Patents

Literature

82results about How to "Large joint surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

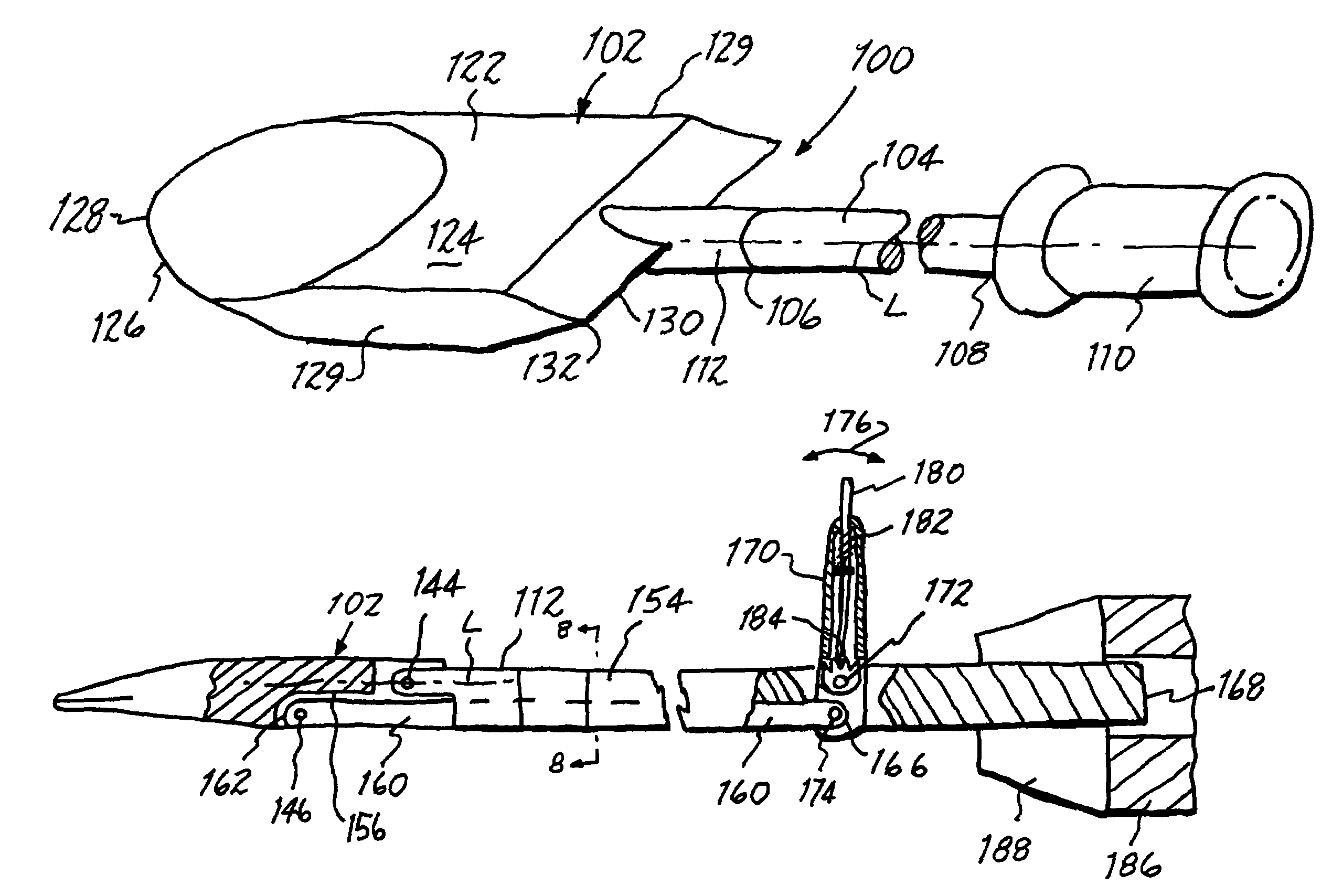

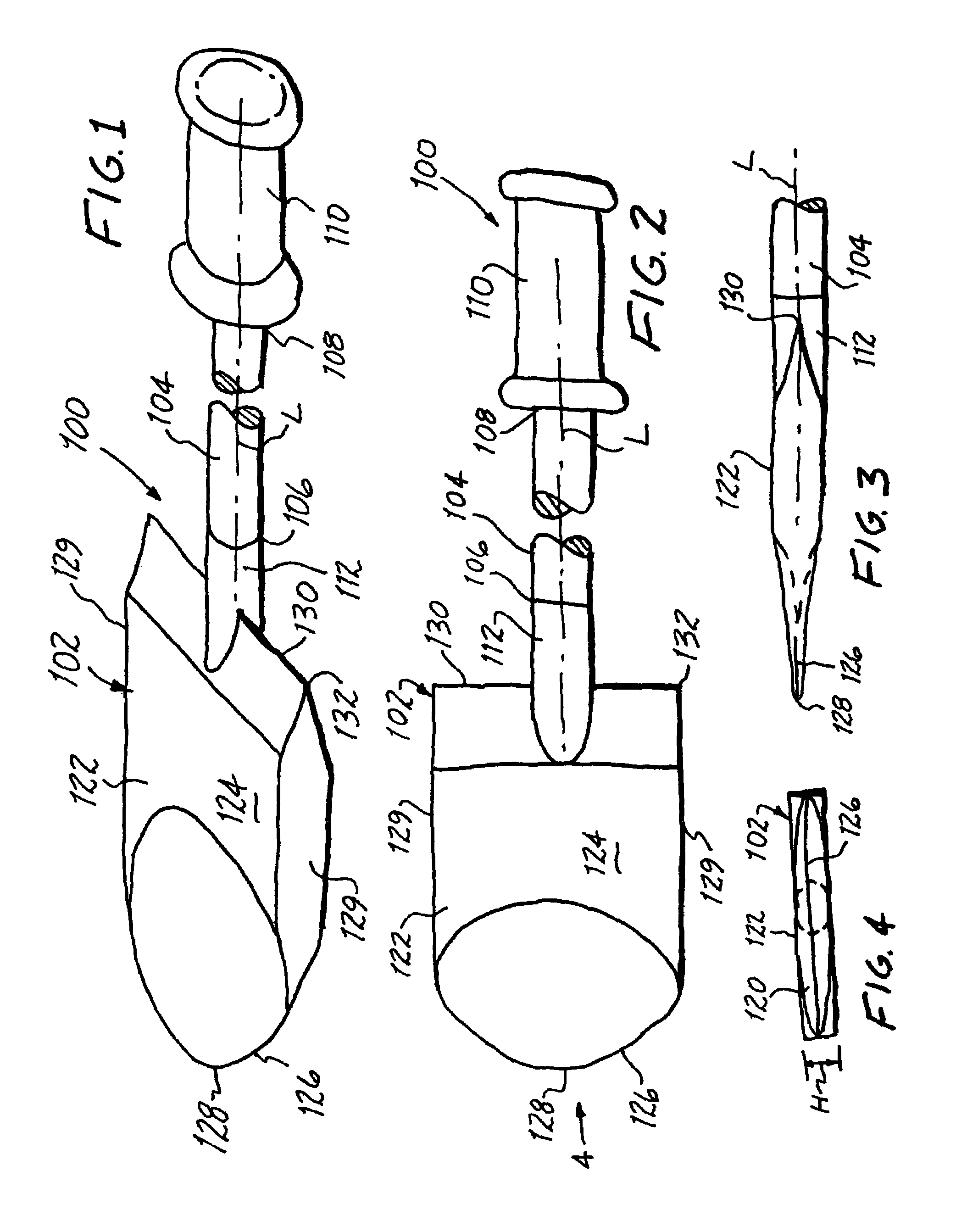

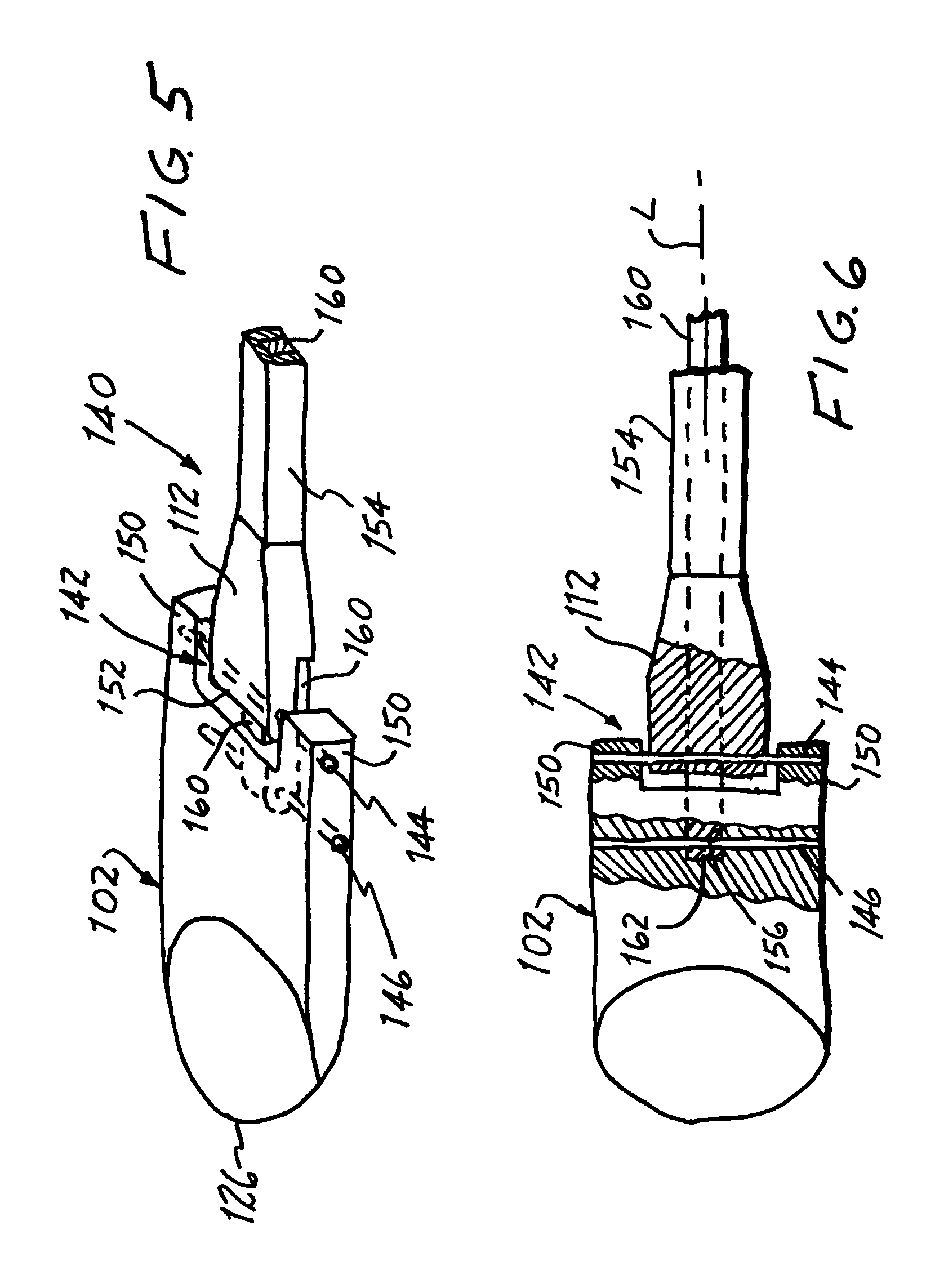

Apparatus and method for the reduction of bone fractures

ActiveUS7442195B1Efficient reductionAvoid disadvantagesInternal osteosythesisNon-surgical orthopedic devicesFracture reductionBone fragment

Reduction of a bone fragment of a bone fracture at a bone fracture site is accomplished through a minimally invasive access passage utilizing instruments having a working head actuated from a location remote from the bone fracture site, between an insertion configuration dimensioned and configured to present a minimal cross-sectional area for ready passage through the minimally invasive access passage and a working configuration dimensioned and configured to establish an essentially rigid working face of substantially greater cross-sectional area than the minimal cross-sectional area. The working head is actuated into the working configuration and manipulated from the remote location while in the working configuration to engage the working face with the bone fragment and manipulate the bone fragment into an anatomically appropriate reduced position at the bone fracture site.

Owner:BEHRENS ALFRED F

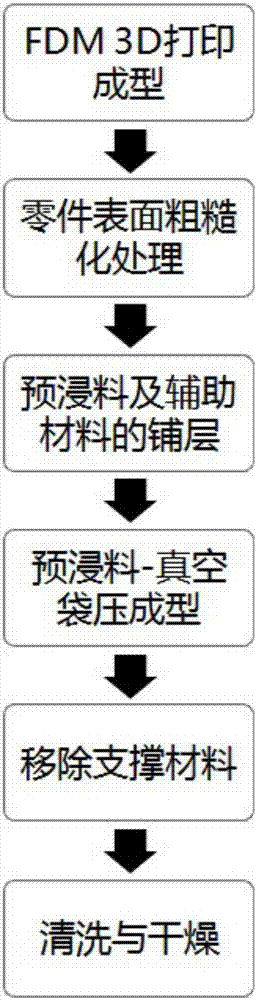

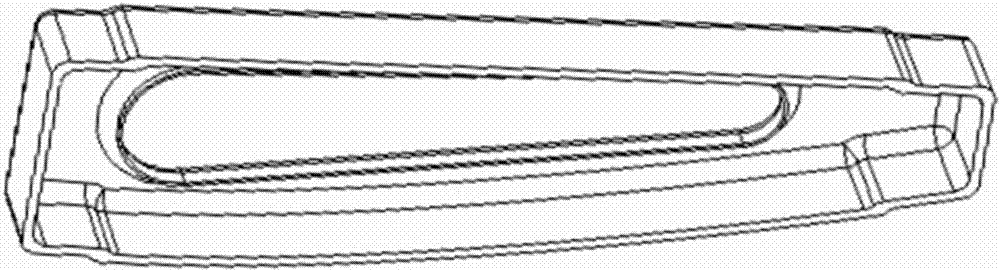

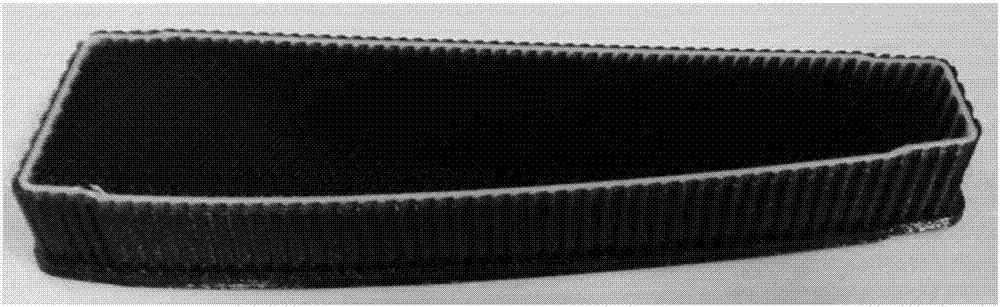

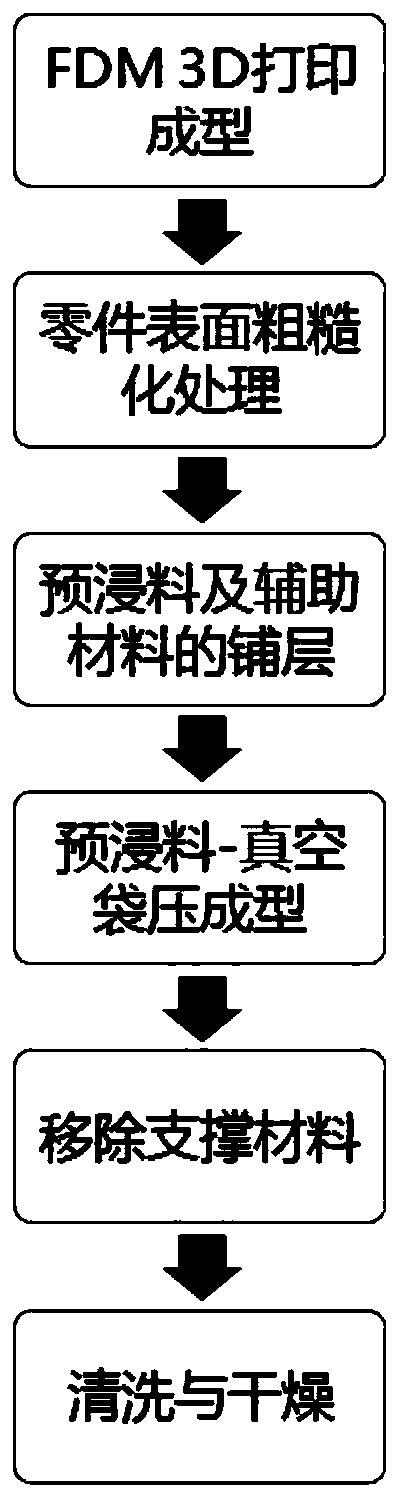

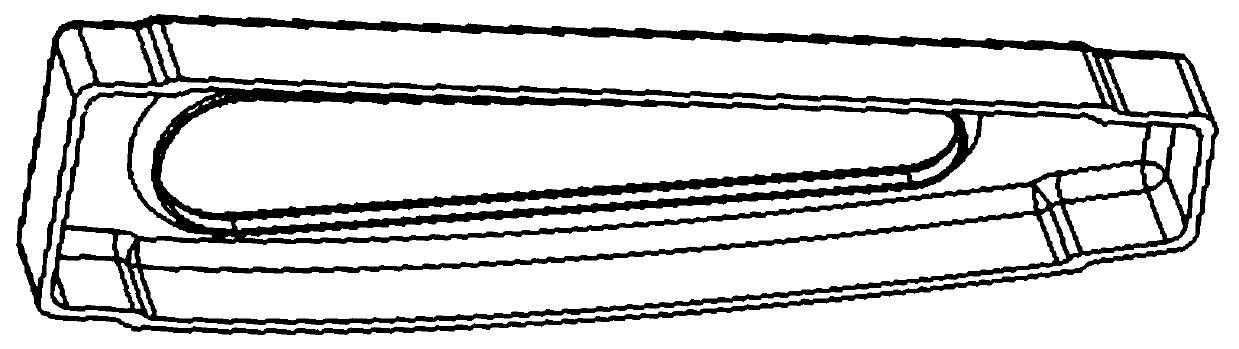

3D printing assisted forming method for fiber reinforced composite material

ActiveCN107187020AImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresFiber-reinforced compositeInvestment material

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

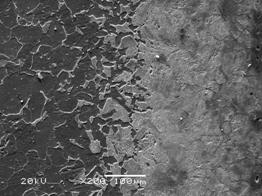

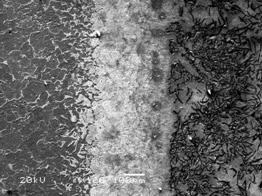

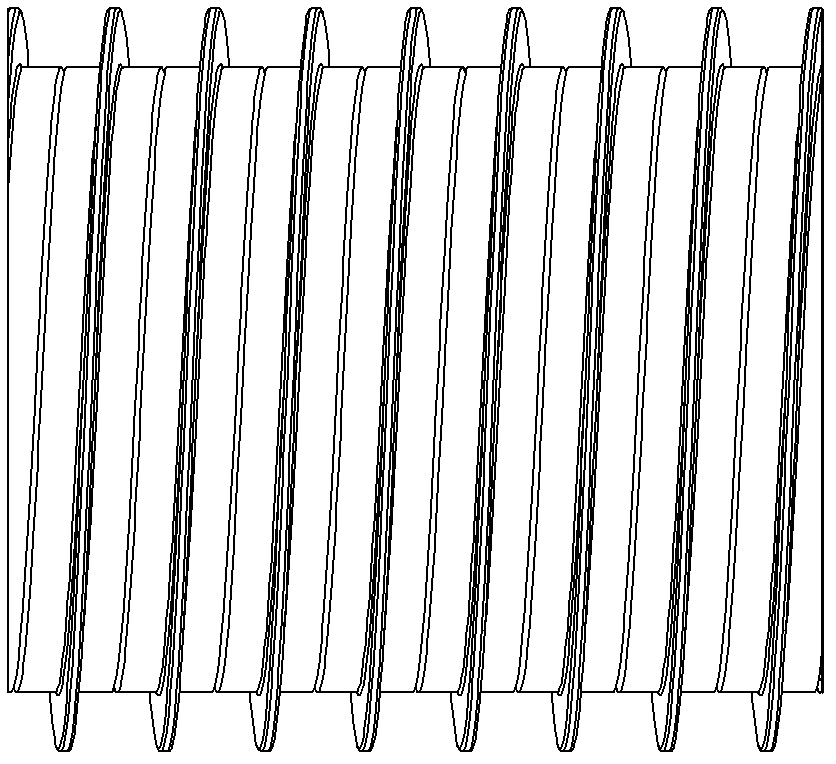

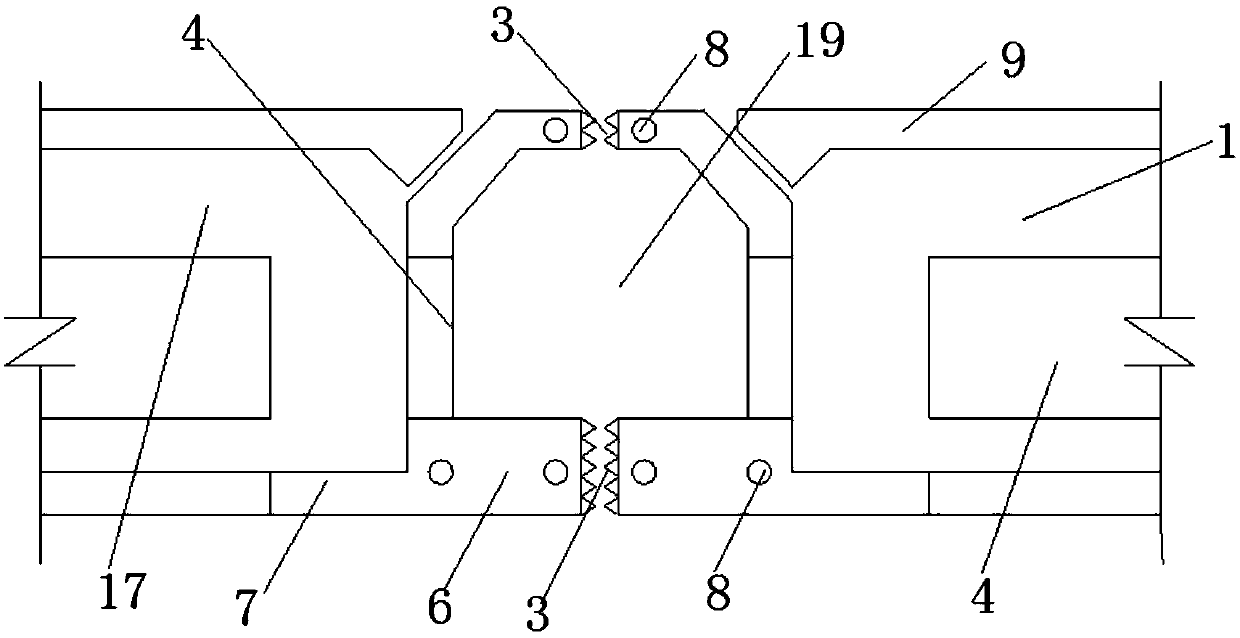

Device and method for producing metal composite sheet strips through corrugated-flat continuous rolling

ActiveCN105057386AHigh bonding strengthUniform deformationMetal rolling arrangementsCrazingContinuous annealing

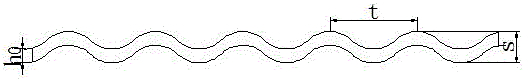

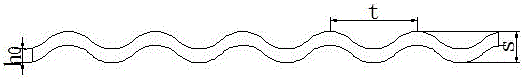

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

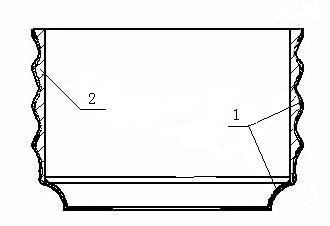

Shaping method of bimetallic composite-material brake drum

The invention discloses a shaping method of a bimetallic composite-material brake drum, and relates to the shaping method of the brake drum. The shaping method includes the steps of manufacturing a brake drum jacket with a waved circumferential pipe wall by using a low carbon steel pipe, placing the brake drum jacket in a horizontal centrifugal casting machine, and pouring molten iron at a certain temperature, thus finishing casting in the casting machine and finally obtaining the brake drum compositing two metal materials of low carbon steel and cast iron. The brake drum compositing two metal materials manufactured according to the shaping method provided by the invention can fully bring respective advantages into play, is high in combination quality of an interface, and light in weight.

