Brewing method of compound Xiaoqu liquor and bacterium cultivation saccharification system adopted by same

A technology for cultivating saccharification and koji wine, which is applied in the field of wine making, which can solve problems such as stimulating drinking habits, unsatisfactory consumers, and single wine body and aroma, so as to improve the quality of wine production, reduce labor intensity of workers, and increase wine production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

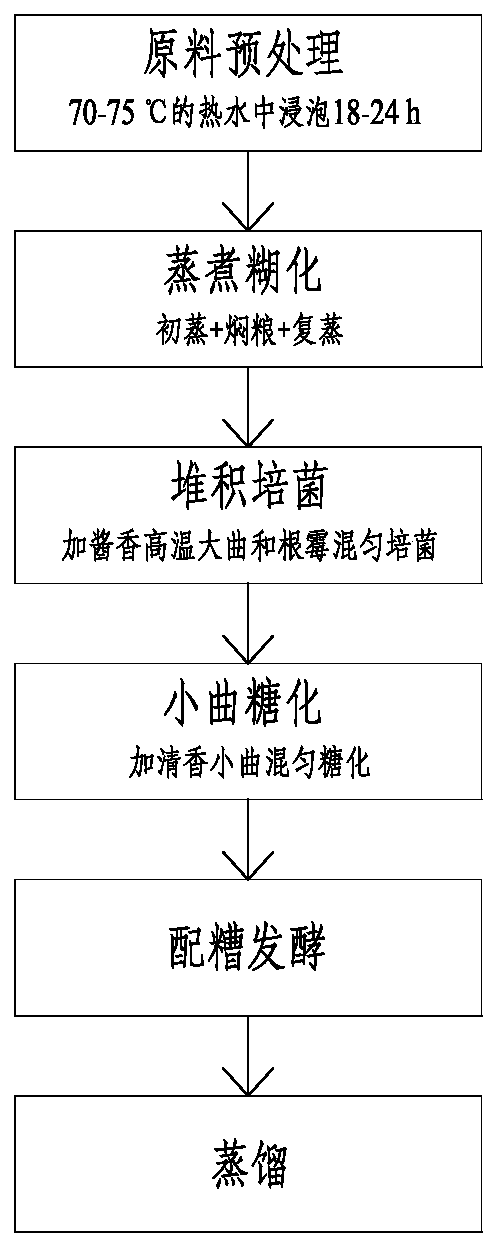

[0061] The embodiment of the present invention provides a kind of brewing method of compound type Xiaoqu wine, such as figure 1 Specifically, the following steps are included:

[0062] S1. Using glutinous sorghum as raw material, cook and gelatinize until it is tender, saliva light and not sticking to the hand, and the opening ratio and water content are controlled to be 90% and 50% respectively;

[0063] In addition, before cooking and gelatinization, it also includes pre-treatment of waxy sorghum raw materials, including impurity removal and soaking treatment, that is, removing impurities such as sorghum husks, dust, stones, etc., and soaking grains so that the sorghum starch can absorb enough water, which is conducive to cooking. gelatinization of starch.

[0064] Cooking and gelatinization use a specially designed special equipment for steaming grains. Put the soaked glutinous sorghum raw materials in the steaming grains pot. First steam under the pressure of 0.10MPa for ...

Embodiment 2

[0070] The embodiment of the present invention provides a kind of brewing method of compound type Xiaoqu wine, such as figure 1 Specifically, the following steps are included:

[0071] S1. Using glutinous sorghum as raw material, cook and gelatinize until it is tender and soft, with a light saliva and does not touch the hand, and the opening ratio and water content are controlled to be 60% and 50% respectively;

[0072] In addition, before cooking and gelatinization, it also includes pre-treatment of waxy sorghum raw materials, including impurity removal and soaking treatment, that is, removing impurities such as sorghum husks, dust, stones, etc., and soaking grains so that the sorghum starch can absorb enough water, which is conducive to cooking. gelatinization of starch.

[0073] Cooking and gelatinization use a specially designed special equipment for steaming grains. Put the soaked glutinous sorghum raw materials in the steaming grains pot. First steam under the pressure ...

