Catalyst for sodium borohydride catalyzing hydrolyzation hydrogen supplying method and preparation thereof

A sodium borohydride, catalytic hydrolysis technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of fast reaction rate, poor safety, and severe hydrogen release and other issues, to achieve low cost, improve binding force, and slow down the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0053] Embodiment 3 (embodiment of the present invention)

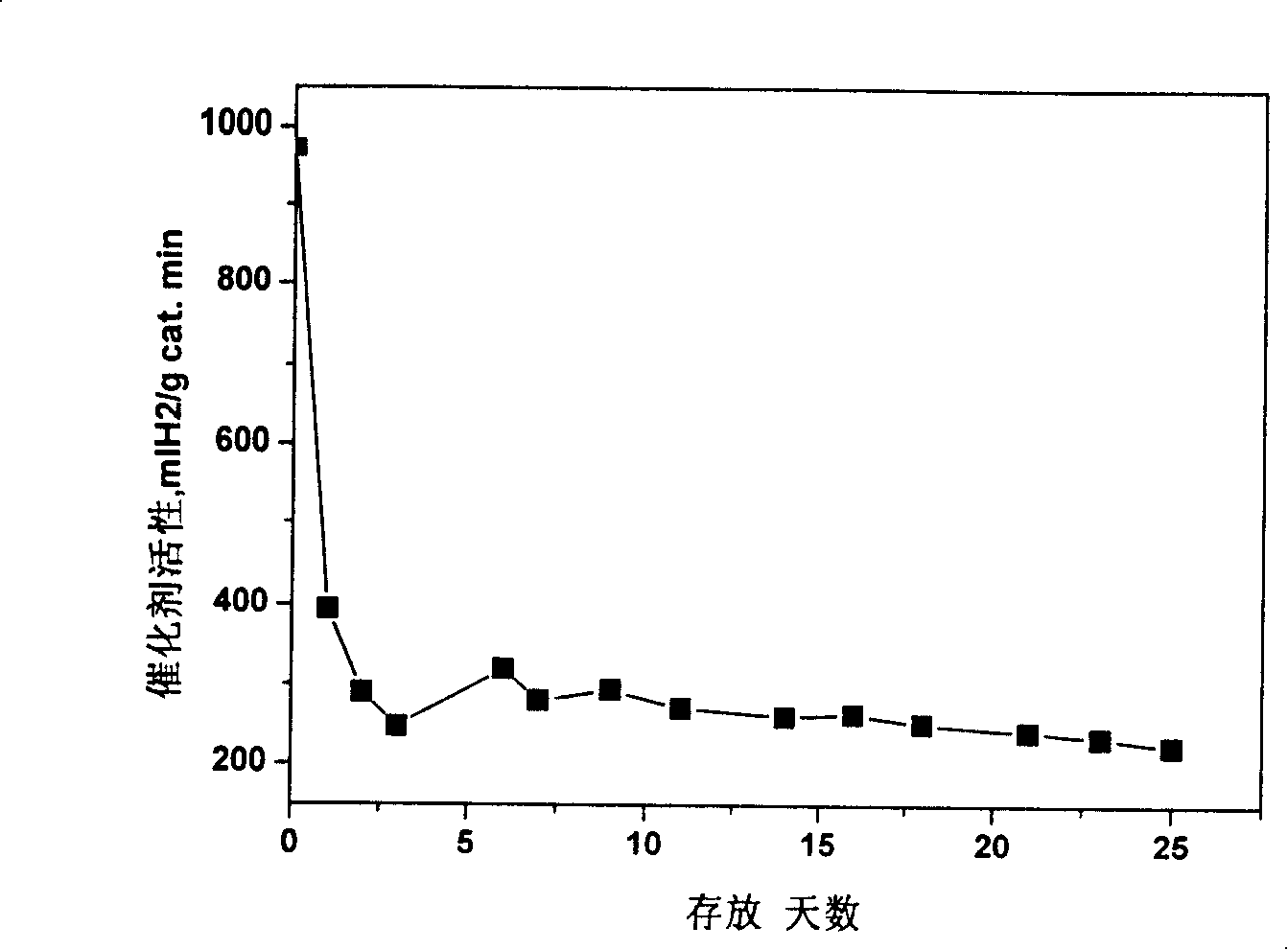

[0054] 80-100 mesh diatomite, dispersed in absolute ethanol and ultrasonically oscillated for 30 minutes, washed with deionized water, filtered and dried, immersed in an acetone solution of palladium acetylacetonate with a palladium concentration of 5-7g / l for 20-25 minutes, and dried ; then immersed in 345-355g / l cobalt chloride solution for 20-30 minutes, filtered, vacuum-dried at 85-95°C, 10-15g / lNaBH 4 Solution reduction; finally immerse in acetone solution with palladium concentration of 5-7g / l palladium acetylacetonate for 20-25 minutes, dry and heat-treat at 280-320°C for 2-3 hours to synthesize diatomite / palladium / cobalt / palladium catalyst, the maximum catalytic The activity is 1000ml mlH 2 / g cat. embodiment 3 synthetic diatomaceous earth / cobalt catalyst catalytic activity decay curve such as image 3 As shown, the decay is 300mlH after two days 2 / g cat. and kept for 25 days, the catalytic activity and st...