Owner:HENAN UNIV OF SCI & TECH

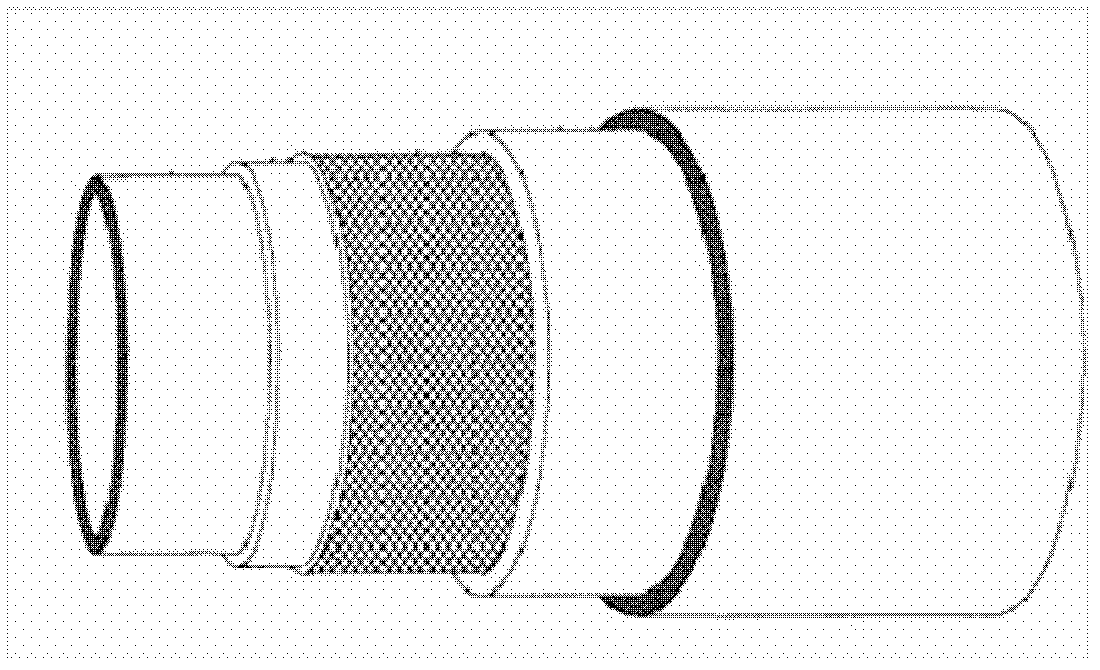

Double composite plastic steel composite pipe and manufacture method thereof

InactiveCN102620066ASave raw materialsLow costRigid pipesTubular articlesInternal pressureMaterial consumption

The invention provides a double composite plastic steel composite pipe and a manufacture method thereof, discloses a method for manufacturing a liquid conveying pipeline with the advantages of high annular rigidity, low material consumption, capability of bearing internal pressure, favorable sanitary performance, long service life, and better comprehensive performance. The basic process comprises steps of: manufacturing a plastic steel strip, manufacturing a plastic steel winding pipe stock by using the plastic steel strip, compounding and winding a metal wire, extruding a hot melt adhesive and coating on an outer surface of the pipe stock and coating a fused plastic on the outer surface of the plastic steel winding pipe stock. Thus both the anti-corrosion performance of plastic and the rigidity of steel belts are utilized; due to the adoption of the embedded steel wire, the internal pressure bearing performance of a buried pipe can be guaranteed; due to the composite structure of the pipe, the consumption of plastic is reduced, and the performance-price ratio of the pipe is greatly improved; and the manufacture method can be used for manufacturing large caliber liquid conveying pipelines, so as to solve the problem that the manufacture of large caliber plastic pipes is difficult in China.

Owner:山东天迈管业有限公司

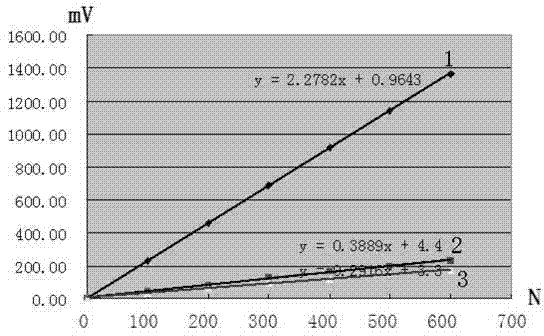

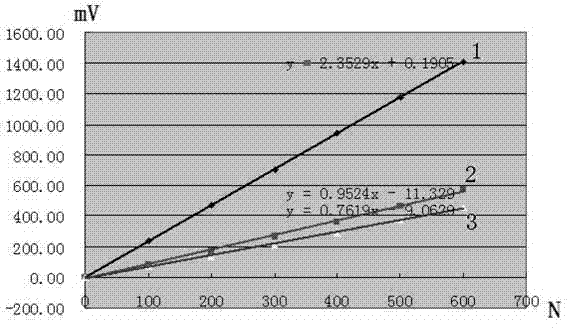

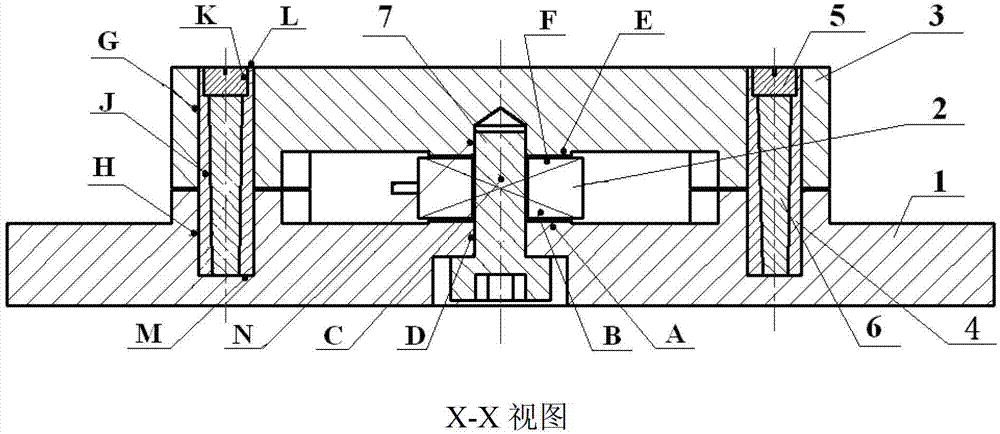

Load-sharing piezoelectric multi-dimensional force measuring device and method for manufacturing the same

InactiveCN103175636ALarge measuring rangeAssembly technology requirements are lowForce measurement using piezo-electric devicesMeasurement deviceMultiple dimension

The invention discloses a load-sharing piezoelectric multi-dimensional force measuring device and a method for manufacturing the same, belongs to the field of piezoelectric sensors, and particularly relates to a testing device. The testing device is required for measuring force in three directions, and ranges of the force in the three directions are similar, and are of ten-thousand Newton classes. The method includes reasonably arranging a plurality of expansion pins on the periphery of a piezoelectric three-directional force sensor, and designing the expansion pins with different diameters so as to implement different load-sharing ratios; enabling the four expansion pins which are uniformly distributed to expand under actions of four taper pins so that a base can be tangentially and rigidly connected with an upper cover plate, and sharing load of force acting on the upper cover plate; and enabling the load-sharing ratios to be adjustable. The load-sharing piezoelectric multi-dimensional force measuring device comprises the base, the piezoelectric three-directional force sensor, the upper cover plate, the four expansion pins, the four taper pins, four set screws and a pre-tightening screw. The load-sharing piezoelectric multi-dimensional force measuring device and the method have the advantages that a testing application range of the piezoelectric multi-dimensional force measuring device is broadened by the method, and the load-sharing piezoelectric multi-dimensional force measuring device is wide in application space in fields of machining, aviation and aerospace.

Owner:DALIAN UNIV OF TECH

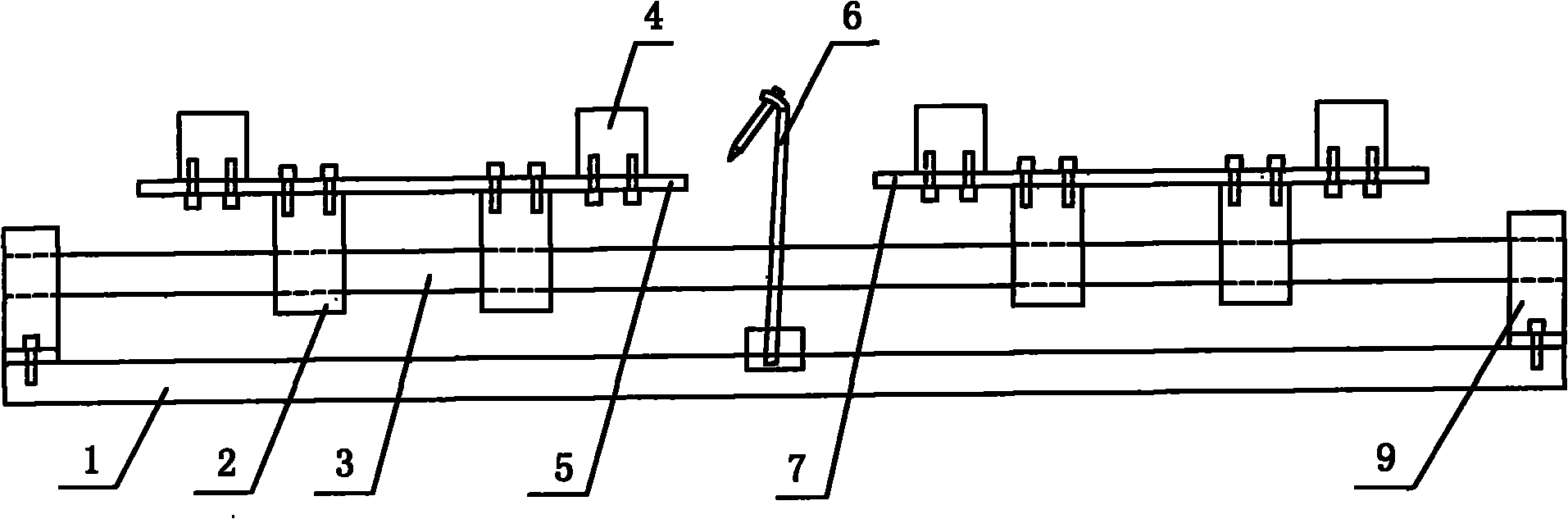

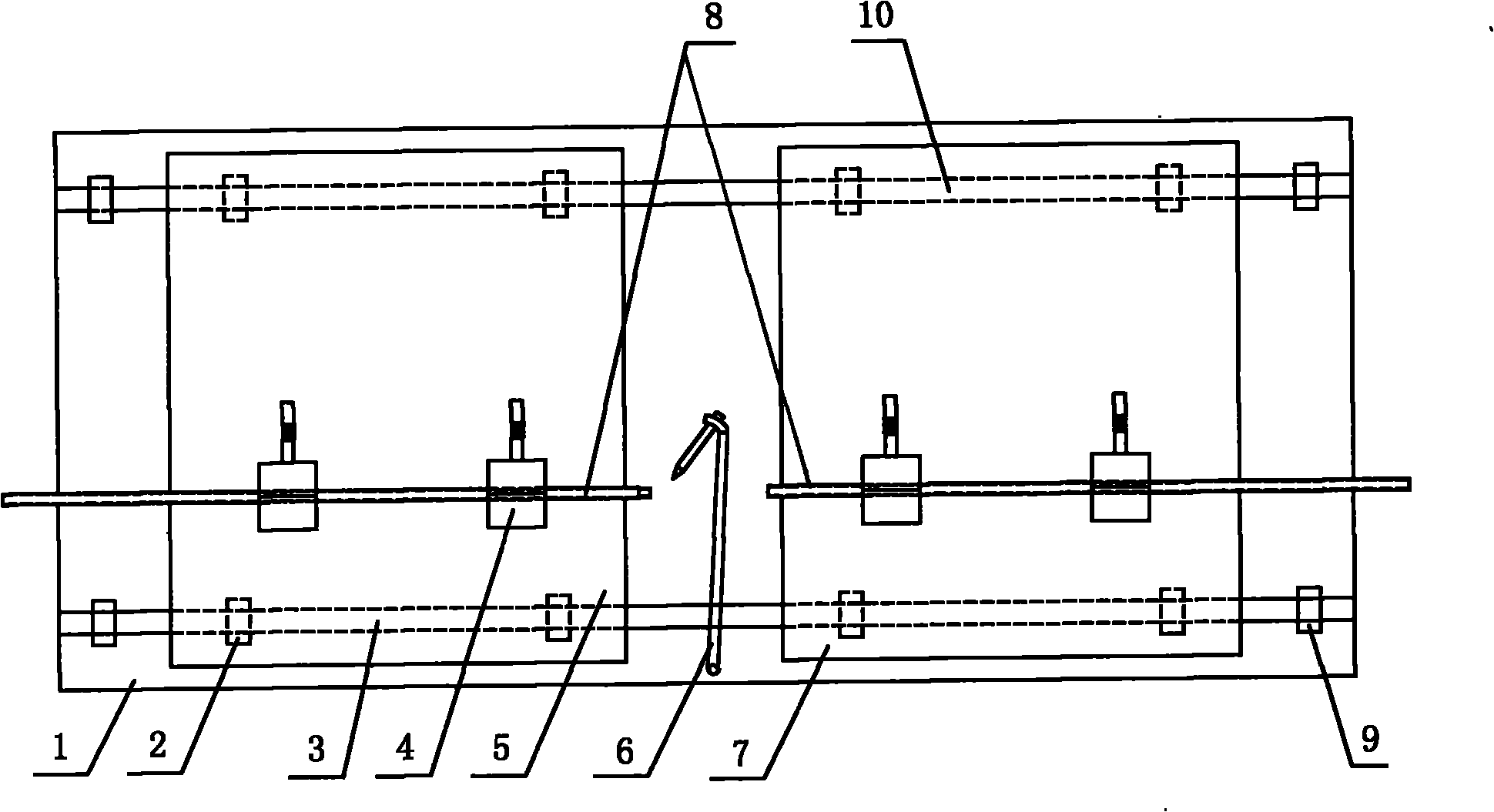

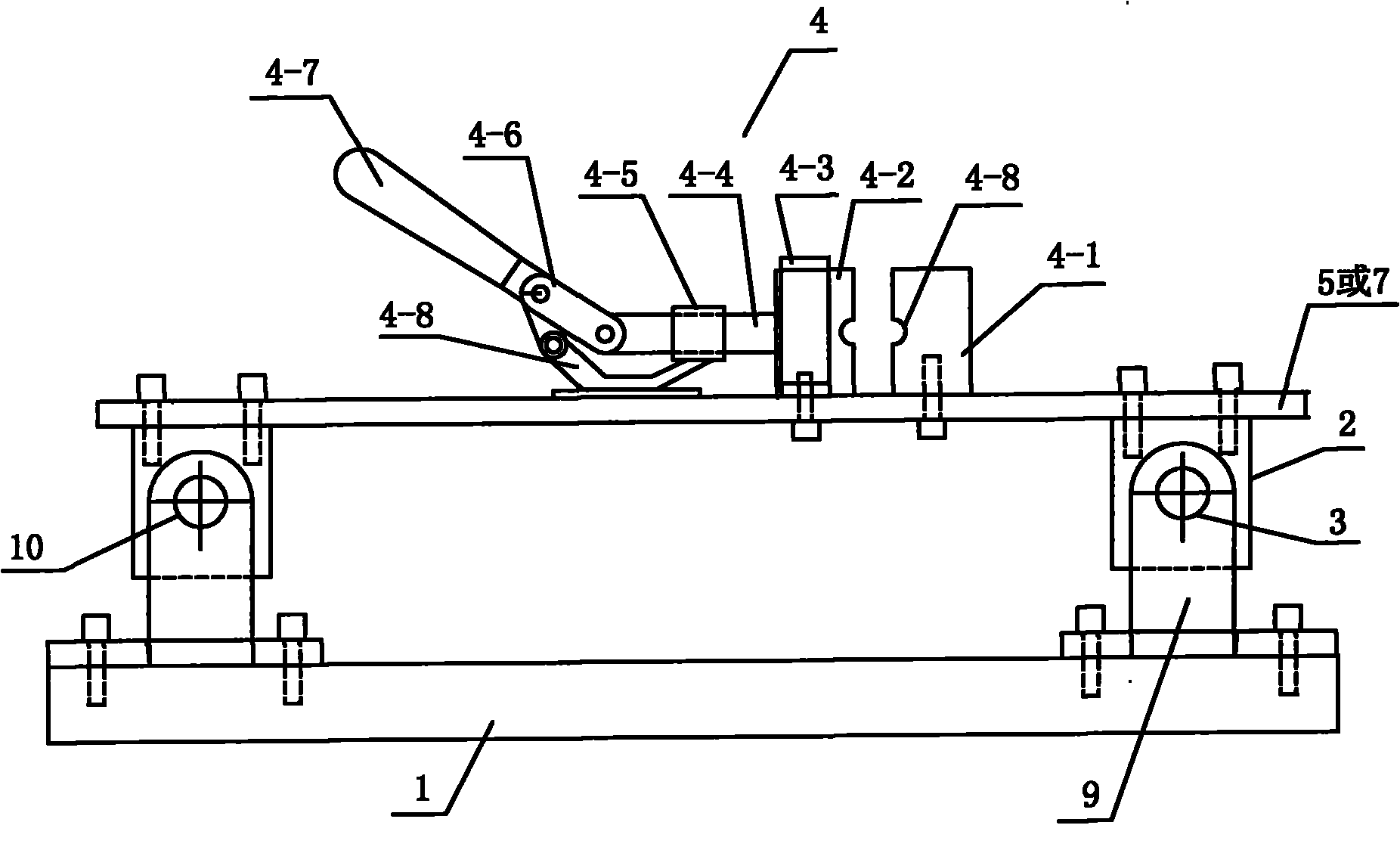

Following device of copper tube inner conductors for radio frequency coaxial cable and following method thereof

ActiveCN101954519AEasy to fixHigh tensile strengthGas flame welding apparatusElectrical conductorCoaxial cable

The invention relates to a following device of copper tube inner conductors for a radio frequency coaxial cable and a following method thereof, in particular to the device for realizing continuous production of the smooth copper tube inner conductors in production of the radio frequency coaxial cable and the following method thereof. The conductor following device comprises copper tube fixtures, a sliding plate unit, a guide rail, a support and a welding torch, wherein, the sliding plate unit is equipped with a sliding plate 1 and a sliding plate 2 which are provided with two groups of the copper tube fixtures respectively; each copper tube fixture comprises a static fixture, a movable fixture, a push rod, a push rod support, a connection rod and a handle; and the welding torch is arranged on the support. The following method comprises the following steps: (1) polishing end surfaces of the two copper tube inner conductors needing welding with a file; (2) clamping the two polished copper tube inner conductors needing welding on the copper tube fixtures respectively; (3) pushing the sliding plates so that end parts of the two copper tube inner conductors get close to each other, putting lined copper tubes on the end parts of the two copper tube inner conductors, and indirectly or directly placing brazing filler metal; and (4) welding with the welding torch by a flame heating method to finally obtain soldered joints of the copper tube inner conductors after condensation.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

Crop straw composite cement-based thermal-insulating wall material and preparation method thereof

ActiveCN108439921AAffect hydration coagulationHigh substance contentSolid waste managementFiberThermal insulation

The invention relates to a crop straw composite cement-based thermal-insulating wall material and a preparation method thereof. The crop straw composite cement-based thermal-insulating wall material is prepared by the preparation method comprising the following steps: (1) cutting off wheat straw and performing steam explosion to obtain an explosion material; (2) washing the explosion material withwater, soaking the washed explosion material in a NaOH solution, and then performing filtering separation, washing and drying to obtain wheat straw fiber; (3) performing silane coupling agent modification on the obtained wheat straw fiber, and then adding metakaolin, stirring and mixing to obtain a fiber premix; and (4) stirring and mixing the fiber premix, cement, polystyrene foam granules, a water reducing agent and water to obtain slurry, and performing pouring molding, standing demolding and maintaining on the slurry. The obtained light-weight thermal-insulating wall material is low in water absorption rate and high in water absorption softening coefficient on the basis that high mechanical property and high thermal insulation property are ensured; and after 50-times freezing and thawing cycle, the compressive strength loss rate does not exceed 10%, the quality loss rate does not exceed 5%, and the crop straw composite cement-based thermal-insulating wall material has high anti-frost property and high durability.

