Patents

Literature

49results about How to "Increase penetration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-containing metal surface treatment agent and preparation method of anti-corrosion coating

InactiveCN104629603AIncrease penetration timeGood bindingLiquid surface applicatorsAnti-corrosive paintsCvd grapheneSurface finishing

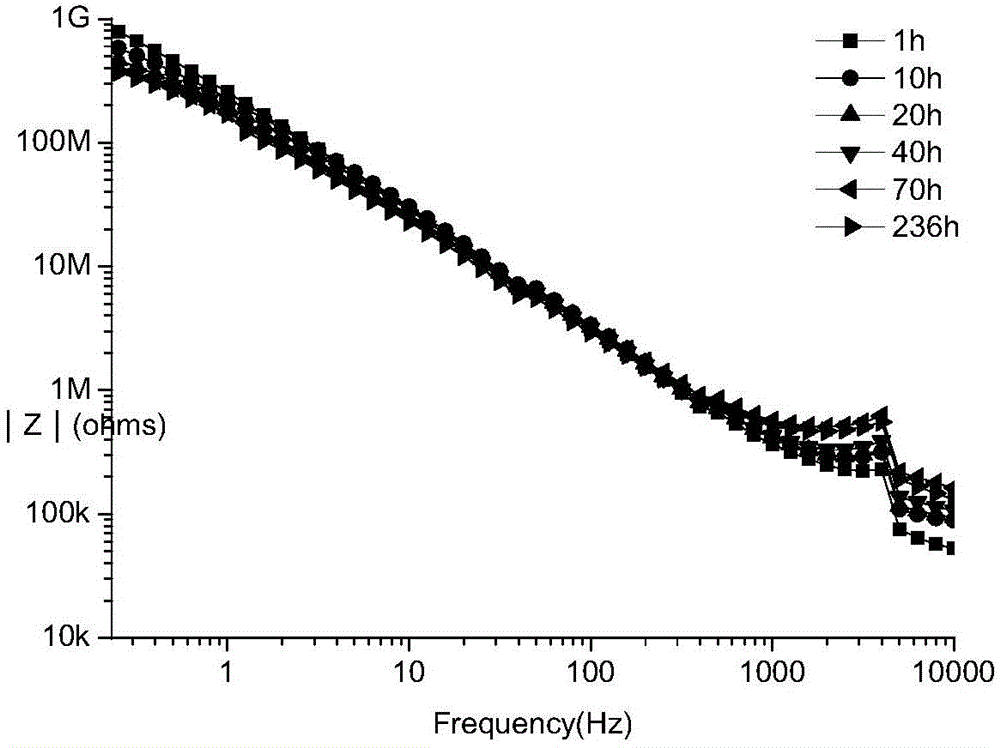

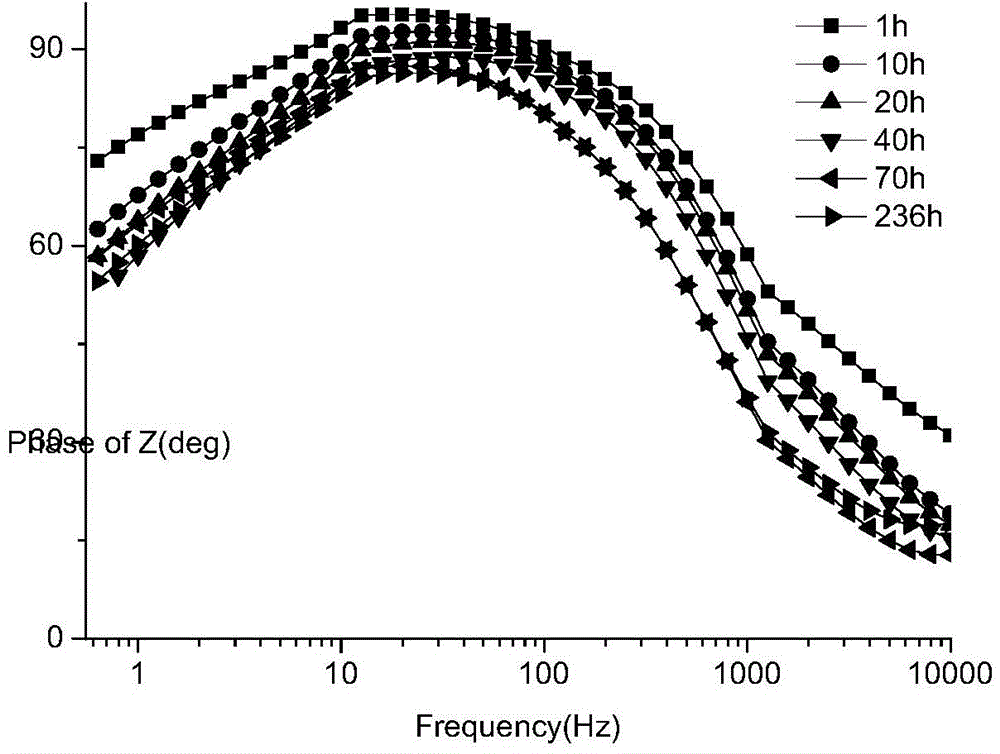

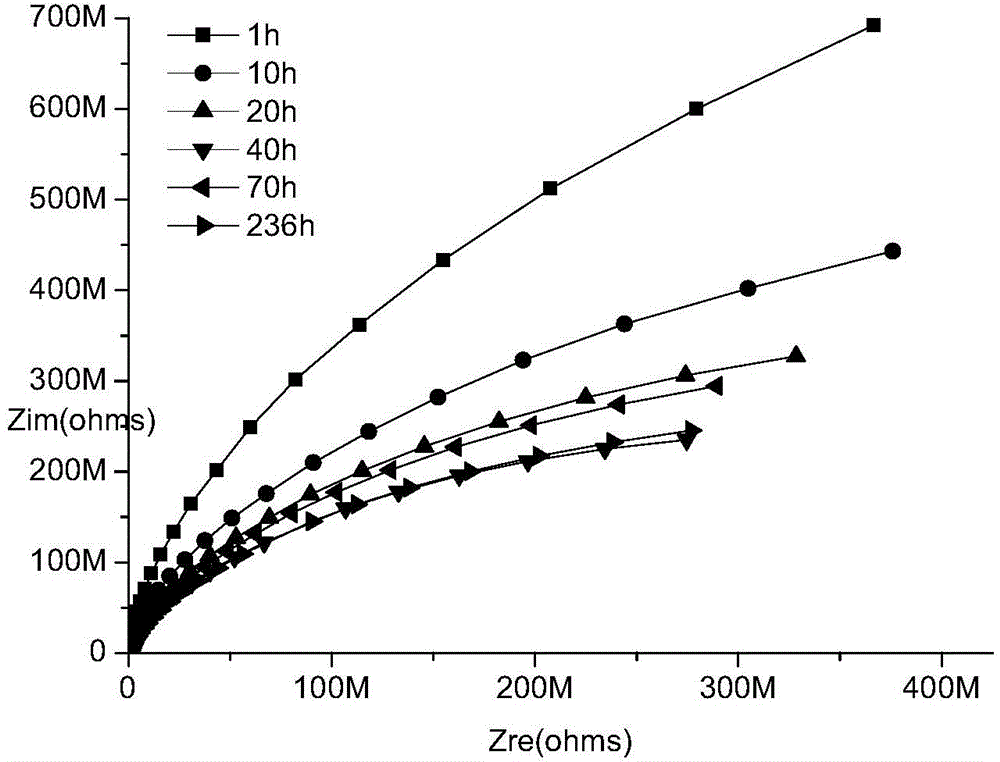

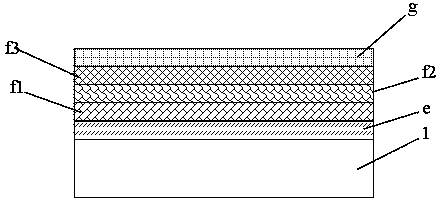

The invention relates to a graphene-containing metal surface treatment agent and a preparation method of an anti-corrosion coating thereof. Graphene oxide is prepared by a chemical oxidation method, and the graphene oxide is subjected to surface modification and reduction so as to obtain good compatibility with a metal surface treatment agent; and the graphene is added into the metal surface treatment agent according to a certain proportion. The treatment agent contains A) waterborne resin, for example, waterborne polyurethane and waterborne acrylic resin; B) a coupling agent, for example, a silane coupling agent and a titanate coupling agent; and C) graphene, wherein the surface state can be graphene oxide, reduced graphene oxide or graphene subjected to surface chemical modification. After the surface treatment agent containing uniformly dispersed graphene, a film is formed on the surface of a metal substrate by a rod coating method, and the film is dried at a certain temperature to obtain a graphene-reinforced composite coating. An electrochemical impedance test method proves that the composite coating has ultrahigh corrosion resistance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