Embodiment 6

[0059] Embodiment 6 (embodiment of the present invention)

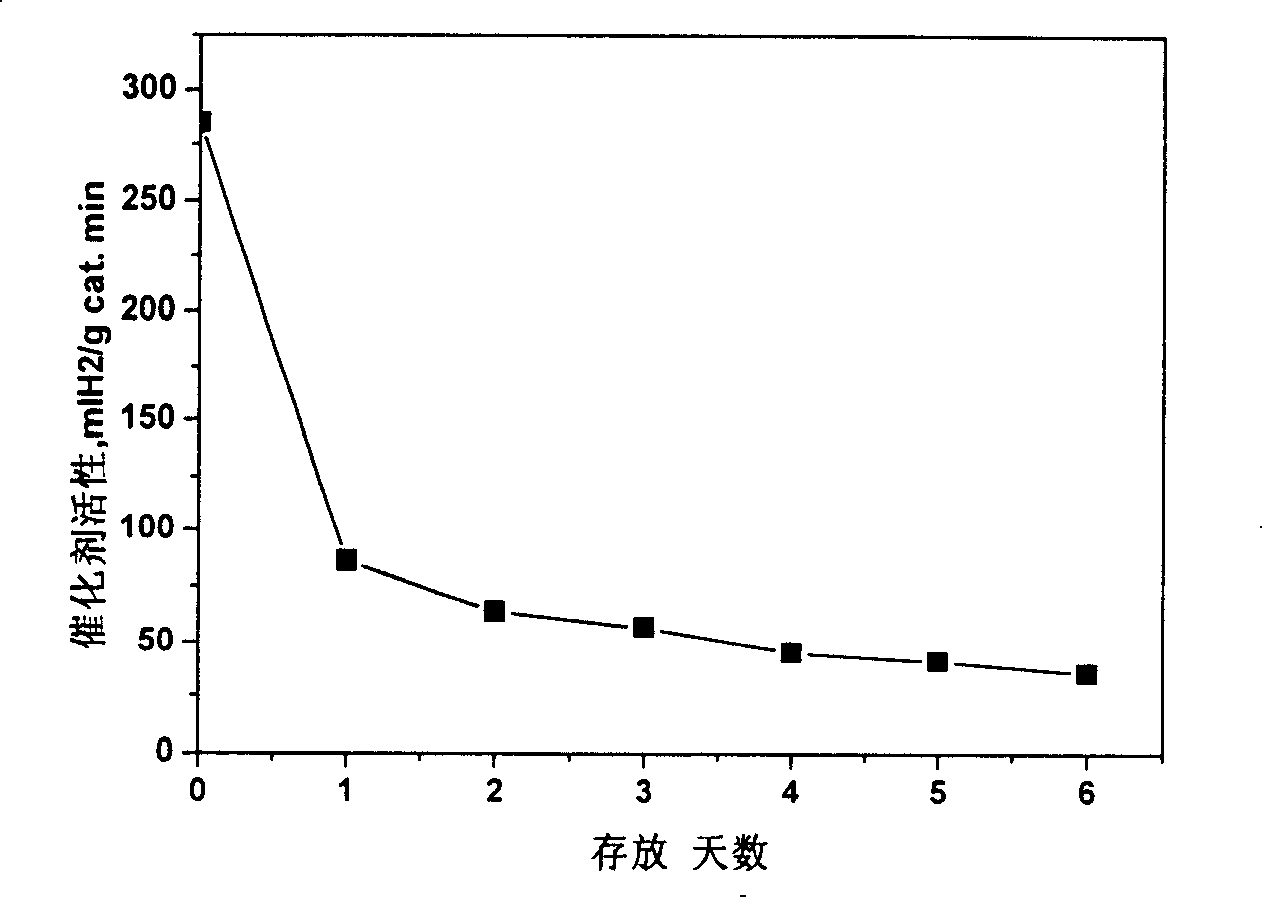

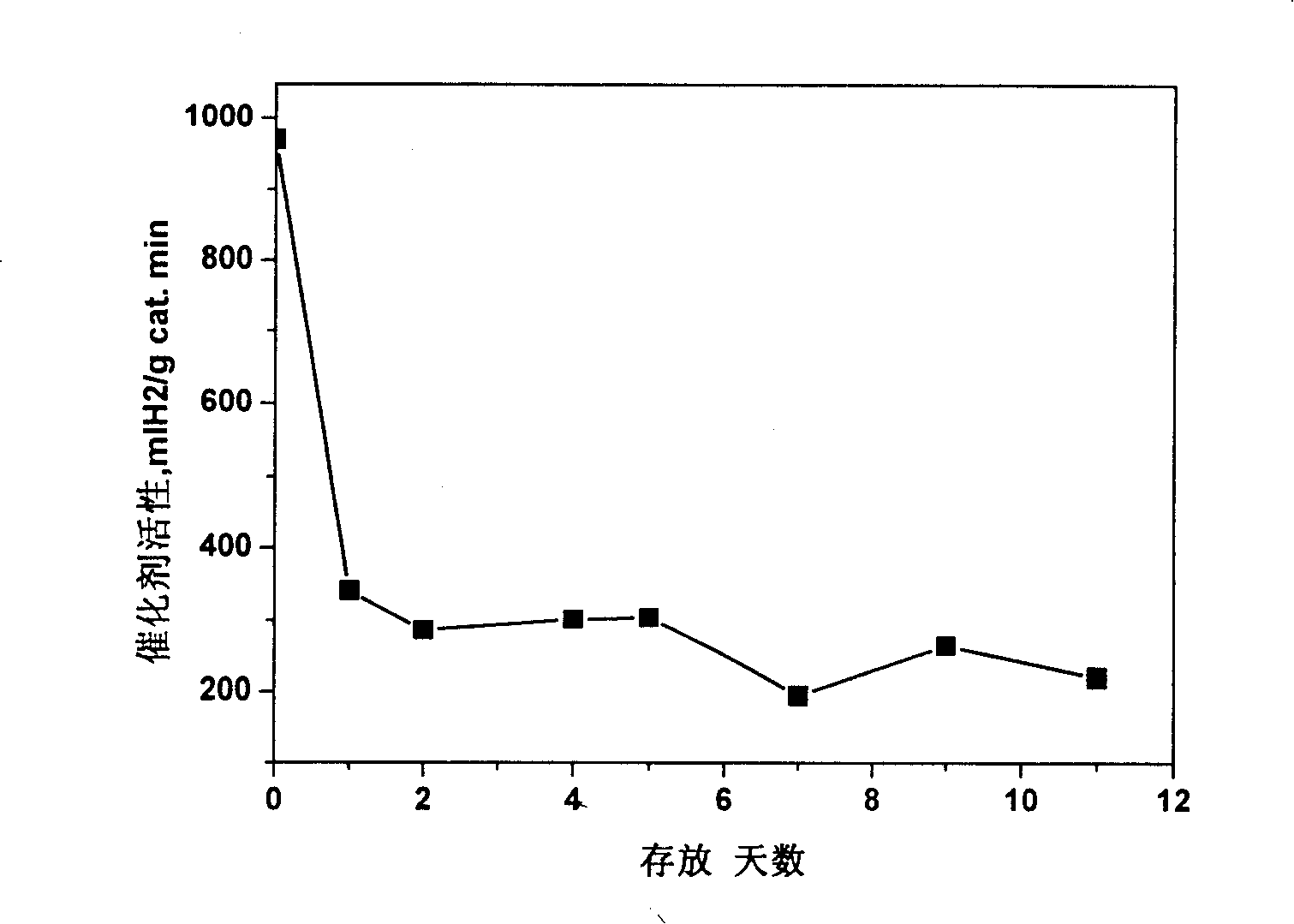

[0060] Wash the nickel foam with hydrochloric acid for 10 minutes, wash it with deionized water, dry it, and put 1.3~1.7g / l Pd, 0.2~0.24g / l NH 4 OH, 17.3-17.7g / l EDTA palladium plating solution for 20-30 minutes, rinsed with deionized water, and vacuum-dried at 65-75°C; then placed in 9.5-10.5g / l CoCl 2 , 59-61g / l sodium tartrate, 2.8-3.2g / l borax, 4.2-4.6g / l sodium borohydride mixed solution electroless cobalt plating for 20-30 minutes, rinsed with deionized water, and vacuum-dried at 65-75°C ; Then add Pd containing 1.3~1.7g / l, 0.2~0.24g / l NH 4 OH, 17.3 ~ 17.7g / l EDTA palladium plating solution electroless palladium plating 20 ~ 30 minutes, deionized water cleaning, 65 ~ 75 ℃ vacuum drying, 280 ~ 320 ℃ 2, 2 ~ 3h vacuum heat treatment, synthetic nickel foam / Palladium / Cobalt Catalyst with a maximum catalytic activity of 100ml H 2 / g cat.min, embodiment 6 synthesizes diatomite / cobalt catalyst catalytic activity de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com