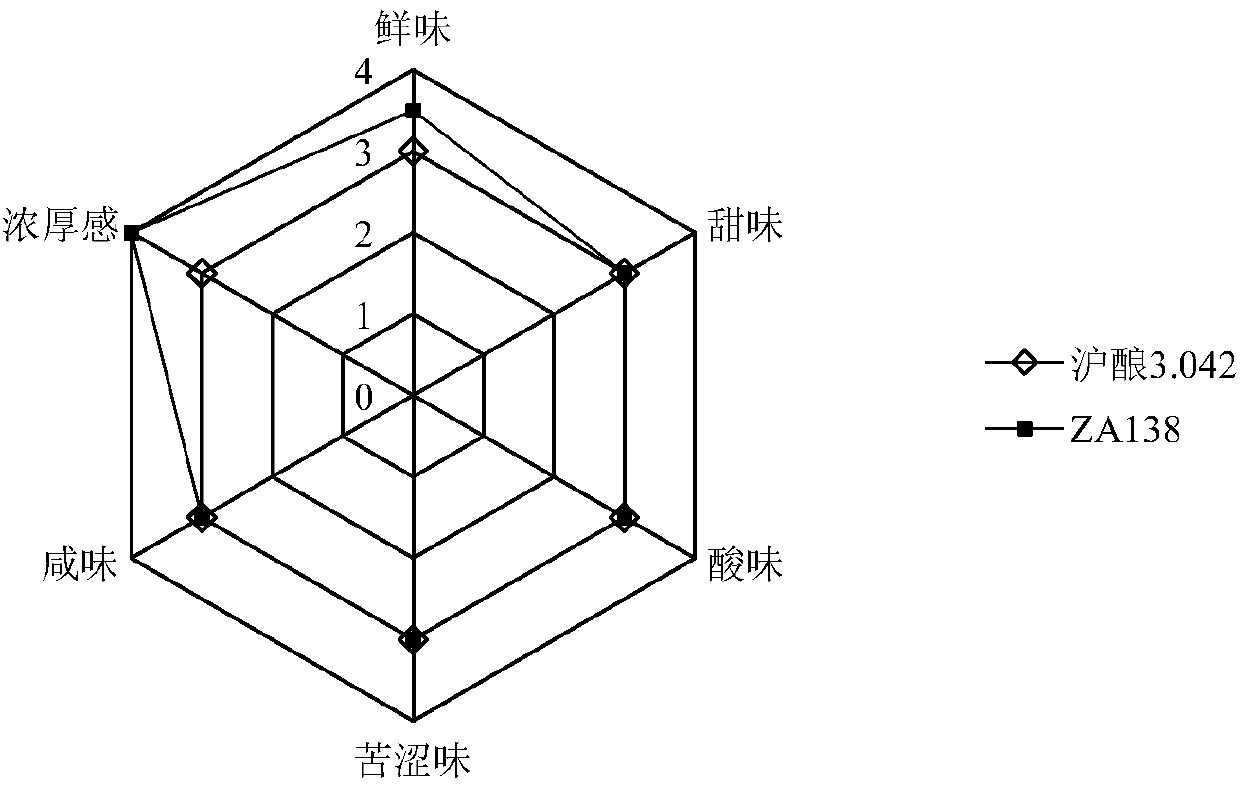

Aspergillus oryzae ZA138 and application thereof

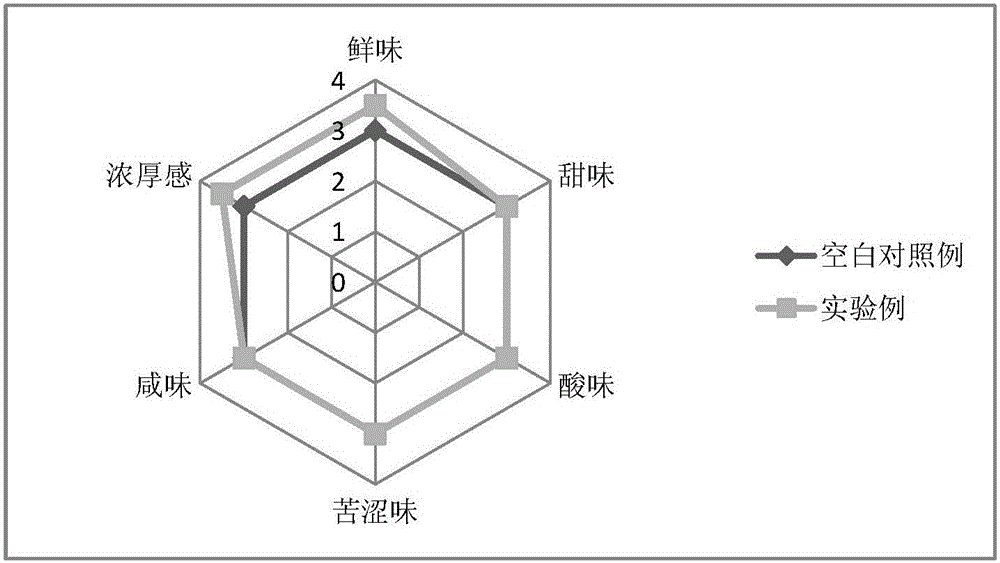

ActiveCN107586729AEasy to trainIncrease protease activityFungiMicroorganism based processesFlavorAspergillus oryzae

The invention relates to aspergillus oryzae ZA138. When the aspergillus oryzae ZA138 is applied at a koji-making stage, the caking phenomenon can be obviously reduced, the oxygen supply and growth ofaspergillus oryzae are prompted, and the activity of protease of finished koji can be obviously enhanced; the amino acid nitrogen content of soy sauce and sauce fermented by making koji using the aspergillus oryzae ZA138 is obviously enhanced, so that the product flavor is obviously improved. The invention also relates to application of aspergillus oryzae ZA138 in koji making. The invention also relates to application of aspergillus oryzae ZA138 in koji making, wherein the finished koji obtained by aspergillus oryzae ZA138 in koji making is used for preparing soy sauce and / or sauce. The invention also relates to application of the aspergillus oryzae ZA138 in preparation of soy sauce and / or sauce.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

