Saccharomyces cerevisiae with low fusel oil yield and application thereof

A technology of Saccharomyces cerevisiae and fusel oil, applied in the field of microorganisms, can solve the problems of large reaction and easy to use, and achieve the effects of improving the post-drinking reaction, improving the quality of liquor, and reducing the content of harmful substances fusel oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

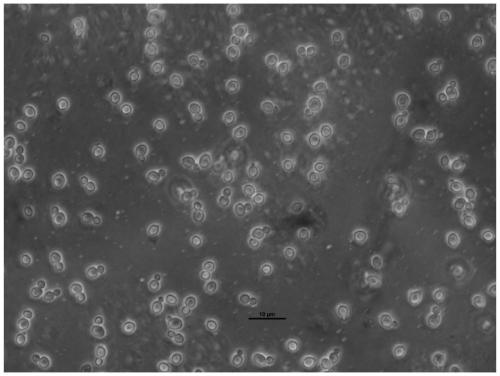

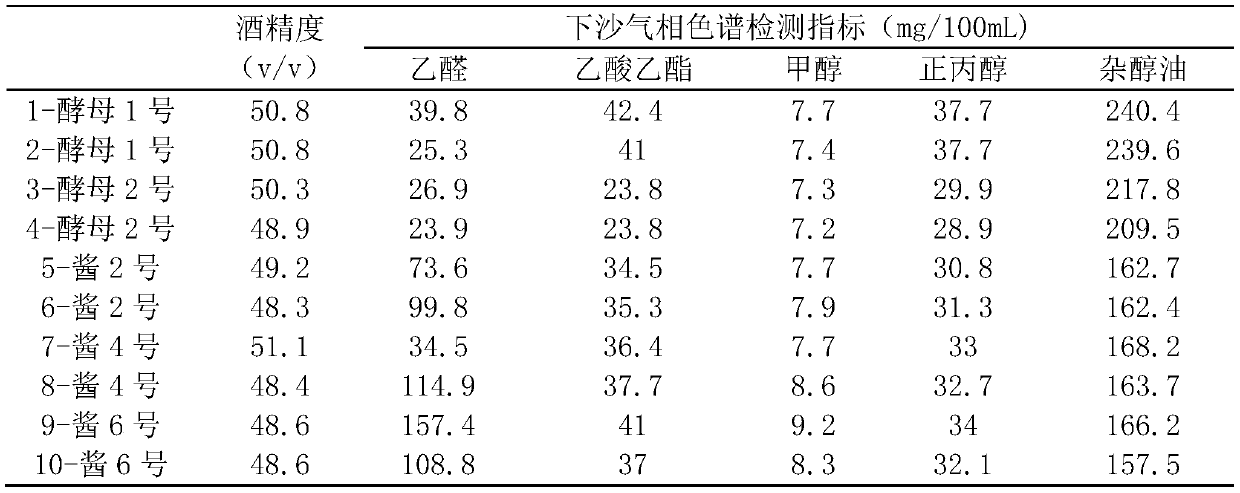

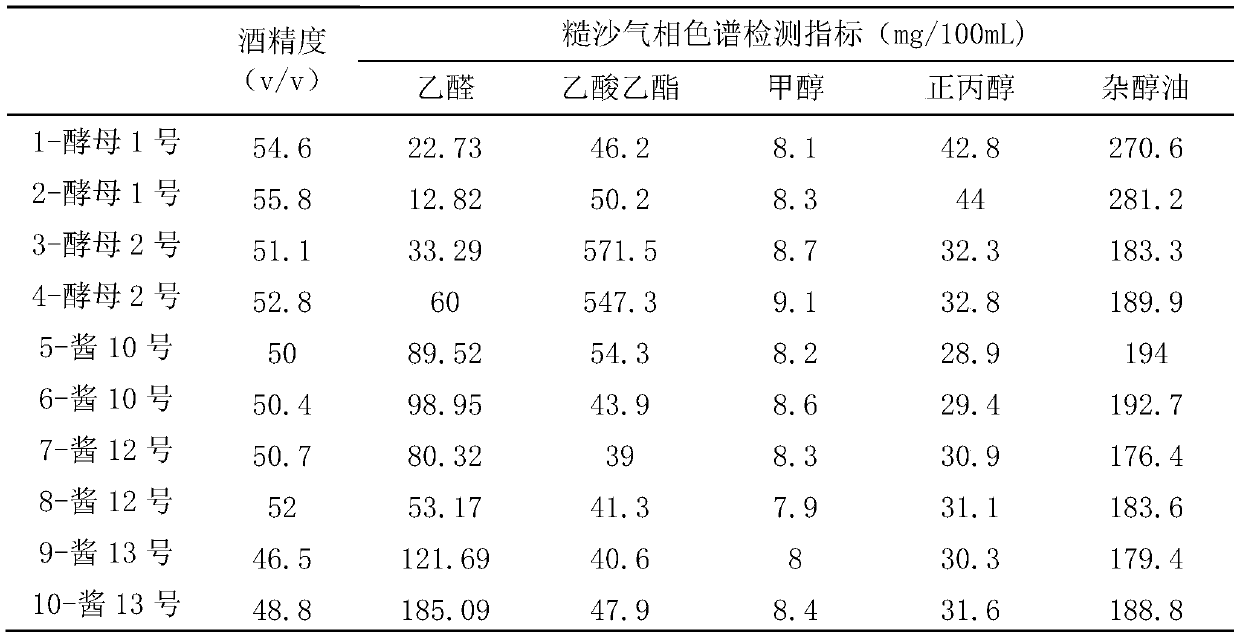

[0017] Example 1 Screening of Saccharomyces cerevisiae strains with low fusel oil production

[0018] 1. Separation and screening of high-yielding wine yeast from fermented grains of Jinpai Maotai Town Liquor Industry

[0019] Material: Jin brand Moutai Town Liquor Industry's down to six rounds of fermented fermented grains

[0020] YPD medium: 10g of yeast powder; 20g of glucose; 20g of peptone; 20g of sodium propionate; 1g of penicillin; Put the bottle in a 121°C sterilizer for 30 minutes and cool it down for later use.

[0021] TTC upper medium: liquid A: glucose 5g; agar 15g; water 900mL. Solution B: 100 mL of 0.5% TTC aqueous solution. Liquid A and liquid B were sterilized in a 121°C autoclave for 30 minutes, cooled to 60°C, mixed and used immediately.

