Double composite plastic steel composite pipe and manufacture method thereof

A steel-plastic composite pipe and double-composite technology, applied in the direction of pipes, rigid pipes, tubular objects, etc., can solve the problems of pipelines that cannot be used to transport liquids under pressure, and achieve the effects of saving plastic raw materials, low pipe cost, and enhanced fracture strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

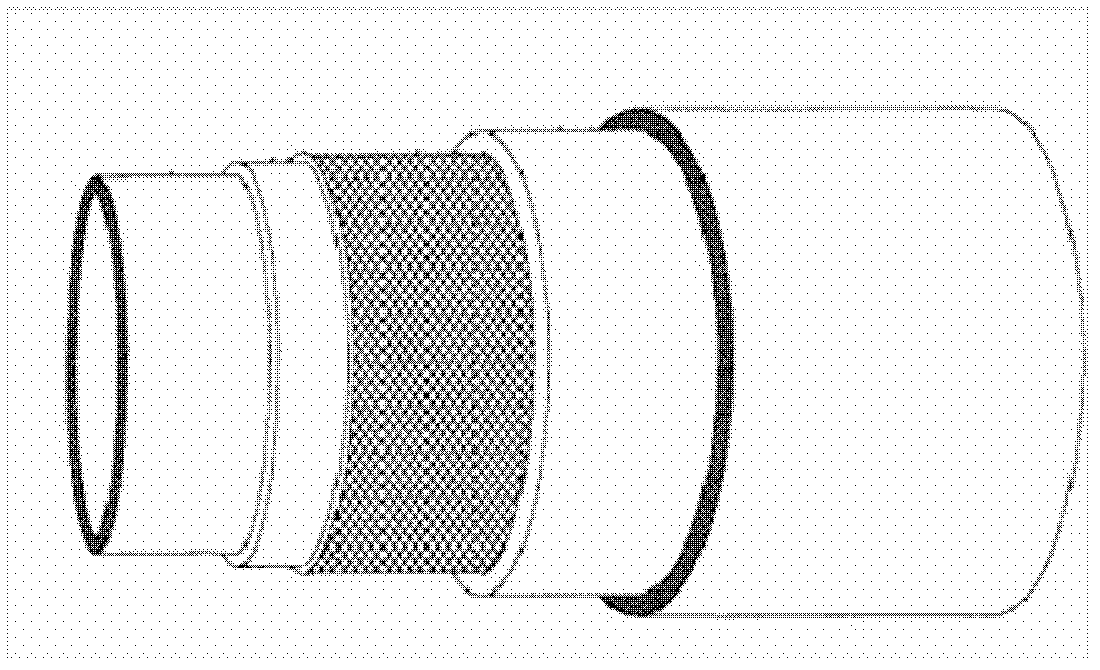

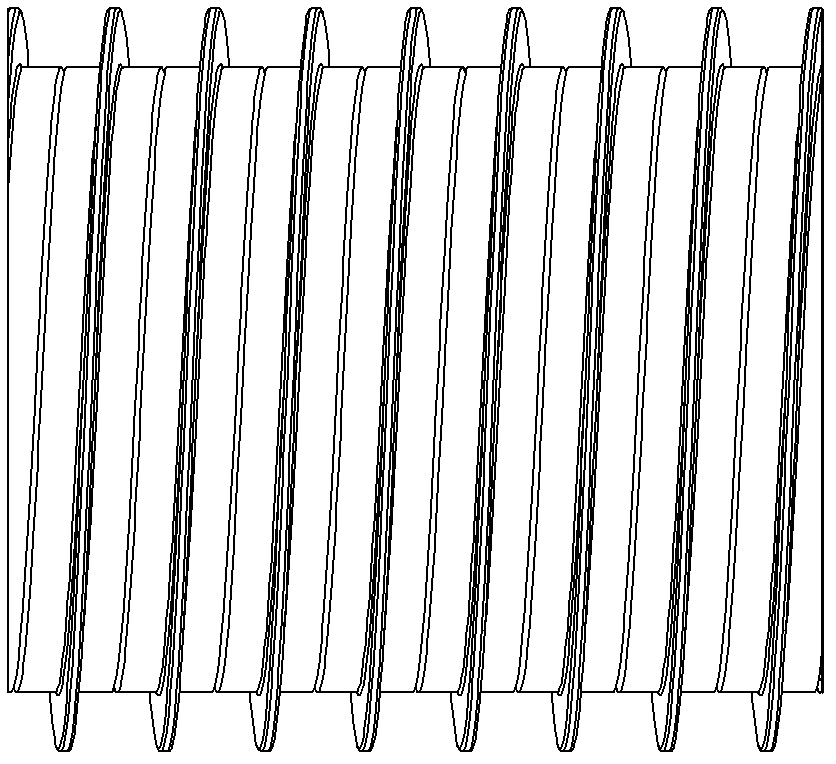

[0041] figure 1 It is a schematic diagram of the traditional steel mesh skeleton tube structure.

[0042] figure 2 It is a schematic diagram of the structure of a traditional polyethylene plastic-steel winding pipe.

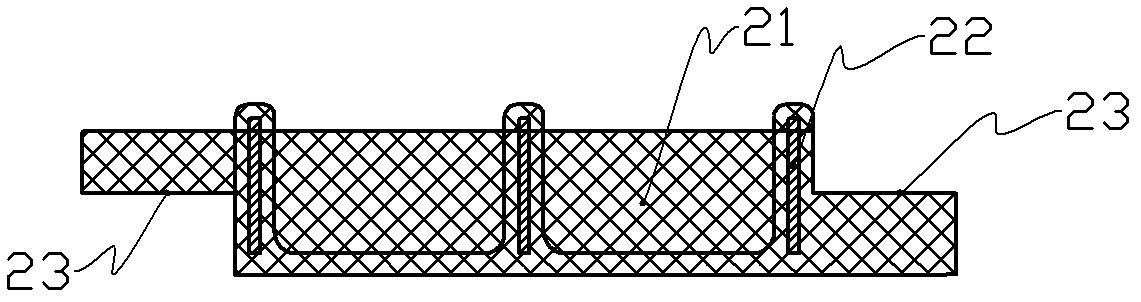

[0043] Such as image 3 As shown, a plastic-steel strip includes an extruded strip body 21, and a vertical steel rib 22 is embedded in the inner rib of the strip body, and the vertical steel rib is essentially a steel strip; The excellent anti-corrosion performance utilizes the rigidity of the vertical steel ribs to ensure the ring rigidity of buried pipes.

[0044] Simultaneously at the side joint of strip body 21 adopts overlapping structure 23, when adjacent strip body is combined like this, the contact area when two side bondings is increased greatly, makes pipe material bonding firmer when bonding, greatly improves the joint strength of the pipe.

[0045] Such as Figure 4 as shown,

[0046] A plastic-steel winding pipe base 24 is formed by winding a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com