Following device of copper tube inner conductors for radio frequency coaxial cable and following method thereof

A technology of radio frequency coaxial cable and splicing device, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of wasting time and waste, achieve uniform assembly clearance, ensure welding quality, and high joint strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

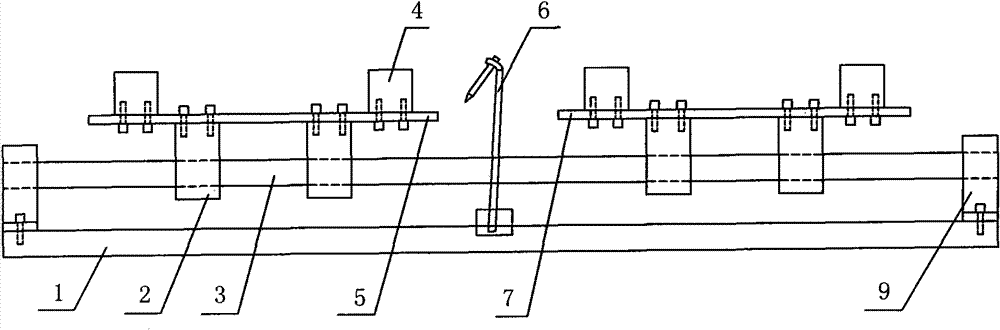

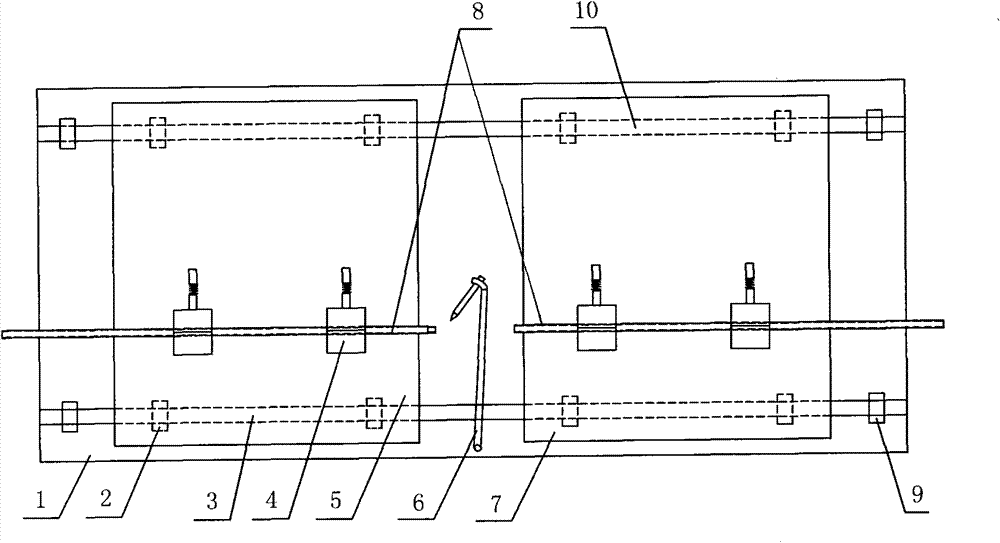

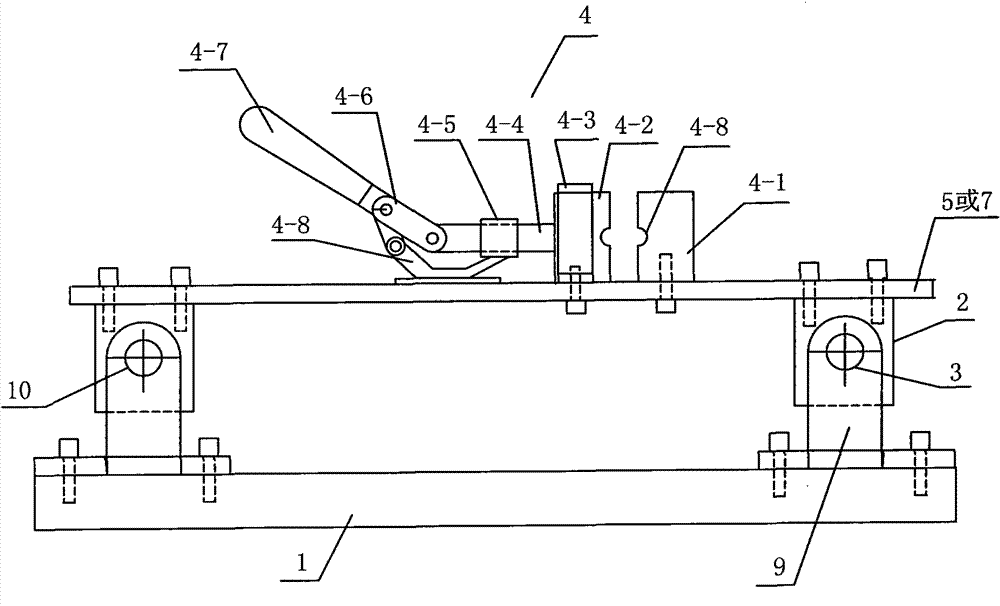

[0038] Example: see figure 1 , 2 3. The copper tube inner conductor welding includes cable copper tube with a diameter of 9.2mm and a wall thickness of 0.45mm. The inner diameter of the copper tube is 8.3mm. The length of the lined copper pipe is 10mm-15mm. After the surface cleaning and end surface treatment of the copper pipe to be welded, the copper pipe fixture 4 of the welding device is clamped, and then see Figure 4 , 5 , Use lined copper tube to insert the inner conductor of the copper tube, and the assembly distance of the inner conductor of the copper tube is 2-2.5mm.

[0039] Operation steps: first unscrew the propane gas switch, ignite the gas, and then slowly unscrew the oxygen switch. At this time, the flame temperature is not high, and there are two layers of white flame cores at the nozzle. When welding, adjust the oxygen switch so that the oxygen and The proportion of propane gas is appropriate, the combustion is sufficient, and the high temperature is obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com