Preparation method of small-molecular wine and production system thereof

A small molecule, distilled wine technology, applied in the field of small molecule wine preparation methods and production systems, can solve problems such as long aging time and damage, and achieve the effects of improving taste and quality, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

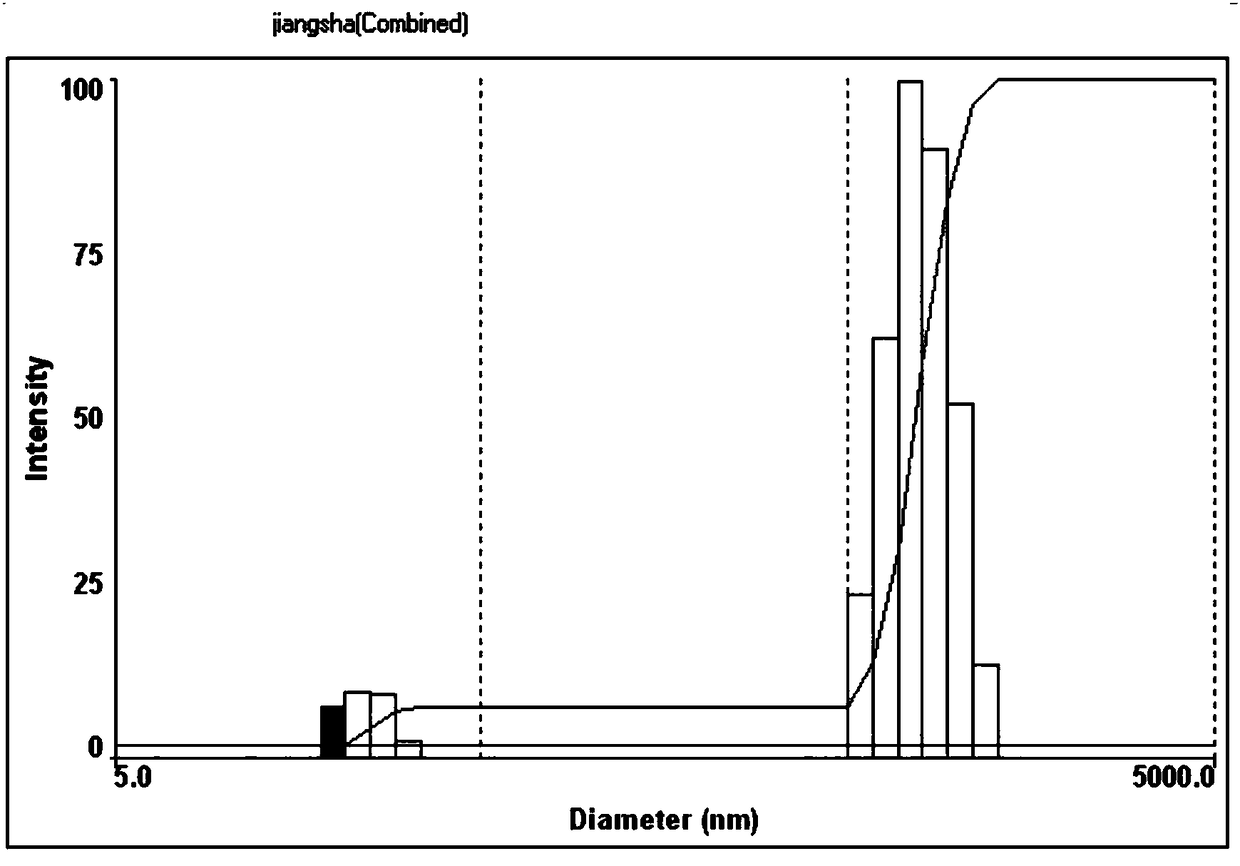

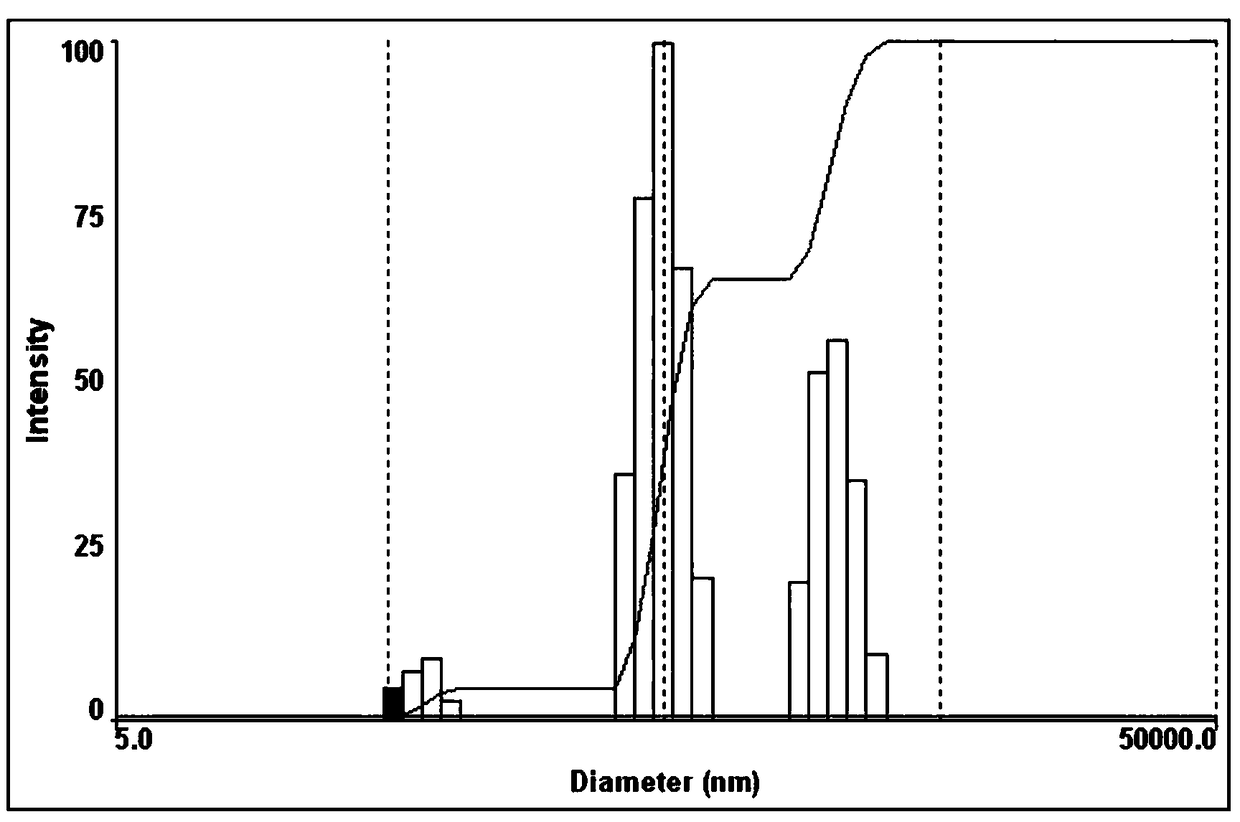

Embodiment 1

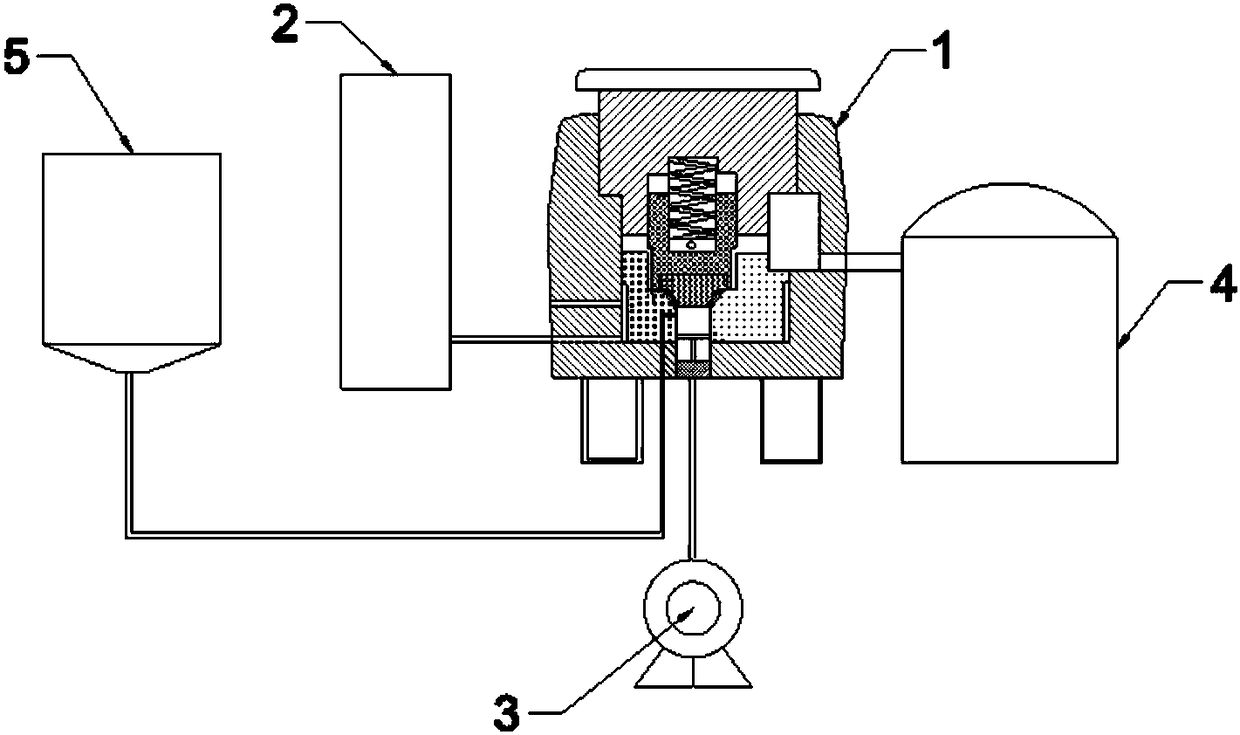

[0035] (1) Fermentation-distillation of the wine-making raw materials, and repeat the above process once, take 1% (weight ratio) of the distilled wine collected in the middle section as the puree wine, and then store the remaining distilled wine as processed wine;

[0036] (2) Transfer the processed wine obtained in step (1) to a water-cooled ultra-high pressure micro-jet system, and cyclically process it once at a pressure of 150 MPa to obtain small-molecule distilled wine and store them separately;