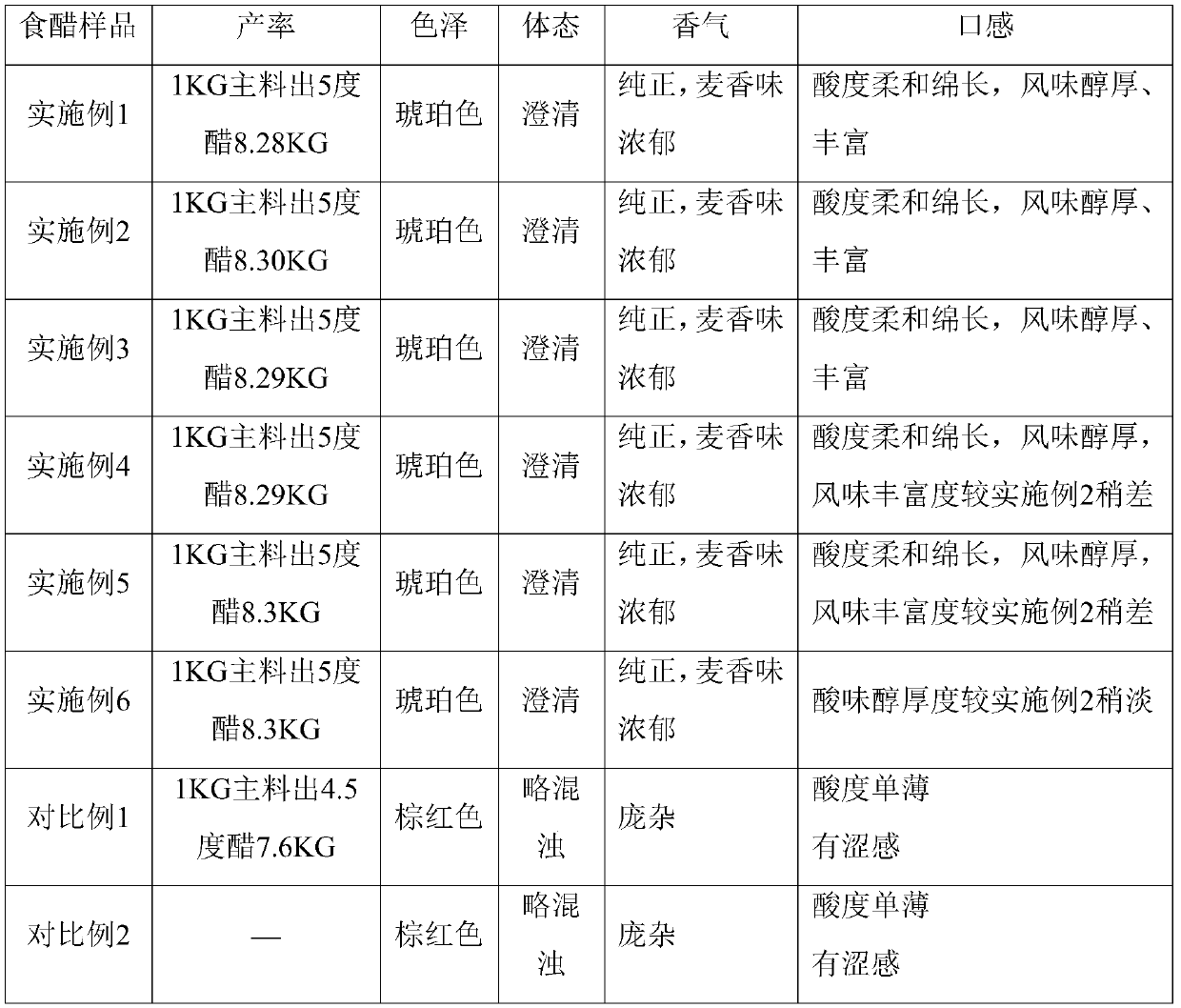

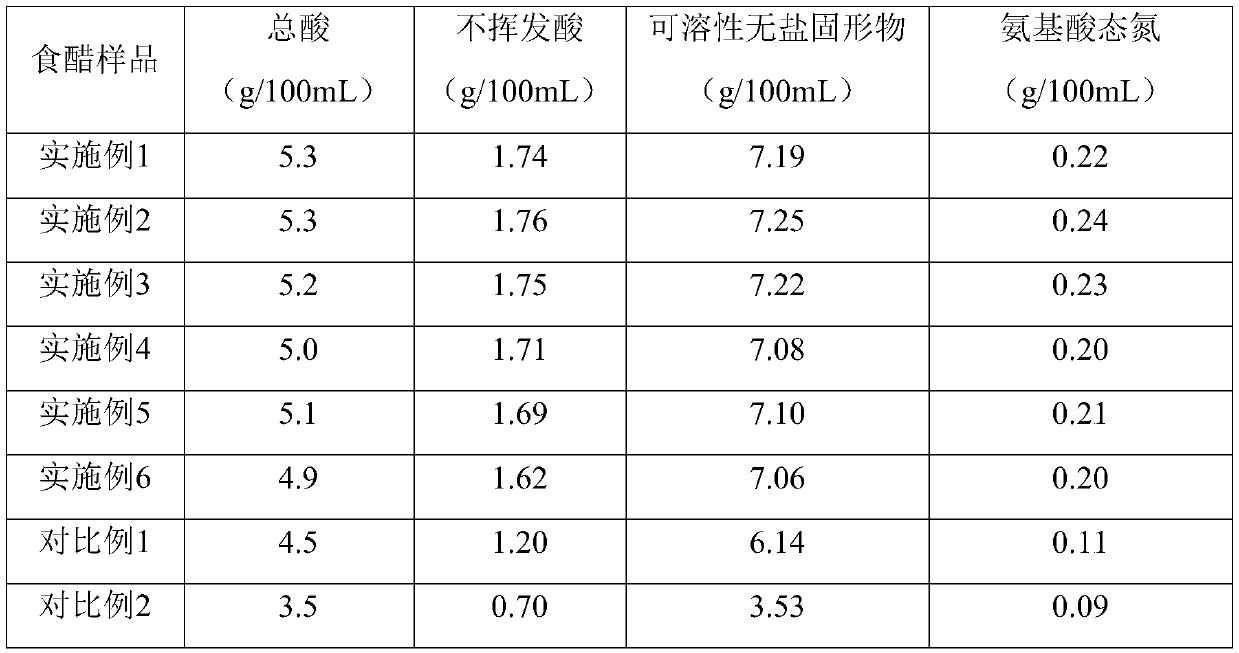

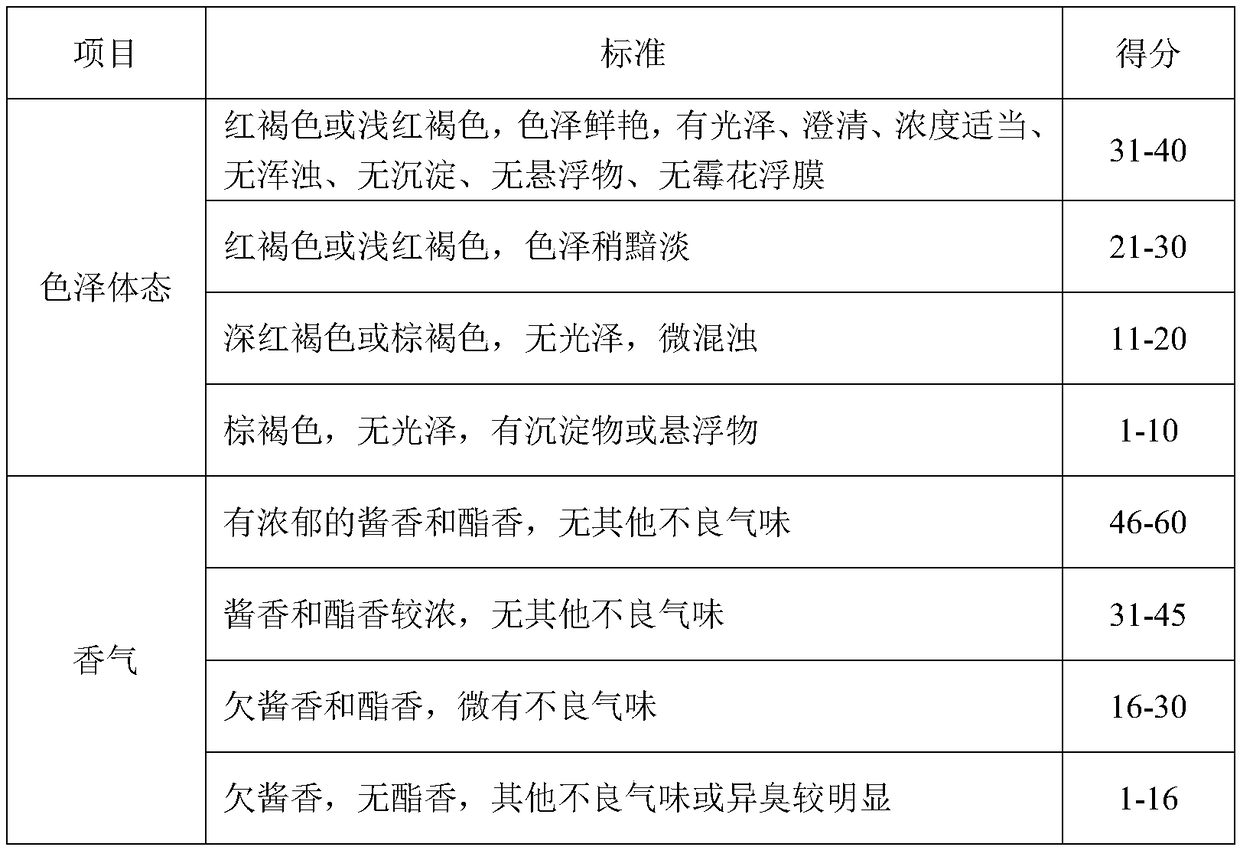

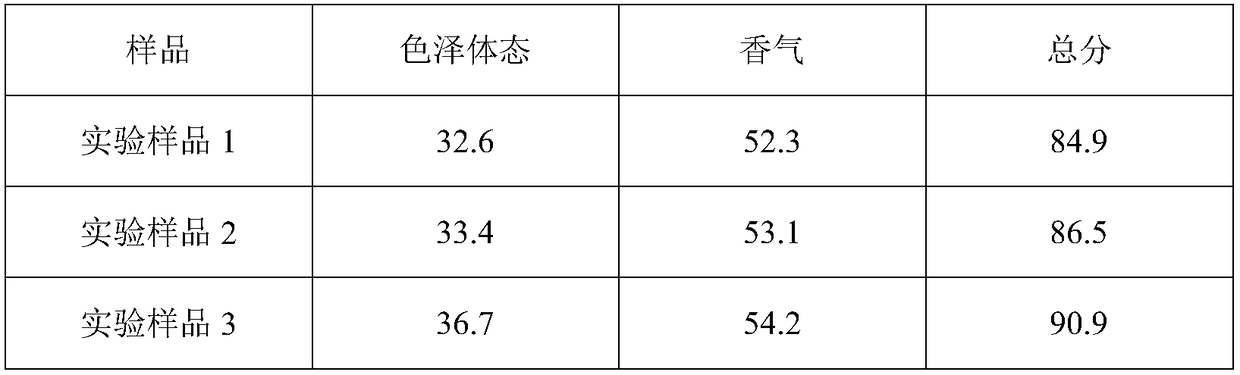

Raw material solid-state method brewing process of vinegar and brewed vinegar

The invention discloses a raw material solid-state method brewing process of vinegar and brewed vinegar. The process includes the following steps: a. wetting 480-530 parts of barley kernels as a culture medium, inoculating 0.7-0.8 part of aspergillus oryzae into the culture medium, and fermenting to prepare wheat kernel koji; b. mixing and pulverizing 480-530 parts of rice flour, 480-530 parts ofsorghum, 80-120 parts of large yellow croaker and 80-120 parts of millet to obtain a raw material mixture; uniformly mixing the raw material mixture, 650-750 parts of wheat kernel koji, 5800-6200 parts of hot water at 55-65 DEG C, 450-550 parts of bran and 1.8-2.2 parts of saccharifying enzyme, saccharifying to obtain saccharified products; c. continuously adding 950-1050 parts of bran, 0.8-1.2 parts of activated dry yeast and 350-400 parts of rice husk, mixing evenly, and fermenting to obtain alcoholized products; d. continuously adding 450-550 parts of bran, 850-900 parts of rice husk and 0.4-1 part of acetic acid bacteria, mixing, and acetifying to obtain a vinegar liquid; and e. drying and brewing the vinegar liquid to prepare the vinegar. The protein substances in the grain of the process are more fully decomposed, the vinegar has clear posture, soft and long acidity, mellow and rich flavor and better taste.

Owner:北京市时利和酿造厂

Soybean sauce microbial immobilization fermentation composition, preparation process and use method

ActiveCN108949592AIncrease reproductive rateImprove fermentation capacityFungiBacteriaAnti stressTrehalose

The invention provides a soybean sauce microbial immobilization fermentation composition, a preparation process and a use method and particularly relates to the technical field of production of seasonings. The fermentation composition includes: low-fat pectin, water, zygosaccharomyces rouxii, zygosaccharomyces sojae, torulopsis etchellsii, pediococcus halophilus, tetracoccus sojae, an MgCl2 solution, egg white, azotobacter chroococcum and trehalose. When being used for fermentation of soybean sauce, the fermentation composition is stirred and mixed with soybean sauce mash, then nitrogen is fedfor performing fermentation; finally the fermented product is filtered to obtain a fermented liquid. The fermentation composition is toxic-free and environment-friendly, is anti-stress and anti-corrosion and can be recycled; when being used for fermentation of soybean sauce, the fermentation composition can reduce fermentation period, and the fermented liquid is high in contents of soluble non-salt solids, total nitrogen and amino acid nitrogen.