Embodiment 3

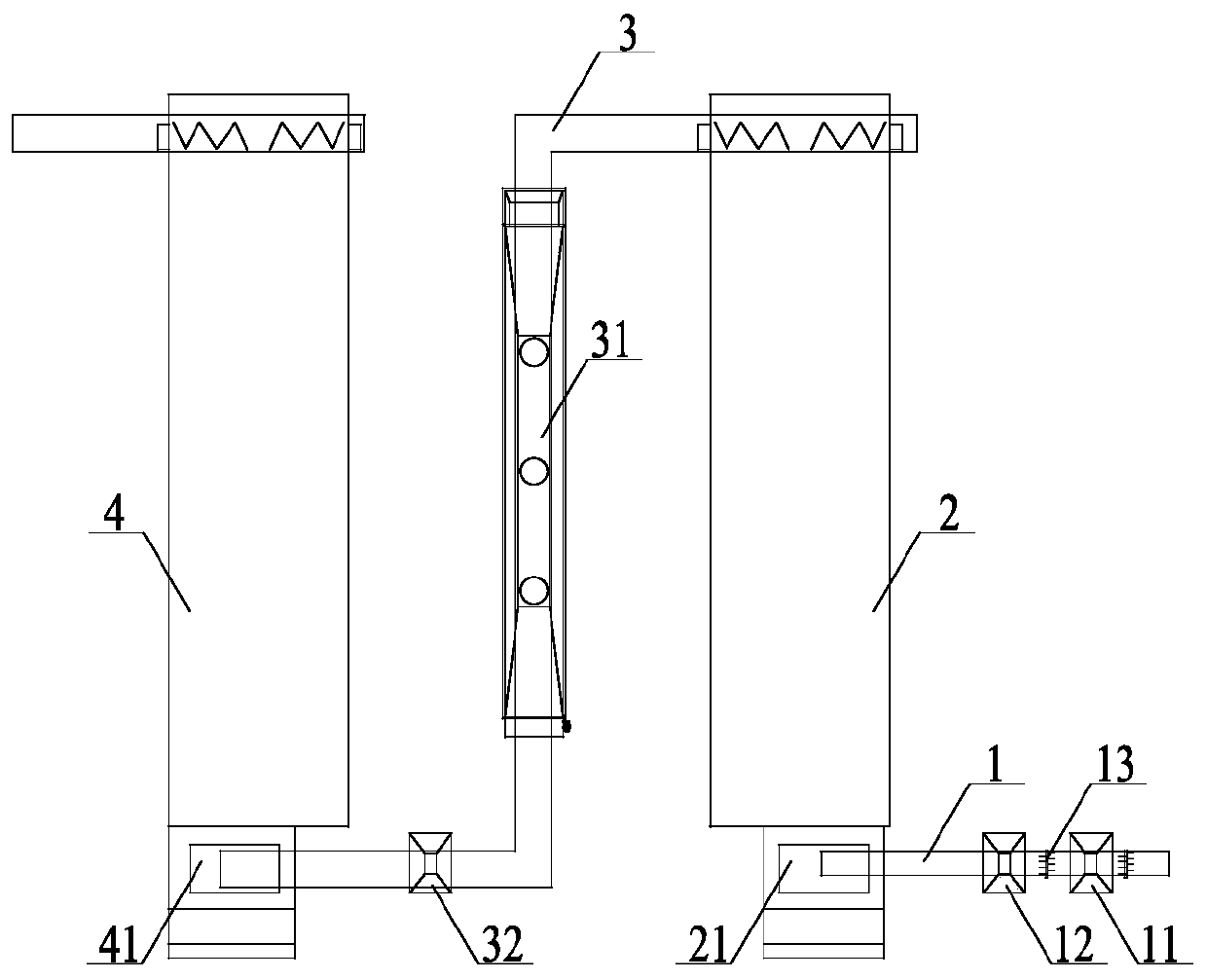

[0079] Embodiment 3 of the present invention provides a kind of culture saccharification system of compound type Xiaoqu wine, such as figure 2 As shown, it specifically includes the cooked grain in-box plate chain 1, the stacking box 2, the grain grain conveyor 3 and the saccharification box 4 which are connected in sequence.

[0080] In detail, the feed end of the stacker 2 is connected to the end of the cooked grain input box chain 1 , and the discharge end of the stacker 2 is connected to the feed end of the saccharification tank 4 through the grain conveyor 3 .

[0081] In detail, in the transportation direction of the above-mentioned cooked grain into the box plate chain 1, a first koji adding machine 11 and a second koji adding machine 12 are arranged in sequence, and in the transportation direction of the above-mentioned grain grain conveyor 3, a koji adding machine 12 is arranged in sequence A low-temperature fermented grain cooler 31 and a third koji adding machine 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com