Method for producing low-carbon olefins

A low-carbon olefin and production method technology, which is applied in ethylene production, chemical instruments and methods, biological raw materials, etc., can solve the problems of raw material impurities, short operation cycle, and low yield of low-carbon olefins, etc., to achieve increased yield, The effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

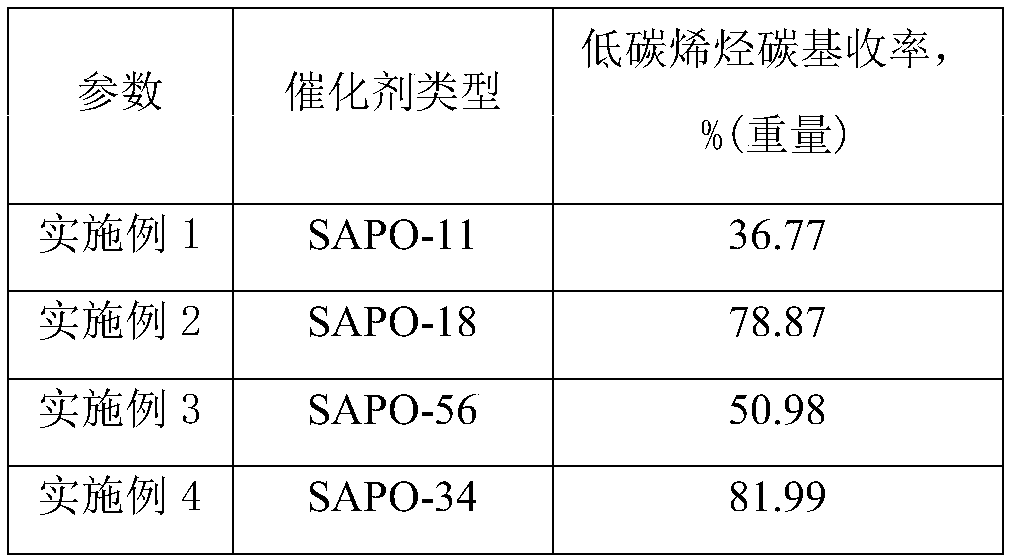

Embodiment 1~4

[0025] In the fluidized bed reaction-regeneration device, crude methanol is used as a raw material, and in a fluidized bed reactor, it is contacted with a silicoaluminophosphate molecular sieve catalyst under effective conditions to generate products including low-carbon olefins. After the catalyst is deactivated Enter the fluidized bed regenerator through the inclined pipe to be produced for regeneration, and the regenerated catalyst returns to the fluidized bed reactor through the regenerated inclined pipe after degassing in the degassing tank; wherein, the purity of methanol in the crude methanol is 95% and contains Impurities, the impurities include fusel alcohols and high-carbon hydrocarbons, the mass content of the impurities is 0.1%, the total mass content of alkali metals in the crude methanol raw material is 0.5 ppm, and the total mass content of iron ions is 0.1 ppm. The crude methanol raw material enters the fluidized bed reactor after being vaporized by the flash ta...

Embodiment 5~7

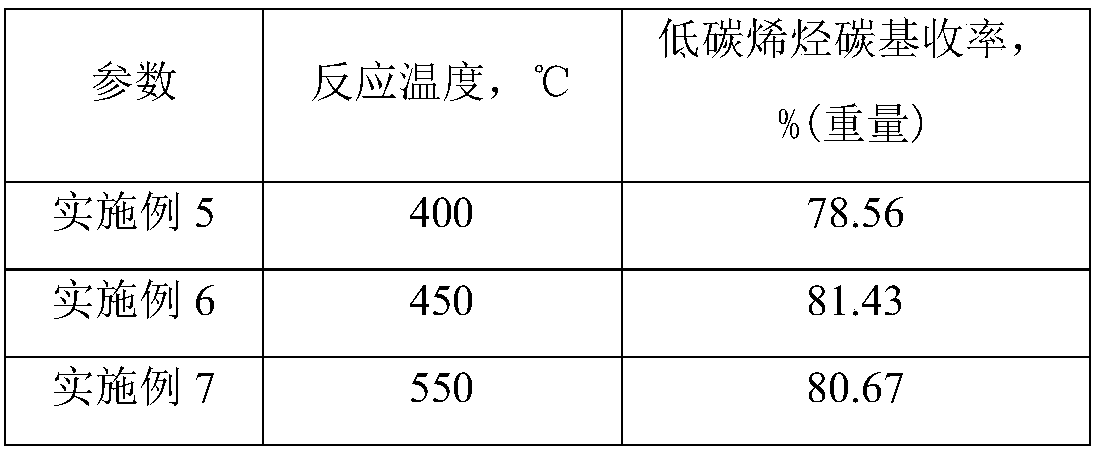

[0029] According to the conditions described in Example 4, only the reactor temperature was changed, and the experimental results are shown in Table 2. The reaction-regeneration unit operated smoothly for 1.8 years.

[0030] Table 2

[0031]

Embodiment 8~10

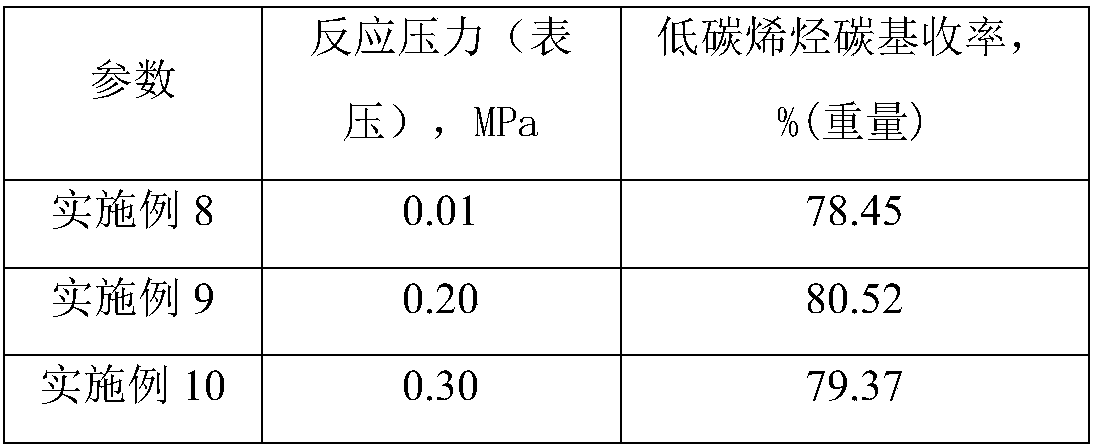

[0033] According to the conditions described in Example 4, only the reaction pressure was changed, and the experimental results are shown in Table 3. The reaction-regeneration unit operated smoothly for 1.8 years.

[0034] table 3

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com