Owner:深圳市中筑营造建设工程有限公司

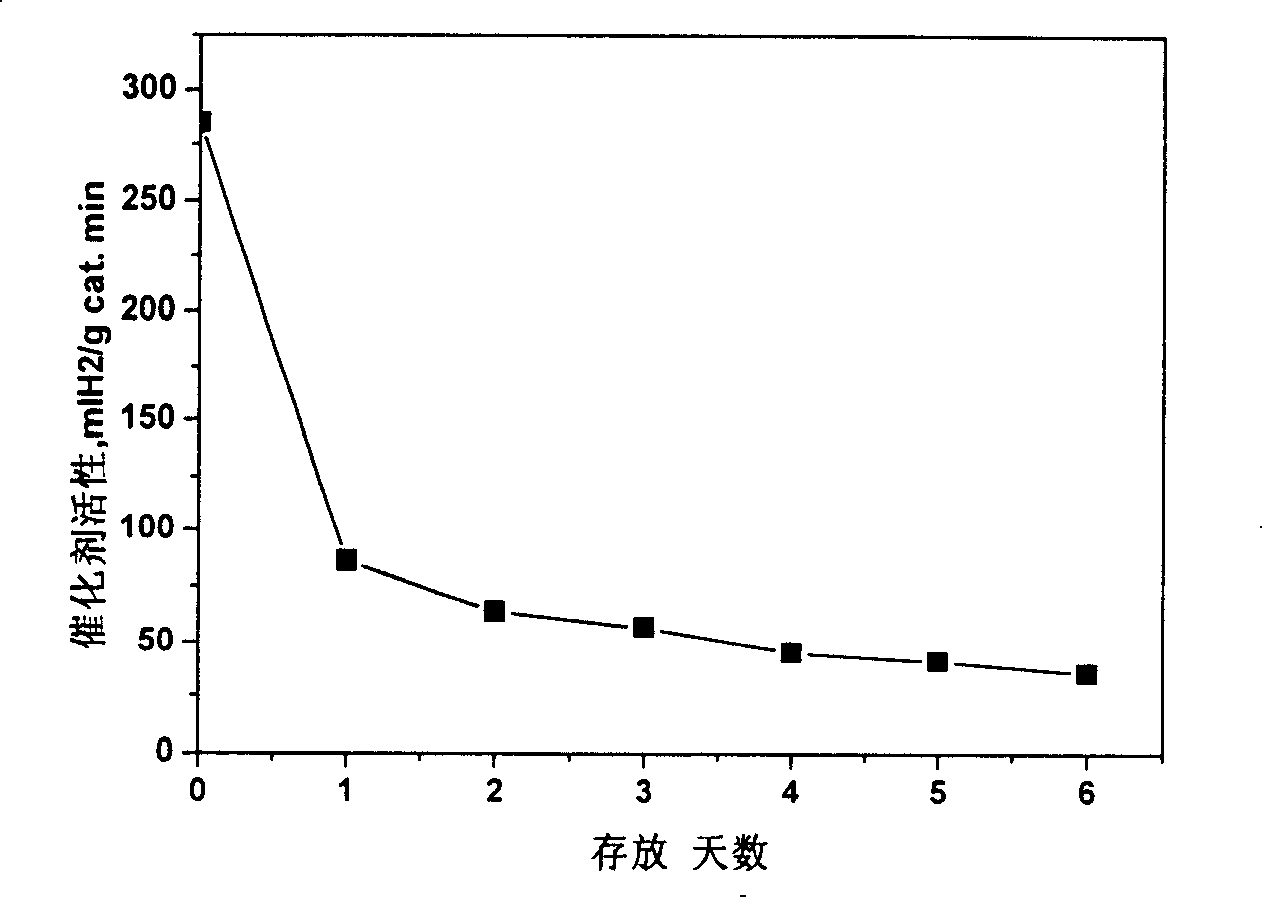

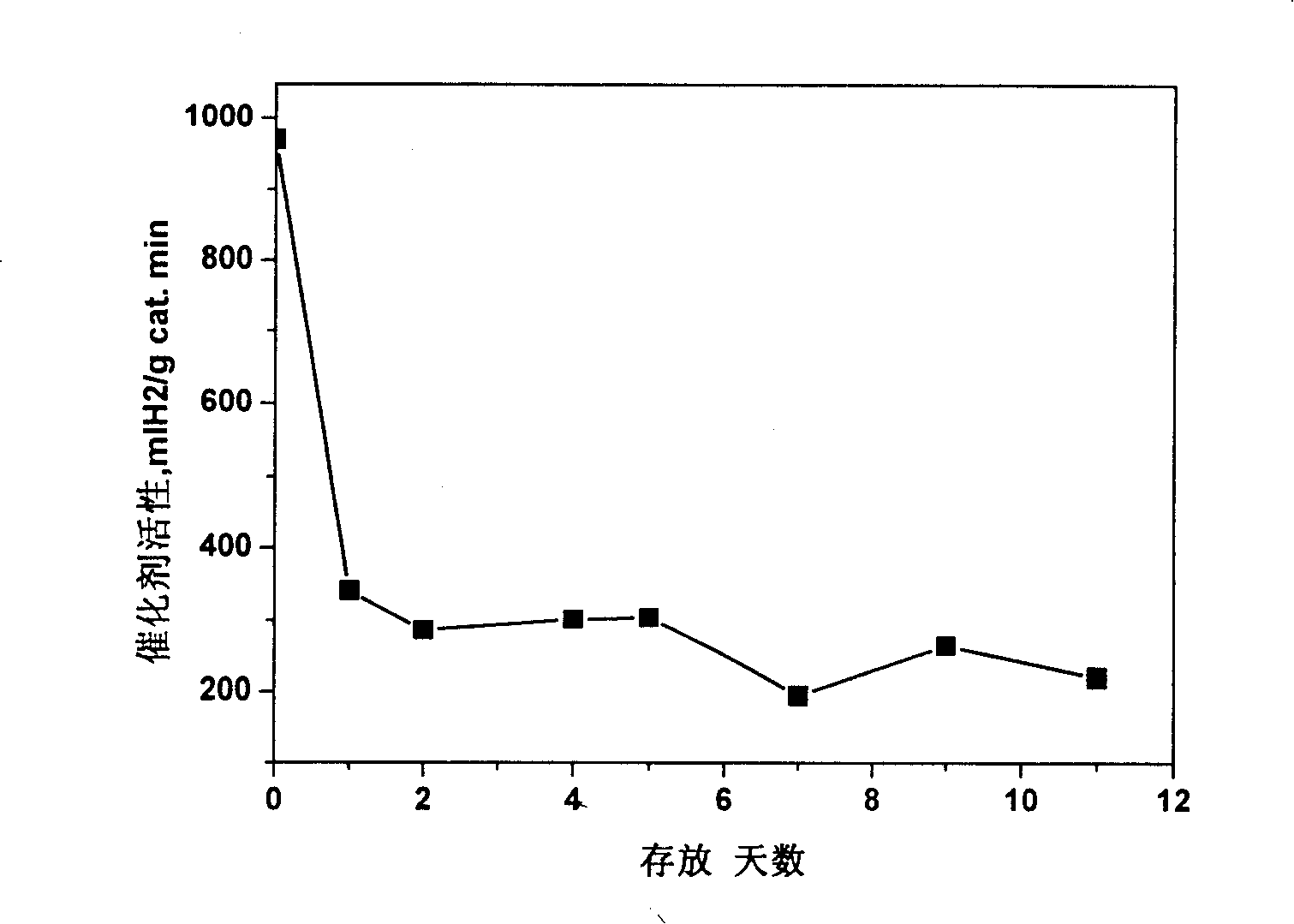

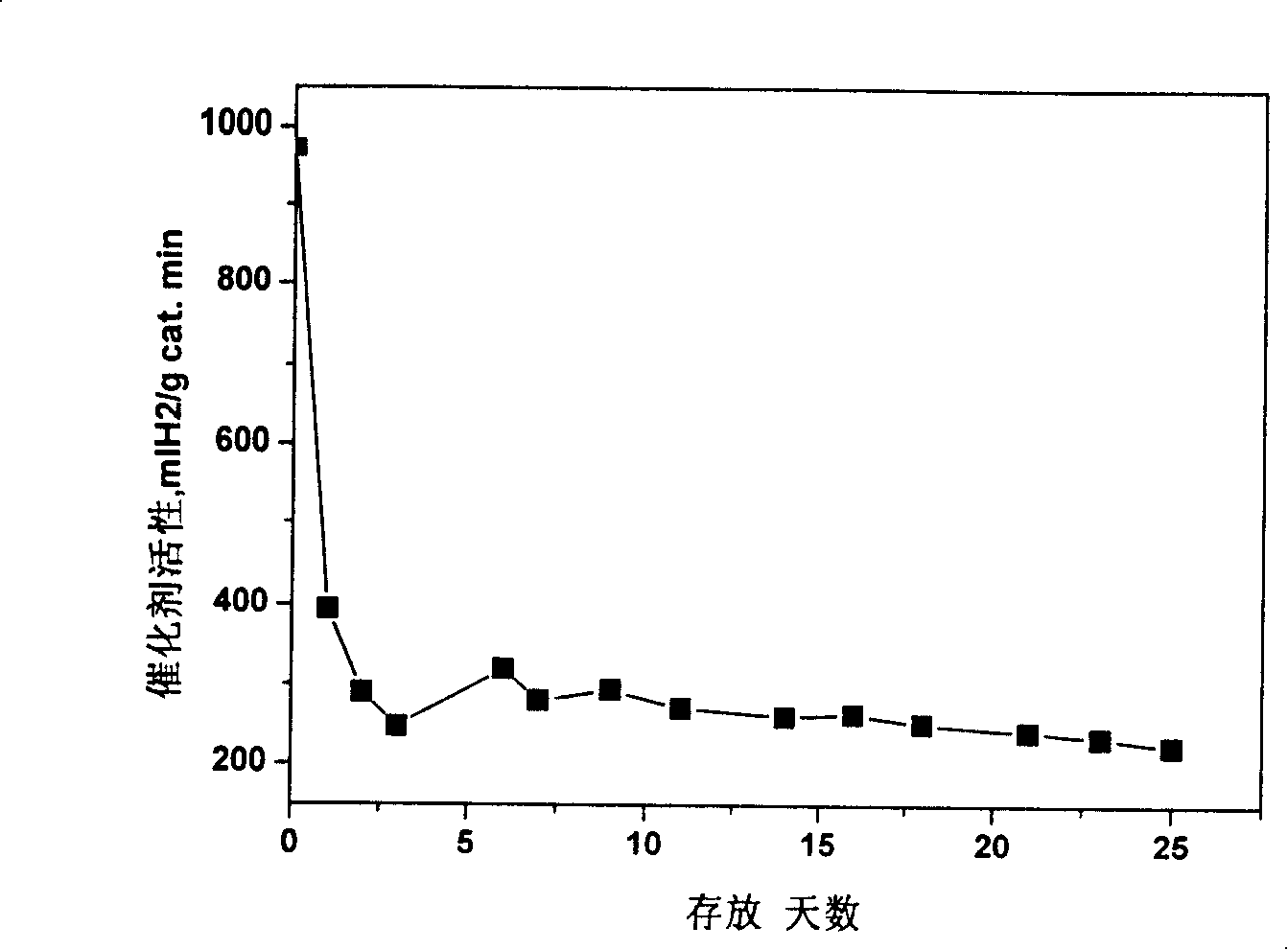

Catalyst for sodium borohydride catalyzing hydrolyzation hydrogen supplying method and preparation thereof

ActiveCN101214444ALow costHigh activityCatalyst carriersCatalyst activation/preparationChemical platingPtru catalyst

The invention relates to a preparation method of a high-cost-performance catalyst for hydrogen supply in catalysis and hydrolysis of sodium borohydride. Foamed nickel or sillitin is taken as the carrier, and a first layer of Pd film and Co film, and a second layer of Pd film are prepared on the carrier through a dipping method or a chemical plating method. The invention has stable performance and low cost, and is palladium / cobalt / palladium sandwich type cobalt-based catalyst, wherein, the Pd in the first layer of Pd film is 1.5 to 2 weight percent of sillitin or foamed nickel; the Co in the Co film is 6.8 to 7.2 weight percent of sillitin or foamed nickel; and the Pd in the second layer of Pd film is 1.5 to 2 weight percent of sillitin or foamed nickel. The catalytic activity of the foamed nickel / palladium / cobalt / palladium catalyst still remains 223mlH2 / g.cat.min after the catalyst is stored in 50g / l NaOH solution for 25 days, and the catalytic activity of the foamed nickel / palladium / cobalt / palladium catalyst still remains 53.5mlH2 / g.cat.min after the catalyst is stored in 50g / l NaOH solution for 22 days.

Owner:GRIMAT ENG INST CO LTD

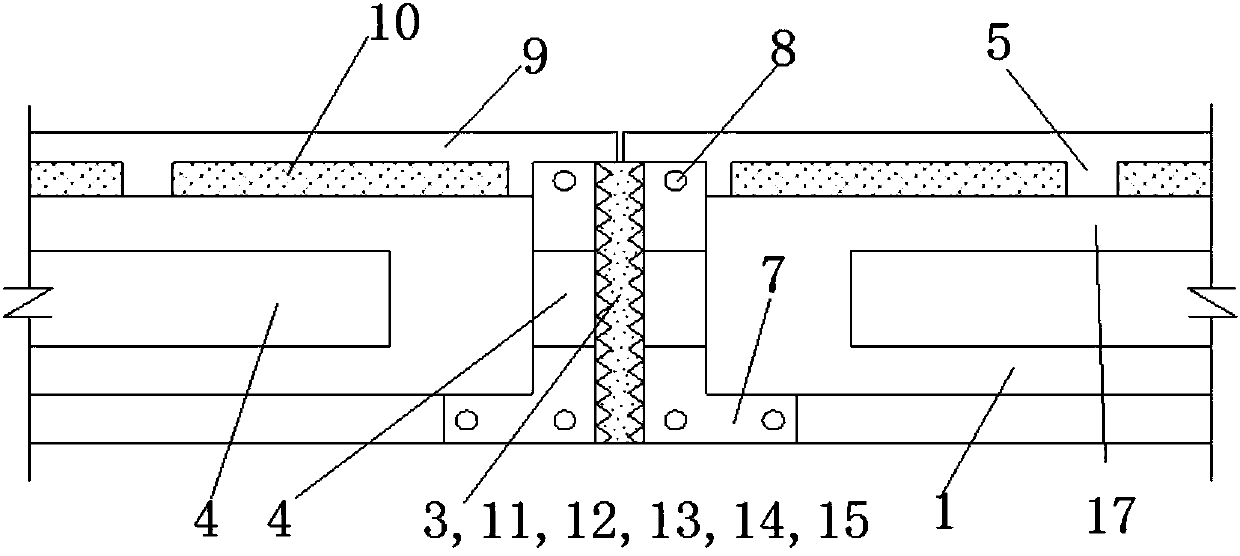

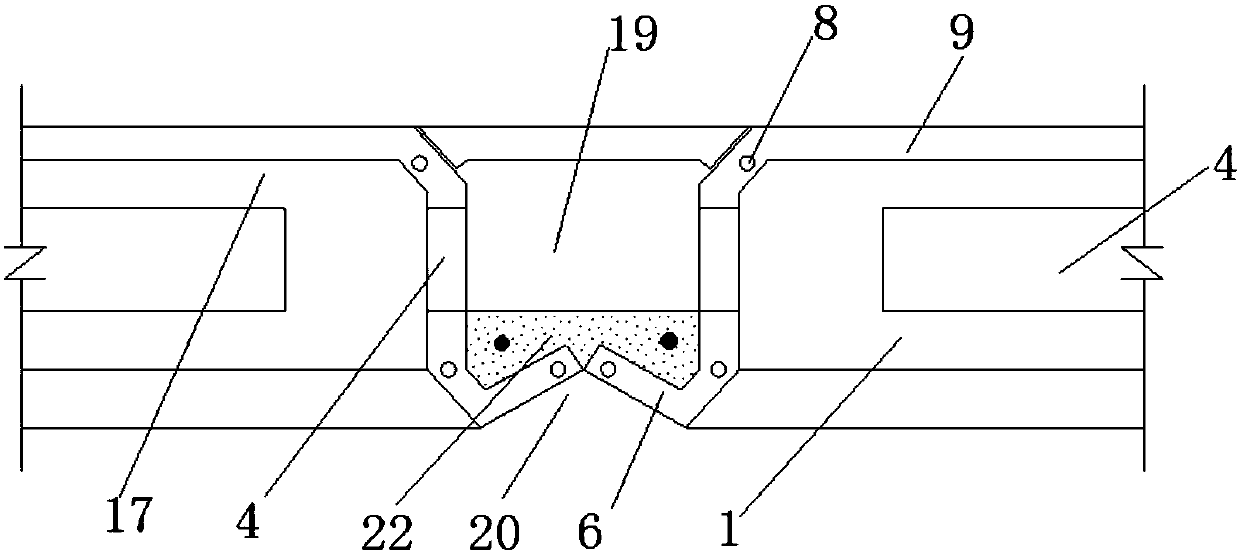

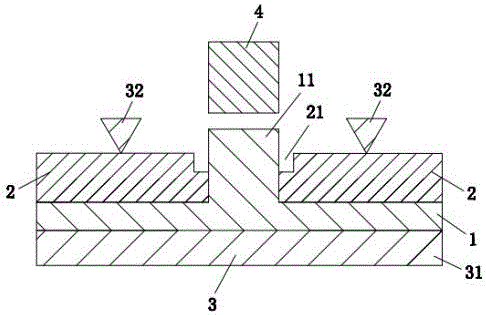

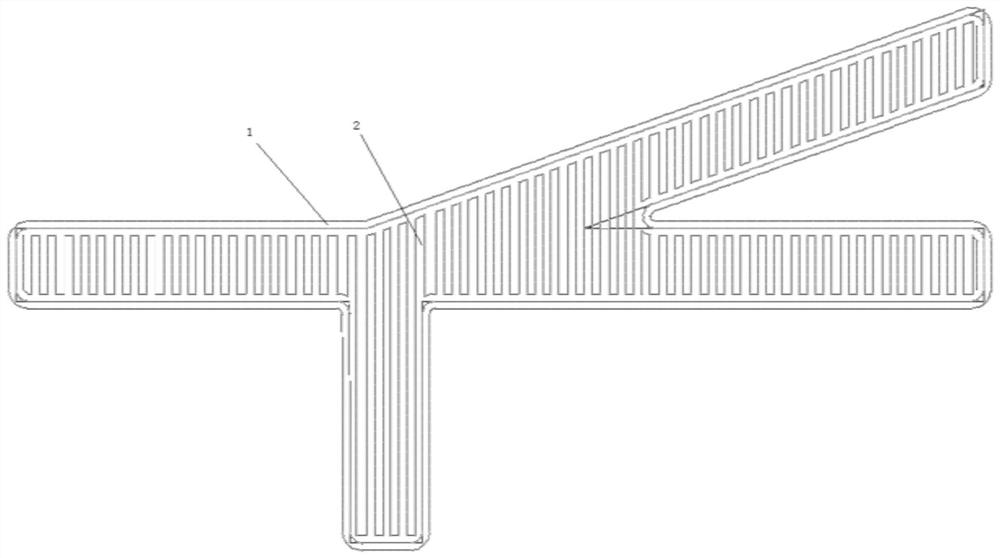

Steel structure tenon-mortise connector and connecting method thereof

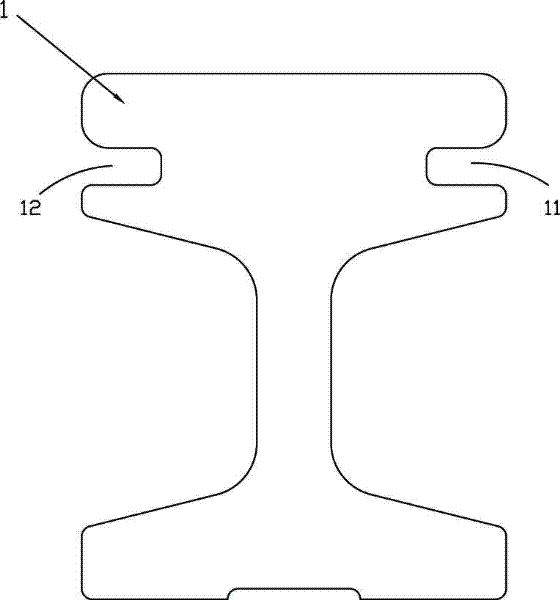

PendingCN107060088AImprove welding qualityReduce pollutionBuilding constructionsTongue and grooveFlange

The invention discloses a steel structure tenon-mortise connector which comprises a tenon and a mortise. The tenon is of an I-steel structure, the mortise is a T-shaped steel sliding groove, and the I-steel structure and the T-shaped steel sliding groove are tightly combined in a tenon-mortise mode. In addition, grooves are formed in the two sides of an upper flange of the I-steel tenon in the height direction correspondingly, protruding heads are arranged on the two sides of a flange of the T-shaped steel sliding groove in the height direction correspondingly, and the protruding heads and the grooves are completely matched. The tenon and the mortise are anchored through a fixing bolt, and are connected with a first steel member and a second steel member correspondingly before connected. The invention further provides a connecting method of the steel structure tenon-mortise connector. The connector between the steel members is the tenon-mortise assembled connector, not only is the size of the original members at the joint not reduced, but also the size is enhanced at the joint, and firm connection of the members is guaranteed; and moreover, the combination face of the tenon-mortise connector is large, high section shear-resistance capacity is achieved, and the safety degree is higher.