[0022] Separation and purification of yeast: Take 5g of fermented grains sample and add 95ml of sterilized distilled water, put it in a shaker at 150r / min and shake it for 30min, put the shaken bacterial suspension in...

Embodiment 2

[0054] Example 2 Identification of Saccharomyces cerevisiae Y267 strain

[0055] 1.18S rDNA sequence analysis

[0056] (1) DNA extraction

[0057] collect bacteria, Soil Genome DNA Extraction Kit for DNA extraction.

[0058] (2) 18S rDNA fragment amplification of Saccharomyces cerevisiae Y267

[0059] Using the extracted Saccharomyces cerevisiae DNA as a template, the fungal 18S rDNA universal primers 18S-P1 and 18S-P2 were used to amplify 18S rDNA fragments. The amplification reaction system is 30 μl, in which Premix Taq TM (TaKaRa Taq TM Version 2.0plusdye) 15 μl, ddH2O 13 μl, primers 18S-P1 and 18S-P2 each 0.5 μl, DNA template 1 μl. Amplification reaction conditions: 94°C for 5min; 94°C for 30s; 55°C for 50s, 72°C for 30s, 32 cycles; 72°C extension for 10mim, 4°C storage.

[0060] (3) 18S rDNA sequence analysis

[0061] The amplified 18S rDNA fragment was sent to Wuhan BGI for sequencing, and the corresponding 18S rDNA amplification sequence results were obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com