Device for extracting fusel oil by alcohol distillation

A fusel oil and alcohol technology, applied in the field of alcohol distillation, can solve the problems of unstable extraction and incomplete separation of fusel oil, and achieve the effects of stable oil extraction and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

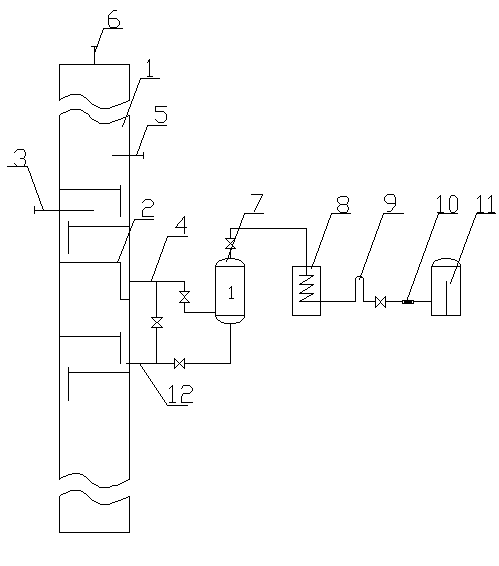

[0014] As shown in the figure, a device for extracting fusel oil by alcohol rectification includes alcohol refining tower 1, tray 2, raw material inlet 3, fusel oil extraction point 4, product outlet 5, and low boiling point impurities extraction point 6 , Fusel oil separator 7, fusel oil cooler 8, observation cover 9, emulsifier 10 and separator 11. Described alcohol refining tower 1 is provided with 90-110 trays 2 from bottom to top, and any tray 1 between the 10th-30 trays from bottom to top is provided with raw material inlet 3, and described The 5-20 trays below the raw material inlet 3 are provided with a fusel oil extraction point 4, and any tray between the 80th-100th trays from bottom to top is provided with a finished product outlet 5, The extraction point 6 of the low-boiling impurity at the top of the alcohol refining col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com