Owner:HOHAI UNIV

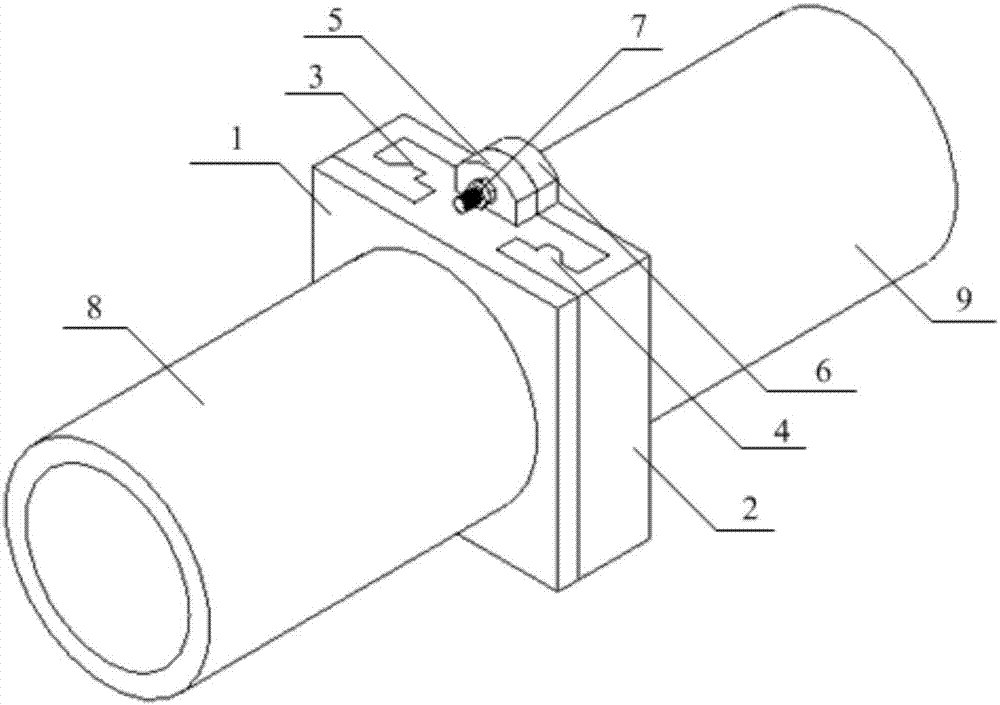

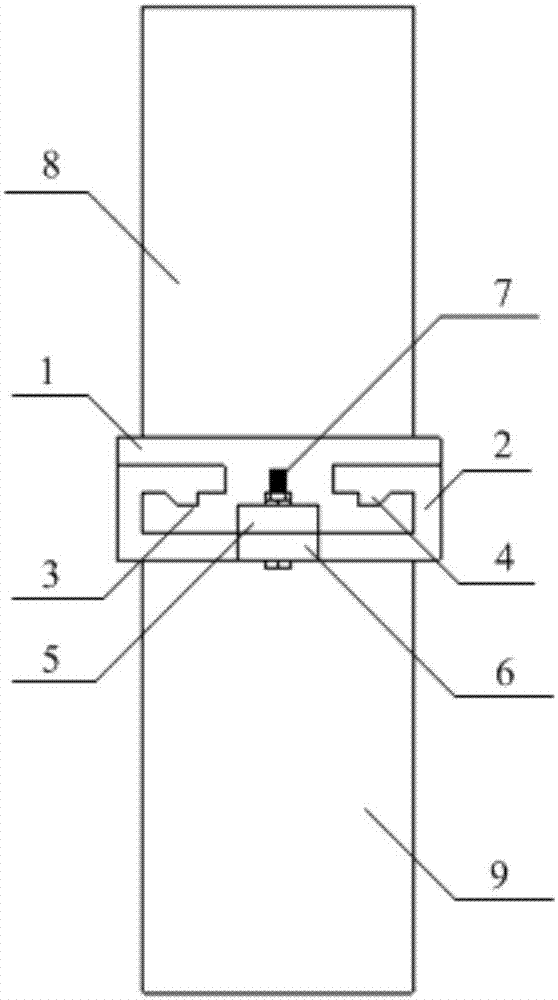

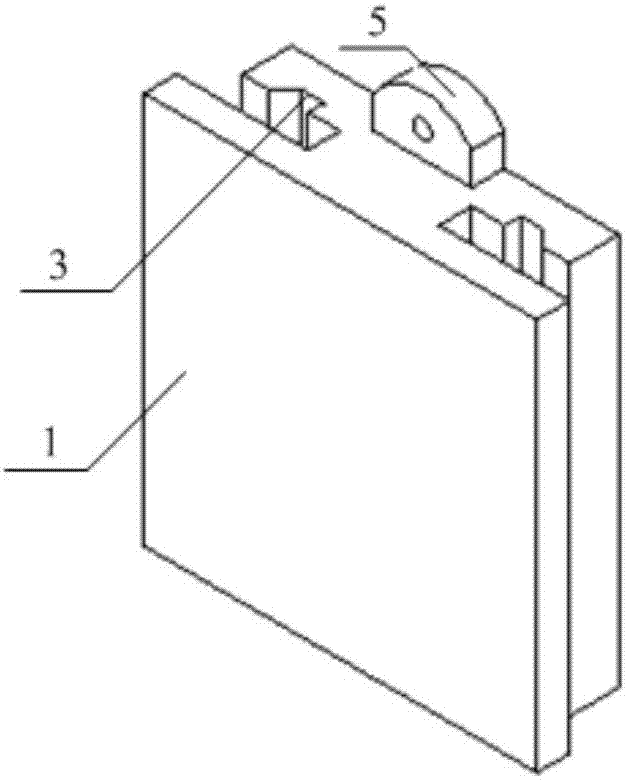

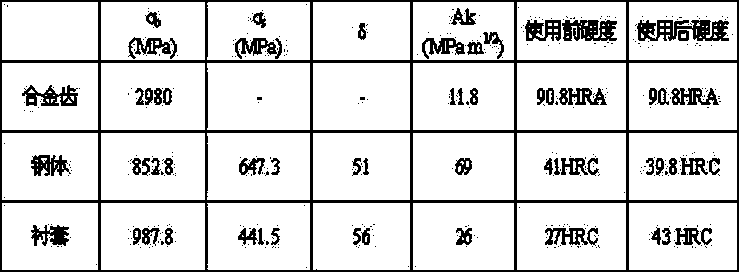

Process for inlaying alloy teeth of rock drilling bit

ActiveCN103850652AReduces the chance of broken (broken) teethLarge joint surfaceDrill bitsInterference fitAlloy

The invention discloses a process for inlaying alloy teeth of a rock drilling bit. The process comprises the steps of 1, selecting a good-quality high manganese round steel and processing the good-quality high manganese round steel into a liner bushing; 2, carrying out vacuum water quenching, tempering and heat preservation on the processed liner bushing, and then carrying out air-cooling treatment; 3, carrying out finish machining on an inner hole of the linear bushing; 4, performing thermal treatment on the linear bushing machined with the inner hole, and pressing the alloy teeth into the linear bushing under appropriate conditions; 5, performing high-speed shot blasting treatment on the teeth-inlaid linear bushing; 6, accurately grinding the outer circular surface of the teeth-inlaid linear bushing; 7, enabling the teeth-inlaid linear bushing to be in interference fit with teeth holes. The process for inlaying the alloy teeth of the rock drilling bit has the advantages that the liner bushing is arranged to sleeve the alloy teeth, so that the holding force is enhanced by enlarging the effective combination surface by increasing the length, and the magnitude of interference can be reduced appropriately without increasing the alloy cost, and therefore, the teeth can be fixed firmly, and also the drilling bit body and the alloy teeth can be protected against damage; meanwhile, under the protection action of the liner bushing, because the stress is basically eliminated in the process of inlaying the teeth in the linear bushing, the phenomena of alloy tooth breakage and steel body collapse are reduced remarkably, and the service life of the drill bit is prolonged.