Owner:广西顶俏食品科技集团有限公司

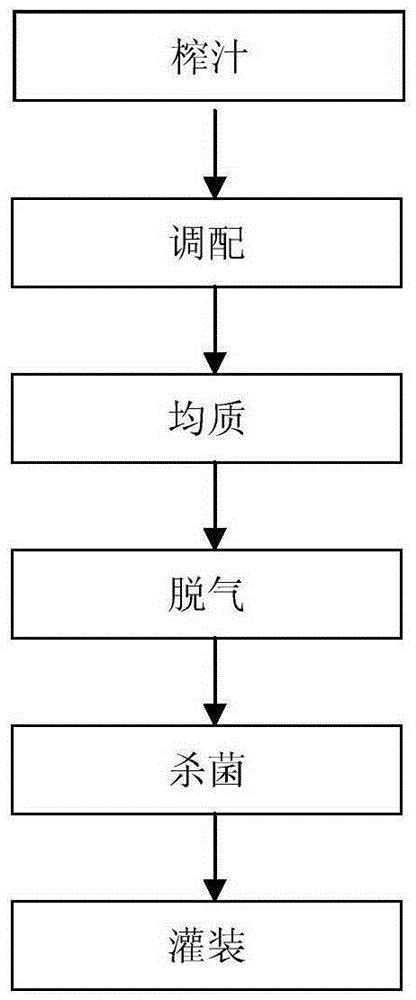

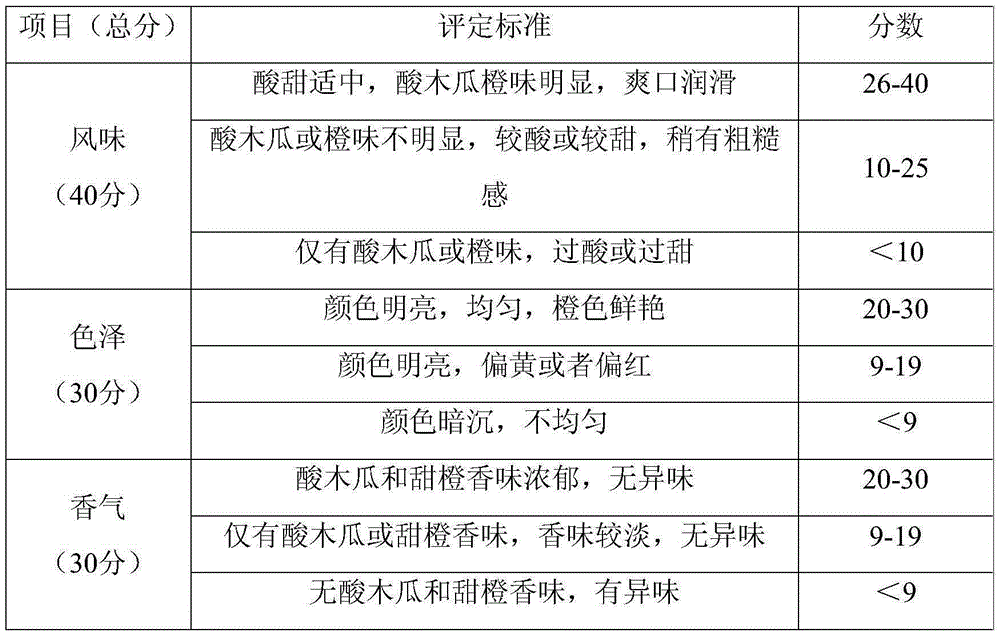

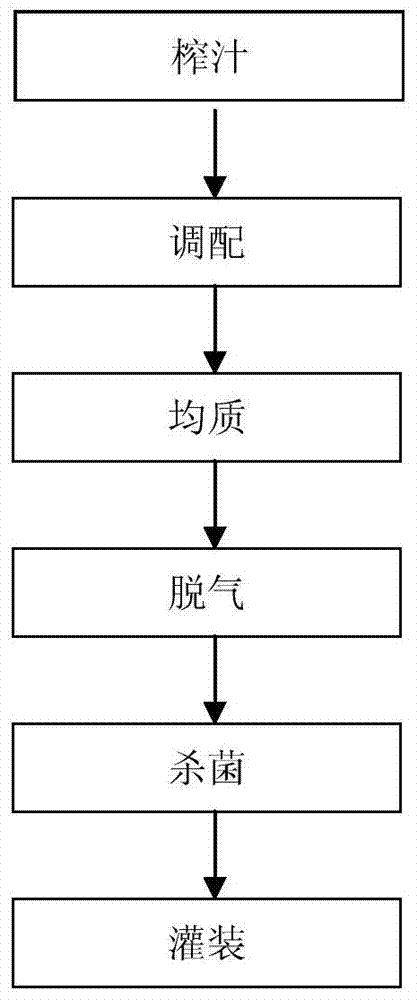

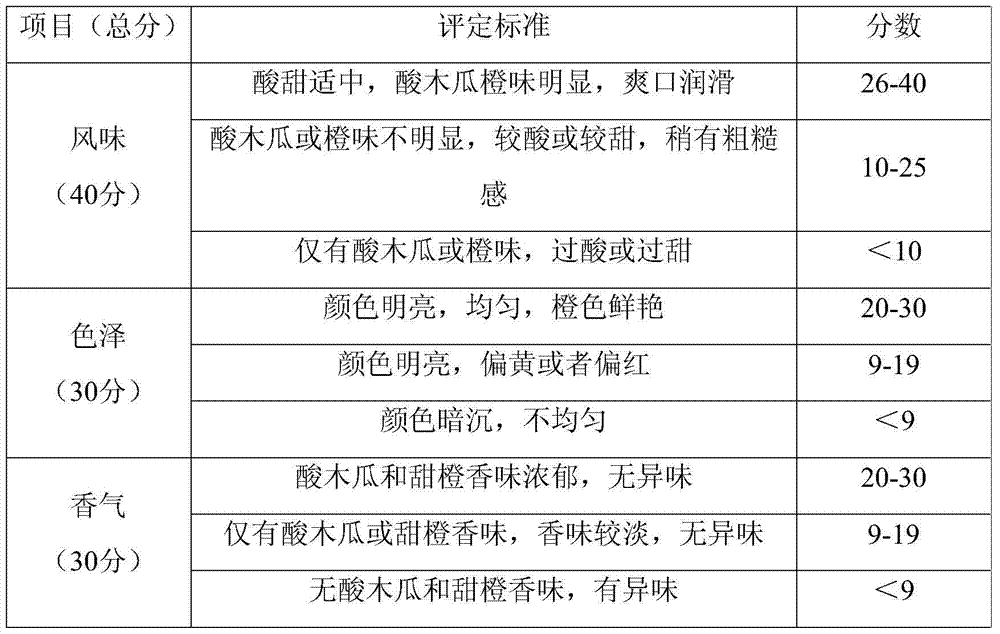

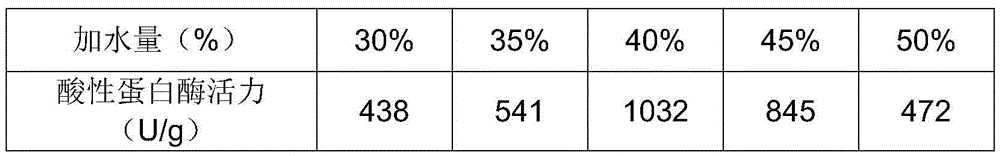

Sweet orange and chaenomeles speciosa fruit drink and preparation method thereof

ActiveCN105360839AVersatile and versatileIncreased nitrogen contentFood scienceNavel orangeOrange juice

The present invention discloses a sweet orange and chaenomeles speciosa fruit drink preparation method. The sweet orange and chaenomeles speciosa fruit drink includes 68.6 v / v%-70.5 v / v% of orange juice, 11.4 v / v%-11.5 v / v% of chaenomeles speciosa fruits, 6 w / v% of sugar, 0.2 w / v% of citric acids, 0.15 w / v% of stabilizer and 18 v / v%-20 v / v% of water. The preparation method comprises juicing, blending, homogenizing, degassing, sterilizing, filling and other steps. The sweet orange and chaenomeles speciosa fruit drink is moderate in sweetness and sourness, has special fragrances of Newhall navel oranges and chaenomeles speciosa fruits in Yunnan province and a double nutrition of the navel oranges and chaenomeles speciosa fruits and is high in nutritional value. The preparation process is simple.