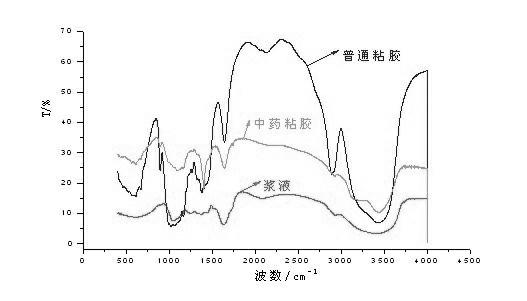

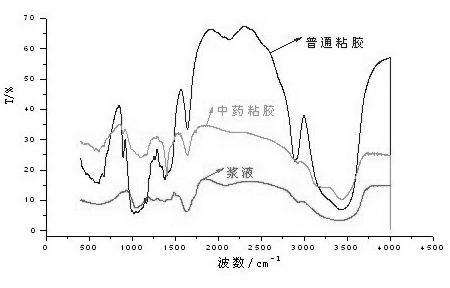

Preparation method of traditional Chinese medicine velvet viscose fiber

InactiveCN102220648AConducive to penetrationStrong targeting effectMonocomponent cellulose artificial filamentWet spinning methodsViscoseTraditional Chinese medicine

The invention discloses a preparation method of viscose fiber, and the technical problem solved by the invention is to provide the preparation method of traditional Chinese medicine velvet viscose fiber capable of releasing and permeating active ingredients in human body for a long time.

Owner:浙江神力针织品有限公司

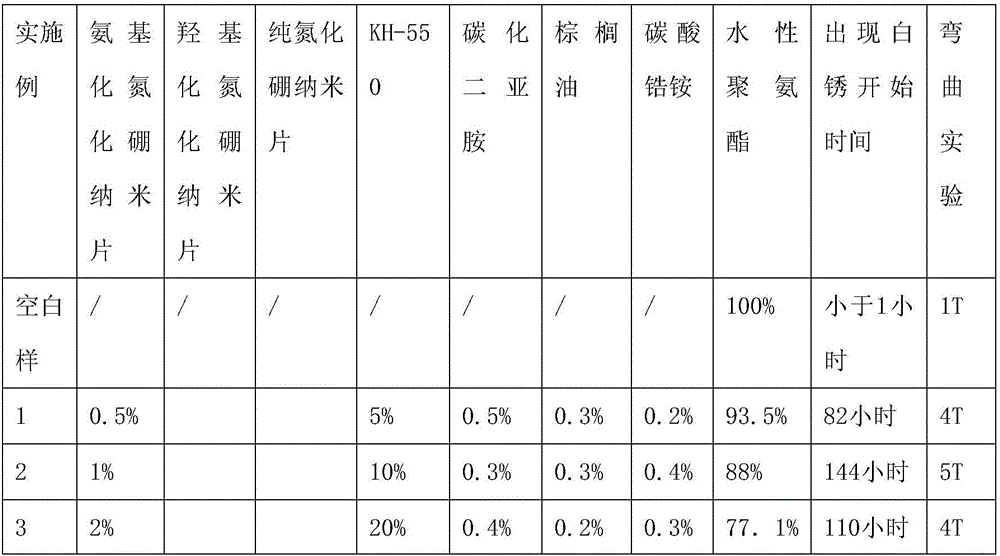

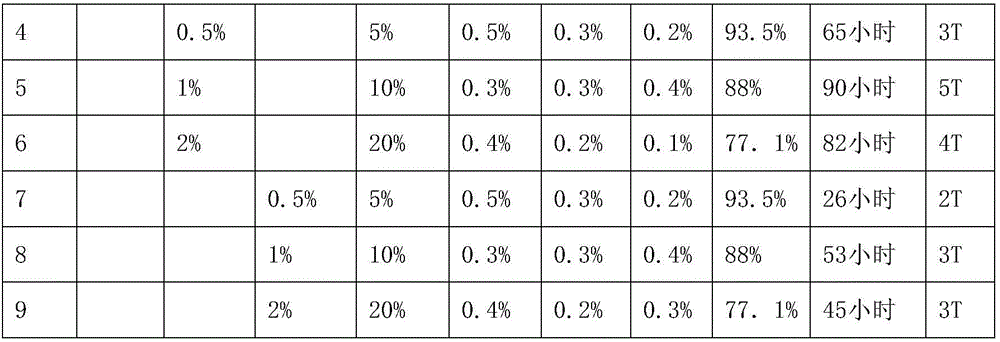

Preparation methods of metal surface treatment agent containing nano boron nitride and corrosion-resistant coating

ActiveCN106010181AGood dispersionGood compatibilityFireproof paintsLiquid surface applicatorsSolid componentSalt spray test

The invention provides a metal surface treatment agent containing nano boron nitride. The metal surface treatment agent is prepared from waterborne resin, a dispersing agent, boron nitride and coating additives, wherein the mass of the solid component in the waterborne resin is 77%-93.5% that of the total solid components of a coating, the mass of the dispersing agent is 5%-20% that of the total solid components of the coating, the mass of boron nitride is 0.5%-2% that of the total solid components of the coating, and the mass of the coating additives is 0.5%-1% that of the total solid components of the coating. The invention further provides a preparation method of the metal surface treatment agent containing nano boron nitride and a method for preparing a corrosion-resistant coating. It is proved through salt spray tests that the composite coating has ultra-high corrosion resistance. The metal surface treatment agent is waterborne paint, the formula does not contain any solvent except water, therefore, emission of volatile organic compounds does not exist, and the metal surface treatment agent meets the environmental protection requirement and is suitable for surface corrosion prevention of metal substrates in industrialized production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