Owner:ZHUZHOU SUNSHINE CEMENTED CARBIDE TOOLS

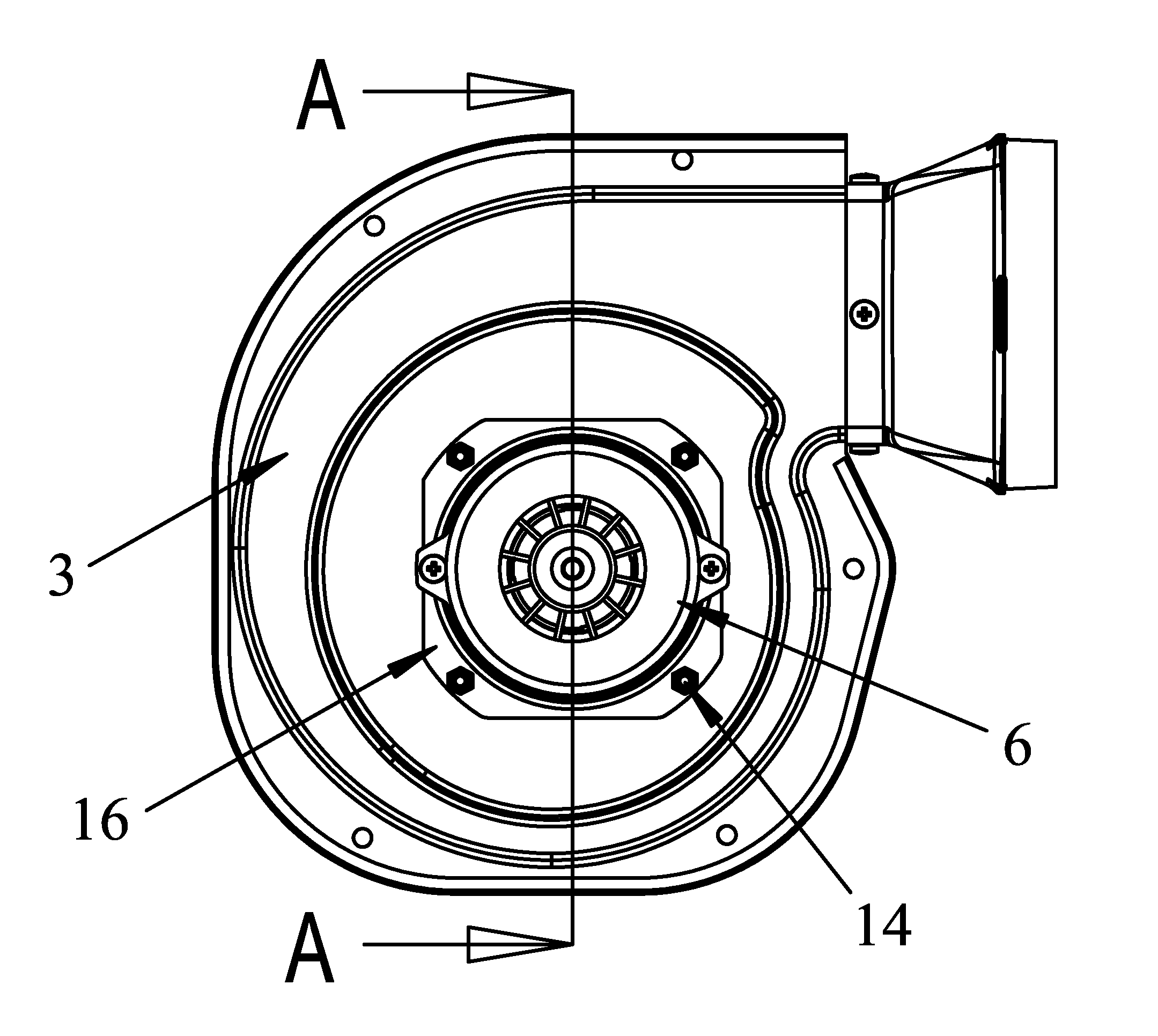

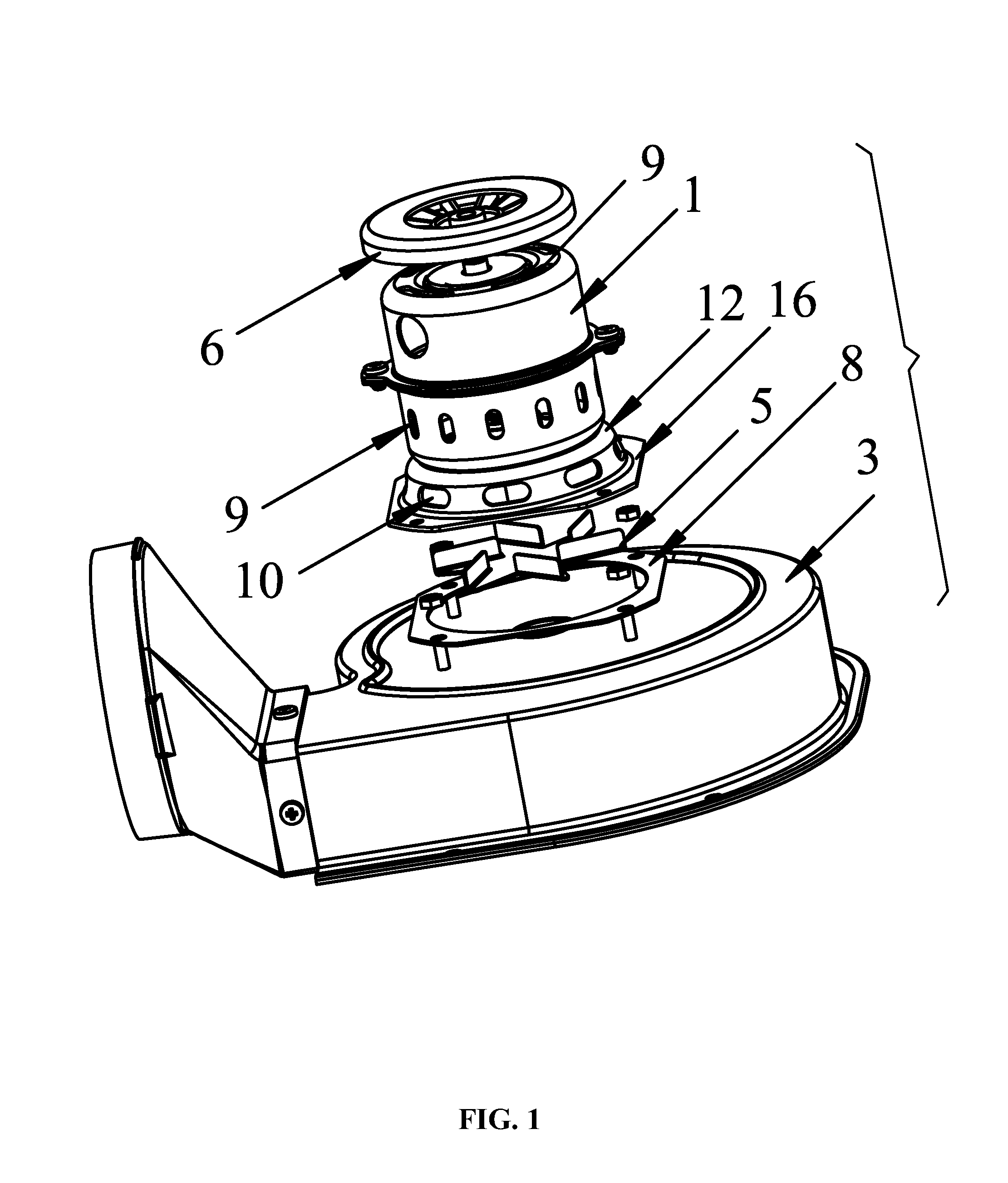

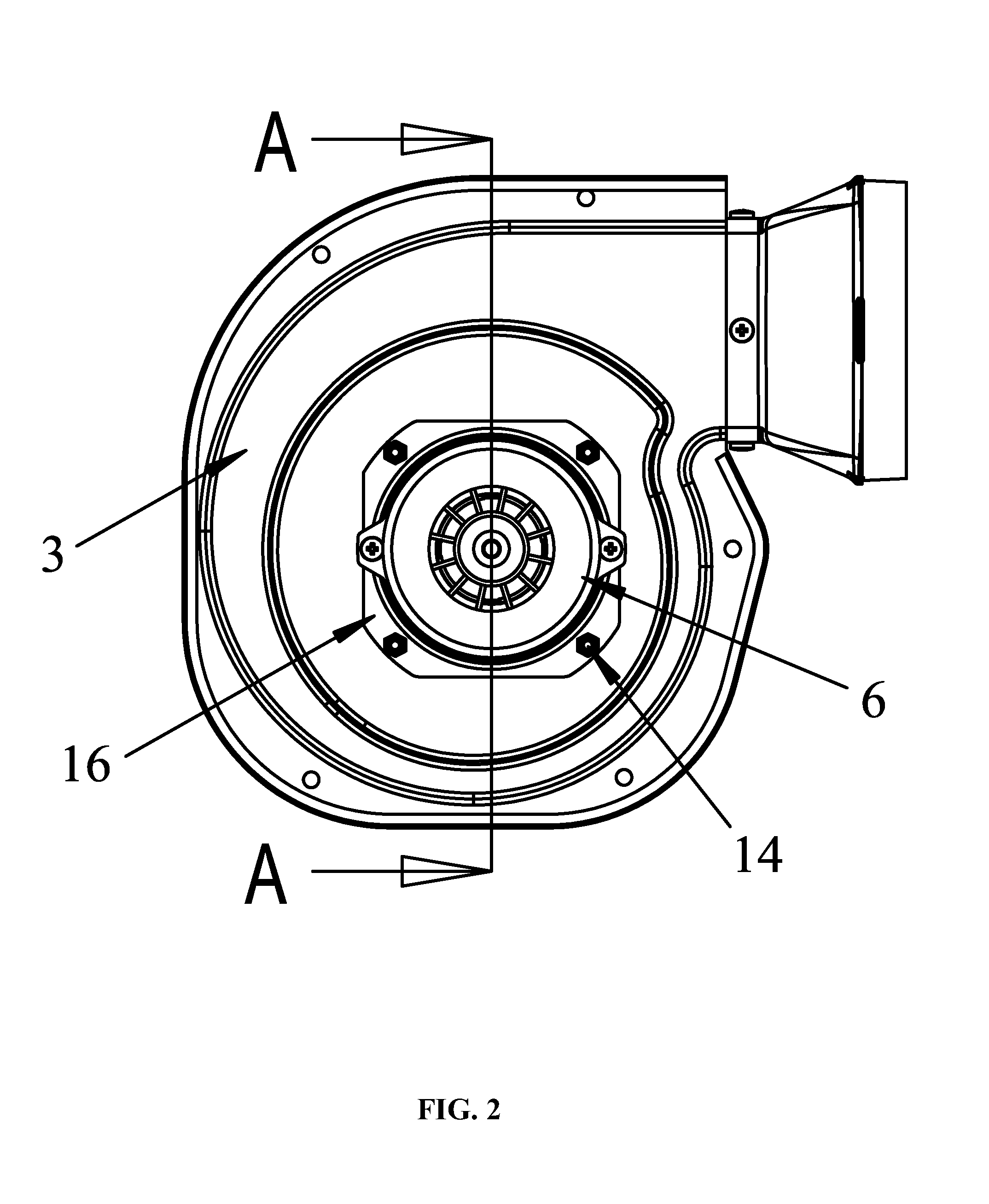

Blower fan

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

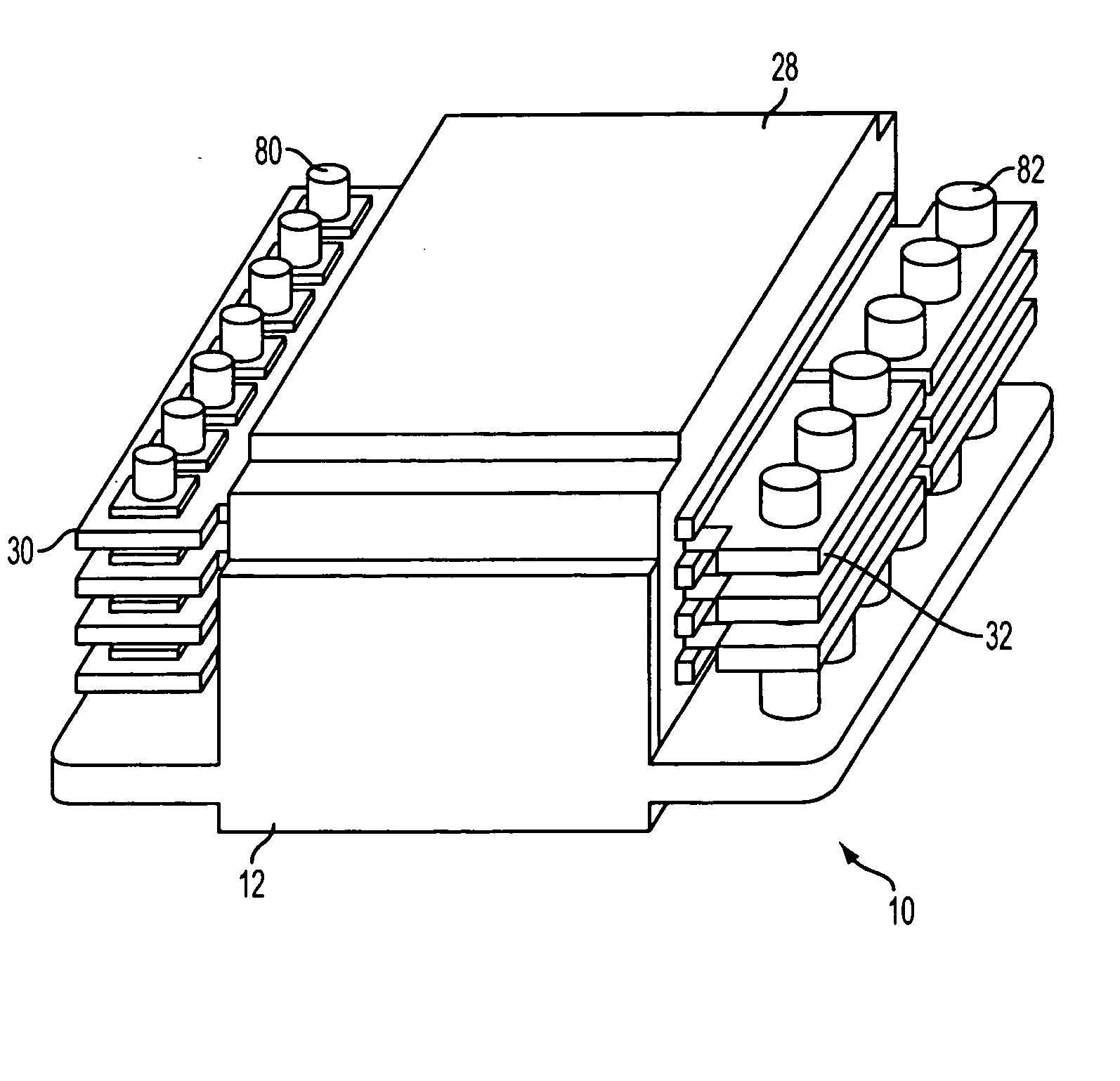

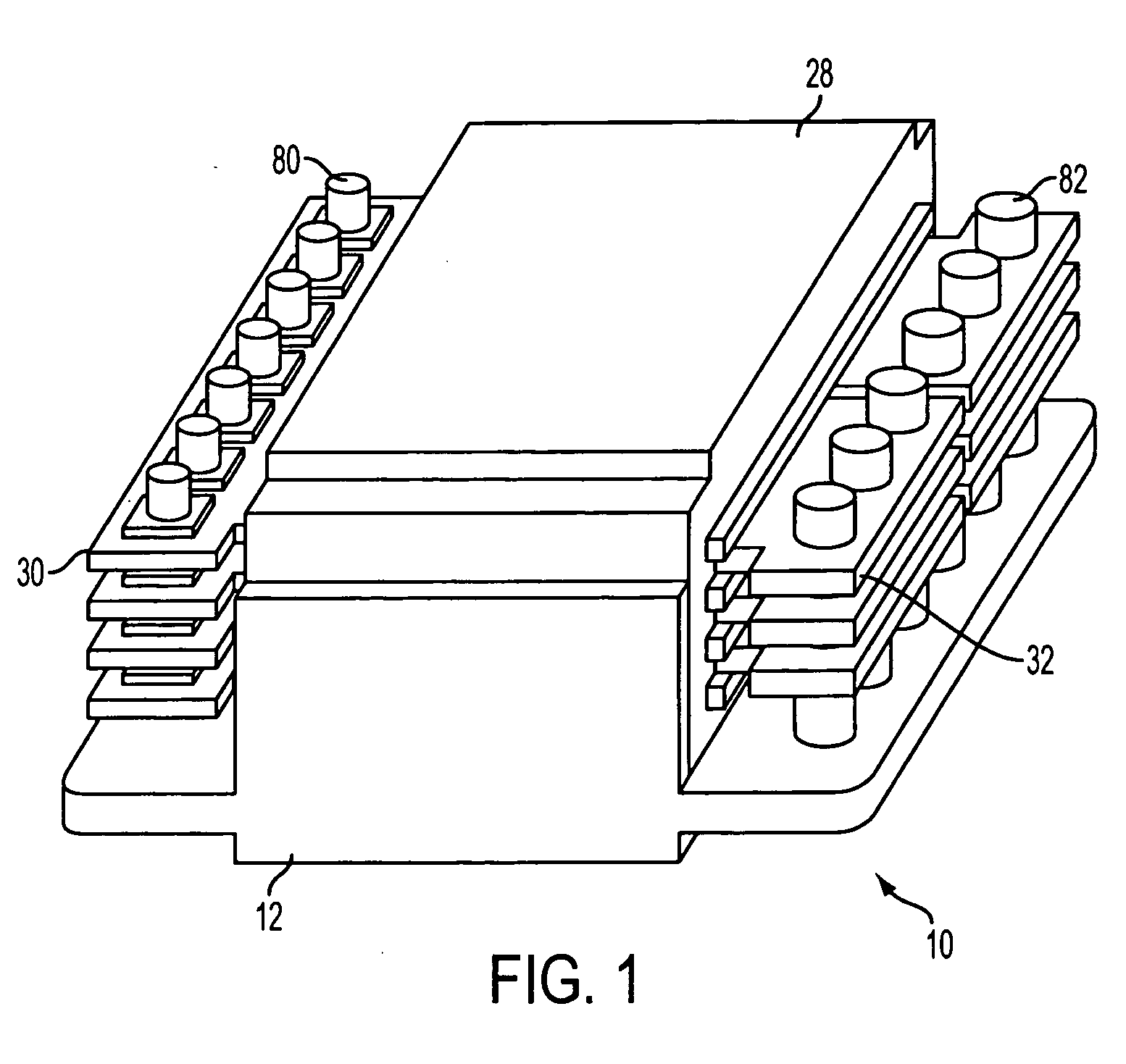

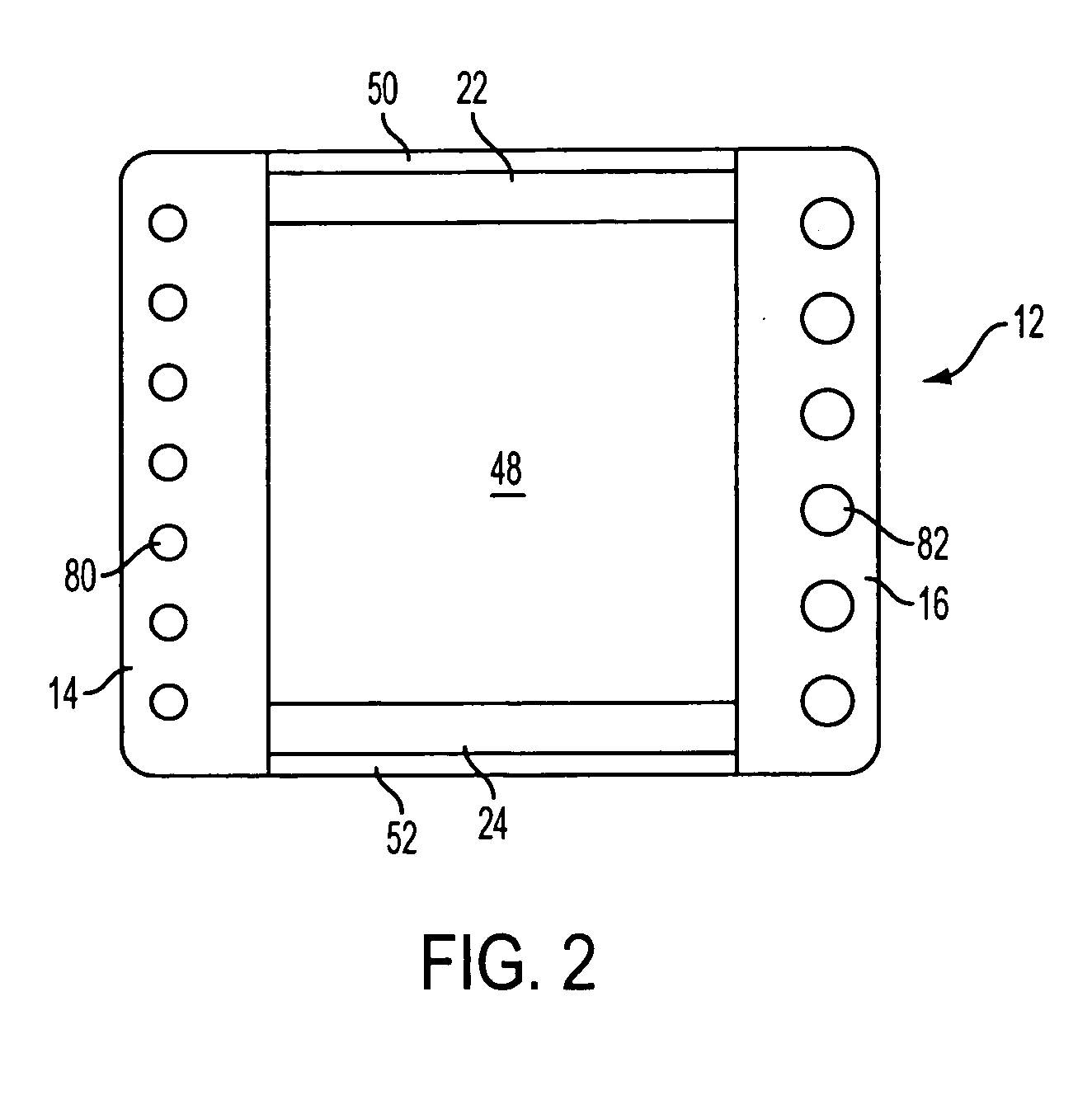

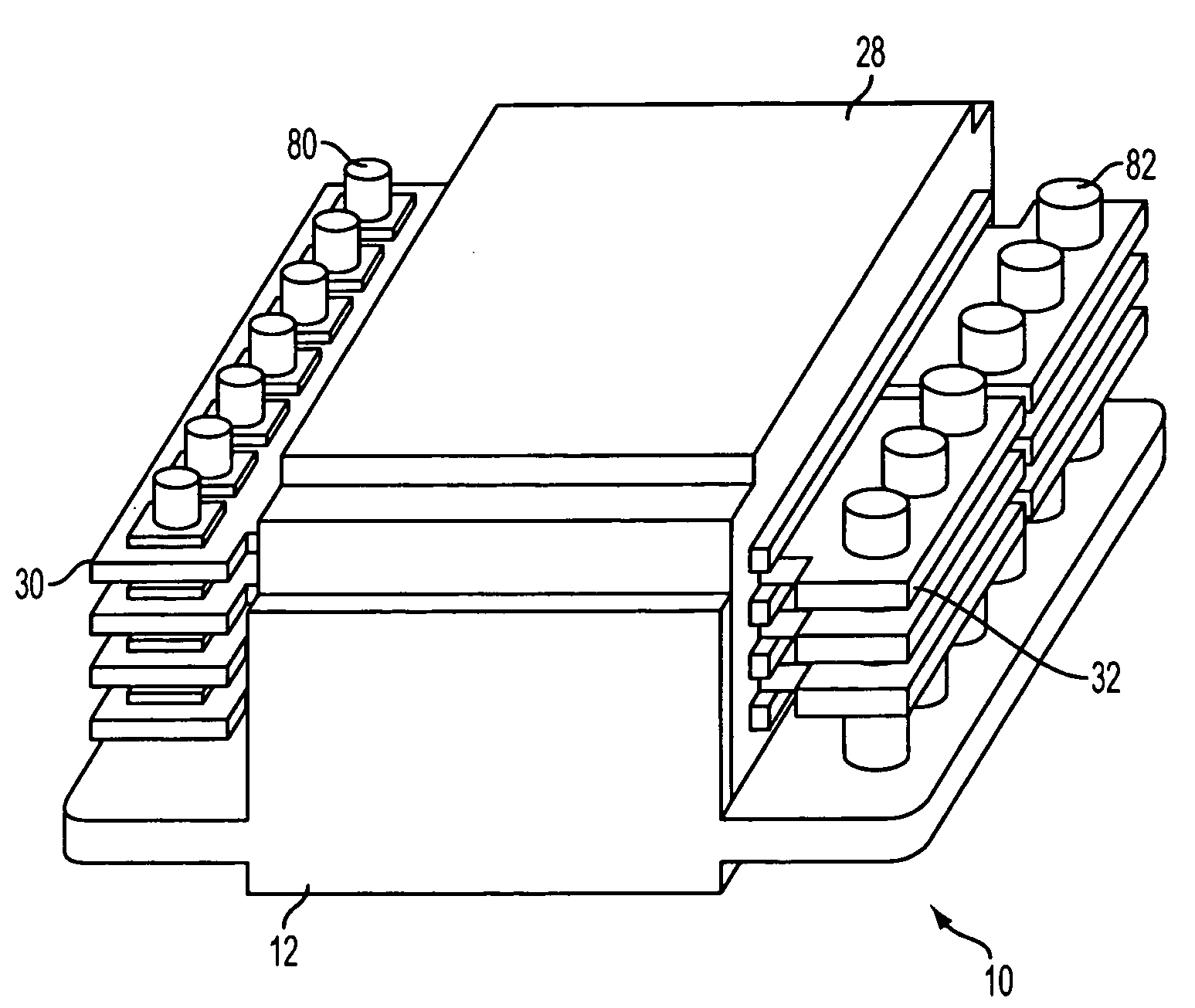

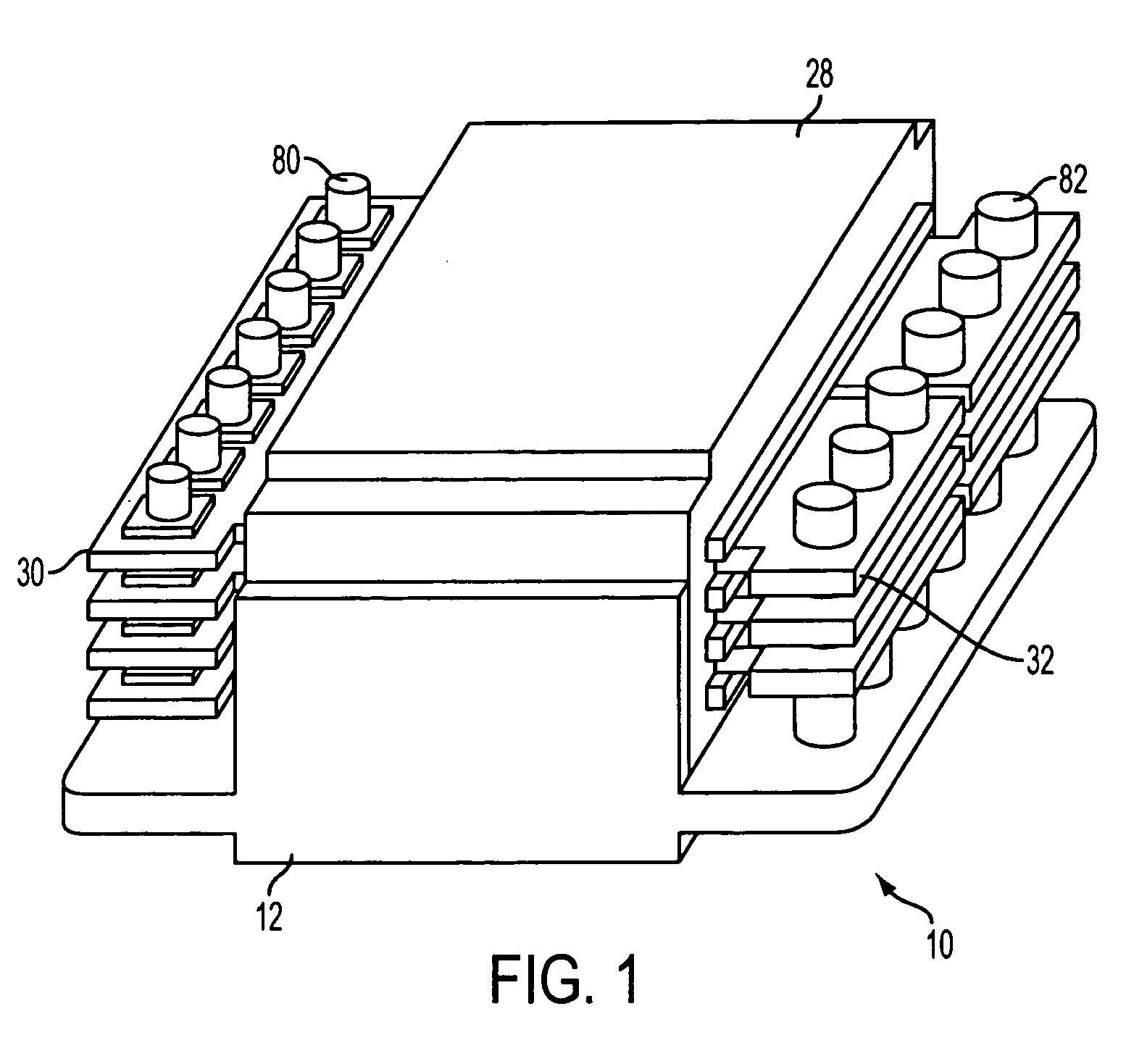

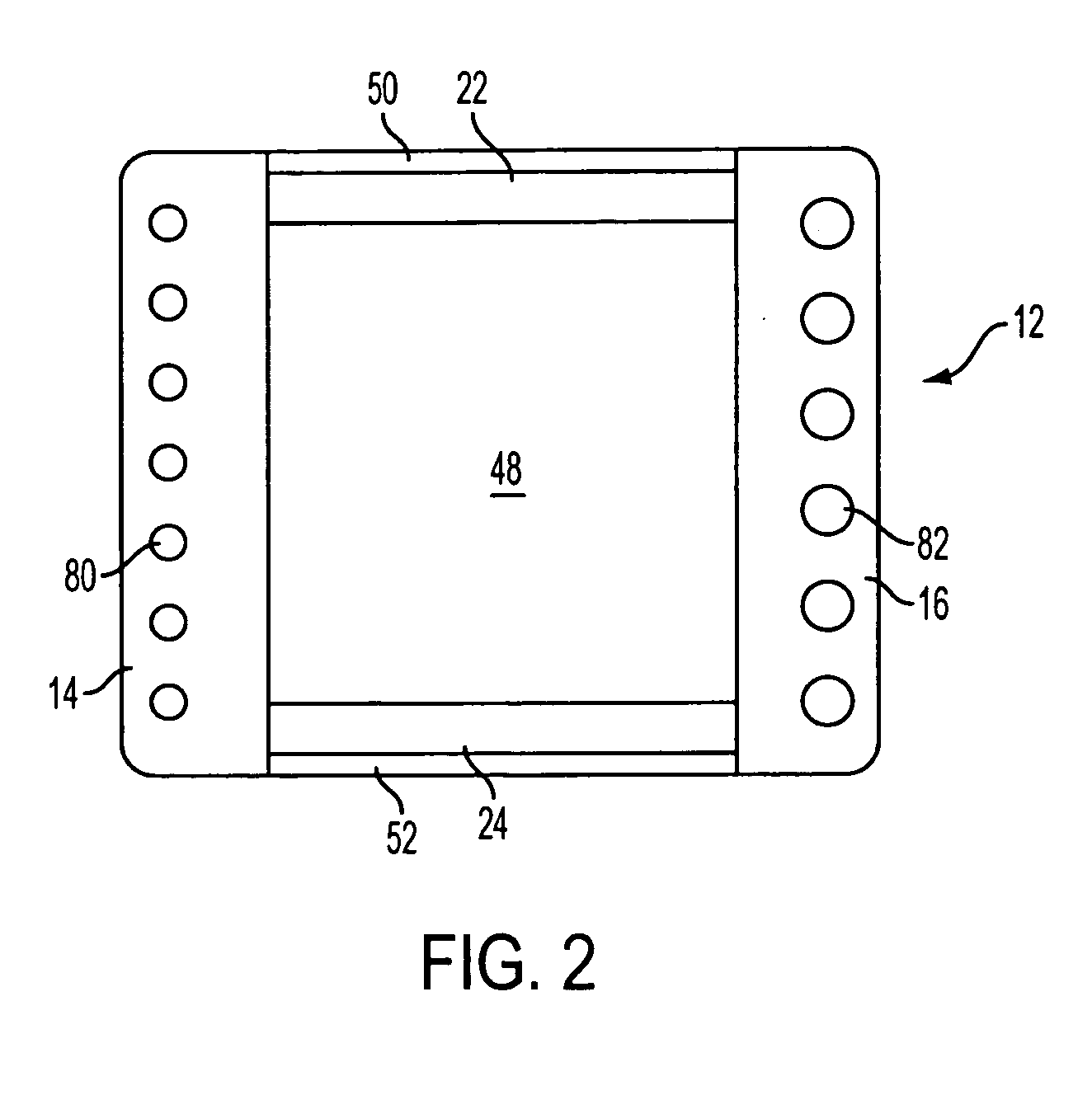

Surface mount magnetic component assembly

InactiveUS20060082431A1Facilitate assemblyLarge bond surfaceTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsEngineeringConductor Coil

Owner:STANDEX ELECTRONICS

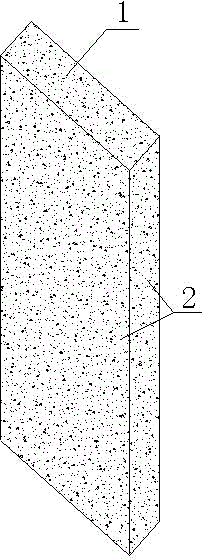

High-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick and preparation method thereof

The invention discloses a high-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick, which is prepared from the following materials by mass: 16.30% of steel fibers, 0.04% of polypropylene fibers, 18.00-19.00% of cement, 5.40-5.60% of water, 2% of fly ash, 2% of slag powder, 2.60-3.00% of silica fume, 15.50-16.50% of sand, 36.00-37.00% of gravel, and 0.36% of an efficient water reducing agent. According to the present invention, the high-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick has excellent compressive resistance, excellent tensile resistance, excellent bending resistance and excellent impact toughness compared to the clay bricks and the ordinary cement bricks, and is the novel high-performance composite material brick integrating high strength, bullet resistance, impact resistance, weight loading, bearing, wear resistance, and environment protection; and the purposes of resource saving and effective arable land and environment protection are achieved.

