Fabricated floor system and construction method

A construction method and prefabricated technology, applied in floors, building components, buildings, etc., can solve the problems of unusable internal space of the structure, high construction difficulty, increased load, etc., so as to save the space occupied by pipelines and reduce concrete The effect of dosage and reduction of layer height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

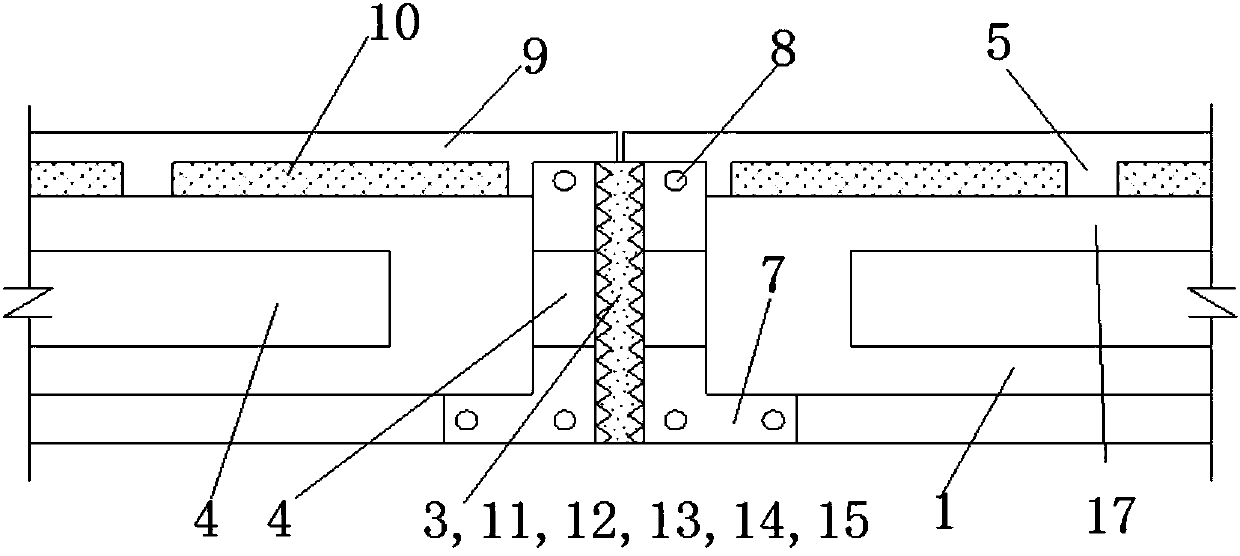

[0048] A prefabricated floor, mass-produced in the factory, floor unit: 9 prefabricated floor slabs with 9 lengths and 1.5 meters in width, 50 mm in thickness, and 150 mm in height and 50 mm in width at the bottom of the plate Figure 13 ); prefabricated rib 1: 0.4 m high, 30 mm thick, 30 (100) mm overhang at the lower end; use 3-grade steel bars, a 6 mm diameter steel bar at the bottom of the rib, and 4 mm diameter steel wire at the bottom of the plate, with a two-way spacing of 200 mm , The end plate is equipped with steel wire mesh or fiber mesh, and the extended rib 2 and the prefabricated rib 1 are integrally poured with C25 concrete and cured by autoclaving.

[0049] A construction method for a prefabricated floor: the construction steps are:

[0050] 1) The above-mentioned prefabricated ribs 1 and prefabricated floor slabs 9 are prefabricated in the factory as a whole and then transported to the construction site;

[0051] 2) The prefabricated concrete floor units are ...