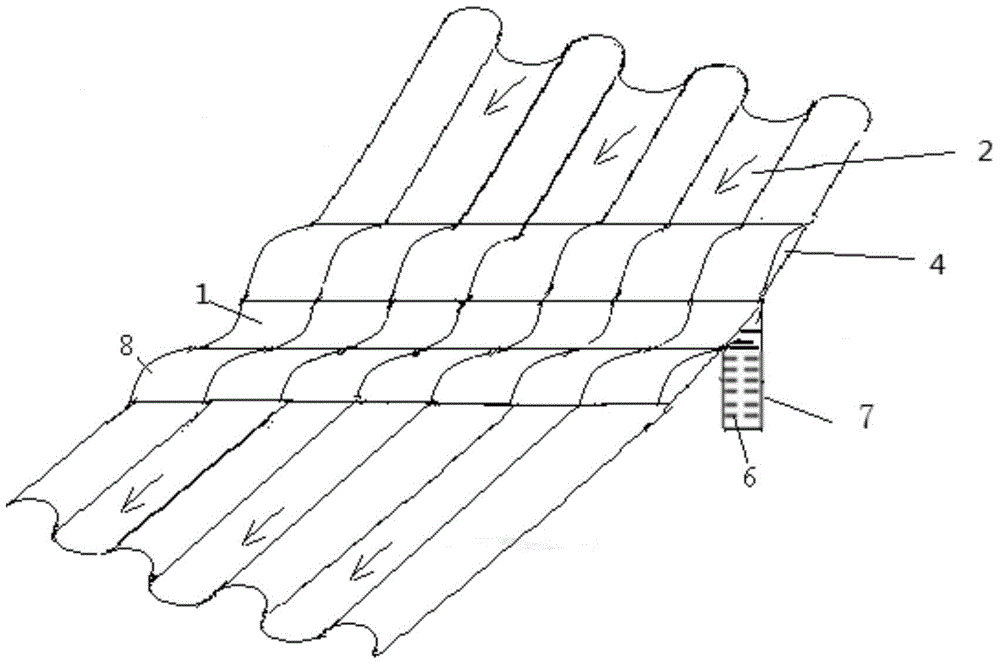

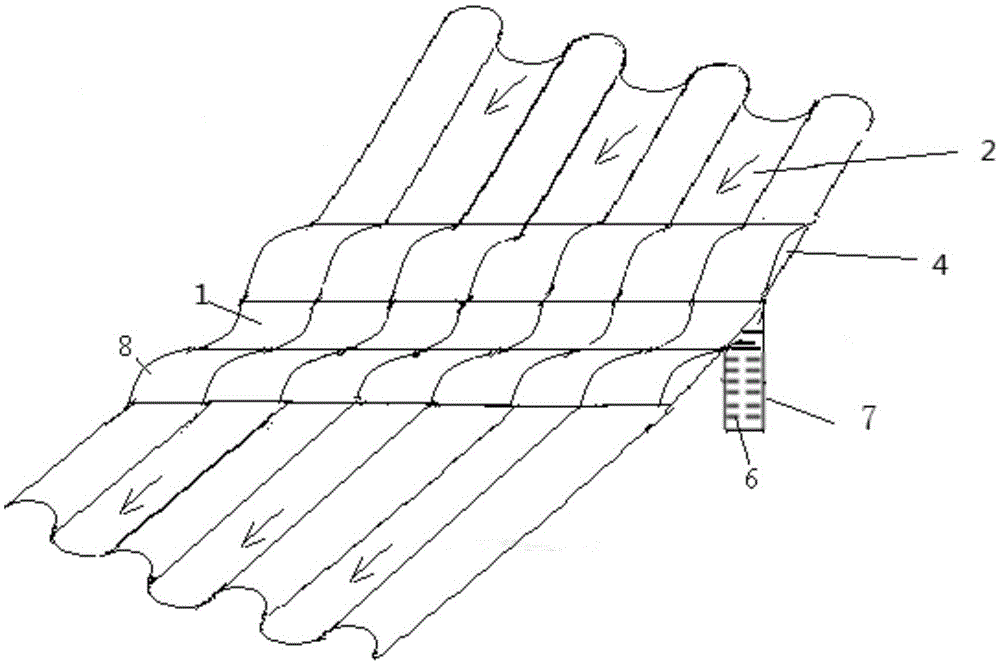

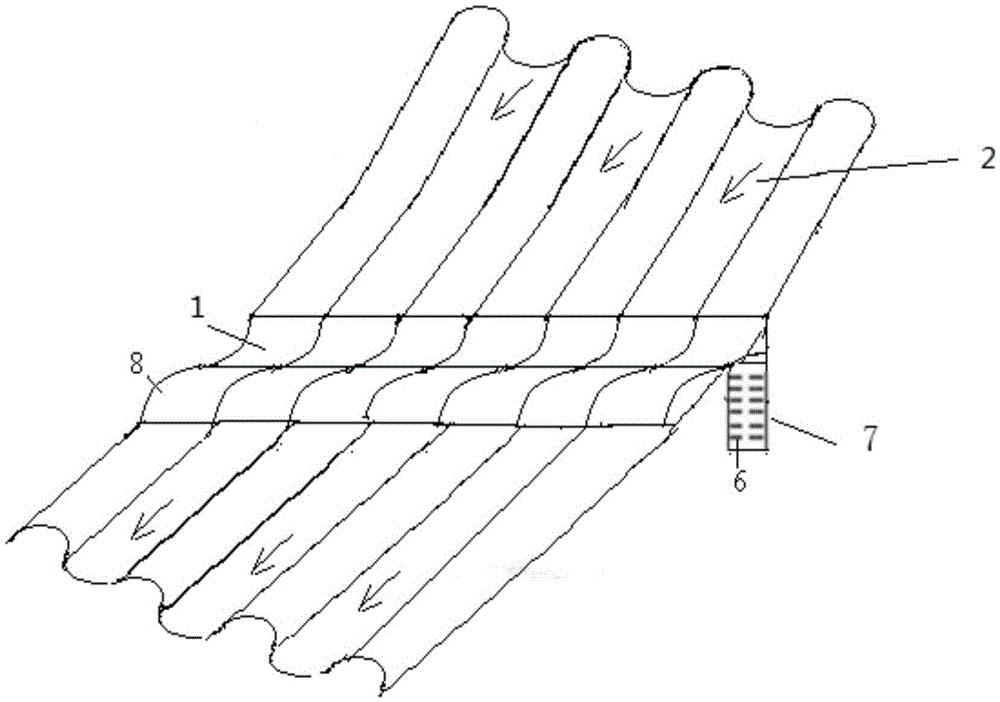

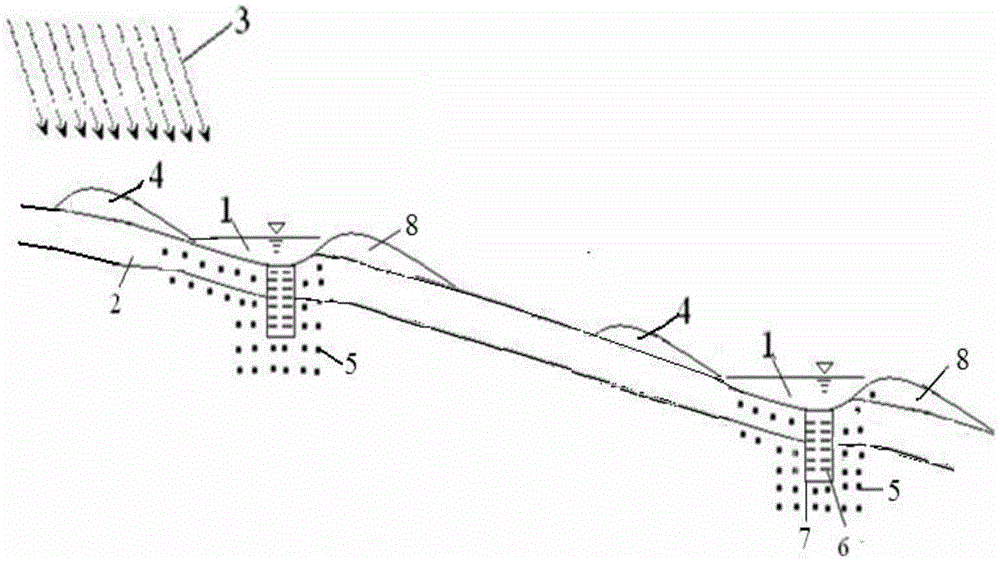

Combined cultivation method for water and soil conservation for sloping farmlands

InactiveCN102498779AReduce churnLoss avoidance or mitigationSoil-working methodsContour plowingBiology

A combined cultivation method for water and soil conservation for sloping farmlands relates to cultivation methods for water and soil conservation and solves the problem that using the single cultivation technique for holding water is unsatisfactorily effective. The combined cultivation method includes: firstly, adjusting ridges of sloping farmlands on downward slopes and inclined slopes under ridge plowing adjusted into transverse slope ridges, and adopting contour farming and belt planting; secondly, building ridges, and planting protective plant belts on the ridges; thirdly, subsoiling forfarming; fourthly, performing furrow damming; and fifthly, performing no-tillage conservation tillage. Furrow subsoiling and furrow damming are technically combined and integrated according to soil and weather characteristics of a black soil area, so that water and soil loss is reduced or avoided for sloping farmlands to the greatest extent, water and soil are conserved, water utilization rate isincreased, and crop yield is increased evidently. By the method, soil saturation and infiltration speed ratio is increased by 24.1% in processing treatment, water utilization rate is increased by more than 15%, crop yield is 30kg per mu, and 100 Yuan per mu is increased..