Owner:HUNAN AGRI PRODS PROCESSING INST

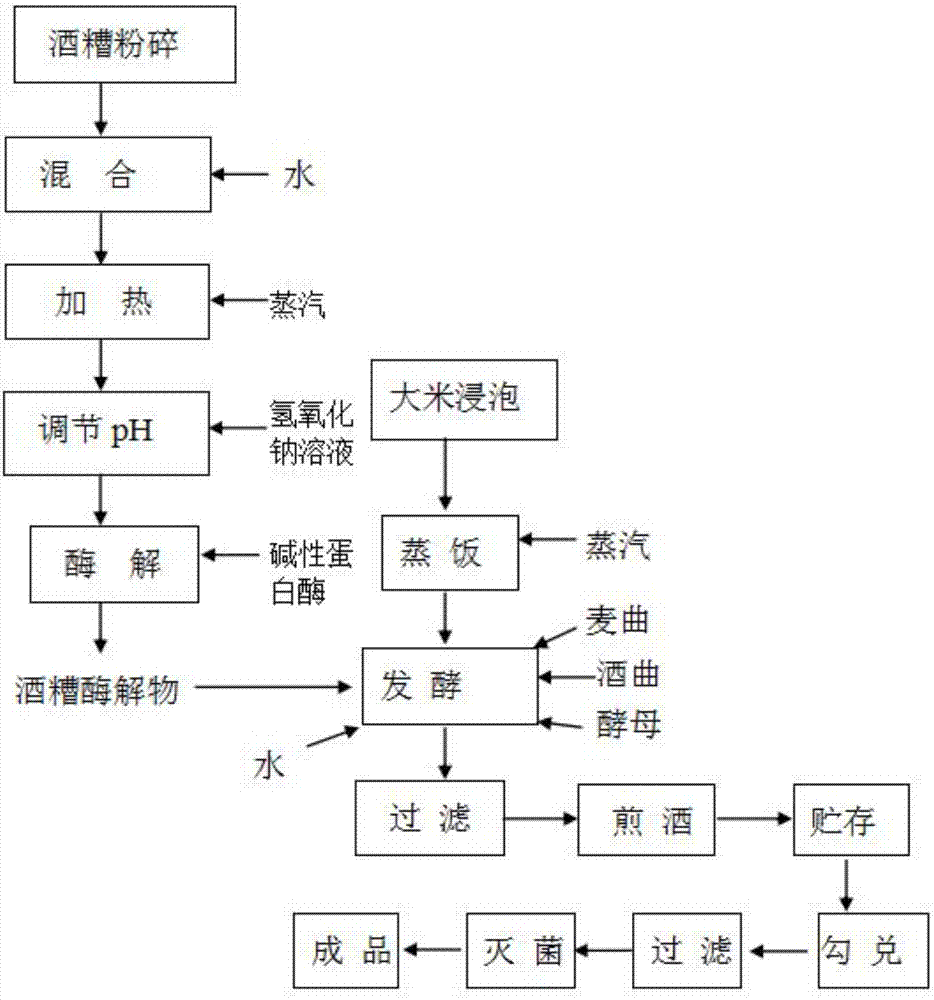

Method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage

The invention discloses a method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage. The method at least comprises the following steps of: mixing pretreated stillage with alkaline protease and performing enzymolysis to obtain stillage enzymatic hydrolysate; adding the prepared stillage enzymatic hydrolysate into steamed rice; adding wheat koji, distiller's yeast and active dry yeast; and performing fermentation. According to the method disclosed by the invention, the stillage enzymatic hydrolysate is obtained from the cooking wine stillage by pulverization, heating and protease treatment, the stillage enzymatic hydrolyzate is added into the rice, the fermentation production of the cooking wine is performed, the content of the amino acid nitrogen in the cooking wine is high, and the delicate flavor of the cooking wine is rich; and in addition, when the cooking wine is produced by using the method, resource utilization of the cooking wine stillage can be achieved, the production cost is reduced and the generation of ''waste residues'' in the production process of the cooking wine is reduced.

Owner:安徽海神黄酒集团有限公司

Method for improving fermentation quality of low-salt fish sauce by using mixed strains of planococcus

ActiveCN111227216AShorten the fermentation cycleLow fermentation temperatureFood scienceBiotechnologyFermentation starter

The invention discloses a method for improving the fermentation quality of low-salt fish sauce by using mixed strains of planococcus, and belongs to the technical field of food microbiology. The production cycle of the fish sauce fermented by using the mixed strains of planococcus (the deposition numbers are CGMCC NO.17057, CGMCC NO.17058, CGMCC NO.17059 and CGMCC NO.17060 correspondingly) is greatly shortened, and the fermentation temperature is reduced. The fish sauce obtained by the method is transparent brownish red, with the unique aroma of aquatic products, and without impurities such assuspension or flocculent. The finished products of the fish sauce are low in salt content and high in amino acid nitrogen content (according to the Chinese fish sauce industry standard, the fish sauce is classified as first-grade fish sauce), the content of volatile basic nitrogen and histamine are lower than the national standard, the prepared fish sauce is delicious and of good quality, and a more stable, safer and more suitable mixed leavening agent is provided for the fermentation of fish sauce.

Owner:JIANGSU UNIV

Moisturizing and skin nourishing chicken soup tin and preparation method thereof

InactiveCN109043367ADeliciousFull of nutritionNatural extract food ingredientsFood ingredient functionsAmomum tsao-koTraditional medicine

The invention belongs to the technical field of food processing, and particularly discloses a moisturizing and skin nourishing chicken soup tin and a preparation method thereof. The chicken soup tin comprises the following raw materials in parts by weight: 1000 to 2000 parts of blackone chicken, 1 to 6 parts of a traditional Chinese medicine composition, and 15 to 50 parts of a flavoring agent, wherein the traditional Chinese medicine composition comprises the following raw materials in parts by weight: 5 to 15 parts of fructus perillae, 5 to 15 parts of brassica juncea, 5 to 10 parts of semenraphani, 5 to 10 parts of hippophae rhamnoides, 5 to 10 parts of zizyphus, 3 to 10 parts of pericarpium citri reticulatae, 3 to 8 parts of atpinia officnarum hange, 1 to 8 parts of semen coicis, 1 to8 parts of piper nigrum, 1 to 5 parts of amygdalus communis, 1 to 5 parts of amomum villosum, and 1 to 5 parts of amomum tsao-ko; and the components are mixed and boiled, so as to form the chicken soup tin. The chicken soup tin is formed by compounding and boiling the blackone chicken and traditional Chinese medicine composition, is rich in nutrition and easy to absorb, has the effect of moisturizing and skin nourishing, and meanwhile is high in sensory quality.

Owner:广西万寿谷投资集团股份有限公司

Sweet orange sour papaya drink and preparation method thereof

ActiveCN105360839BStrong complementarityVersatile and versatileFood scienceNutritive valuesPapaya family

The present invention discloses a sweet orange and chaenomeles speciosa fruit drink preparation method. The sweet orange and chaenomeles speciosa fruit drink includes 68.6 v / v%-70.5 v / v% of orange juice, 11.4 v / v%-11.5 v / v% of chaenomeles speciosa fruits, 6 w / v% of sugar, 0.2 w / v% of citric acids, 0.15 w / v% of stabilizer and 18 v / v%-20 v / v% of water. The preparation method comprises juicing, blending, homogenizing, degassing, sterilizing, filling and other steps. The sweet orange and chaenomeles speciosa fruit drink is moderate in sweetness and sourness, has special fragrances of Newhall navel oranges and chaenomeles speciosa fruits in Yunnan province and a double nutrition of the navel oranges and chaenomeles speciosa fruits and is high in nutritional value. The preparation process is simple.

Owner:HUNAN AGRI PRODS PROCESSING INST

Fermented soy sauce and preparation method thereof

The invention relates to the field of food processing, and particularly discloses fermented soy sauce and a preparation method thereof. The preparation method comprises the following steps: a, mixing the soaked soybeans with the wheat kernels, and then curing to obtain a mixture; b, at the temperature of 35-40 DEG C, mixing the mixture, koji and flour for koji making to obtain soy sauce koji, then uniformly mixing the soy sauce koji with a salt solution to obtain fermented mash, controlling the temperature of the fermented mash to be 45-50 DEG C, performing early-stage fermentation, then adding the salt solution, continuing later-stage fermentation, pumping out soy in the fully fermented mash, and performing solarization under light, thereby obtaining the fermented soy sauce. The fermented soy sauce prepared by the preparation method disclosed by the invention is relatively high in reducing sugar content, relatively high in amino acid nitrogen content, relatively high in palatable taste degree, bright in color and luster, rich and mellow in sauce flavor, natural in fresh, sweet and salty mixture, free of additives such as a preservative, a flavor enhancer, a sweetening agent and a coloring agent, and is healthy and safe.

Owner:北京市时利和酿造厂

Preparation method for glutathione-enriched nucleic acid yeast powder

InactiveCN105581345AAvoid wastingReduce processing costsFungiAnimal feeding stuffTotal nitrogenWaste material

The invention relates to a preparation method for nucleic acid yeast powder. The yeast powder is rich in glutathione and is obtained through the steps that mother liquor obtained after glutathione is extracted is pretreated and then mixed with fresh yeast, and enzymolysis and drying are performed. The preparation method of the yeast autolysis powder comprises the following steps that 1, the mother liquor obtained after glutathione is extracted is pretreated; 2, the mother liquor is settled; 3, primary enzymolysis is performed; 4, secondary enzymolysis is performed; 5, after secondary enzymolysis is finished, the glutathione-enriched nucleic acid yeast autolysis powder is obtained through spray drying. The preparation method has the advantages that the mother liquor obtained after glutathione is extracted is recycled in a reasonable mode, the waste material is changed into things of value, and waste of glutathione and the amino acid polypeptide ingredients is avoided; the obtained autolysis powder is high in content of total nitrogen and amino acid nitrogen, high in nutritional value, low in ash content and good in product quality.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