Embodiment 2

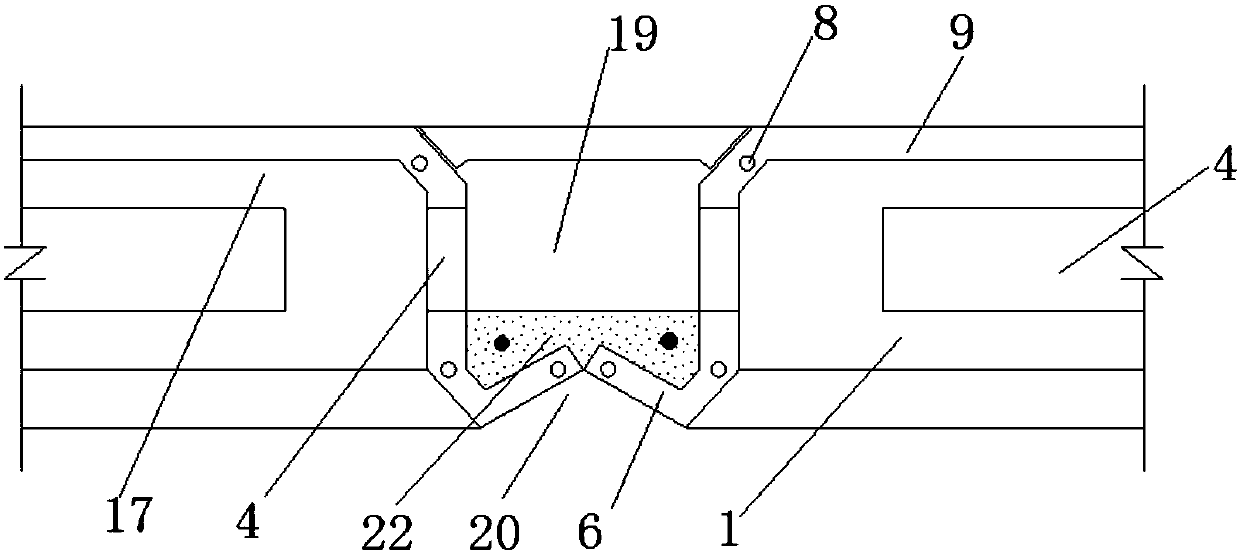

[0056] A prefabricated floor unit (such as Figure 9 ), the prefabricated floor 9 and the prefabricated rib 1 are prefabricated respectively, and the rest are the same as in Embodiment 1.

[0057] A construction method for a prefabricated floor: the construction steps are:

[0058] 1) The above prefabricated ribs 1 and prefabricated floor slabs 9 are respectively prefabricated in the factory and then transported to the construction site;

[0059] 2) The prefabricated concrete floor units are arranged and installed according to the design requirements, and the four corners of the hoarding are supported on the vertical supports;

[0060] 3) Buckle the prefabricated floor 9 on the top of the prefabricated rib 1;

[0061] 4) Install dense rib (beam) reinforcement and pour C30 concrete in the groove between the prefabricated floor slabs 9 according to the design requirements;

[0062] 5) Remove the vertical support at the bottom after the concrete curing reaches strength.

Embodiment 3

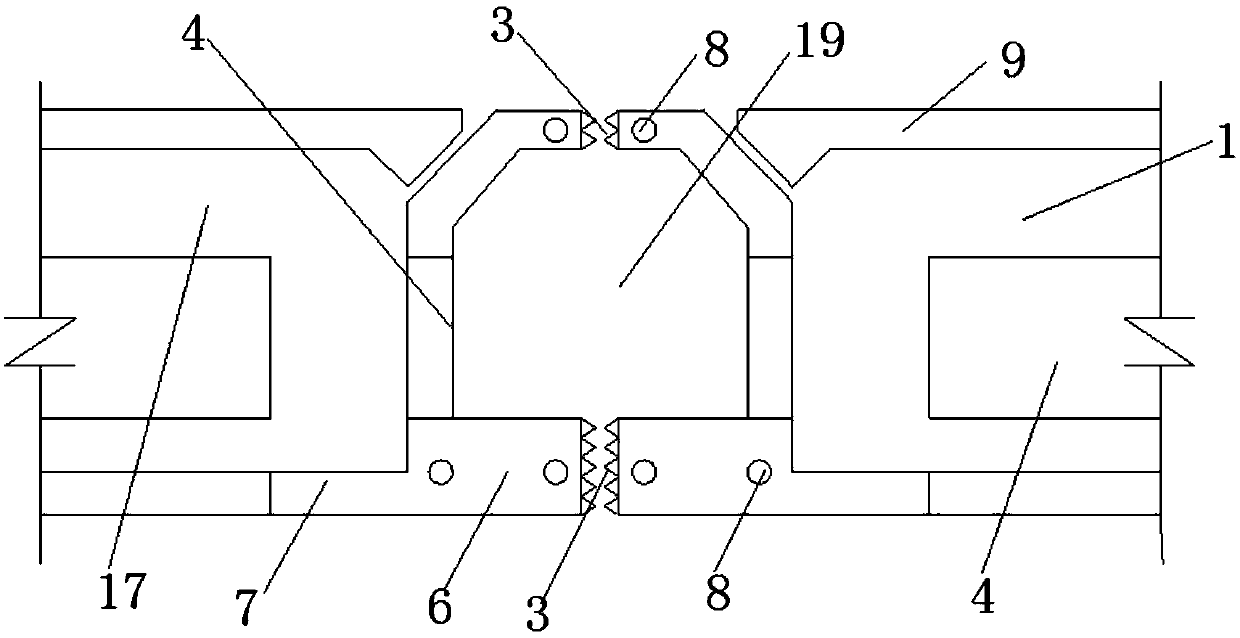

[0064] A prefabricated floor, mass-produced in the factory, floor unit: 9 prefabricated floor slabs with 9 lengths and 1.5 meters in width, 50 mm in thickness, and 150 mm in height and 50 mm in width at the bottom of the plate Figure 13 ); prefabricated rib 1: 0.4 m high, 30 mm thick, 30 (100) mm overhang at the lower end; use 3-grade steel bars, a 6 mm diameter steel bar at the bottom of the rib, and 4 mm diameter steel wire at the bottom of the plate, with a two-way spacing of 200 mm , The end plate is equipped with steel wire mesh or fiber mesh, and the extended rib 2 and the prefabricated rib 1 are integrally poured with C25 concrete and cured by autoclaving.

[0065] A construction method for a prefabricated floor: the construction steps are:

[0066] 1) The floor unit is prefabricated in the factory and delivered to the construction site;

[0067] 2) The floor units are arranged and installed on the vertical supports according to the design requirements;

[0068] 3) I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com