Polyurethane composition for jogging area of plastic venue and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

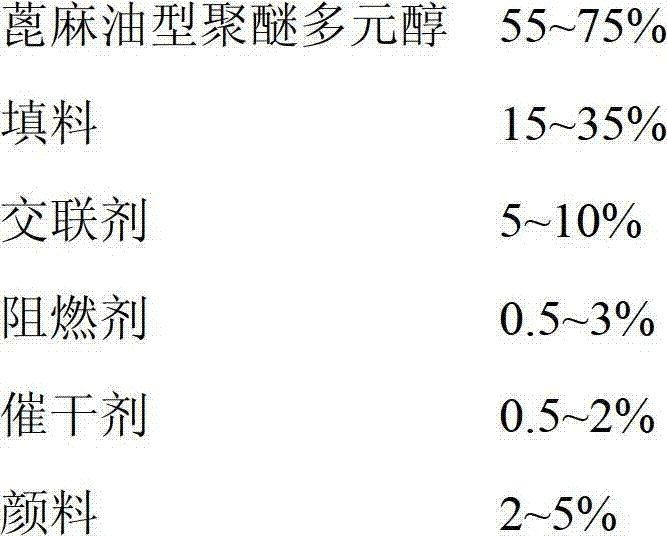

Method used

Image

Examples

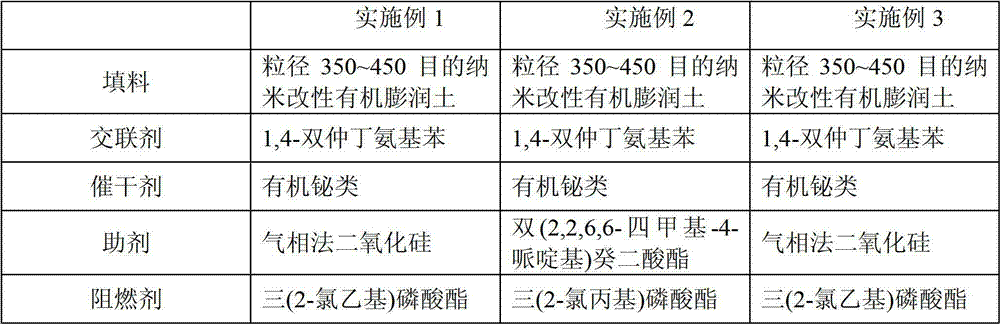

Embodiment 1

[0028] Prepare 100 grams of component A, and weigh them separately: 59.5 grams of castor oil-type polyether polyol (with castor oil as the starter, average functionality of 2.7, molecular weight of 3000), 8 grams of crosslinking agent, 22.5 grams of filler, 1 gram of flame retardant, 1 gram of drier, 2.0 grams of additives, 3 grams of red iron oxide, 3 grams of water, put the weighed castor oil polyether polyol into the container and stir, then add the weighed The cross-linking agent, filler, flame retardant, auxiliary agent, drier, pigment, under the condition of rotating speed of 500r / min, after stirring for 30 minutes, and then under the condition of 1000r / min, disperse for 30 minutes, then add water, in Under the condition of 500r / min, disperse for 10 minutes, then pack into barrels;

[0029] Prepare 100 grams of component B, add 60 grams of castor oil-based polyether polyol (with castor oil as the initiator, average functionality of 2.7, molecular weight of 6000) into a t...

Embodiment 2

[0032] Prepare 100 grams of component A material, weigh them separately: 55 grams of castor oil polyether polyol (with castor oil as the starter, average functionality 2.7, molecular weight 4000), 6 grams of crosslinking agent, 30 grams of filler, 0.5 grams of flame retardant, 1.5 grams of drier, 2 grams of additives, 2 grams of red iron oxide, 3 grams of water, first put the weighed castor oil type polyether polyol into the vessel and stir, then add Good cross-linking agents, fillers, flame retardants, additives, drier, pigments, at a speed of 500r / min, stir for 30 minutes, then disperse at 1000r / min for 30 minutes, then add water, Under the condition of 500r / min, disperse for 10 minutes, and load into barrels;

[0033] To prepare 100 grams of component B, add 70 grams of castor oil-based polyether polyol (with castor oil as the initiator, with an average functionality of 2.7 and a molecular weight of 5,000) into a three-necked bottle at room temperature, and stir at 90°C , ...

Embodiment 3

[0036] Prepare 100 grams of component A, and weigh them separately: 70 grams of castor oil-type polyether polyol (with castor oil as the starter, average functionality of 2.7, molecular weight of 5000), 5 grams of crosslinking agent, 15 grams of filler, 2 grams of flame retardant, 1 gram of drier, 2 grams of additives, 3 grams of red iron oxide, 2 grams of water, first put the weighed castor oil type polyether polyol into the vessel and stir, then add Good cross-linking agents, fillers, flame retardants, additives, drier, pigments, at a speed of 500r / min, stir for 30 minutes, then disperse at 1000r / min for 30 minutes, then add water, Under the condition of 500r / min, disperse for 10 minutes, and load into barrels;

[0037] Prepare 100 grams of component B, add 50 grams of castor oil-type polyether polyol (with castor oil as the initiator, average functionality of 2.7, molecular weight of 4000) into a three-necked bottle at room temperature, and stir at 100°C , vacuumize (-0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com