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Anti-wrinkle tidying method for pure cotton fabric

InactiveCN101942750AImprove wrinkle resistanceImprove flatnessSucessive textile treatmentsFibre treatmentOrganic acidBrute force

The invention relates to an anti-wrinkle tidying method for a pure cotton fabric, sequentially comprising the following processes: shell fabric preparation, pre-limbering, resin padding, curing, rinsing, post-limbering and preshrinking. The method has the main technical characteristic that the padding formula used in the resin padding process comprises the following components by concentration: 80-120g / L of 2D resin, 80-100g / L of oxalaldehyde resin, 40g / L of 1,3-Dimethylurea, 40g / L of magnesium chloride activated by organic acid, 20-40g / L of brute-force protective agent, 1-2g / L of penetrating agent and the balance of water. The invention has reasonable design, and fully utilizes the advantages of two types of the resins and catalysts; the tidied pure cotton fabric has the characteristics of higher planeness, higher brute force, favorable abrasive resistance, lower formaldehyde content and the like; and the garment made of the tidied pure cotton fabric has the characteristics of comfortable wearing, beautiful appearance and strong durability.

Owner:TIANJIN TIANGE TEXTILE

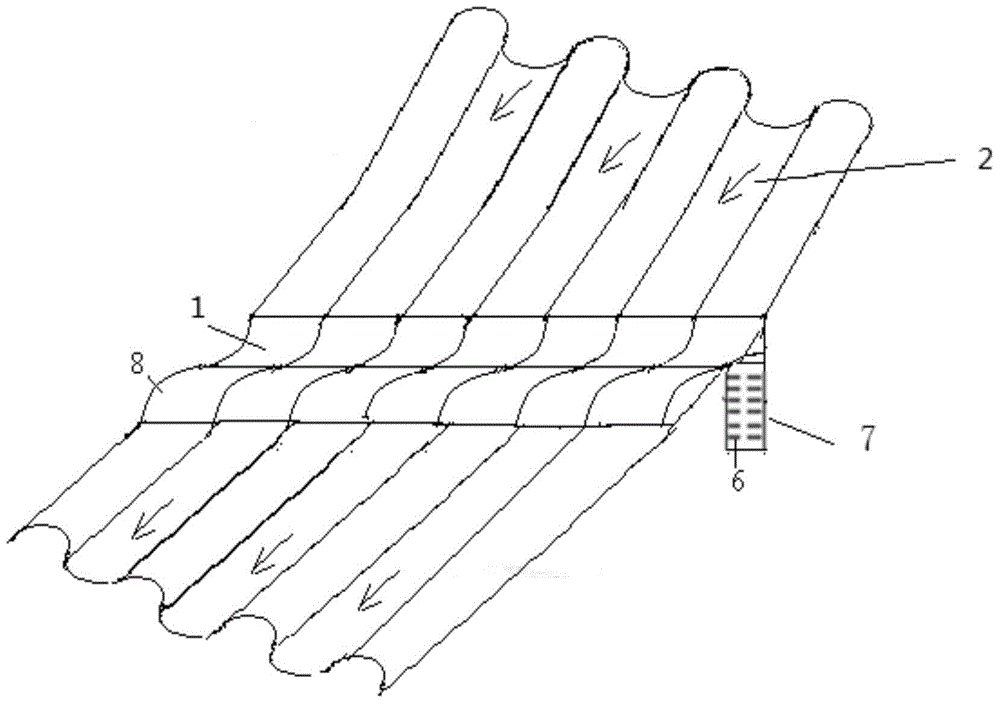

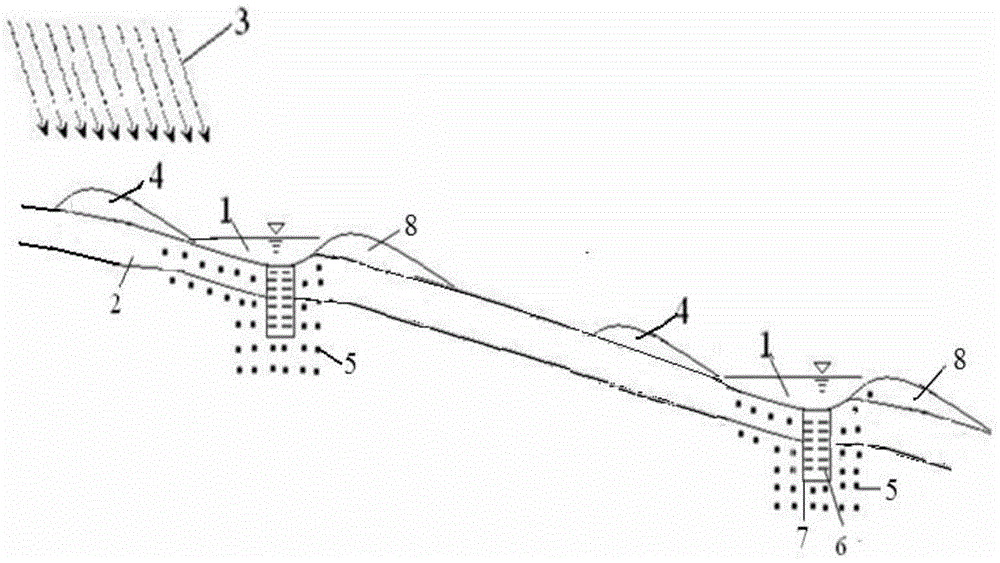

Method for counter-slope surface soil thickness increasing,permeation increasing and soil preparing of slope croplands

InactiveCN104604385AReduce churnImproved utilization of in-situ storageSoil-working methodsSoil horizonPermeation

The invention discloses a method for counter-slope surface soil thickness increasing,permeation increasing and soil preparing of slope croplands, and relates to a method for permeation increasing and soil preparing of slope croplands. The method aims at solving the technical problems that at present, through a method for preventing and controlling water and soil loss of slope croplands, the height equality is hard to achieve, the occupied cultivation area is large, surface soil layers are disorganized, and the output reduction is caused. The method includes the steps of conducting shoveling in the direction opposite to the water running direction of a furrow and upwards pushing topsoil to form an inner channel, digging a groove in the pit bottom of the inner channel, filling the groove with a mixture of straw, fine sand and topsoil, placing deep soil dug out of a water storage permeation increasing groove on the lower portion in the water running direction of the furrow, and conducting backfill on the surface of the inner channel and the surface of a counter-slope surface soil ridge so that the bottom of the inner channel can be located on the same horizontal line. The method has the advantages that the rainfall water level can be reduced, the water and soil conservation effect is improved, the soil and nutrient loss of slope cropland surface layers is reduced, the ridge directions of the slope croplands are not changed, no land area is occupied, and the method is particularly suitable for slope croplands in black soil regions in the Northeast with vast territory, sparse population and shallow topsoil.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

