A reinforced connection structure between metal inserts and plastic parts

A metal insert and connection structure technology, applied in the direction of non-removable pipe connection, passing element, pipe/pipe joint/pipe fitting, etc., can solve the problem of metal insert and plastic parts being separated, affecting the sealing effect and safety of use, etc. problem, to prevent disengagement and increase the effect of the joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

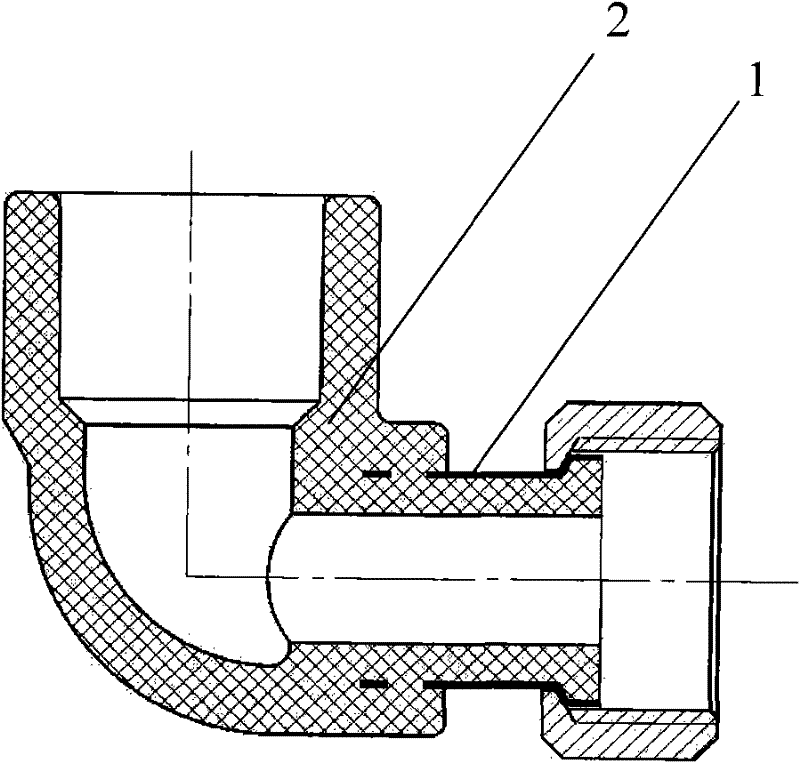

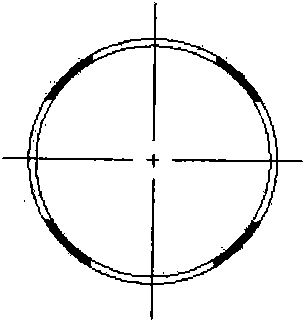

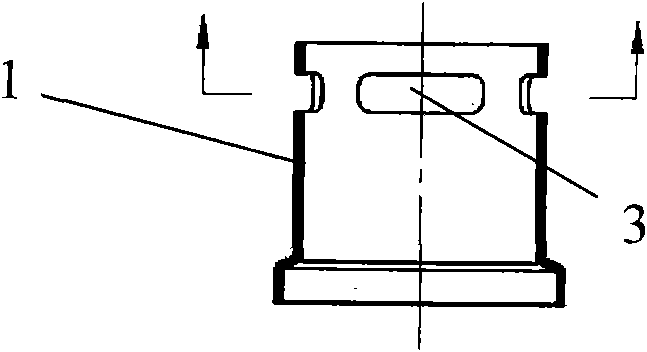

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the reinforced connection structure between the metal insert and the plastic part of the present invention is composed of a plastic part 2 and a metal insert 1. The inner section of the metal insert 1 is cylindrical and embedded in the plastic In the part 2, wherein, at least one number of protrusions, or pits 5, or through holes 3, or thorns 4 are arranged on the inner circumferential surface of the metal insert 1 along the circumferential direction, any one of the The protrusions, or pits 5 , or through holes 3 , or thorns 4 are all surrounded or filled by the plastic part 2 .

[0019] Further, at least one number of protrusions are provided on the inner circumference of the metal insert 1 , and the back side of any one of the protrusions is in the shape of a pit.

[0020] Alternatively, at least one number of through holes 3 are provided on the inner circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com