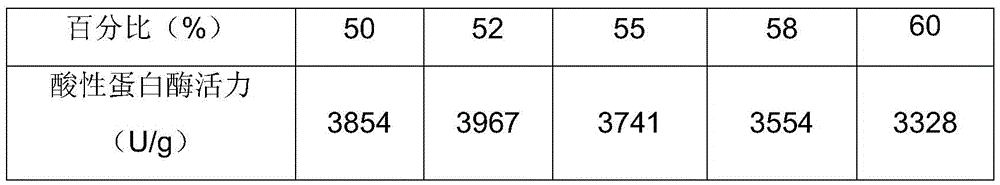

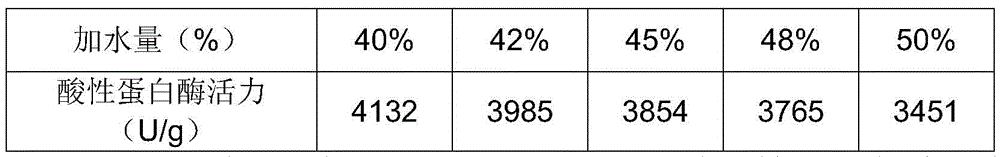

Soy sauce brewing method for increasing amino acid yield by utilizing enzyme preparation

ActiveCN105639591AIncrease the types of enzymesPromote decompositionFood scienceMaillard reactionEnzyme system

The invention discloses a soy sauce brewing method for increasing an amino acid yield by utilizing an enzyme preparation. The soy sauce brewing method comprises the following steps: mixing aspergillus oryzae and / or aspergillus sojae with cooked soybean and starchy auxiliary materials, and then fermenting to prepare soy sauce koji; mixing the obtained soy sauce koji with salt water to prepare soy sauce mash, and then fermenting in nature to obtain soy sauce; adding the enzyme preparation which accounts for 3 percent to 10 percent of the total weight of a koji making material into the soy sauce mash, wherein the enzyme preparation is obtained by fermenting aspergillus niger and desalted sauce residue, and acid proteinase activity of the enzyme preparation is 2000 U / g or above. According to the method disclosed by the invention, by adding the enzyme preparation during fermentation, an enzyme system lacking in the aspergillus oryzae and / or aspergillus sojae is remedied, the acid proteinase activity of the soy sauce mash is increased, amino acid content in natural soy sauce is increased, occurrence of Maillard reaction is promoted, and a soy sauce flavor is promoted.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

Production method of pleurotus eryngii cooking wine

InactiveCN108949420AImprove qualityImprove health care effectAlcoholic beverage preparationFermentationChemistry

The invention discloses a production method of pleurotus eryngii cooking wine. The cooking wine is prepared by taking polished round-grained rice as a main material and pleurotus eryngii as an auxiliary material through fermenting. The method at least comprises the following steps: adding yellow rice wine distiller's yeast and activated dry yeast into steamed rice and fermenting; after fermentingto 48h, adding the pleurotus eryngii subjected to enzymolysis through cellulase and papain into fermented rice; continuing fermenting; and after fermentation is finished, filtering, boiling wine, storing, blending and sterilizing to obtain the cooking wine. The pleurotus eryngii has abundant protein content; however, cellulose prevents microorganisms from utilizing the protein, and the pleurotus eryngii subjected to the enzymolysis through the cellulase and the papain is added into the fermented rice, so that the utilization rate of the pleurotus eryngii is easy to increase; compared with a manner of adding a pleurotus eryngii enzymolysis product in the initial period of fermentation, the production method has the advantages that the pleurotus eryngii cooking wine provided by the inventionhas a more obvious pleurotus eryngii flavor; the content of amino acid state nitrogen, free amino acid and volatile matters is relatively high; and the pleurotus eryngii cooking wine has a special rich alcohol aroma and a unique flavor of the pleurotus eryngii.

