Primary-drum feeding rack of tire building machine and implementation method thereof

A tire building machine and feeding rack technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of large operation space and high production cost, and achieve the advantages of reducing labor, saving space, and ensuring dynamic balance and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

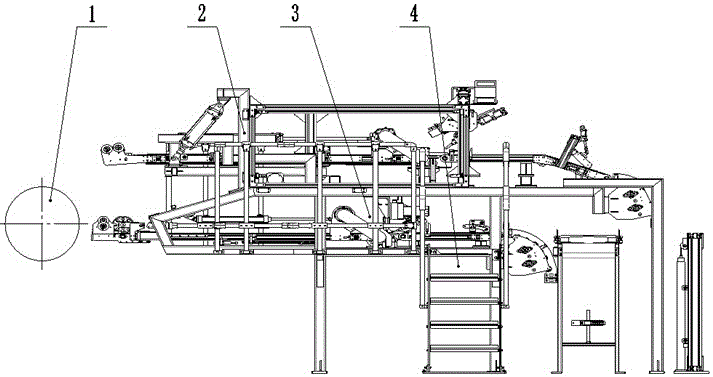

[0028] Such as figure 1 As shown, the present invention is a tire building machine primary drum feeding rack, which includes a primary drum 1, an upper apex conveying device 2, a sidewall conveying device 3, and a supporting frame 4; the primary drum 1 is located at the front, The upper apex conveying device 2 is installed on the inner upper layer of the supporting frame 4, the sidewall conveying device 3 is installed on the lower inner layer of the supporting frame 4, and the upper apex conveying device 2 and the sidewall conveying device 3 are stacked in the longitudinal direction of the primary drum 1 Directly behind; the upper apex conveying device 2 can be pushed forward and then turned down. Compared with the traditional stacked feeding rack, this mechanism saves space and reserves a larger operating space for the operator.

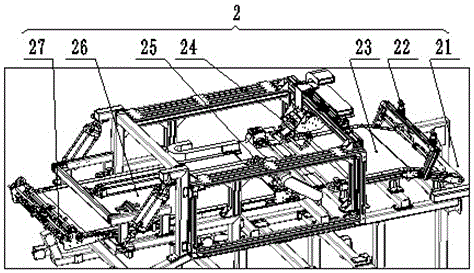

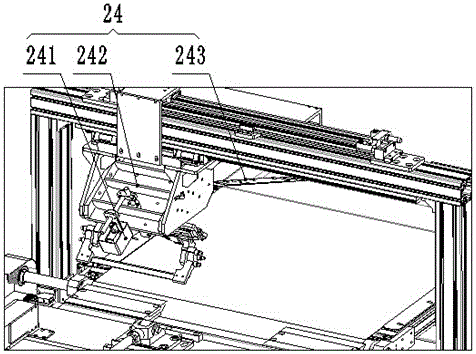

[0029] refer to figure 2 , the structure schematic diagram of the apex conveying device of the present invention, the upper apex conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com