Method for removing fusel oil in yellow rice wine

A technology for fusel oil and yellow rice wine, which is applied in the field of removing harmful substances in alcoholic beverages. It can solve problems such as poor specificity, loss of flavor, and taste cracking, and achieve the effects of easy operation, easy solution, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

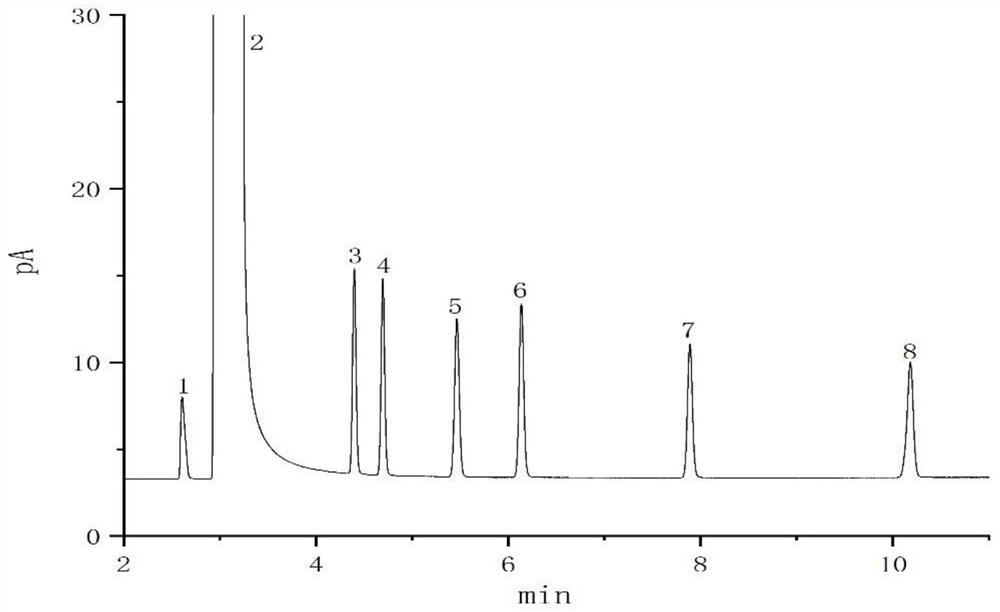

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of specific macroporous resin by membrane hole drop-suspension polymerization

[0047] Water phase: In 300mL of deionized water, add 0.2% (ie 0.6g) of carrageenan and 0.4% (ie 1.2g) of gelatin, stir to dissolve, then add 0.4% (ie 1.2g) of aluminum hydroxide, and finally Add 0.05% (ie 0.15 g) of sodium dodecylsulfonate.

[0048] Non-aqueous phase: After mixing 30 mL of styrene, 5 mL of divinylbenzene and 30 g of n-hexane evenly, add 0.5 g of dibenzoyl peroxide (BPO), mix and dissolve.

[0049] The non-aqueous phase was added dropwise to the aqueous phase (the volume ratio of the non-aqueous phase and the aqueous phase was 1:8) through a 0.2 μm aluminum oxide ceramic membrane, while stirring and mixing rapidly. After the dropwise addition is completed, the temperature of the feed liquid is raised to 80°C, kept for 2 hours, then raised to 85°C, kept for 1 hour, finally raised to 95°C, kept for 6 hours, cooled to room temperature, and the reaction is c...