Owner:安徽海神黄酒集团有限公司

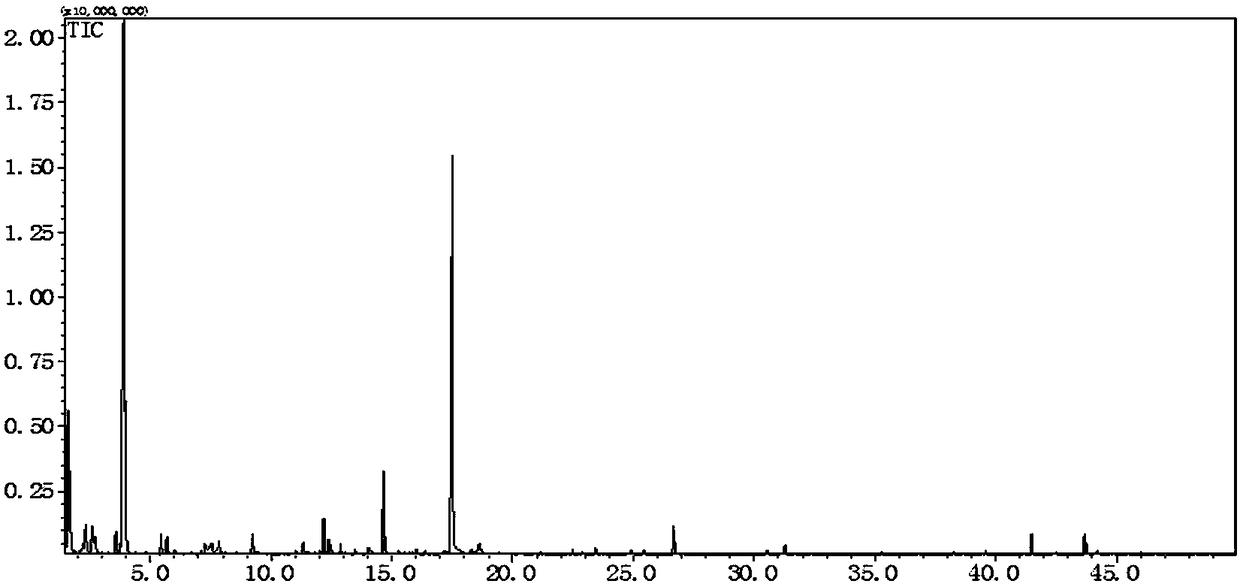

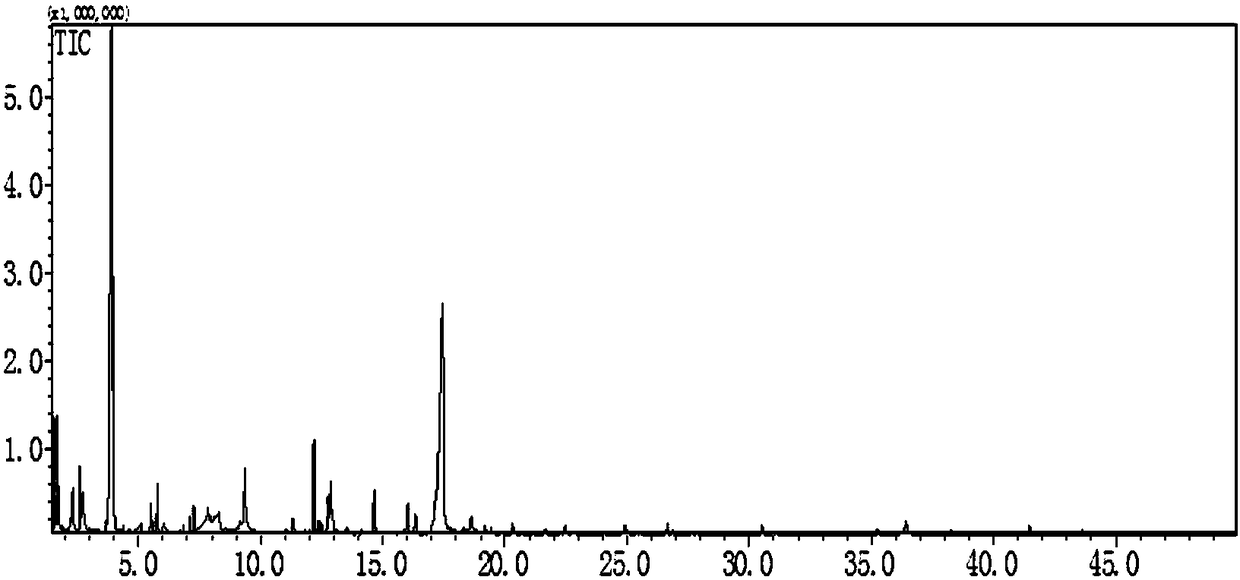

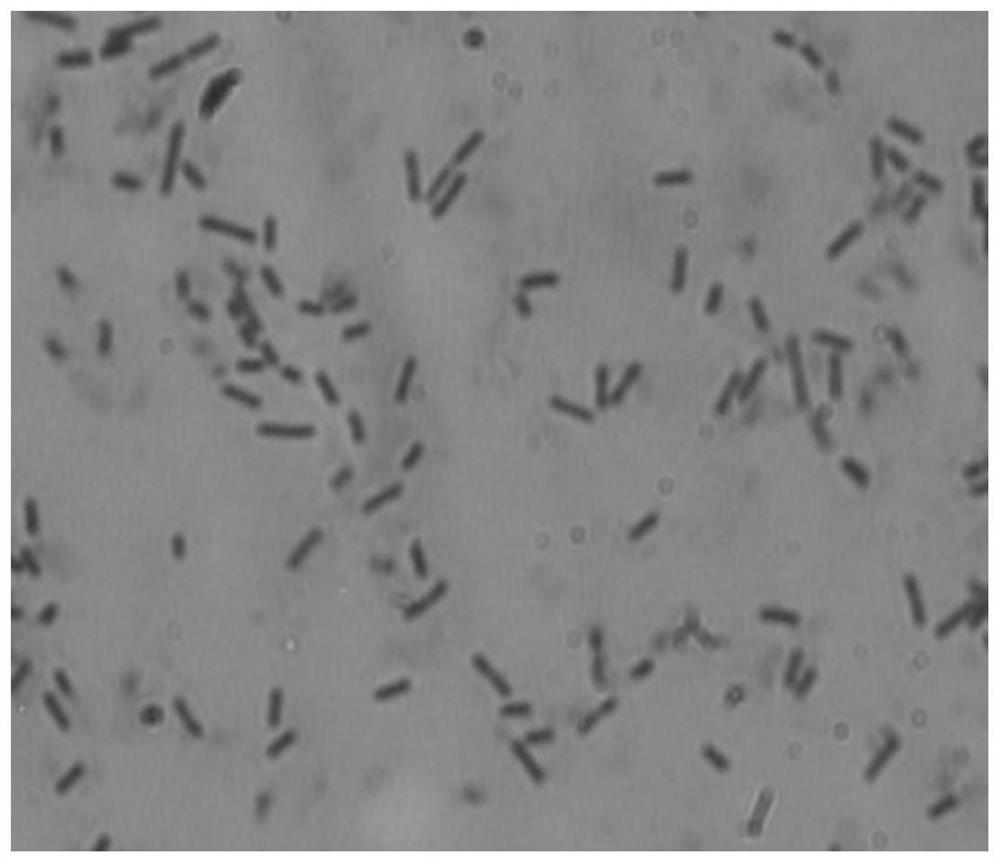

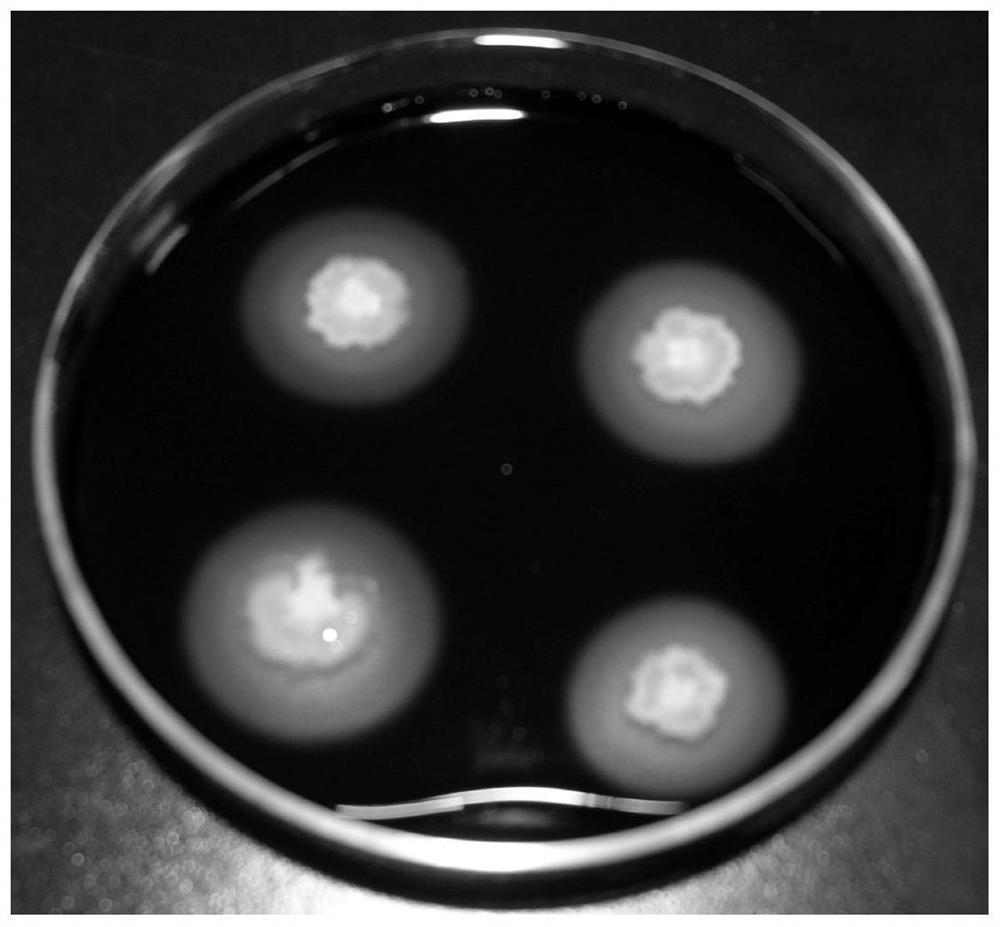

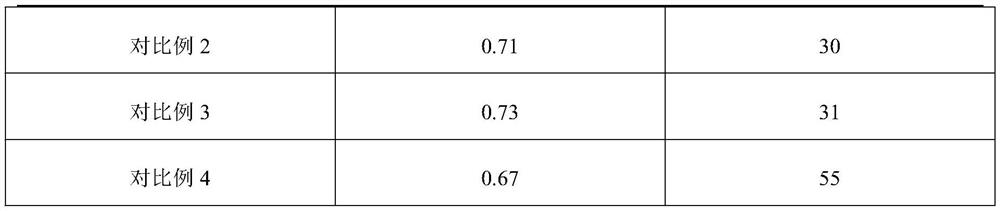

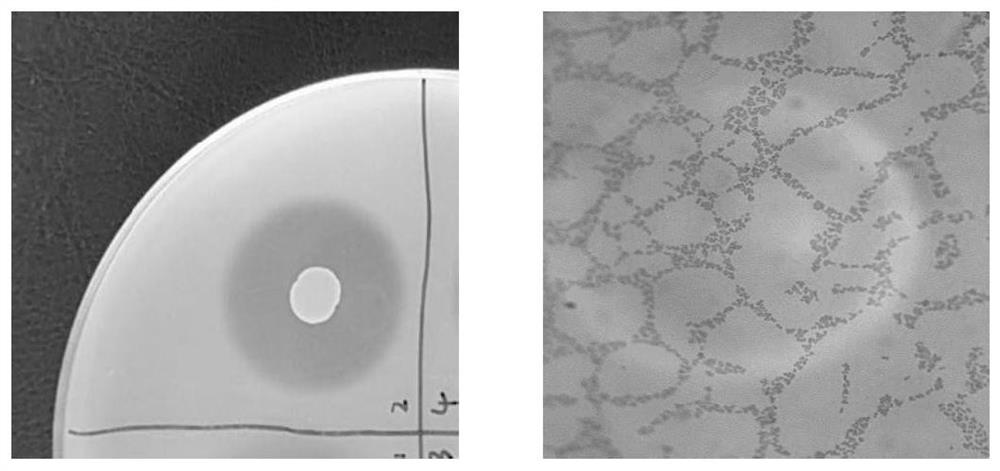

A strain of Bacillus subtilis and its application in soy sauce fermentation

ActiveCN106754508BHigh amino acid nitrogen contentIncreased content of volatile flavor componentsBacteriaMicroorganism based processesBiotechnologyVolatile flavor

