Pediococcus acidilactici and application thereof

A technology of Pediococcus lactis and strains, applied in the field of microorganisms, can solve problems such as the adverse effects of fermented mash, and achieve the effects of improved flavor, improved product quality, and easy cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

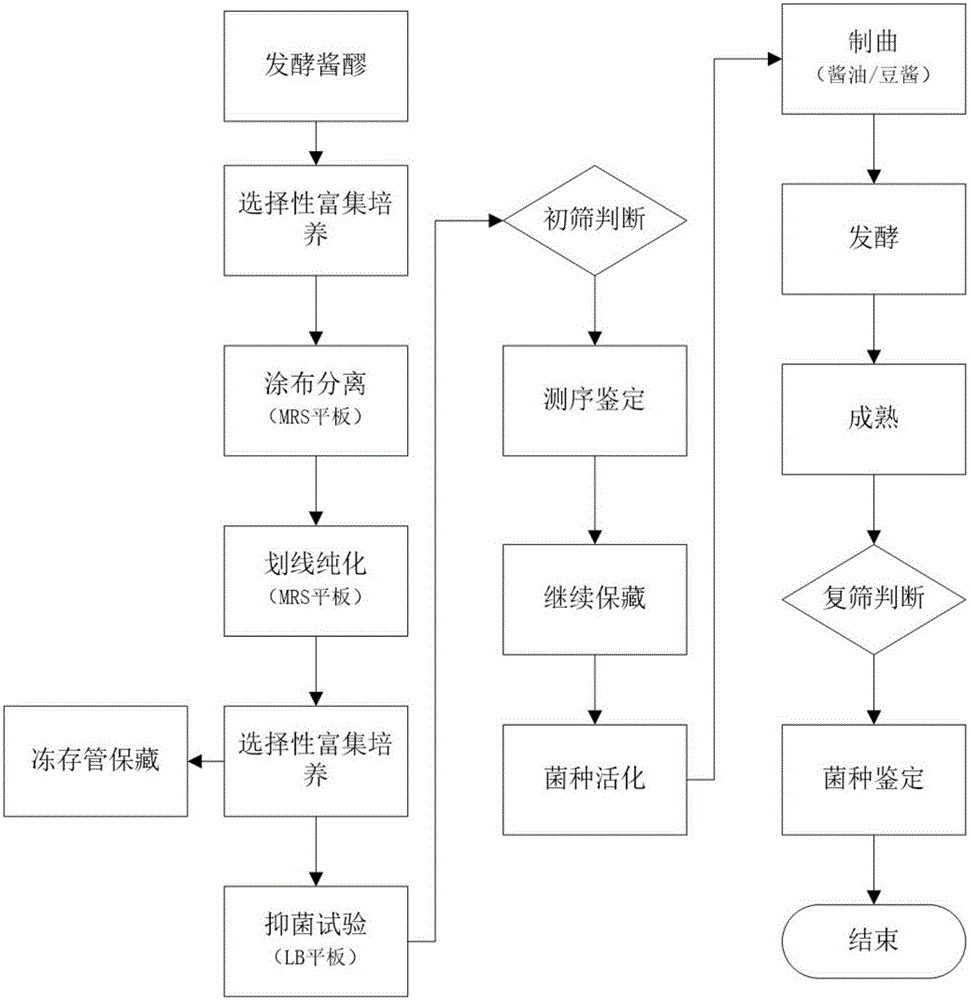

Method used

Image

Examples

Embodiment 1

[0059] Weigh commercial MRS broth medium, add distilled water to dissolve according to the product instructions, sterilize at 121°C for 15 minutes, and cool down for later use. Take out the preserved Pediococcus lactis (ZF559) and Lactobacillus plantarum cryopreservation tube strains (Huyao 1.08), respectively thaw these two strains in a water bath at 40°C for 1 min, and then inoculate them at 1v / v% under sterile conditions Quantitatively inoculate Pediococcus lactis (ZF559) and Lactobacillus plantarum strains (Shanghai Niang 1.08) into MRS broth culture medium respectively, and culture them statically at 30°C to 35°C for 24 hours to obtain concentrations of 10 8 Pediococcus lactis culture solution and Lactobacillus plantarum culture solution with more than CFU / mL should be stored in a 4°C refrigerator for later use.

Embodiment 2

[0060] Example 2 Application of Pediococcus lactis ZF559 in the preparation of high-salt dilute fermented soy sauce

[0061] 1. Koji making

[0062] The koji is prepared by using defatted soybeans and wheat flour as raw materials, wherein the mass ratio of defatted soybeans and wheat flour is 6.5:3.5. A blank control example and an experimental example are set respectively, the blank control example is only inoculated with Aspergillus oryzae, and the experimental example is simultaneously inoculated with Aspergillus oryzae and Pediococcus lactis ZF559 of the present invention. The inoculum amount of Aspergillus oryzae in the blank control example and the experimental example is the same, both being 0.5wt%. See Table 2 for the inoculation amount of Pediococcus lactis ZF559 in the experimental example.