Embodiment 2

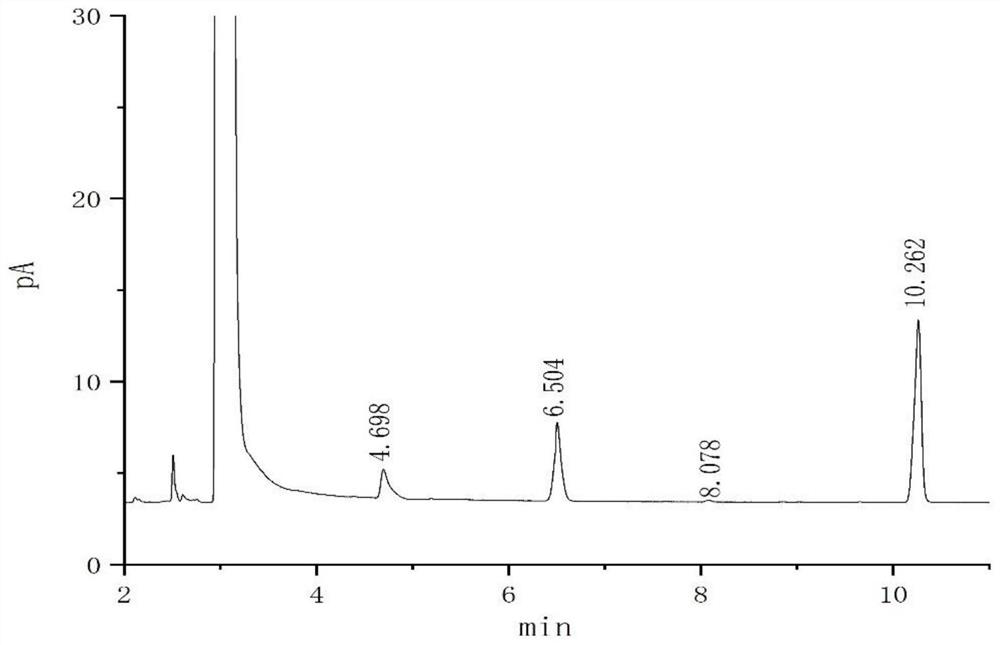

[0054] Embodiment 2: Using low-temperature ultrafiltration membrane filtration combined with 10% specific resin to adsorb rice wine

[0055] Under the conditions of a pressure of 0.1 MPa and 8°C, a certain amount of rice wine was filtered with an ultrafiltration membrane (PES, polyethersulfone) with a molecular weight cut-off of 10,000 Dalton, and the permeate was collected. Accurately weigh 15 g of the specific macroporous resin prepared in Example 1, add 150 mL of the filtrate (permeate) filtered by the ultrafiltration membrane, and adsorb for 2 h at 25° C. and 150 rpm. The fusel oil in rice wine decreased from 229.8mg / L before treatment to 53.31mg / L, and the removal rate was 76.8%.

Embodiment 3

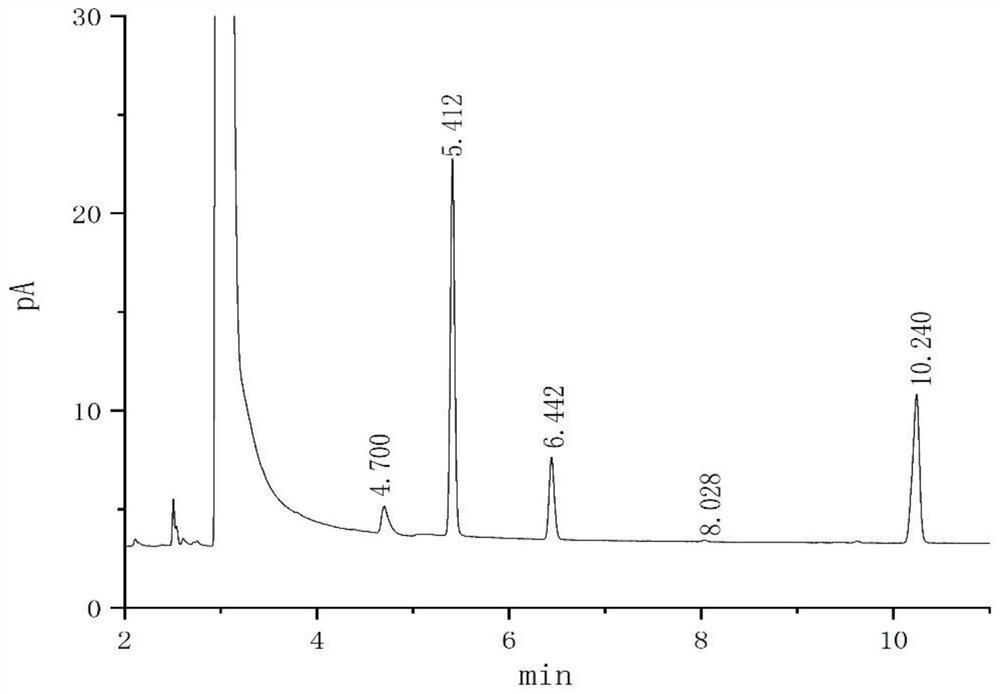

[0060] Embodiment 3: Effect of specific resin adsorption fusel oil under different contact times

[0061] 10 g of the specific resin prepared in Example 1 was loaded into a PEG glass chromatography column, and 300 mL of rice wine was flowed through the adsorption column from top to bottom, and the adsorption time was recorded. When the contact time with the specific resin was 80min, the removal rate of fusel oil was 56.0%. When the contact time with the specific resin was 50min, the removal rate of fusel oil was 48.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com