Method for reducing acid and removing fusel oil of plum wine

A technology of green plum wine and fusel oil, which is applied in the field of fruit wine quality improvement, can solve the problem of high content of fusel oil, and achieve the effects of small influence on flavor, content reduction, and ease of easy topping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

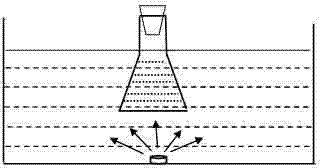

[0024] Embodiment 1: Adopt anion exchange resin D314 to carry out acid reduction and first 28kHz and then 45kHz ultrasonic wave to remove fusel oil

[0025]Anion exchange resin D314 is first soaked in 100g / L NaCl solution for 18-20 hours, rinsed with distilled water until the liquid is clear and free of impurities, then alternately soaked in 1mol / L HCl and NaOH solution 3-5 times the volume of the resin for 4 hours, and rinsed with distilled water in the middle To neutral, so cycle 3 times, the anion exchange resin is OH type after pretreatment. Accurately measure 5mL of pretreated resin into a conical flask, add 200mL plum wine, the total acid of untreated plum wine is 12.81g / L, absorb at 15°C, keep stirring and measure the acidity of green plum wine. When the adsorption time reached 4 hours, the adsorption of plum wine by D314 resin reached equilibrium, and the total acidity decreased to 9.14g / L, and the acid reduction range reached 28.65%. The elution effect of the used D3...

Embodiment 2

[0027] Embodiment 2: adopt anion exchange resin D314 to carry out acid reduction and first 45kHz and then 28kHz ultrasonic wave to remove fusel oil

[0028] Anion exchange resin D314 is first soaked in 100g / L NaCl solution for 18-20 hours, rinsed with distilled water until the liquid is clear and free of impurities, then alternately soaked in 1mol / L HCl and NaOH solution 3-5 times the volume of the resin for 4 hours, and rinsed with distilled water in the middle To neutral, so cycle 3 times, the anion exchange resin is OH type after pretreatment. Accurately measure 5mL of pretreated resin into a conical flask, add 200mL plum wine, the total acid of untreated plum wine is 12.81g / L, absorb at 15°C, keep stirring and measure the acidity of green plum wine. When the adsorption time reached 4 hours, the adsorption of plum wine by D314 resin reached equilibrium state. At this time, the total acid of green plum wine dropped to 9.14g / L, and the acid reduction range reached 28.65%. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com