Owner:HUANGHE S & T COLLEGE

Composite film material for manufacturing liquid package sealing tape and preparation method thereof

InactiveCN106183294ANot easy to stretchNot easy to cutLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolyester

The invention belongs to the field of sealing materials, and in particular relates to a composite film material used for making liquid packaging sealing strips. The invention comprises a double-sided corona biaxially stretched polyester film layer, wherein one side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with a first metallocene polyethylene resin film layer, a first low-density polyethylene resin film layer, the second metallocene polyethylene resin film layer, the other side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with the third metallocene polyethylene resin film layer, the second low density polyethylene resin film layer , the fourth metallocene polyethylene resin film layer. The strip-shaped sealing strip prepared from the composite film material of the present invention is not easy to stretch and cut off during use, and has strong peel strength, good low-temperature heat-sealability, smoothness and medium resistance. Composite film materials provide domestic manufacturers with more choices about sealing strips for liquid aseptic liquid packaging.

Owner:程淋

Fabricated floor system and construction method

The invention discloses a fabricated floor system and a construction method. The fabricated floor system is composed of prefabricated ribs and prefabricated floor slabs, or a plurality of prefabricated floor system units which are composed of the prefabricated ribs and the prefabricated floor slabs and prefabricated bottom plates are directly supported on a bottom support for being assembled and connected at a construction site to form the entire floor system, and the entire floor system is supported on a main beam or a pillar after the bottom support is removed. The slabs of the floor systemunits of the fabricated floor system are completely prefabricated, all or most of the ribs and beams of the floor system units are prefabricated in a factory, and the prefabricated ribs (beams) of theadjacent floor system units are connected to the entire rib-beam floor system by adopting cast-in-place concrete laminated ribs (beams), or laminated flanges or pressure grouting during on-site construction installation. According to the fabricated floor system and the construction method, the fabricated floor system is prefabricated in bathes in the factory according to standard rib (beam) slabunits, and a lot of construction period can be saved; and the prefabricated rib (beam) slab units serve as formworks of the ribs (beams), the formworks of cast-in-place laminated ribs (beams) or the laminated flanges are omitted, so that construction is convenient and quick.

Owner:贵州皆盈科技开发有限公司

Surface mount magnetic component assembly

InactiveUS7129809B2Easy to assembleAssisting in alignment during assemblyTransformers/reacts mounting/support/suspensionTransformers/inductances coils/windings/connectionsSurface mountingConductor Coil

A planar magnetic device comprising a molded header and a planar core assembly, and a method of making a planar magnetic device. The molded header has first, second, third, and fourth sides and an aperture in the center. The first side has a plurality of terminals positioned through it. The third and fourth sides have upper surfaces that are lower than the upper surfaces of the first side. The planar core assembly comprises planar windings and a core. One side of the planar winding has a plurality of terminals with through-holes so that the primary terminals of the header are positioned through the through-holes. The core surrounds at least a portion of the planar windings. The core is shaped so that a first portion of the core is positioned in the aperture, a second portion of the core is positioned on the upper surface of the third side, and a third portion of the core is positioned on the upper surface of the fourth side.

Owner:STANDEX ELECTRONICS

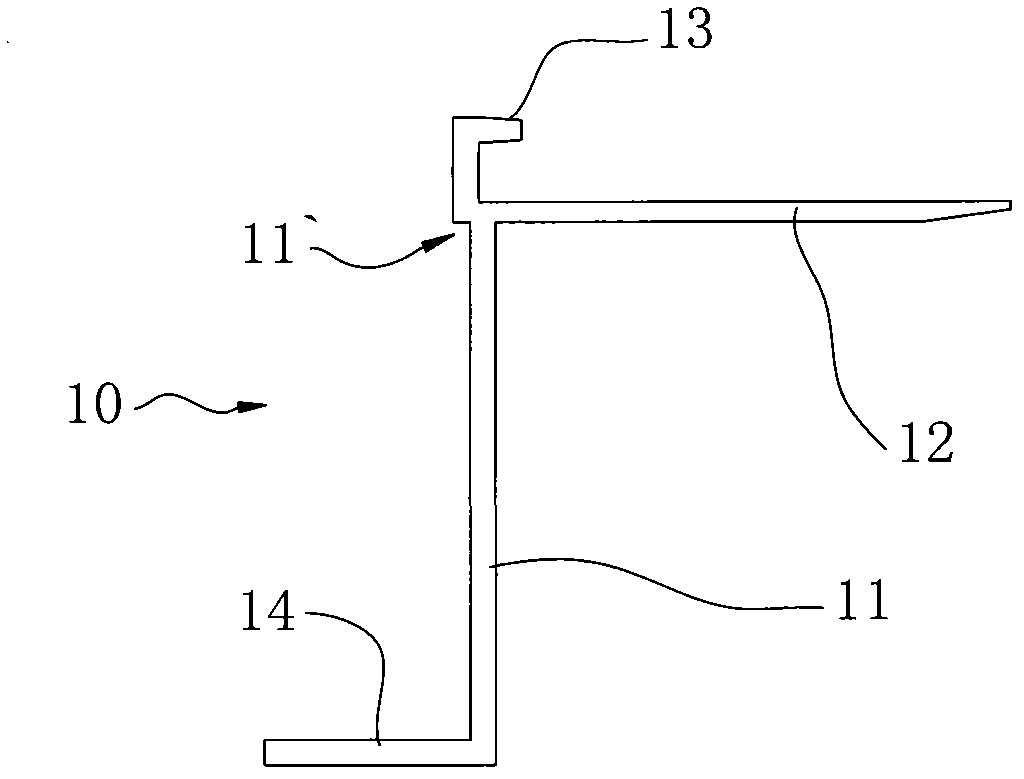

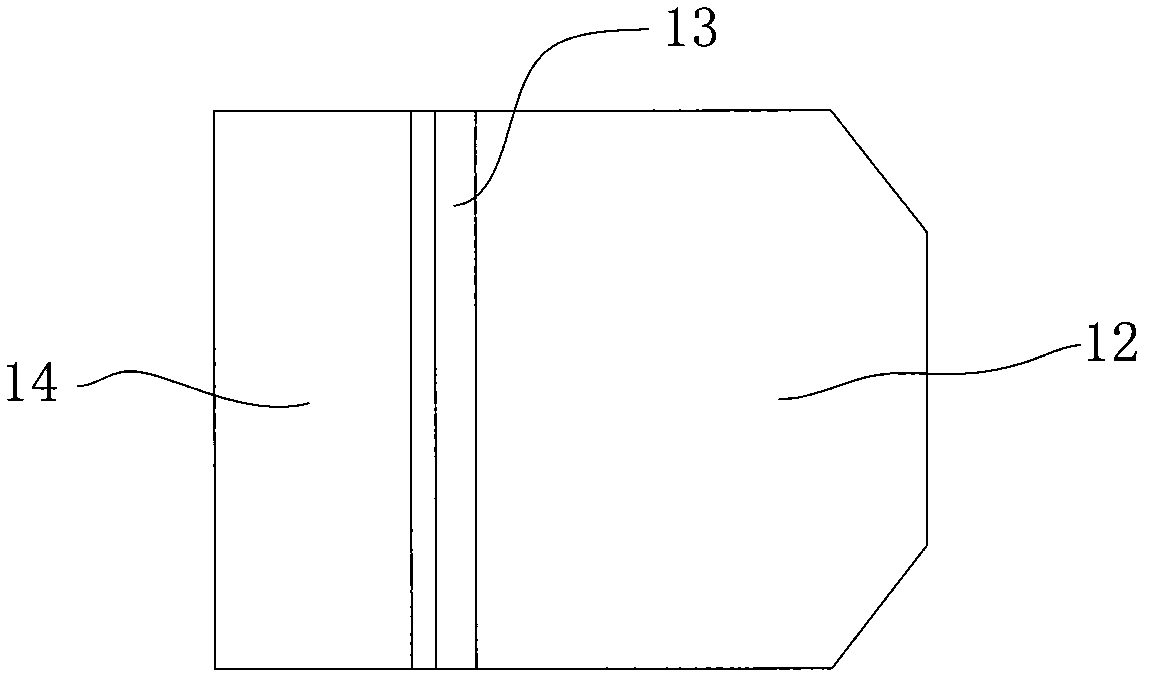

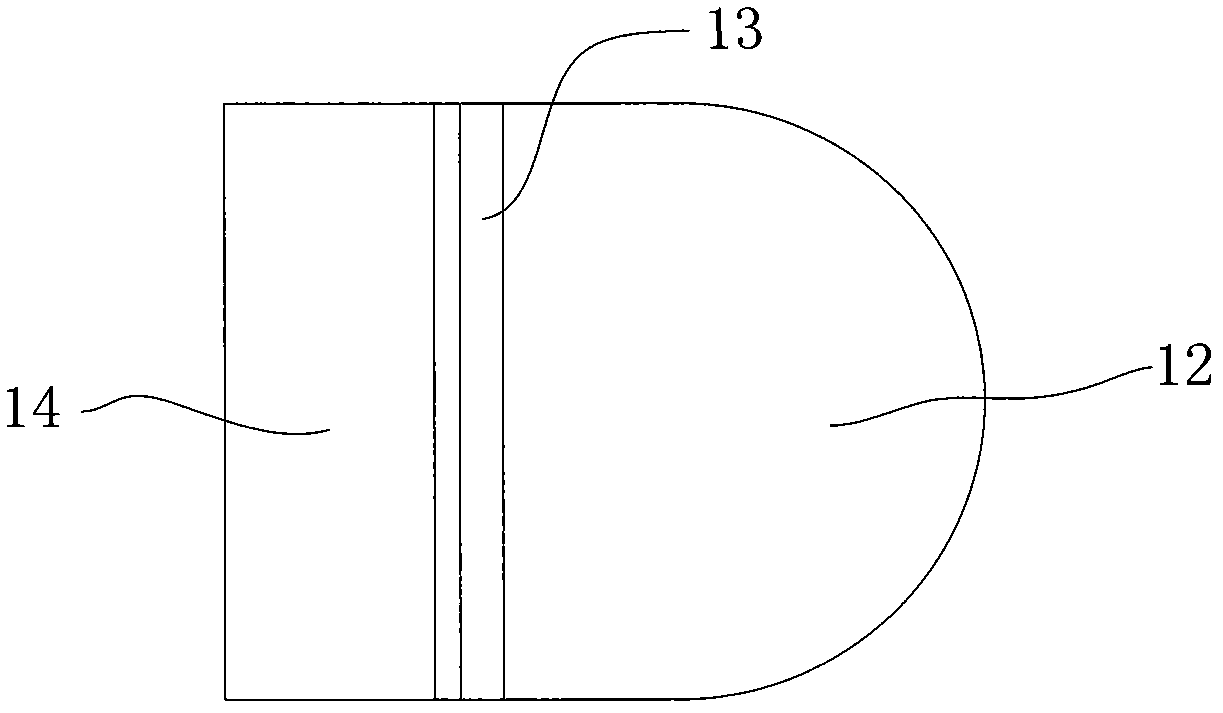

Integrated board fastener

The invention relates to a fastener, in particular to a fastener special for connecting an insulation board with a wall. The fastener comprises a board body vertical to the wall surface, a first board body inserted into the insulation board, and a connection board body for connecting the wall, wherein the first board body and the connection board body are positioned on opposite board surfaces of the board body and are parallel to the wall surface respectively. The fastener is characterized in that: the board surface of the board body is provided with a concave-convex part; because the board surface of the board body is provided with the concave-convex part, the bonding surface of the board body and sealant is larger and bonding is firmer. Therefore, the board body and the sealant are prevented from being separated and cracked, rainwater is prevented from permeating, thermal insulation and moisture-proof effects of the insulation board are improved and the service life of the insulation board is prolonged.

Owner:安徽根源光大高深新材料有限公司

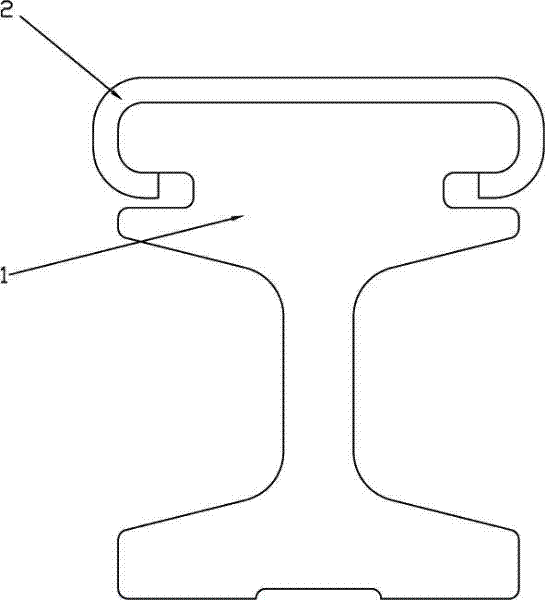

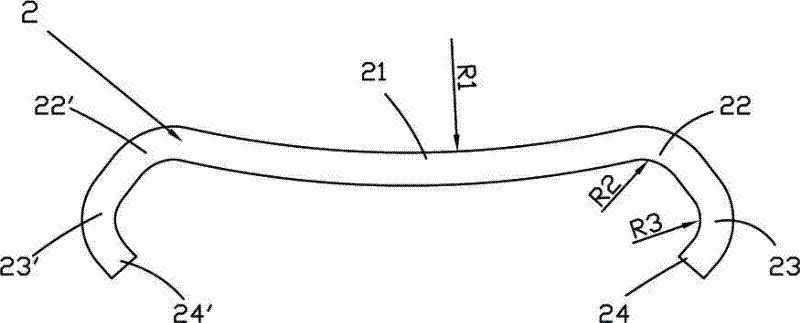

Method for manufacturing steel-aluminum composite conductor rail

The invention discloses a method for manufacturing a steel-aluminum composite conductor rail, comprising the following steps of: a) preparing an aluminum rail: preparing an I-shaped aluminum rail by a mould through hot extrusion molding, wherein the two side surfaces of the upper end of the aluminum rail are provided with grooves; b) prefabricating a C-shaped stainless steel strip: cutting a stainless steel coil into stripy stainless steel strips, and cold bending and rolling by a cold bending unit to form a stainless steel strip with a C-shaped section, wherein the formed stainless steel strip comprises a base part, a first bending part, a second bending part and a clip part, the first bending part is formed by extending from the two sides of the base part and bending downwards, the second bending part is formed by extending from the first bending part and bending inwards, and the clip part is formed by extending from the second bending part; and c), compounding the C-shaped stainless steel strip and the aluminum rail, wherein the clip parts at two ends of the C-shaped stainless steel strip are embedded in the grooves on the two sides of the upper end of the aluminum rail, and the C-shaped stainless steel strip is completely attached to the upper part of the aluminum rail. According to the method in the invention, the stainless steel strip and the aluminum rail are closely combined, the combined surface is large, the transition resistance is small, deformation is not liable to occur after forming, a local heating mode is adopted during rolling compounding to facilitate forming, machining is not needed after rolling forming, and the production efficiency is greatly improved.

Owner:SHANGHAI SANY PRECISION MACHINERY

A 3D printing-assisted molding method for fiber-reinforced composite materials

ActiveCN107187020BImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresInvestment materialFiber-reinforced composite

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

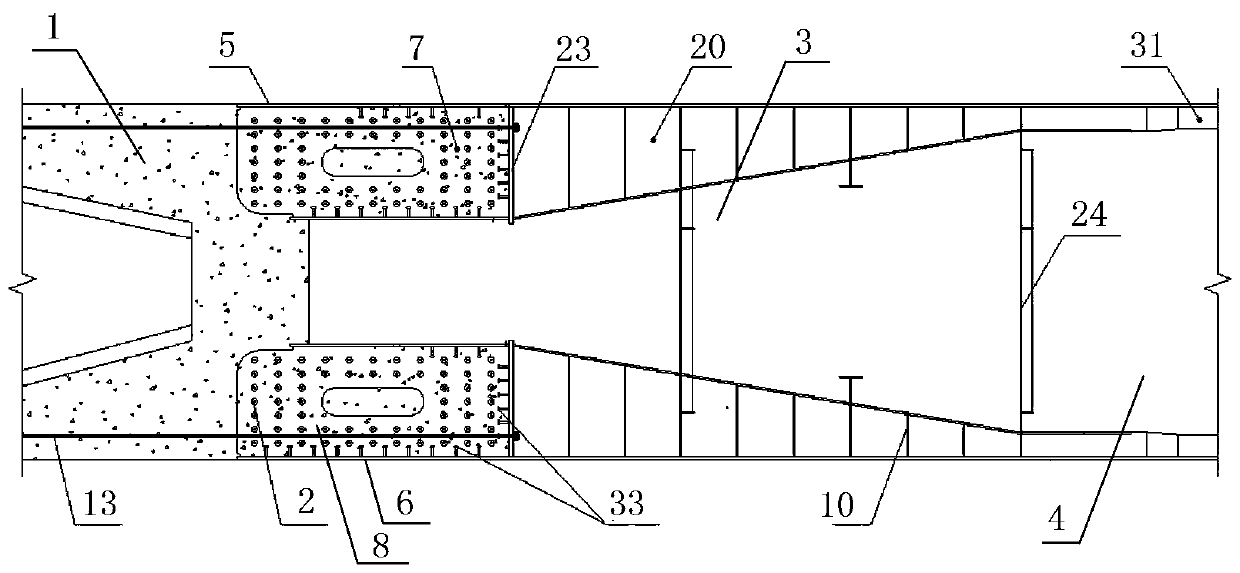

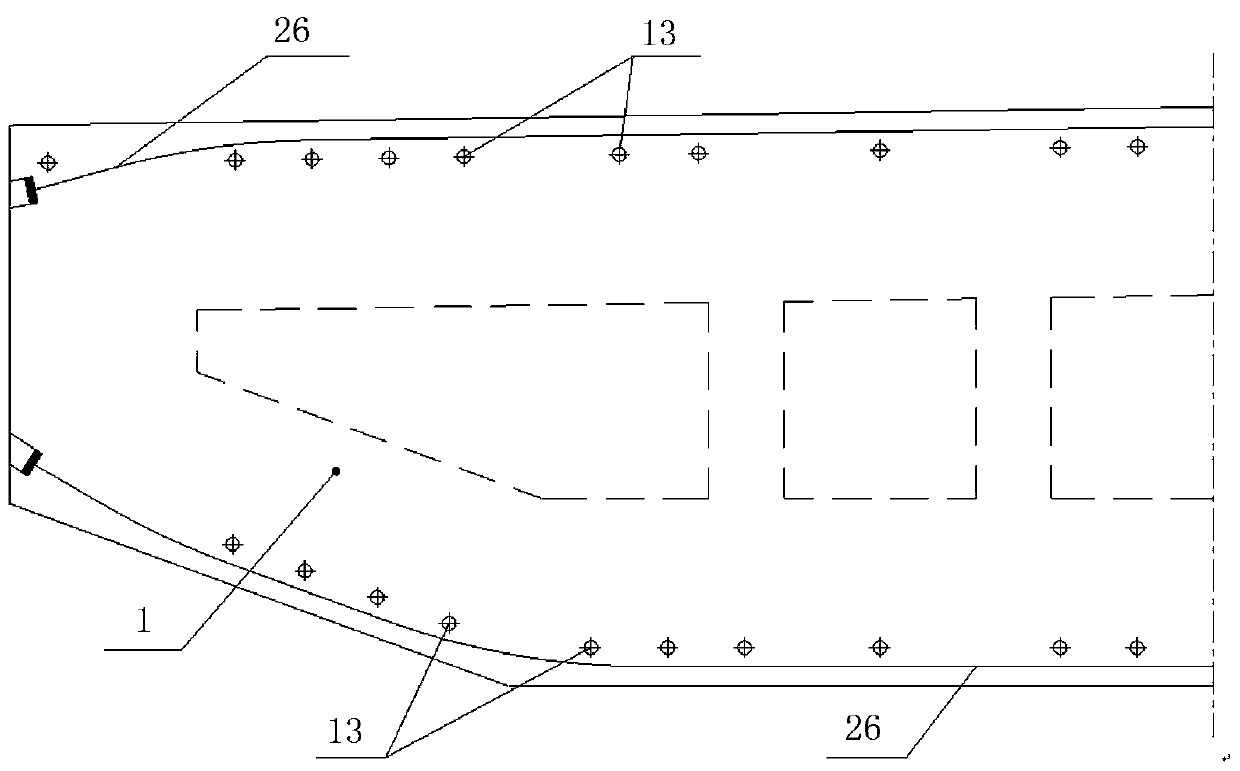

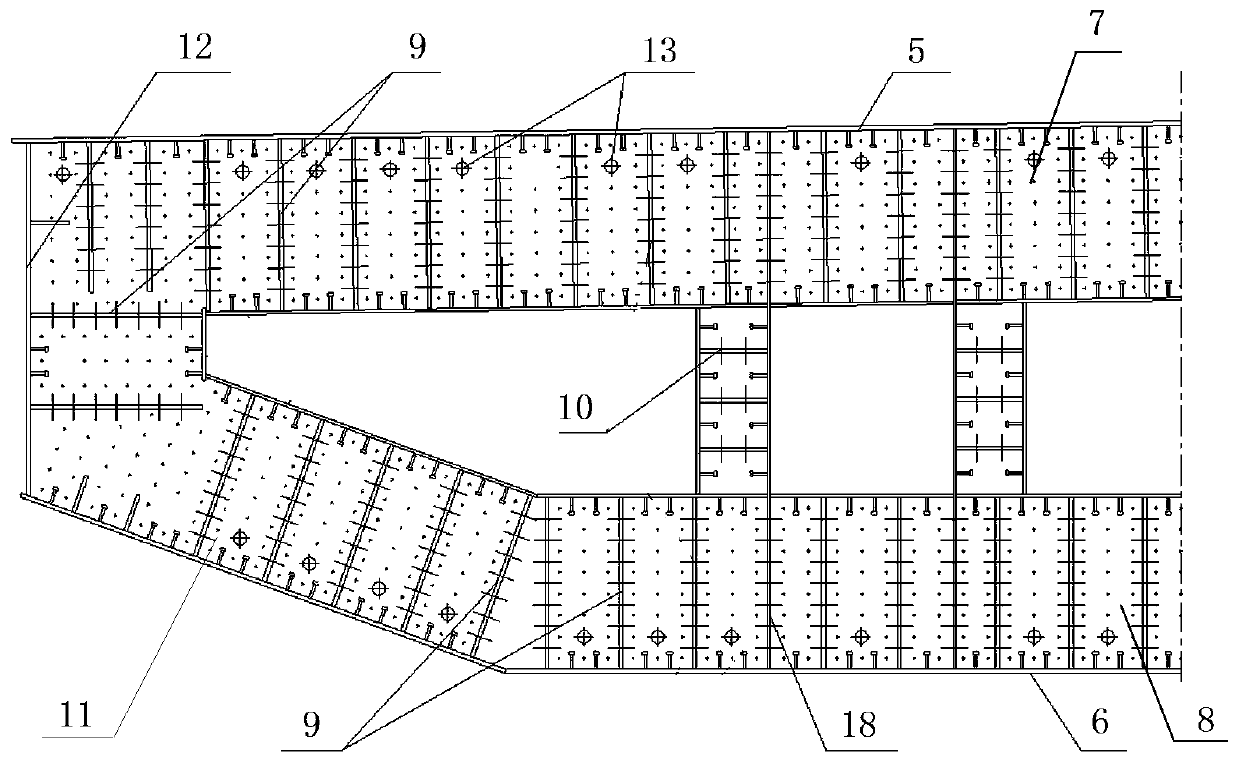

Steel-concrete combination segment structure equipped with cells and used for long-span self-anchored suspension bridge