[0037] (3) Blend the pure liquor obtained in step (1) with the small-molecule distilled liquor obtained in step (2) in proportion, and store for 1-3 months at room temperature to obtain the finished product.

Embodiment 2

[0039] (1) Fermenting and distilling the brewing materials, repeating the above process 5 times, taking 5% (weight ratio) of the distilled wine collected in the middle section as the pure liquor, and then storing the remaining distilled wine as processed wine;

[0040] (2) Move the processed wine obtained in step (1) to a water-cooled ultra-high pressure micro-jet system, and cyclically process it twice at a pressure of 200 MPa to obtain small-molecule distilled wine and store them separately;

[0041] (3) Blend the pure liquor obtained in step (1) with the small-molecule distilled liquor obtained in step (2) in proportion, and store for 1-3 months at room temperature to obtain the finished product.

Embodiment 3

[0043] (1) Fermentation-distillation of the wine-making raw materials, and repeat the above process 7 times, take 10% (weight ratio) of the distilled wine collected in the middle section as the pure liquor, and then store the remaining distilled wine as processed wine;

[0044] (2) Move the processed wine obtained in step (1) to a water-cooled ultra-high pressure micro-jet system, and cyclically process 3 times under a pressure of 300 MPa to obtain small-molecule distilled wine, which is stored separately;

[0045] (3) Blend the pure liquor obtained in step (1) with the small-molecule distilled liquor obtained in step (2) in proportion, and store for 3 months at room temperature.

[0046] (4) Add the finished product obtained in step (3) to 0.01%-1% of 10-80-year-old wine, and store it at room temperature for another 6-12 months to obtain a good product.

[0047] Method for preparing small molecule fruit wine

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com