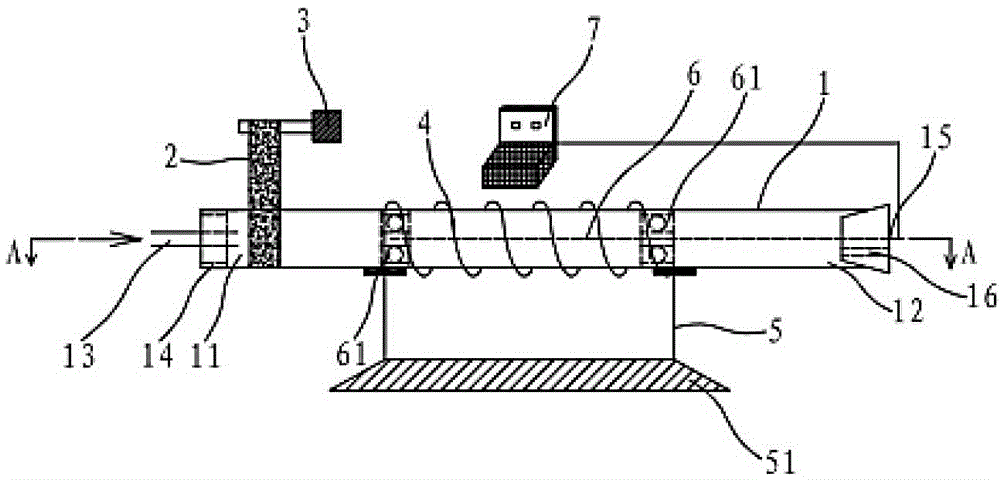

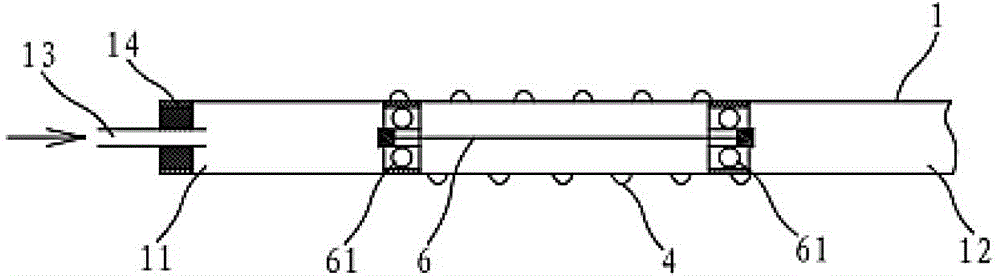

Device and method for modifying activated carbon adsorbent by using rotating low-temperature plasma

InactiveCN104549153ASave raw materialsPreparation conditions are ripeGas treatmentMethane captureVolatile organic compoundActivated carbon

The invention discloses a device for modifying an activated carbon adsorbent by using a rotating low-temperature plasma. A track is transmitted by a motor, and is wound on a quartz tube reactor, and the two ends of the quartz tube reactor are provided with an air inlet and an air outlet; a joint of an air inlet pipe is installed in the air inlet by means of a sealed bearing, and a discharge area is formed in the middle of the quartz tube reactor and is interspersed in a grounding coil; the diameter of the grounding coil is greater than the outer diameter of the quartz tube reactor, and the grounding coil is erected on a grounding support; a corona wire is erected inside the discharge area of the quartz tube reactor by means of a rolling bearing, penetrates out of the air outlet of the quartz tube reactor and is connected with an alternating current power supply. The invention also discloses a corresponding method. The device and the method provided by the invention have the advantages of easiness in operation, environment friendliness, economy, and large-scale production, the obtained absorbent is in a granular shape, the penetration time of the adsorbent can be prolonged, the CH4 adsorption capacity of the adsorbent can be increased, and the device and the method can be used for effectively enriching and separating CH4 gas with the concentration of 0.2% or used for the treatment field of volatile organic compounds (VOCs).