PendingCN110835884AImprove mechanical performanceAdapt to structural needsSuspension bridgeBridge structural detailsStress concentrationConcrete beams

The invention discloses a steel-concrete combination segment structure equipped with cells and used for a long-span self-anchored suspension bridge. A variable-height stiffening segment is provided with a bottom plate. The steel-concrete combination segment structure sequentially comprises a concrete cross beam segment, a steel cell segment, a steel beam stiffening variable-height segment and a steel beam stiffening constant-height segment. The steel-concrete combination segment structure has the beneficial effects of reasonable design, simple structure, and convenient and efficient construction. The steel-concrete combination segment structure also has the beneficial effects of optimizing the stress performance of a steel-concrete combination segment, adapting to structural needs of the long-span self-anchored suspension bridge, enlarging a combination surface of a combination part by virtue of the structure with the cells, forming multi-directional restraints on filled concrete, enhancing the combination of a steel beam and a concrete beam, improving the stress condition on the concrete at the combination part, bringing the functions of connectors into full play by virtue of theconstruction mode of rear pressure-bearing plates, enabling the force transmission to be clear and definite, achieving relatively small stress concentration at the combination surface, enabling the concrete of the cells and a main beam to form a continuous structure, facilitating concrete pouring construction, and enabling the concrete at the roots of the connectors to be not prone to disintegration.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Electric-conducting carbon felt and lead tab connection method

ActiveCN106695193AThe process method is simpleEasy to implementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention discloses an electric-conducting carbon felt and lead tab connection method. The connection method includes the steps of clipping electric-conducting carbon felt and flaky lead tabs according to sizes, and flatly overlaying the flaky lead tabs on one or two sides of a frame of the electric-conducting carbon felt prior to spot welding. The electric-conducting carbon felt and lead tab connection method has the advantages that connection between the lead tabs and the electric-conducting carbon felt is achieved through a spot welding technology, the connection technology is reasonable in design and easy to implement, most importantly, resistance heat formed by spot welding enables the lead tabs to melt locally, liquid lead alloy at the position permeates into seams of the electric-conducting carbon felt, and a mutual jogged structure is formed after cooling; a tightly connected joint is formed through staggered jogging and is nearly doubled in connection strength as compared with that of a product in the same specification in the prior art, and accordingly electric conductivity is also improved remarkably.

Owner:SHUANGDENG GRP

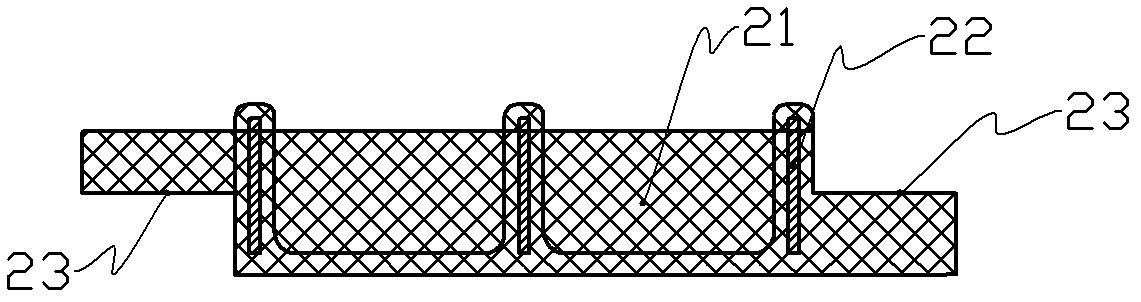

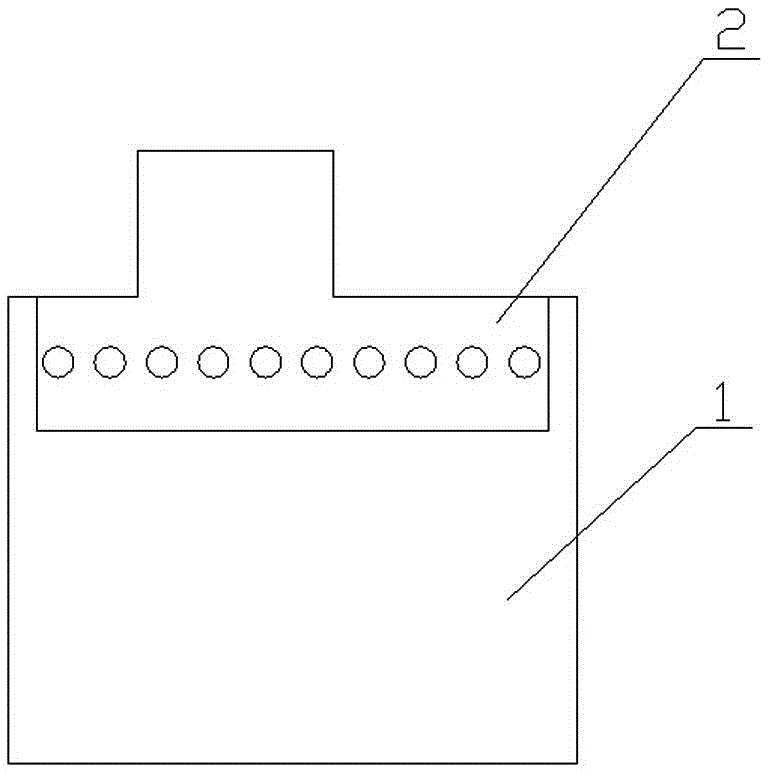

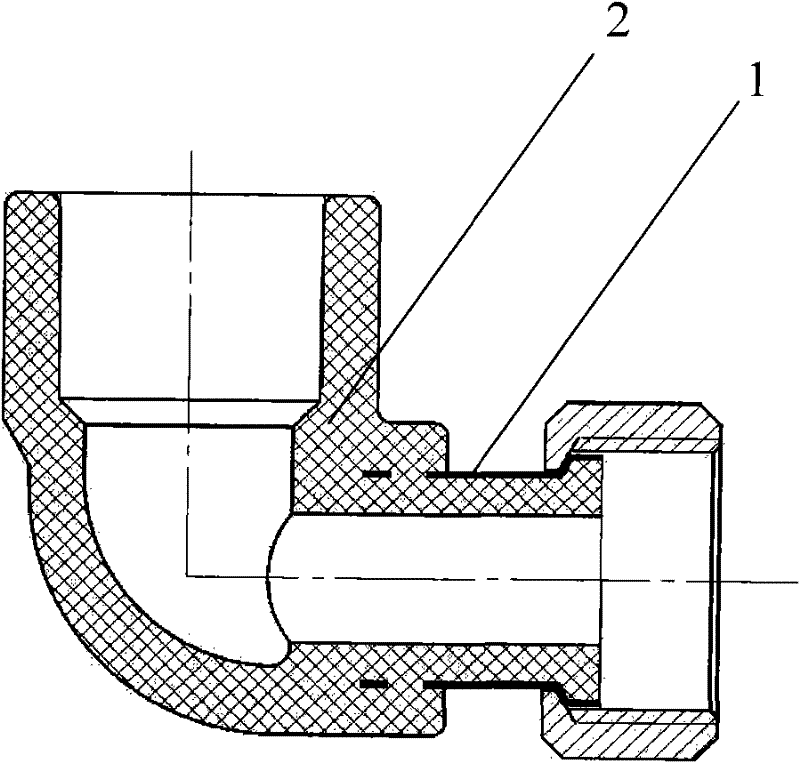

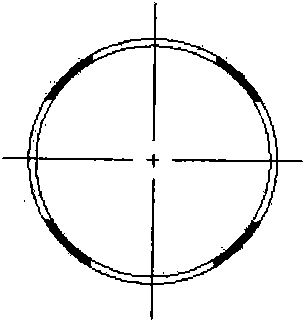

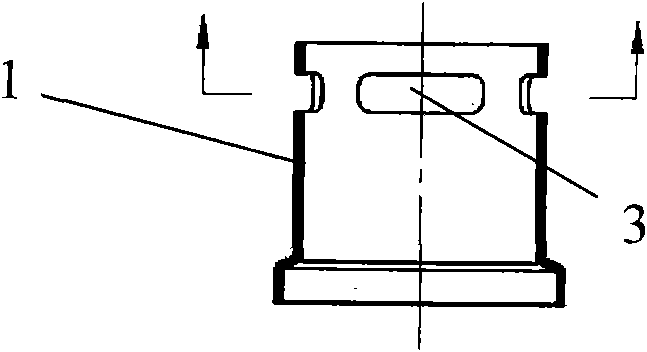

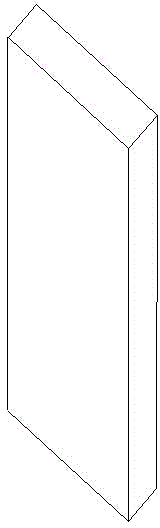

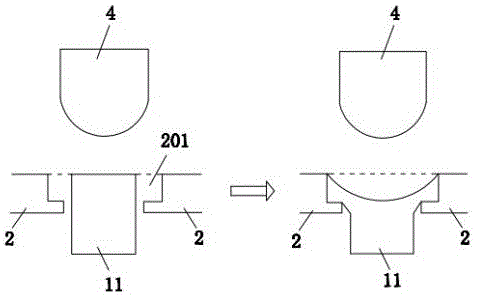

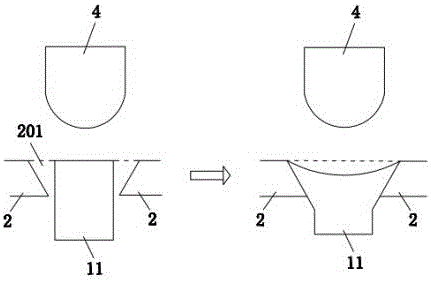

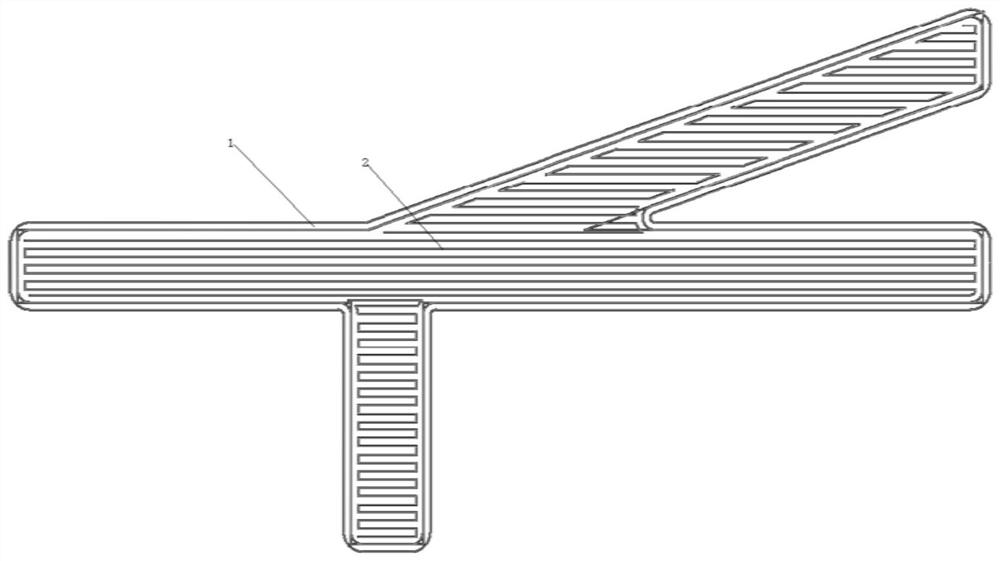

A reinforced connection structure between metal inserts and plastic parts

InactiveCN102269301ALarge joint surfacePrevent disengagementNon-disconnectible pipe-jointsEngineeringMechanical engineering

A reinforced connection structure between a metal insert and a plastic part. It is composed of a plastic part and a metal insert. The inner section of the metal insert is cylindrical and embedded in the plastic part. At least one number of protrusions, or pits, or through holes, or thorns are provided in the circumferential direction, and any one of the protrusions, or pits, or through holes, or thorns is surrounded or filled by plastic parts. When the plastic part is injection molded, the plastic can pass through the hole or be filled into the pit, thereby increasing the joint surface between the metal insert and the plastic part, and the plastic part is located in the direction of the metal insert, effectively preventing the metal The insert is disengaged from the plastic part.

Owner:上海龙胜实业有限公司

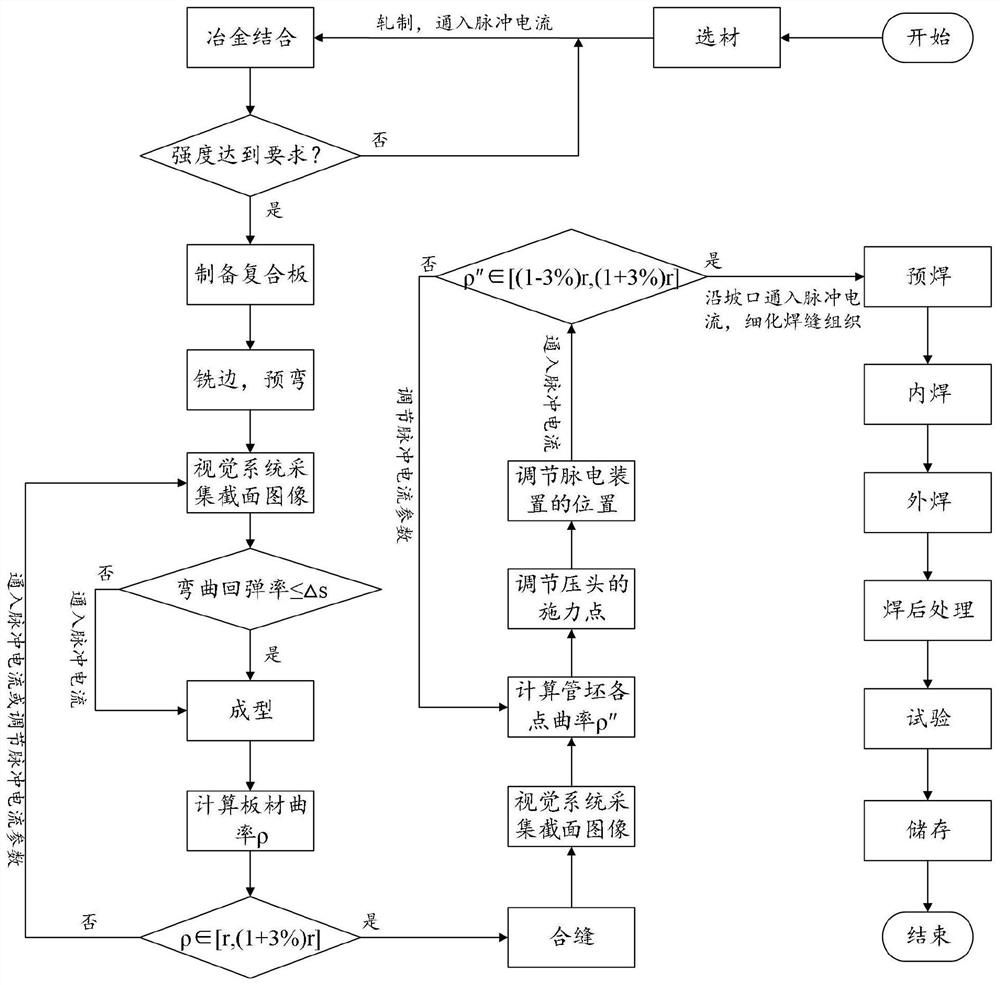

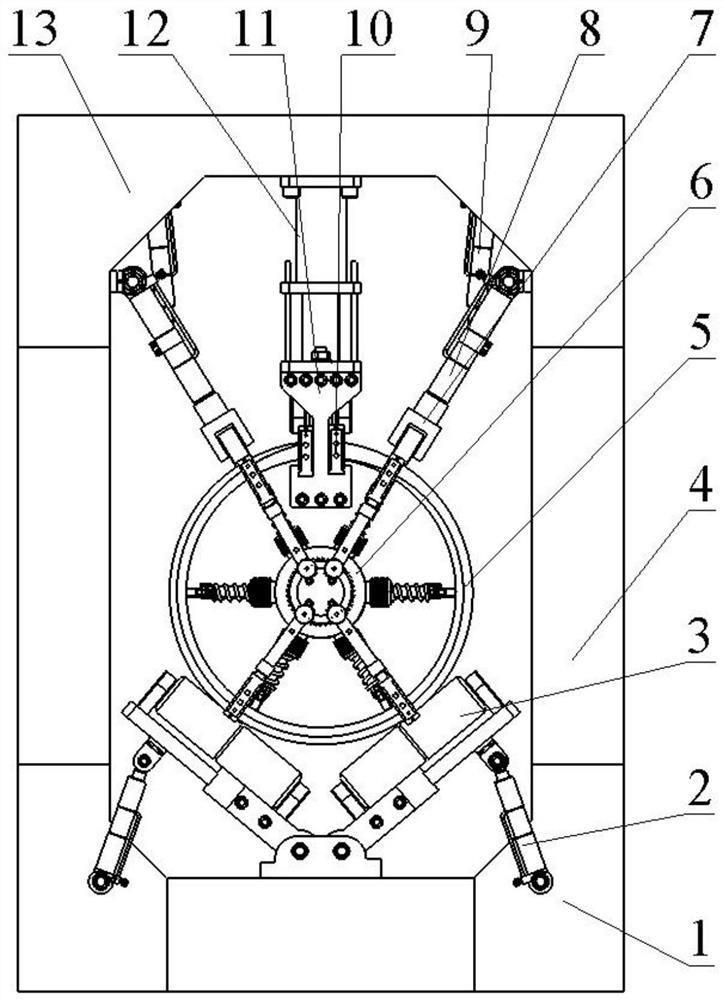

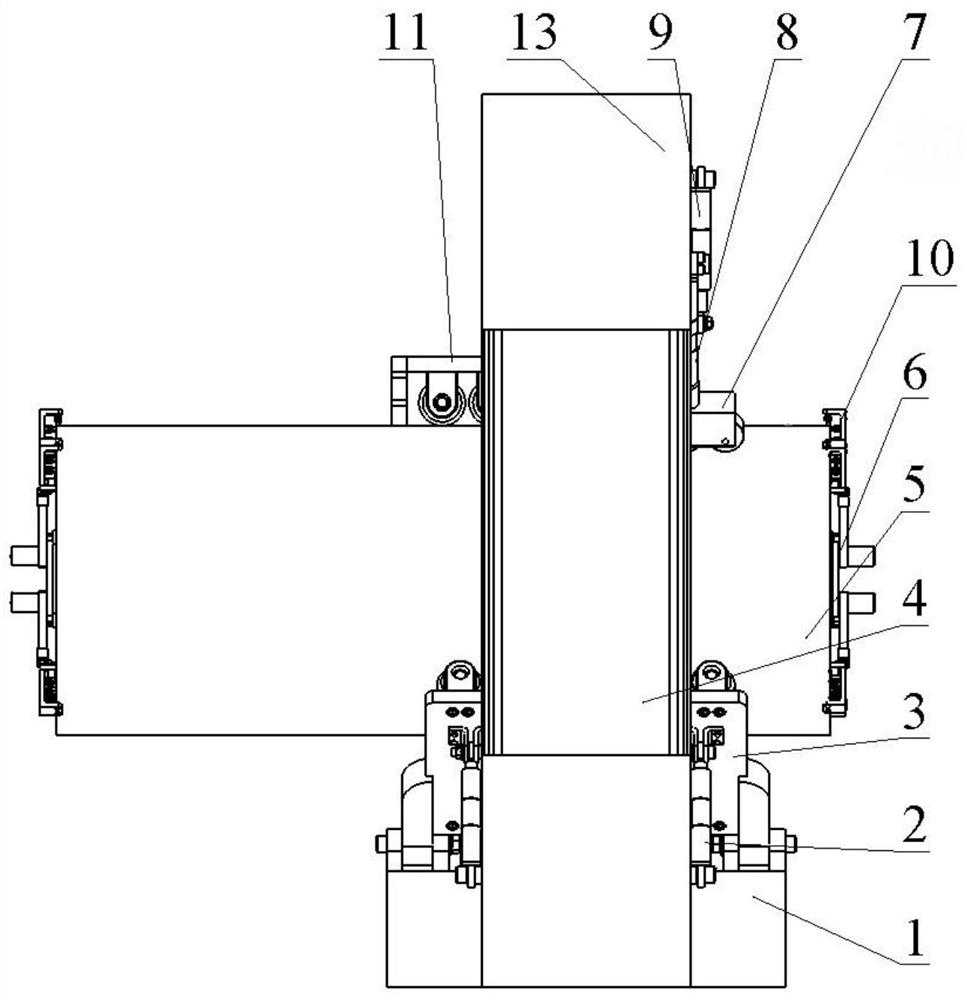

Manufacturing method of composite oil pipe and joint closing device

The invention discloses a manufacturing method of a composite oil pipe and a joint closing device. The joint closing device comprises a pulse current applying device controlled by a machine vision system. In the joint closing process, the machine vision system can track and judge the position with the maximum pipe blank deformation resistance in real time, so that the position of a pulse current applying electrode is adjusted, pulse current is introduced into the position with the maximum pipe blank deformation resistance, intelligent control is achieved, the deformation resistance is reduced,cracks generated by stress concentration are reduced, the extrusion force of a force application mechanism of the joint closing device is reduced, and the joint closing effect is better guaranteed. The composite oil pipe adopts the manufacturing method of metallurgical composite steel plates, molding and welding, is high in bonding strength and excellent in comprehensive performance, can adapt tohigh-temperature, high-pressure and high-corrosion severe environments, and reduces the exploitation cost of an oil and gas field containing acid gas.

