Raw material solid-state method brewing process of vinegar and brewed vinegar

A solid-state method and vinegar technology, applied in the field of vinegar brewing, can solve the problems of incomplete decomposition and transformation of protein substances, turbidity and precipitation of vinegar body, poor taste and flavor, etc., to improve taste and flavor, and better taste , Improve the effect of taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

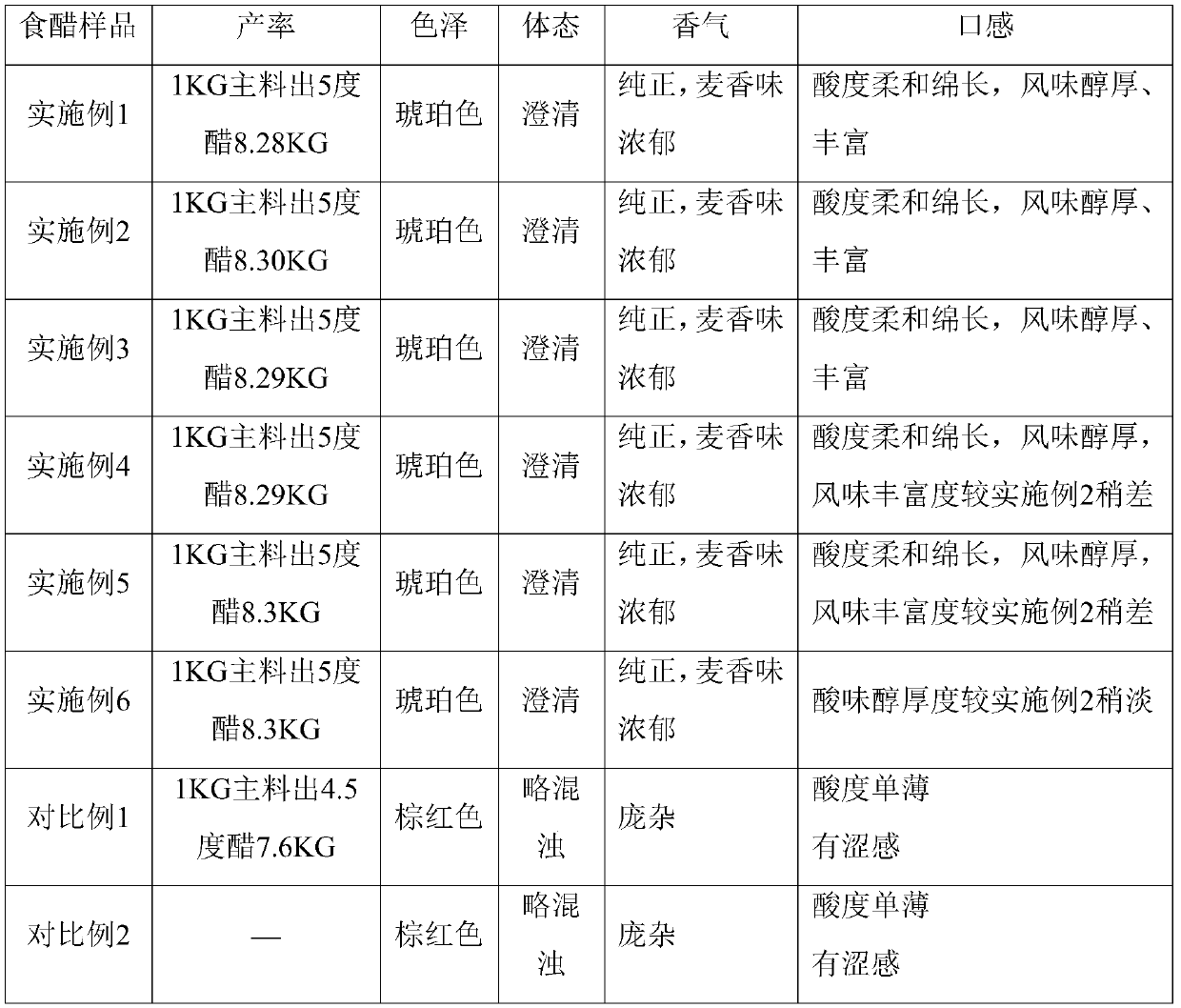

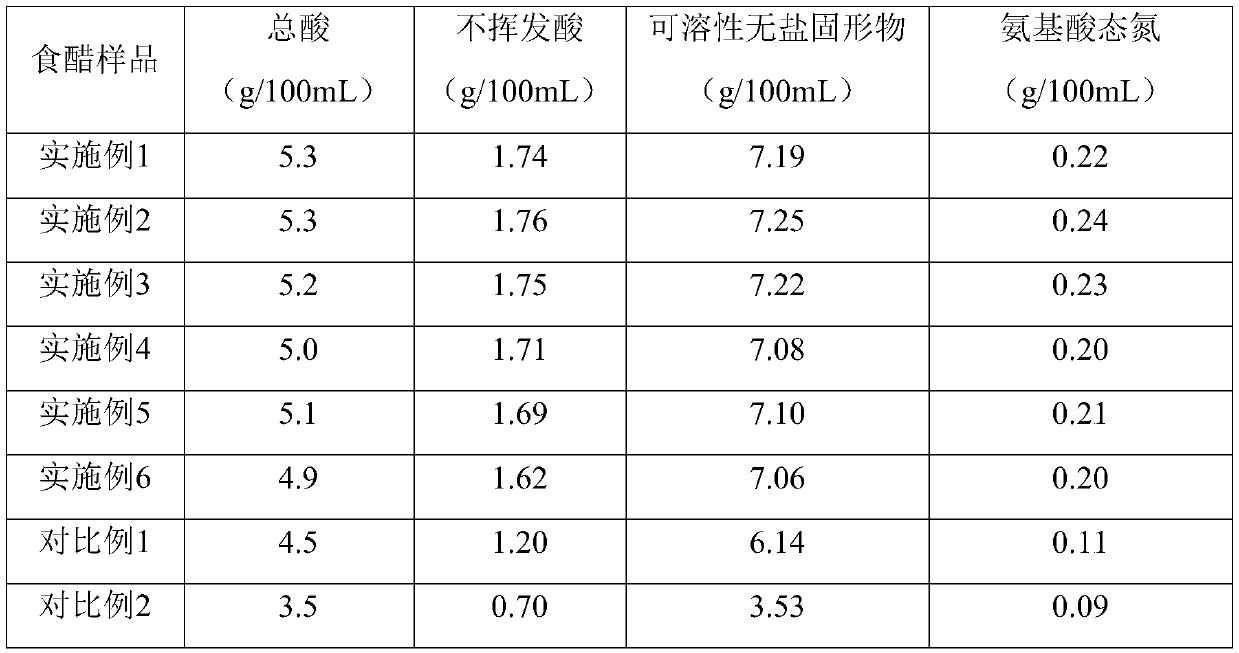

Examples

Embodiment 1

[0046] A kind of vinegar, its raw meal solid state method brewing process comprises the following steps:

[0047] a, Koji making: in parts by weight, 480 parts of barley kernels were soaked in 1050 parts of water for 6 hours, then the water was drained as a culture medium, 0.8 parts of Aspergillus oryzae were inoculated into the culture medium, and the fermentation temperature was 28° C. The fermentation time For 24h, Mairenqu was obtained;

[0048] b, saccharification: by weight, mix and pulverize 480 parts of rice noodles, 530 parts of sorghum, 80 parts of rhubarb rice, and 120 parts of millet, and pass through an 80-mesh sieve to obtain a raw material mixture; Put 3100 parts of hot water at 55°C into the fermentation tank, mix evenly, and start saccharification; when saccharification is carried out for 22 hours, add 3100 parts of hot water at 55°C for the second time, and add 450 parts of bran and 2.2 parts of saccharification enzyme and mix well, continue Saccharification f...

Embodiment 2

[0053] A kind of vinegar, its raw meal solid state method brewing process comprises the following steps:

[0054] a, Koji making: in parts by weight, 500 parts of barley kernels were soaked in 1000 parts of water for 7 hours, and then the water was released as a culture medium, and 0.75 parts of Aspergillus oryzae were inoculated into the culture medium, and the fermentation temperature was 30 ° C. The fermentation time For 26h, wheat kernel song was obtained;

[0055] b, saccharification: by weight, mix and pulverize 500 parts of rice noodles, 500 parts of sorghum, 100 parts of rhubarb rice, and 100 parts of millet, and pass through an 80-mesh sieve to obtain a raw material mixture; Put 3000 parts of hot water at 60°C into the fermentation tank, mix evenly, and start saccharification; when the saccharification is carried out for 24 hours, add 3000 parts of hot water at 60°C for the second time, and add 500 parts of bran and 2 parts of saccharification enzyme, mix well, and co...

Embodiment 3

[0060] A kind of vinegar, its raw meal solid state method brewing process comprises the following steps:

[0061] a, Koji making: in parts by weight, 530 parts of barley kernels were soaked in 950 parts of water for 8 hours, and then the water was drained as a culture medium, and 0.7 parts of Aspergillus oryzae were inoculated into the culture medium, and the fermentation temperature was 32° C. The fermentation time For 28h, wheat kernel song was obtained;

[0062] b, saccharification: by weight, mix and pulverize 530 parts of rice noodles, 480 parts of sorghum, 120 parts of rhubarb rice, and 80 parts of millet, and pass through an 80-mesh sieve to obtain a raw material mixture; Put 2900 parts of hot water at 65°C into the fermentation tank, mix evenly, and start saccharification; when saccharification is carried out for 26 hours, add 2900 parts of hot water at 65°C for the second time, and add 550 parts of bran and 1.8 parts of saccharification enzyme and mix well, continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com