Owner:FUJIAN ZIJIN ENVIRONMENT ENG TECH

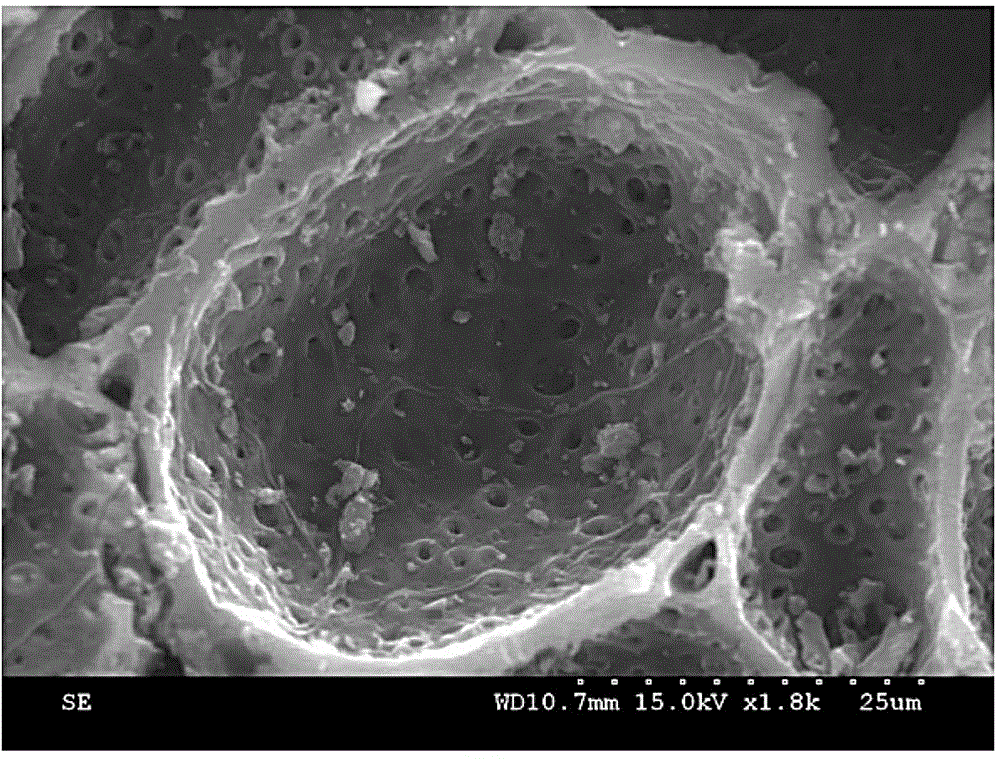

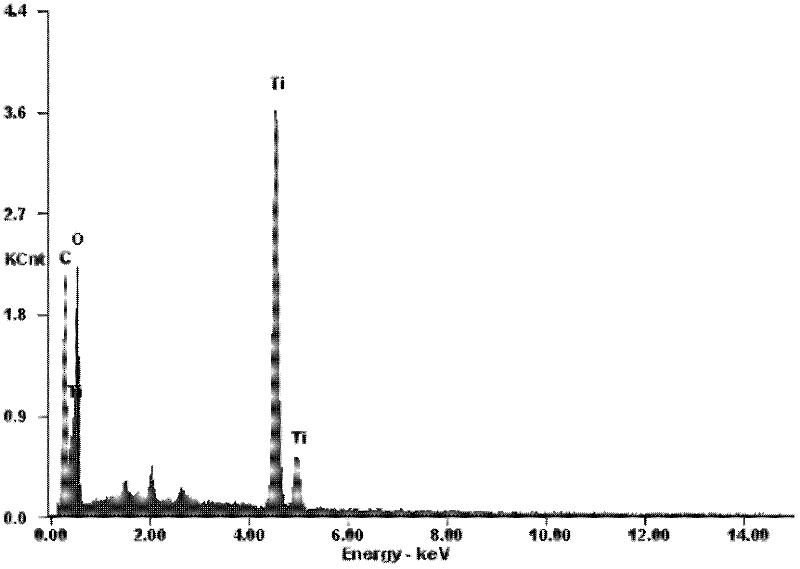

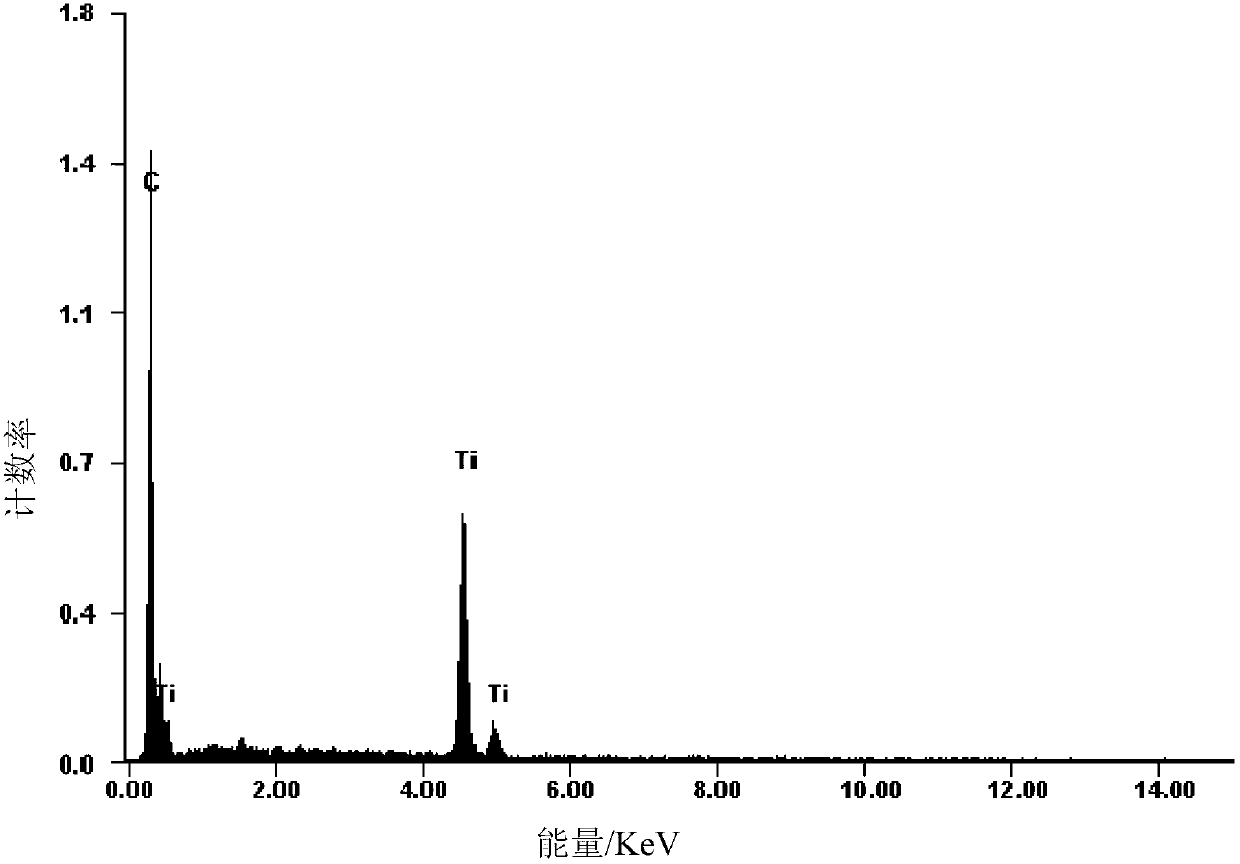

Preparation method of activated carbon adsorbent loaded with titanium dioxide

The invention relates to a preparation method of activated carbon adsorbent loaded with titanium dioxide, which belongs to the technical field of absorbent. The method comprises the following specific steps that: the activated carbon is pre-treated, washed and dried; titanium trichloride (TiCl3) solution is prepared into titanium trichloride-hydrogen chloride (TiCl3-HCl) solution with different molar concentration, and the TiCl3-HCl solution is transferred to the polyfluortetraethylene liner of a stainless steel reaction kettle; the treated activated carbon is added into the TiCl3-HCl solution, and the stainless steel reaction kettle is screwed and put into an electric heating constant temperature blowing dry box to be treated by hydrothermal treatment; and the activated carbon after hydrothermal treatment is washed and dried, and the activated carbon absorbent loaded with titanium dioxide is obtained. The preparation method of activated carbon adsorbent loaded with titanium dioxide has a simple process, is convenient to operate, obtains granular loaded absorbent, can improve the penetration time of the absorbent, does not use any organic solvent, nearly has no pollution in a production process, meets the requirements of sustainable development, and is an environmental-friendly production process.

Owner:BEIJING UNIV OF TECH

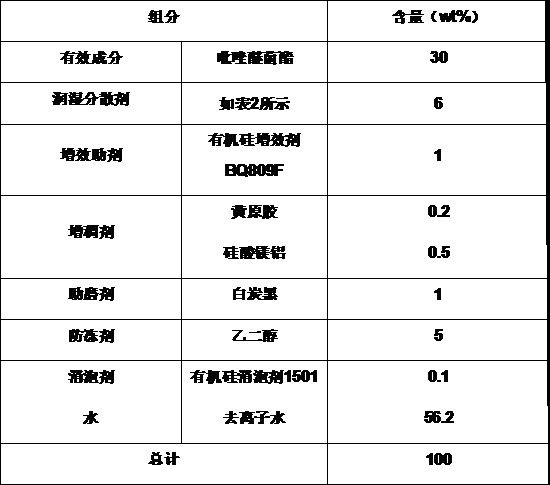

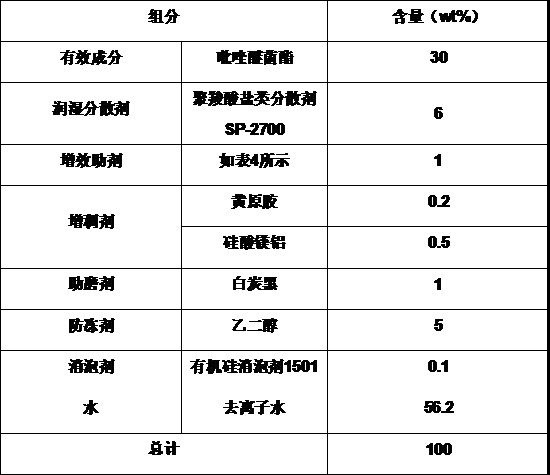

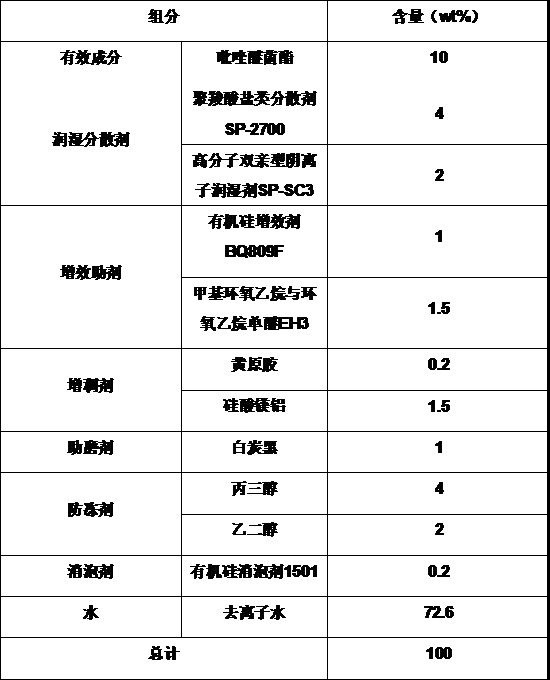

Pyraclostrobin suspending agent and preparation method thereof

ActiveCN112042663AGuaranteed stabilityExcellent heat storage and water analysis rateBiocidePlant growth regulatorsSuspending AgentsEnvironmental engineering

The invention provides a pyraclostrobin suspending agent and a preparation method thereof. The pyraclostrobin suspending agent comprises pyraclostrobin, a wetting dispersant, a thickener, an antifreezing agent, a defoamer, a synergistic aid, a grinding aid and water. According to the pyraclostrobin suspending agent, the particle sizes of the components in the suspension are ground to be smaller than or equal to 1 micron, the pesticide effect of the pyraclostrobin suspending agent can be improved, the unit area application amount of pyraclostrobin is effectively reduced, and pesticide resistance is avoided. Besides, the inventor screens proper wetting dispersant, synergistic assistant, thickener, grinding aid and proportion thereof to improve the stability of the suspension, so that the long-term stability of the suspension can be maintained even if the particle size of the components in the suspension is ground to be less than or equal to 1 mu m.

Owner:HUIZHOU YINNONG TECH

Technique for promoting dye permeability and depth of active dye

ActiveCN108103694AIncrease penetration timeAvoid the problem that it is not easy to penetrate into the fiberLiquid/gas/vapor removalTextile storageTextile printerFiber

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a technique for promoting dye permeability and depth of active dye. The dyeing processing flowis pretreatment fabric->dye padding->piling->first drying->padding with fixation fluid->gas steaming-> high temperature soaping->second drying-> post finishing; the piling temperature is 20-26 DEG C and the piling time is 4-10 hours. The method can increase the permeation time of the dye in the inner part of the fabric, avoid the problems that the continuous dyeing padding time is short and the dye is directly dried after dyeing and the dye is not easy to permeate to the inner part of fiber, avoid the problems of too early fixation of dye and fiber due to the mixing of the cold rolling dye andthe fixation fluid and the dye permeability effect of the active dye goes bad, and promote the permeability of dye; the dye can be fully dissolved and absorbed and spread to the fiber; the techniqueis good for the reaction of dye and fiber in the subsequent fixation, and able to improve the dyeing rate and the utilization rate of the dye; through contrast, the dyeing depth can be promoted by about 15%, and the dyeing cost is greatly reduced.

