Production device and method of wave flat continuous rolling metal composite thin plate strip

A technology of metal cladding and production method, applied in the direction of metal rolling, etc., can solve the problems of the clad strip, large residual stress, poor bonding performance of the composite interface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

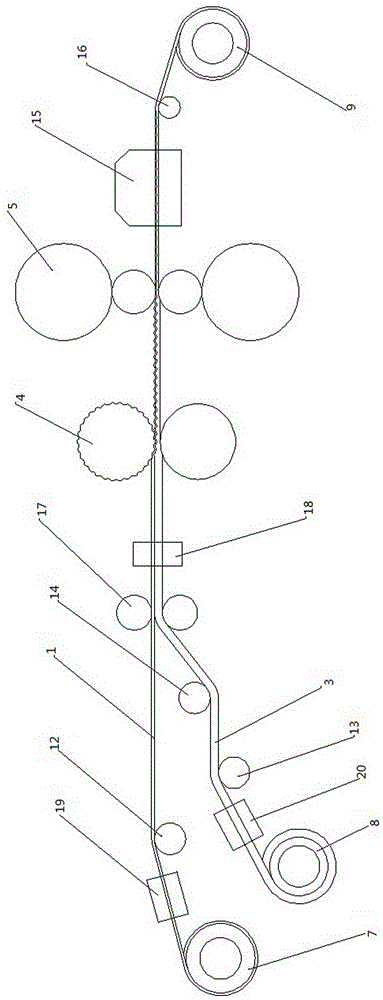

[0046] Use attached figure 1 The shown device adopts this method to prepare carbon steel-copper double-layer cold-rolled composite strip:

[0047] The production device of wave flat continuous rolling metal composite sheet strip is characterized in that it includes a two-roll corrugator (4), a four-roll flat mill (5), and a pinch roll (17) arranged in front of the two-roll corrugator (4). ), the welding device for the head of the composite base material (18), a guide device is provided between the pinch roll (17) and the two-roll corrugator (4), and 3# is set before the pinch roll (17) Guide roller (12), 4# guide roller (13), 5# guide roller (14), 1# uncoiler (7), 2# uncoiler (8), 3# guide roller (12) and 1# uncoiler (7) Set between 1# cleaning unit (19), 4# guide roller (13) and 2# uncoiler (8), set 2# cleaning unit (20), two-roller corrugating mill (4) and four Roller flat rolling mill (5) is equipped with roller table and guide device to form continuous rolling relationsh...

Embodiment 2

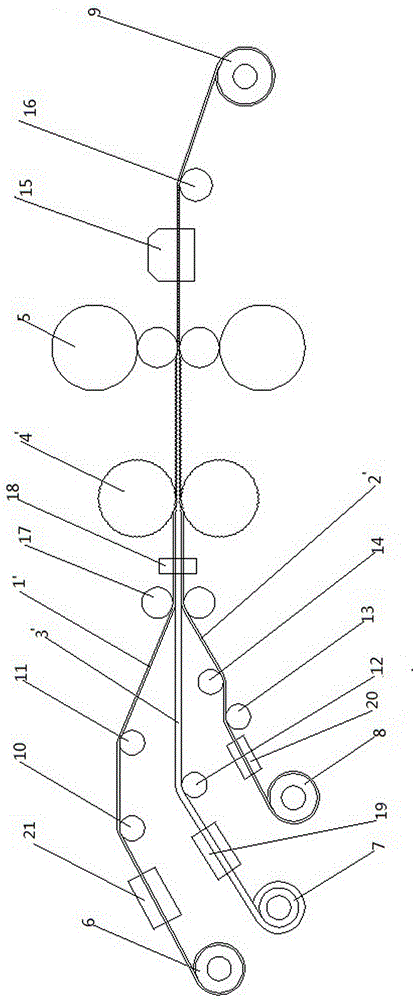

[0055] Use attached figure 2 The shown device adopts this method to prepare titanium steel-aluminum-stainless steel three-layer cold-rolled composite strip:

[0056] The production device of wave flat continuous rolling metal composite thin plate strip is characterized in that it includes a two-roll corrugator (4'), a four-roll flat mill (5), and a pinch roller arranged in front of the two-roll corrugator (4'). (17) The welding device (18) for the head of the composite base material. A guide device is provided between the pinch roll (17) and the two-roller corrugator (4'). Before the pinch roll (17) is pressed Set 1# guide roller (10), 2# guide roller (11), 3# guide roller (12), 4# guide roller (13), 5# guide roller (14), 3# uncoiler (6), 1 # uncoiler (7) and 2# uncoiler (8), 3# guide roller (12) and 1# uncoiler (7) are set up 1# please wash unit (21), 4# guide roller (13) and 2# cleaning unit (20) is set between 2# uncoiler (8), 3# cleaning unit (21) is set between 1# guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com