Owner:广东万慕仪器有限公司

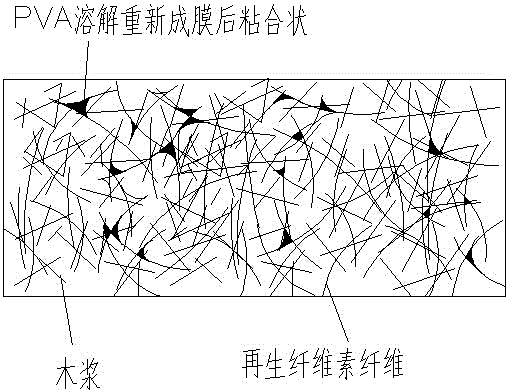

Hot-melt enhanced type flushable full-degradable non-woven material and manufacturing method thereof

ActiveCN104790122AMeet the requirements for entanglement strengthLarge joint surfaceNon-woven fabricsRegenerating fibersHot melt

The invention relates to a hot-melt enhanced type flushable full-degradable non-woven material and a manufacturing method thereof. The hot-melt enhanced type flushable full-degradable non-woven material can achieve flushable and full-degradable effects with the percentage being 100% and has good strength. PVA hot-melt fiber accounts for 1%-5%, and end values are included; regenerated fiber accounts for 1%-50%, and end values are included; wood pulp accounts for 45%-98%, and end values are included. The hot-melt enhanced type flushable full-degradable non-woven material has the advantages that the hot-melt enhanced type flushable full-degradable non-woven material can satisfy the requirement for entanglement intensity of regenerated non-woven materials and can be flushed quickly under the action of water impact; after hot-melt PVA is added, 100% biodegradation can be achieved while product strength is enhanced by using bonding fiber; due to the design that the surface of regenerated cellulose fiber is napped, the junction surface of the surface of the regenerated non-woven material is increased, the purposes of solving the problem of small entanglement force and being high in entanglement intensity are achieved, and the hot-melt enhanced type flushable full-degradable non-woven material can be flushed quickly under the action of water impact.

Owner:HANGZHOU NBOND NONWOVENS

Joining method of amorphous alloy electronic productshell and middle plate

InactiveCN106659008AIncrease the joint surfaceGood bonding strengthElectrical apparatus casings/cabinets/drawersSizingBonding strength

The inventionrelates to the technical field of the production of an amorphous alloy product, and in particular relates to a joining method of an amorphous alloy electronic product shell and a middle plate. The method comprises the following steps: step one, pre-bonding; step two, heating; step three, pressing according to a molten-state gravity effect; and step four, cooling and sizing. By use of the joining method disclosed by the invention, a convex column structure of the amorphous alloy electronic product shell is heated to Tg and more, wherein the Tg is the glass transformationtemperature, and the heating process is controlled according to a TTT graph so as to prevent convex column structure of the amorphous alloy electronic product shell from generating the crystallization. Furthermore, a chamfer structure or a circular concave structure region can be filled with amorphous alloy in the bonding so as to form an inverted buckling structure, thereby enhancing the bonding strength performance by increasing the bonding surface in the bonding. The bonding strength of theamorphous alloy electronic product shell and the middle plate is good, and the method has the advantages of being mass in production, high in production efficiency and low in production cost.

Owner:DONGGUAN PROMETAL TECH CO LTD

Production device and method of wave flat continuous rolling metal composite thin plate strip

ActiveCN105057386BHigh bonding strengthUniform deformationMetal rolling arrangementsMetal sheetContinuous annealing

The invention discloses a device and method for producing metal composite sheet strips through corrugated-flat continuous rolling. The method is characterized in that a base material steel coil and a composite material steel coil are uncoiled through uncoilers, cleaned through a cleaning device to remove oxide layers and then rolled into a composite sheet strip through a corrugated-flat cold continuous rolling unit, and the composite sheet strip is annealed through a continuous annealing device and then coiled to obtain a composite sheet coil. The corrugated-flat cold continuous rolling unit is composed of a double-roller corrugated rolling mill and a four-roller flat rolling unit. When double-layer sheet strips need to be produced, a roller system of the double-roller corrugated rolling mill comprises a corrugated roller and a flat roller, and the corrugated roller always makes contact with a large-deformation-resistance metal layer; when three-layer sheets need to be produced, the roller system of the double-roller corrugated rolling mill comprises two corrugated rollers, and the two corrugated rollers make contact with a large-deformation-resistance composite layer. In corrugation section dimensions, the corrugation depth is s, and the corrugation width is t; the thickness of the large-deformation-resistance metal layer is h0, i.e., s / h0=(0.1-10), and t=(10-20)s. By using the corrugated-flat cold continuous rolling unit, the problem that composite sheet strips buckle, crack and have large residual stress due to the difference of deformation resistances of dissimilar metals is solved, and the composite ratio is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

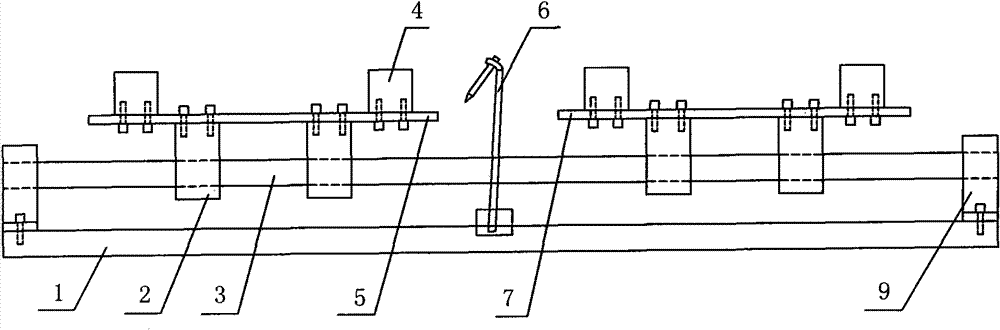

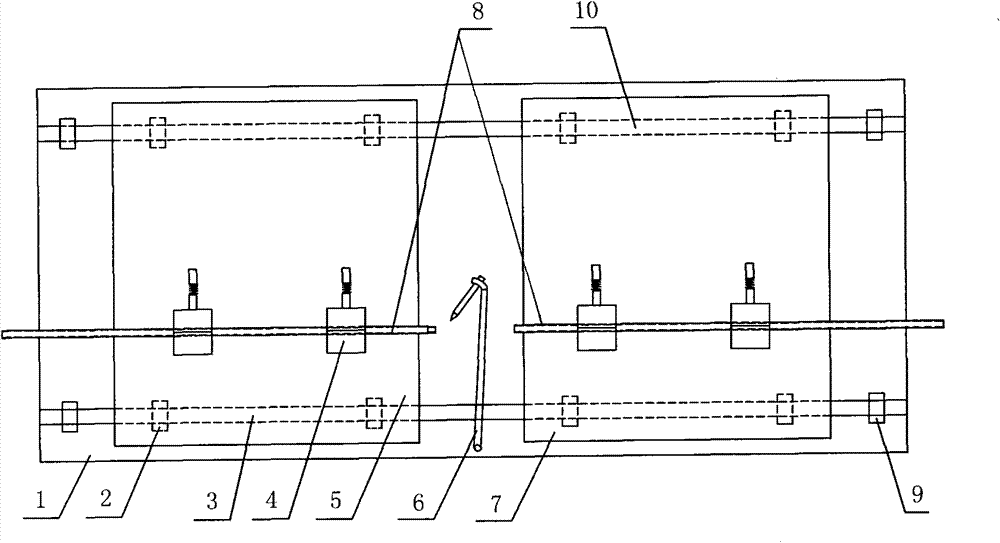

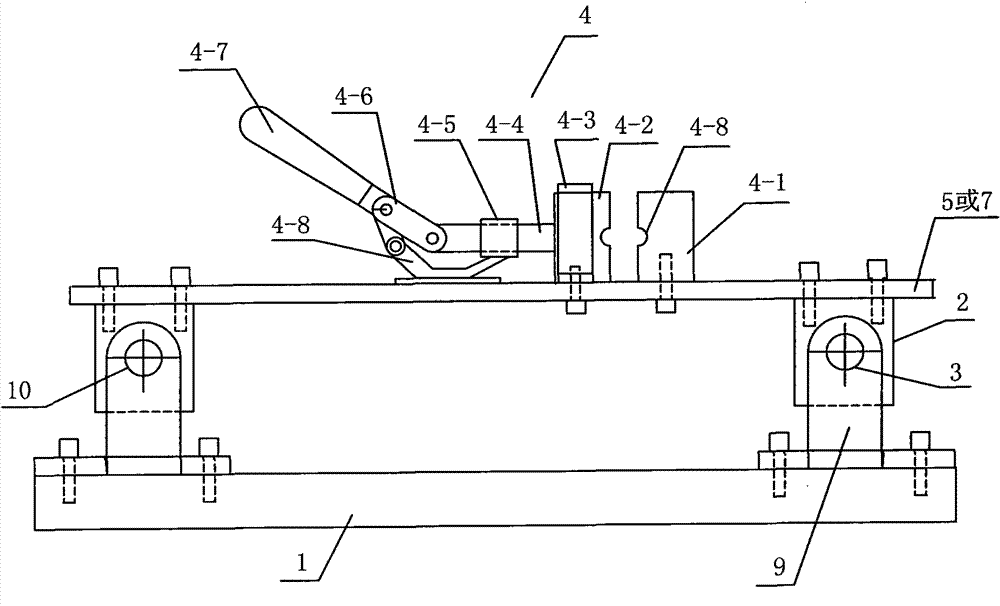

Following device of copper tube inner conductors for radio frequency coaxial cable and following method thereof

ActiveCN101954519BEasy to fixHigh tensile strengthGas flame welding apparatusElectrical conductorCoaxial cable

The invention relates to a following device of copper tube inner conductors for a radio frequency coaxial cable and a following method thereof, in particular to the device for realizing continuous production of the smooth copper tube inner conductors in production of the radio frequency coaxial cable and the following method thereof. The conductor following device comprises copper tube fixtures, a sliding plate unit, a guide rail, a support and a welding torch, wherein, the sliding plate unit is equipped with a sliding plate 1 and a sliding plate 2 which are provided with two groups of the copper tube fixtures respectively; each copper tube fixture comprises a static fixture, a movable fixture, a push rod, a push rod support, a connection rod and a handle; and the welding torch is arranged on the support. The following method comprises the following steps: (1) polishing end surfaces of the two copper tube inner conductors needing welding with a file; (2) clamping the two polished copper tube inner conductors needing welding on the copper tube fixtures respectively; (3) pushing the sliding plates so that end parts of the two copper tube inner conductors get close to each other, putting lined copper tubes on the end parts of the two copper tube inner conductors, and indirectly or directly placing brazing filler metal; and (4) welding with the welding torch by a flame heating method to finally obtain soldered joints of the copper tube inner conductors after condensation.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

Manufacturing forming method of electric arc fuse additive

InactiveCN111644729APrevent collapseImprove Surface Forming QualityAdditive manufacturing apparatusWelding accessoriesManufactured formEngineering

The invention discloses a manufacturing forming method of an electric arc fuse additive. The method comprises the following steps: separating a part to be formed into an inner layer filling area and an outer layer outline along a slice layer, so that a forming filling path of an inner ring and an outer ring is formed, then depositing the inner layer filling area or the outer layer outline according to the inner layer filling area and the outer layer outline of the slice layer, and after the inner layer filling area or outer layer outline deposition is completed, finally, carrying out outer layer outline deposition or inner layer filling area deposition. The forming filling path and interlayer staggered deposition are combined, in the deposition process of each layer, the outer layer outline is deposited firstly, then the inner structure is deposited, or the inner area is deposited firstly, then the outer outline is deposited, thus collapse caused by outflow of metal molten drops at theboundary can be avoided, the surface forming quality is improved, meanwhile, the inner-layer deposition and outer-layer deposition are adopted, so that two-layer deposition cooling is facilitated, and the deposition efficiency is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

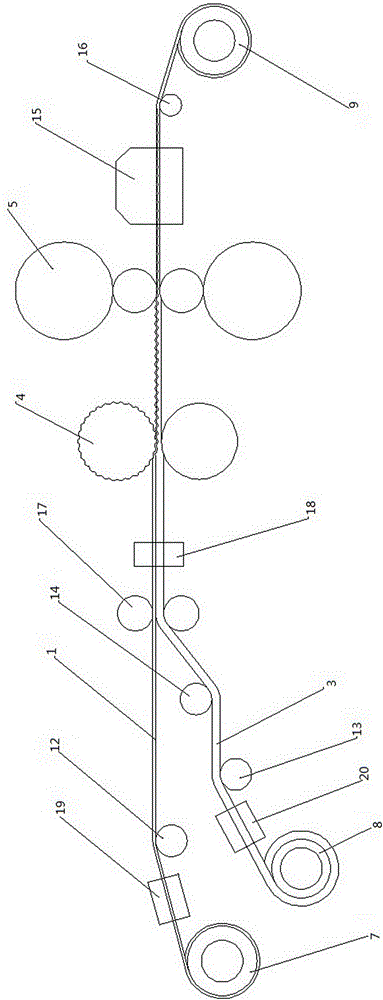

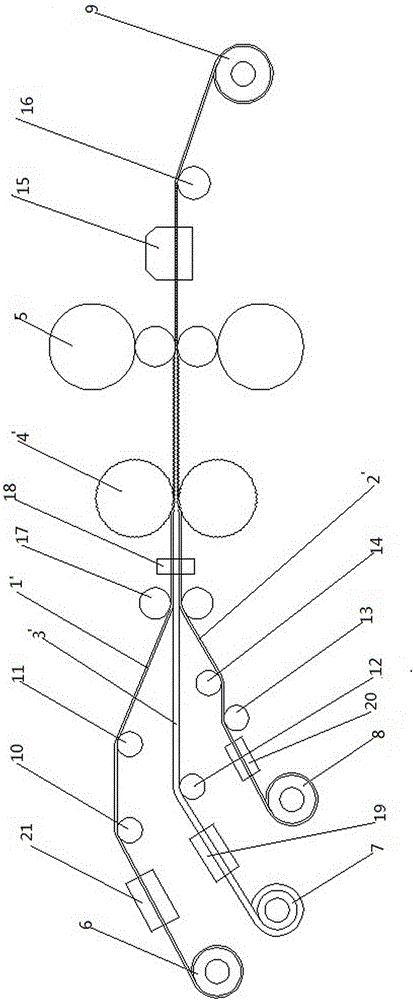

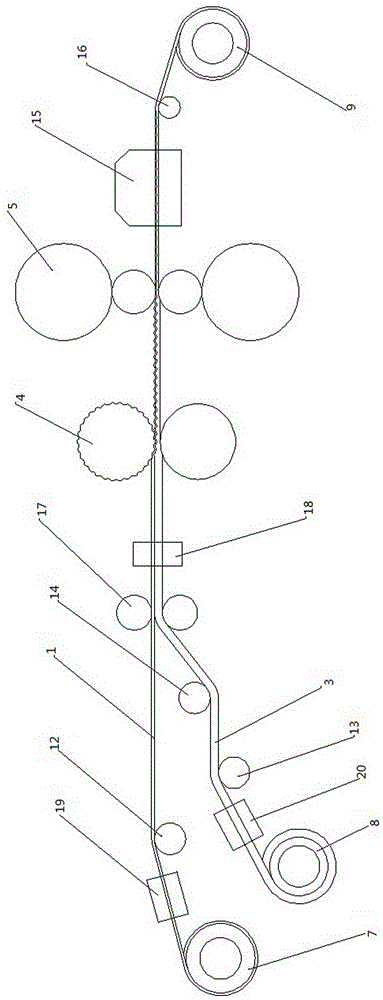

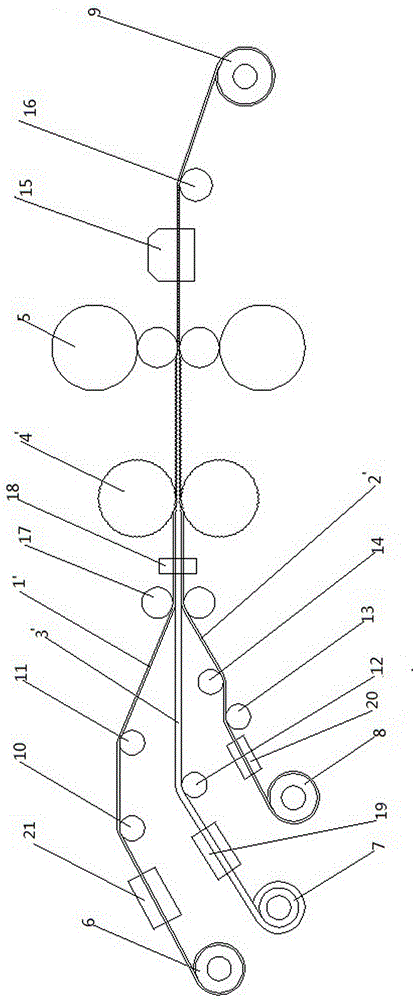

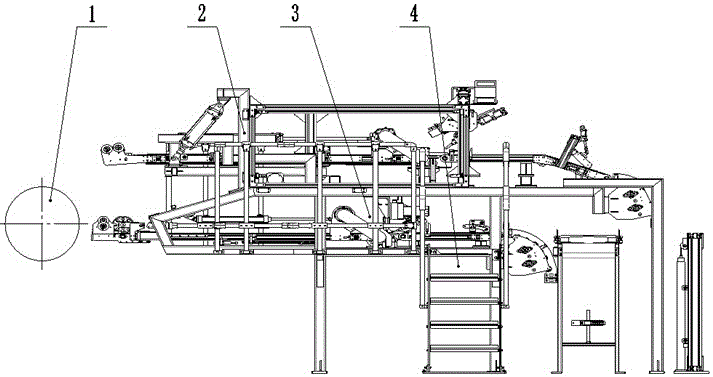

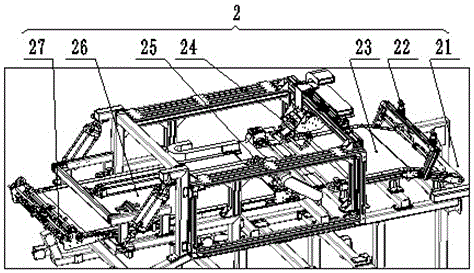

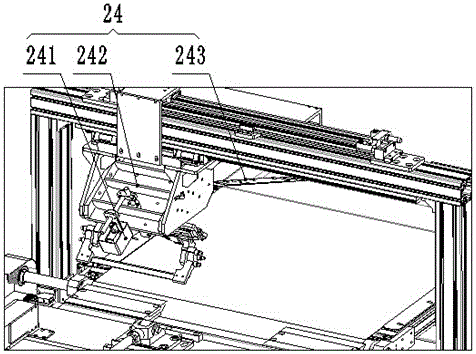

Primary-drum feeding rack of tire building machine and implementation method thereof

The invention discloses a primary-drum feeding rack of a tire building machine. The primary-drum feeding rack comprises a primary drum, a supporting framework, an upper bead filler conveying device and a tire-sidewall conveying device, wherein the upper bead filler conveying device and the tire-sidewall conveying device are mounted in the supporting framework in a laminating manner and are arranged right behind the primary drum along a longitudinal direction. The upper bead filler conveying device located at an upper layer can be pushed forward and then be turned upside down, so the primary-drum feeding rack saves more space compared with a laminated feeding rack; a hot-knife cutting device is used for rapidly cutting upper bead filler, so rapid high-efficiency filler upper bead cutting and a smooth cutting surface are realized at set accurate temperature; and an ultrasonic knife cutting device is used at a tire sidewall, and through dynamic adjustment of the ultrasonic knife cutting device with a rubber compound and changing of the frequency of the body of an ultrasonic knife, the rubber compound cut through transverse or longitudinal cutting has neat and smooth fracture and is free of burnt rubber. The primary-drum feeding rack of the tire building machine is compact in structure and easy to install and debug, and can highly efficiently realize high-quality carcass shaping of a tire. The invention also discloses an implementation method for the primary-drum feeding rack of the tire building machine.

Owner:DINGHAN TECH XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com