Owner:鲁丰织染有限公司

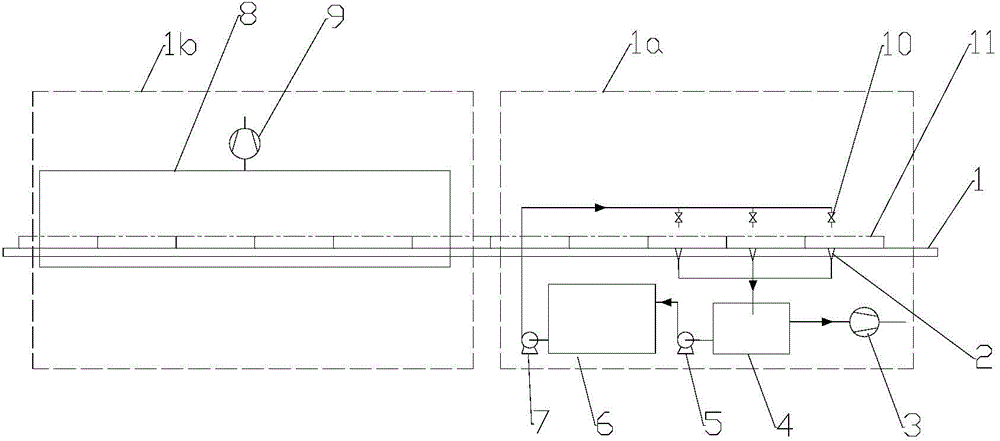

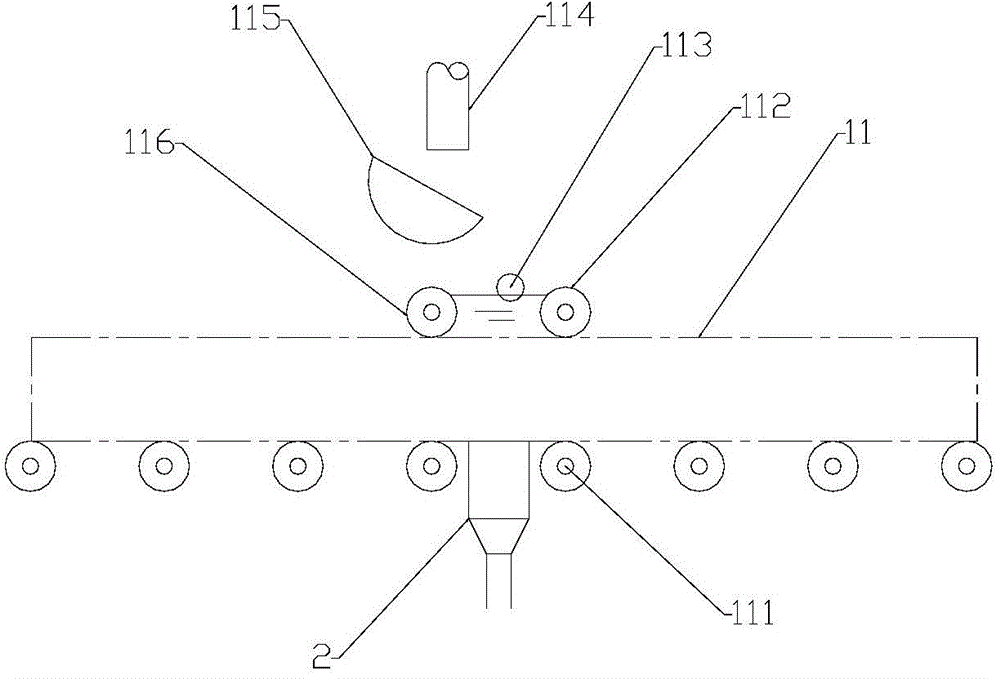

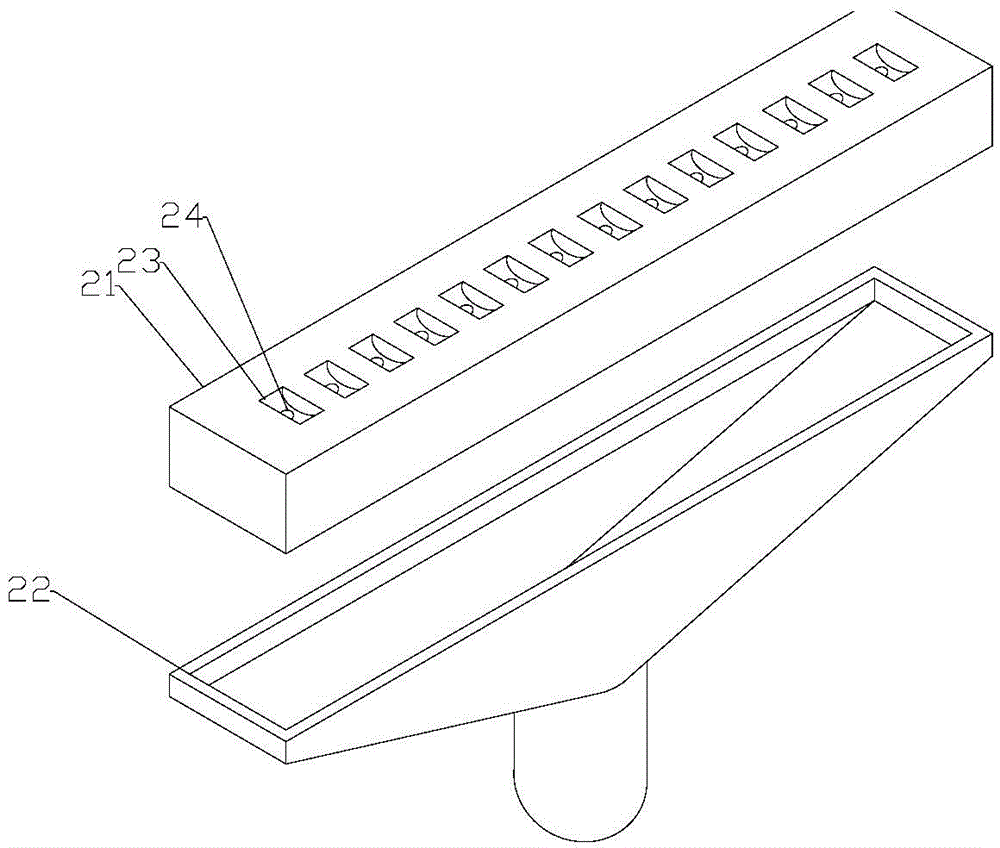

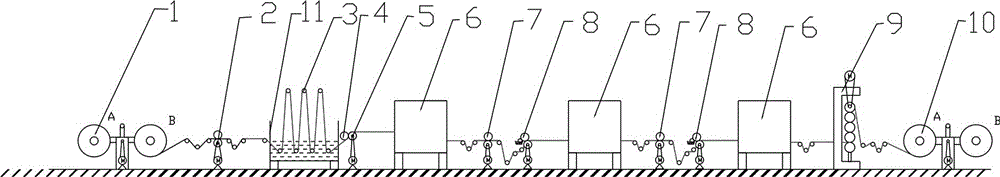

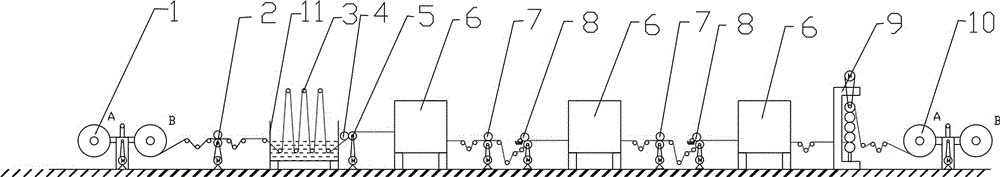

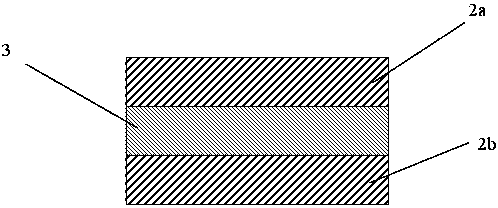

Production method and production equipment of fireproof polystyrene board

ActiveCN104385633ALittle change in thermal conductivityReduce dosageFlat articlesVapor–liquid separatorGas phase