[0063] The method of making koji is: first add defatted soybeans to 1 times the weight of water, mix well and moisten the water for 1 hour, cook under high pressure at 0.1Mpa ...

Embodiment 3

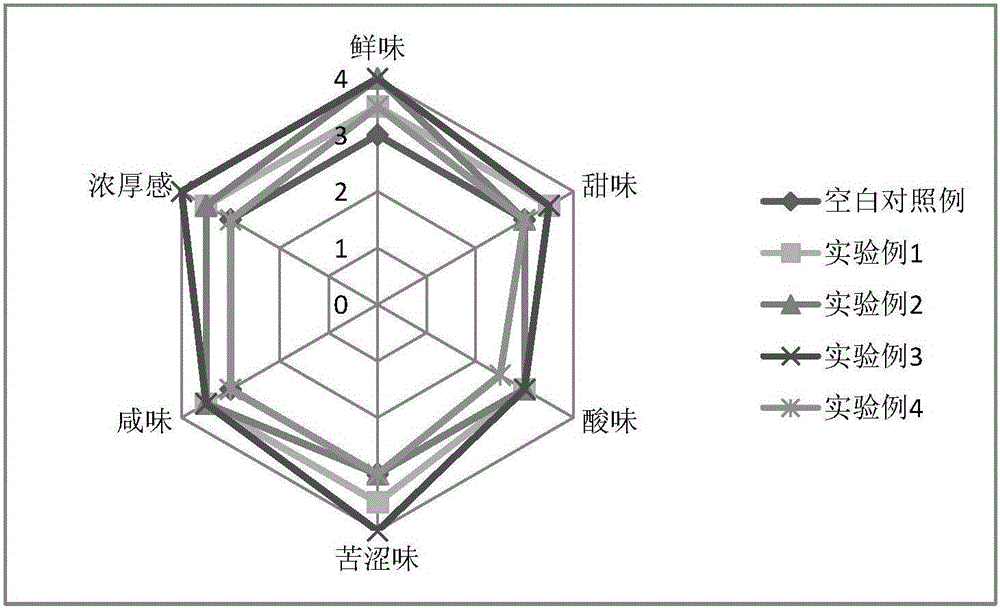

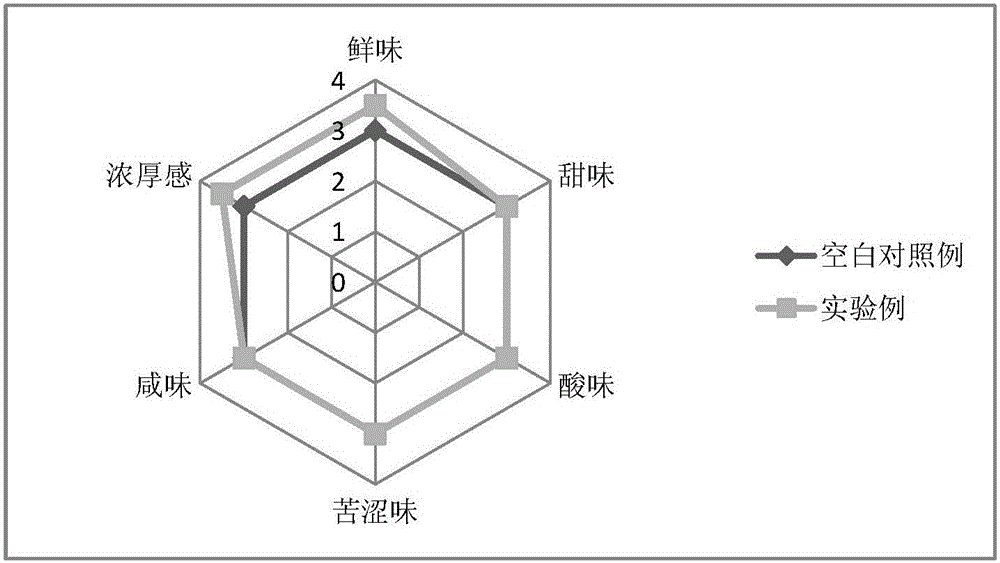

[0075] Example 3 Application of Pediococcus lactis ZF559 in the preparation of low-salt heat preservation fermented soy sauce

[0076] 1. Koji making

[0077] The koji is prepared by using defatted soybeans and wheat flour as raw materials, wherein the mass ratio of defatted soybeans and wheat flour is 6.5:3.5. A blank control example and an experimental example are set respectively, the blank control example is only inoculated with Aspergillus oryzae, and the experimental example is simultaneously inoculated with Aspergillus oryzae and Pediococcus lactis ZF559 of the present invention. The inoculum amount of Aspergillus oryzae in the blank control example and the experimental example is the same, both being 0.5wt%. The inoculum size of Pediococcus lactis ZF559 in the experimental example is 10 5 CFU / g koji.

[0078] The method for making koji is described in embodiment two.

[0079] 2. Fermentation

[0080] In this embodiment, the koji is fermented using a low-salt heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com