High-strength and high-toughness graphene composite ceramics

A graphene composite, high-strength and toughness technology, applied in the field of ceramics, can solve the problems of limiting the application range and popularization of ceramic materials, and achieve the effect of being suitable for industrial production, wide application range, and stronger toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

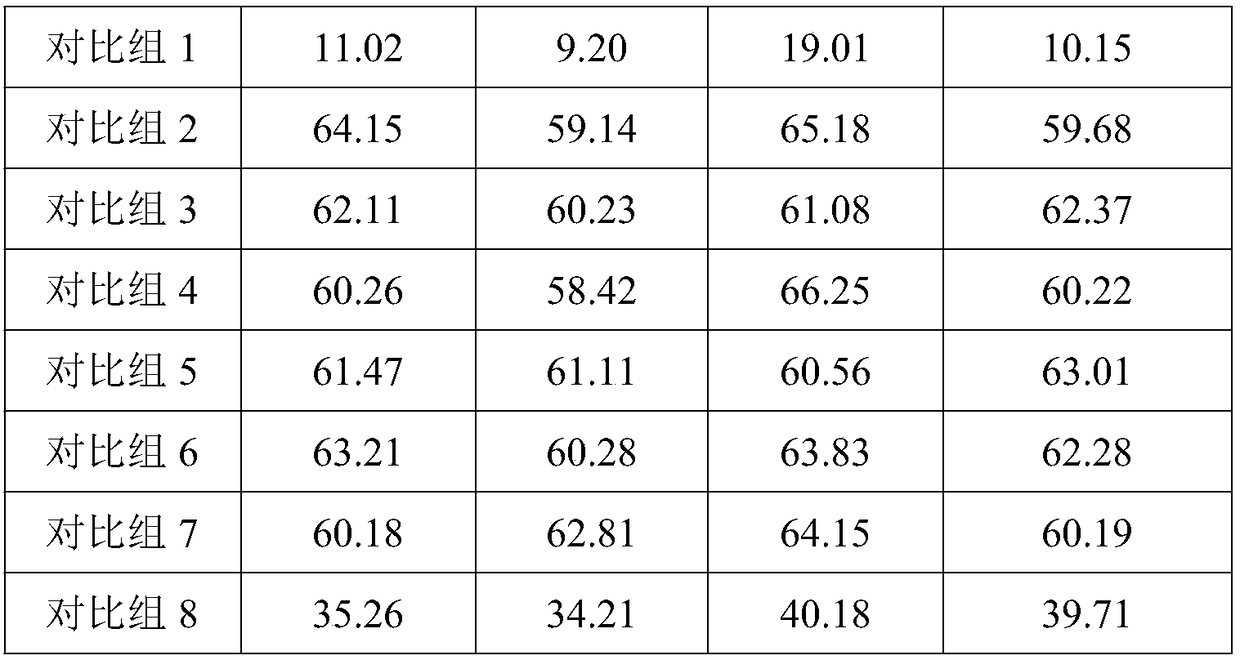

Examples

Embodiment 1

[0030] 1. A graphene composite ceramic with high strength and toughness, made of the following components by weight:

[0031] (1) Green body: 5 parts of iron oxide, 6 parts of anorthite, 8 parts of potassium feldspar, 6 parts of attapulgite, 13 parts of spodumene, 6 parts of graphene, 4 parts of nano-titanium dioxide fiber powder, silicon carbide crystal 3 parts of whiskers, 4 parts of barium sulfate, 3 parts of glass beads;

[0032] (2) Glaze: 7 parts of kaolin, 3 parts of graphene, 2 parts of nano-titanium dioxide fiber powder, 2 parts of bamboo charcoal powder, 3 parts of silicon carbide whiskers, 2 parts of barium sulfate, 3 parts of glass beads, 7 parts of potassium feldspar , 6 parts of quartz sand, 7 parts of talcum powder, 6 parts of olivine, 4 parts of bamboo charcoal powder, 2 parts of iron oxide, 7 parts of aluminum oxide, 5 parts of magnesium oxide, 6 parts of zirconium silicate, 3 parts of zinc oxide, 4 parts of lutetium oxide share.

[0033] 2, the preparation ...

Embodiment 2

[0038] 1. A graphene composite ceramic with high strength and toughness, made of the following components by weight:

[0039] (1) Green body: 3 parts of iron oxide, 4 parts of anorthite, 5 parts of potassium feldspar, 4 parts of attapulgite, 10 parts of spodumene, 7 parts of graphene, 6 parts of nano titanium dioxide fiber powder, silicon carbide crystal 5 parts of beard, 5 parts of barium sulfate, and 5 parts of glass beads;

[0040] (2) Glaze: 10 parts of kaolin, 5 parts of graphene, 3 parts of nano-titanium dioxide fiber powder, 2 parts of bamboo charcoal powder, 5 parts of silicon carbide whiskers, 3 parts of barium sulfate, 4 parts of glass beads, 5 parts of potassium feldspar , 3 parts of quartz sand, 4 parts of talcum powder, 3 parts of olivine, 2 parts of bamboo charcoal powder, 1 part of iron oxide, 5 parts of aluminum oxide, 3 parts of magnesium oxide, 4 parts of zirconium silicate, 2 parts of zinc oxide, 2 parts of lutetium oxide share.

[0041] 2. The preparation...

Embodiment 3

[0043] 1. A graphene composite ceramic with high strength and toughness, made of the following components by weight:

[0044] (1) Green body: 8 parts of iron oxide, 8 parts of anorthite, 10 parts of potassium feldspar, 8 parts of attapulgite, 15 parts of spodumene, 5 parts of graphene, 3 parts of nano-titanium dioxide fiber powder, silicon carbide crystal 2 parts of silk, 3 parts of barium sulfate, 2 parts of glass microspheres;

[0045] (2) Glaze: 4 parts of kaolin, 2 parts of graphene, 1 part of nano-titanium dioxide fiber powder, 1 part of bamboo charcoal powder, 2 parts of silicon carbide whiskers, 1 part of barium sulfate, 1 part of glass microspheres, 10 parts of potassium feldspar , 8 parts of quartz sand, 9 parts of talcum powder, 8 parts of olivine, 5 parts of bamboo charcoal powder, 3 parts of iron oxide, 9 parts of aluminum oxide, 7 parts of magnesium oxide, 8 parts of zirconium silicate, 5 parts of zinc oxide, and 6 parts of lutetium oxide share.

[0046] 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com