A Bacillus subtilis strain, the Bacillus subtilis strain is preserved in the China Center for Type Culture Collection, named Bacillus subtilis CS1.03, and its preservation number in the China Center for Type Culture Collection is CCTCC NO: M 2015791. The Bacillus subtilis strain can be used in the fermentation of soy sauce to increase the aroma. The specific operation during application is: mix the finished koji for making soy sauce and salt water evenly according to a mass ratio, and then heat-preserve and ferment to obtain the soy sauce fermented grains; The bacterial liquid of Bacillus CS1.03 is sprayed into the above-mentioned sauce fermented grains, and the first-stage fermentation is carried out at room temperature; after the completion of the first-stage fermentation, it is poured with salt water for fermentation, and finally raw soy sauce is obtained. The application of the bacillus subtilis strain of the present invention in soy sauce fermentation and aroma enhancement can significantly increase the content of amino acid nitrogen and volatile flavor components in the soy sauce, making the soy sauce rich in flavor and high in quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

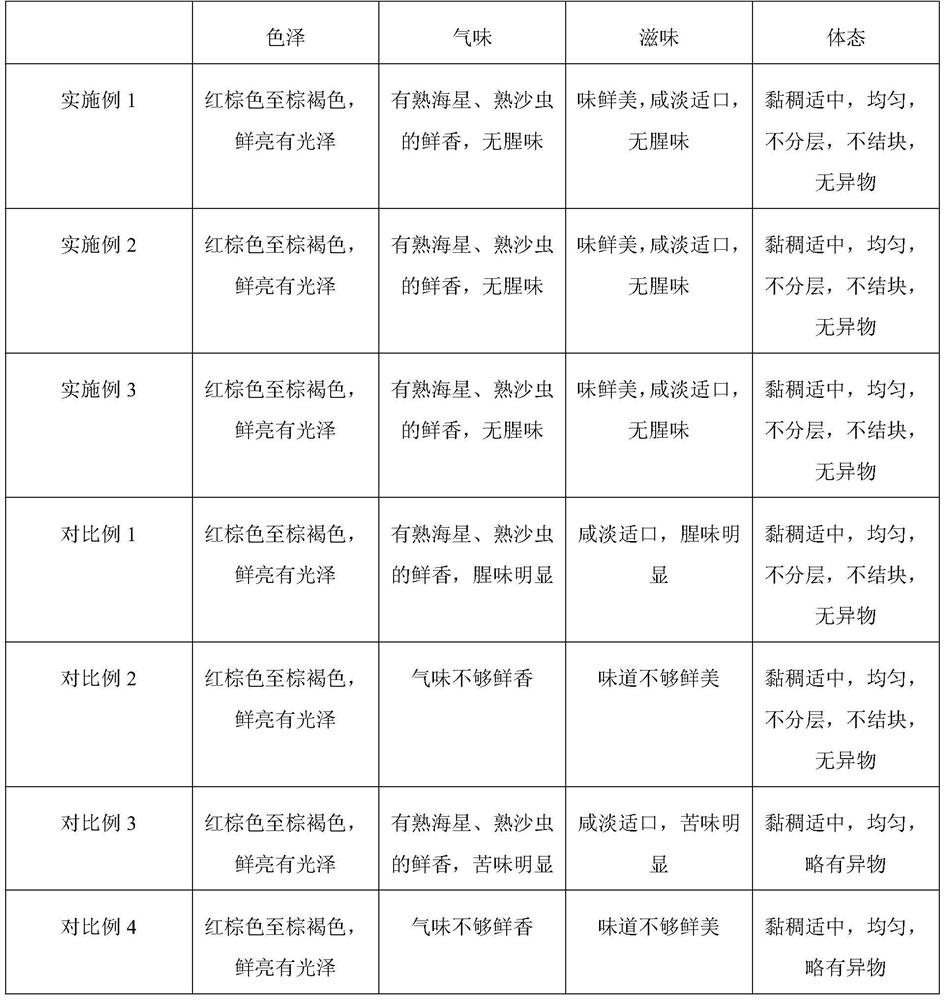

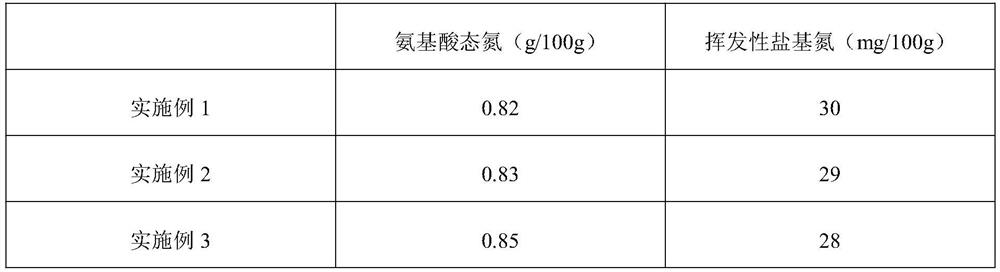

Soy sauce containing starfish and sandworms and preparation method of soy sauce

InactiveCN111713683ARich animal protein raw materialsExcellent technical indicatorsFungiBacteriaProteaseBiotechnology

The invention provides a soy sauce containing starfish and sandworms and a preparation method of the soy sauce. The preparation method comprises the steps of firstly, stripping fresh starfish to obtain two parts of starfish cream and starfish echino skin, adding an amomum cardamomum and haw extracting solution containing compound proteinase to the starfish cream and the fresh sandworms, performingchopping to obtain chopped materials, performing enzymolysis and performing microwave degradation to obtain pretreated meat paste; and performing microwave drying on the starfish echino skin to prepare dry starfish echino skin, performing cooking and performing fermentation, to obtain the soy sauce product. The soy sauce is mainly made from the starfish and the sandworms as main raw materials, animal source protein raw materials which are unfrequent in the market are enriched, in the brewing process, self fishy smell of the starfish, the sandworms and the like can be reduced, toxin componentscontained in the starfish can be removed, and the technical indexes of the obtained soy sauce product are excellent.

Owner:崔艳兰

A method for improving the fermentation quality of low-salt fish sauce by using mixed strains of kinetococci

ActiveCN111227216BShorten the fermentation cycleLow fermentation temperatureFood scienceBiotechnologyMicroorganism

The invention discloses a method for improving the fermentation quality of low-salt fish sauce by using mixed strains of kinetococcus, and relates to the field of food microbe technology application. The production period of fish sauce fermented by using the mixed strains of motile coccus (preservation numbers are CGMCC NO.17057, CGMCC NO.17058, CGMCC NO.17059 and CGMCC NO.17060) is greatly shortened and the fermentation temperature is lowered. The fish sauce obtained by this method is transparent brown-red, has the unique aroma of aquatic products, and has no suspended or flocculent impurities. The finished fish sauce has low salt content, high amino acid nitrogen content (according to the Chinese fish sauce industry standard, the fish sauce is classified as first-grade fish sauce), and the content of volatile basic nitrogen and histamine is lower than the national standard. The fish sauce is delicious and of high quality, providing a more stable, safer and more suitable mixed starter for fish sauce fermentation.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com