The invention discloses a production method and production equipment of a fireproof polystyrene board. The production method comprises the following steps: pouring or spraying a liquid fire retardant on the upper surface of a polystyrene board, vacuumizing the polystyrene board on the lower surface of the polystyrene board to ensure that the liquid fire retardant flows through pores inside the whole polystyrene board from top to inside under the actions of gravity and a pressure difference so as to wrap the surfaces of polystyrene beads; and then drying to ensure that the fire retardant is cured. The production equipment comprises a conveyor line for conveying the polystyrene board, and a fire retardant container, wherein a fire retardant spreader is arranged above a permeating section of the conveyor line, the fire retardant spreader is communicated with the fire retardant container through a pipeline as well as a control valve and / or pump. The production equipment further comprises a vacuum pump, wherein the vacuum pump is connected with a gas phase outlet of a gas-liquid separator, an inlet of the gas-liquid separator is communicated with a gas collector by virtue of a pipeline, a gas inlet of the gas collector is formed in a position of a conveying surface of the permeating section of the conveyor line and faces upwards; on a curing section of the conveyor line, the conveyor line penetrates through a curing furnace. According to the invention, the production efficiency is high and the product quality is good; the fireproof performance can reach an A2 level.

Owner:天津佳华炜业建材科技有限公司

3D science paper as well as production method and production equipment thereof

ActiveCN104562848AHigh hardnessImprove wear resistanceNon-fibrous pulp additionPaper/cardboardCross-linkEnvironmental resistance

The invention provides 3D science paper as well as a production method and production equipment thereof. The 3D science paper is prepared by soaking printing decorative paper serving as a raw material into glue with high transparency, wherein the glue comprises the following components in percentage by weight: 20-30% of polyurethane, 30-50% of acrylic resin, 1-3% of a cross-linking agent, 1-3% of a curing agent, 3-5% of a permeating agent, 1% of a flatting agent and the balance of water. The 3D science paper has an extremely good homochromatic effect, does not have chromatic aberration, is high in hardness, scratch-resistant, wear-proof and good in toughness, can be bent for 180 degrees without cracking, and is favorable for packaging. Moreover, the raw materials, aids, resin and the like in the production process of the product are water-soluble, so the 3D science paper is nontoxic and environmentally friendly.

Owner:HANGZHOU TALENT DECORATION PAPER

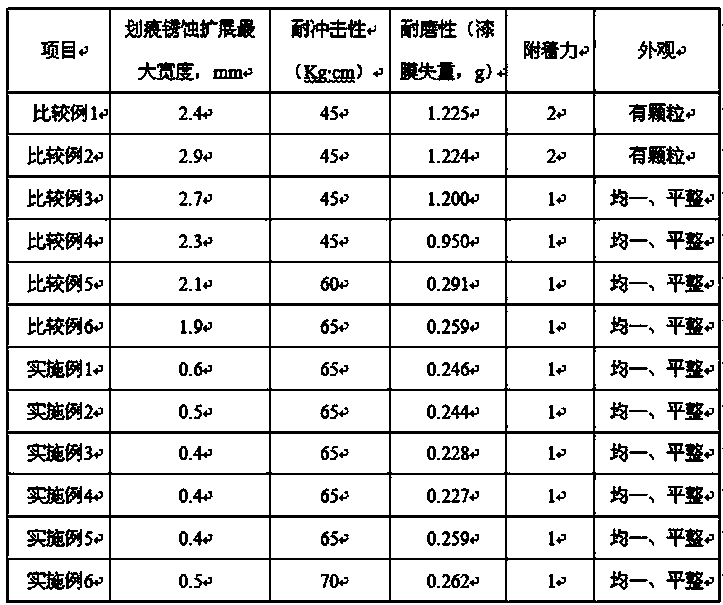

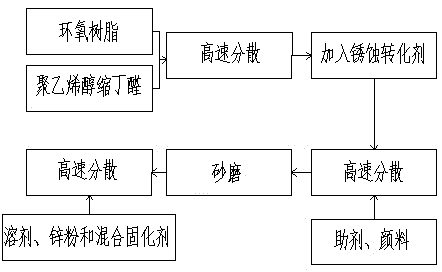

Aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and preparation method thereof

ActiveCN103834264AWith \"passivation\"Has a \"sustained release\" effectAnti-corrosive paintsEpoxy resin coatingsCoating systemFirming agent

The invention discloses aluminum oxide-containing polyaniline zinc powder flake epoxy heavy anti-corrosion coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises the following components in parts by mass: 35-85 parts of epoxy resin, 0.5-25 parts of polyaniline zinc powder flake, 0.1-10 parts of aluminum oxide, 0.1-5 parts of pigment, 1-15 parts of packing, 0.01-2 parts of anti-sag agent, 0.01-0.5 part of dispersant, 0.01-2 parts of flatting agent, 0.01-0.5 part of deforming agent and 5-40 parts of mixed solvent; and the component B comprises the following components in parts by mass: 40-90 parts of amine curing agent and 10-60 parts of solvent; and the coating is prepared by mixing and stirring the component A and the component B for 1-5 minutes according to a mass ratio being 1: (0.1-1):1. The corrosion resistance, seawater erosion and abrasion resistance, ageing resistance and anti-penetrating property of the coating system are obviously improved; and the coating can be applied to heavy anti-corrosion engineering in fields of petrochemical equipment, pipelines, offshore oil platforms, berthing facilities, ships and the like.

Owner:HOHAI UNIV

Antirust paint processing transmission tower surface and preparation method thereof

InactiveCN104403512AGood flexibilityReduce brittlenessAnti-corrosive paintsEpoxy resin coatingsTransmission towerZinc phosphate

The invention discloses antirust paint processing a transmission tower surface and a preparation method thereof, and relates to the technical field of transmission tower surface protection. The antirust paint processing the transmission tower surface comprises, 15%-17% of epoxy resin E-44, 6%-9% of polyvinyl butyral, 5%-7% of zinc phosphate, 3%-6% of aluminum triphosphate, 1%-4% of zinc borate, 20%-40% of flake zinc powder, 1%-2% of organic bentonite, 4%-7% of a corrosion conversion agent, 20%-26% of a solvent, and 4%-7% of a mixed curing agent. The paint is excellent in corrosion resistance, strong in adhesive force with the transmission tower surface, not easy to fall off and long in protective life, the preparation technology is simple and easy to operate, and automatic production can be realized.

Owner:WENZHOU TAICHANG TOWER MFG

High-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick and preparation method thereof

The invention discloses a high-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick, which is prepared from the following materials by mass: 16.30% of steel fibers, 0.04% of polypropylene fibers, 18.00-19.00% of cement, 5.40-5.60% of water, 2% of fly ash, 2% of slag powder, 2.60-3.00% of silica fume, 15.50-16.50% of sand, 36.00-37.00% of gravel, and 0.36% of an efficient water reducing agent. According to the present invention, the high-content grading fiber recycling aggregate concrete bulletproof explosion-proof brick has excellent compressive resistance, excellent tensile resistance, excellent bending resistance and excellent impact toughness compared to the clay bricks and the ordinary cement bricks, and is the novel high-performance composite material brick integrating high strength, bullet resistance, impact resistance, weight loading, bearing, wear resistance, and environment protection; and the purposes of resource saving and effective arable land and environment protection are achieved.

Owner:HUANGHE S & T COLLEGE

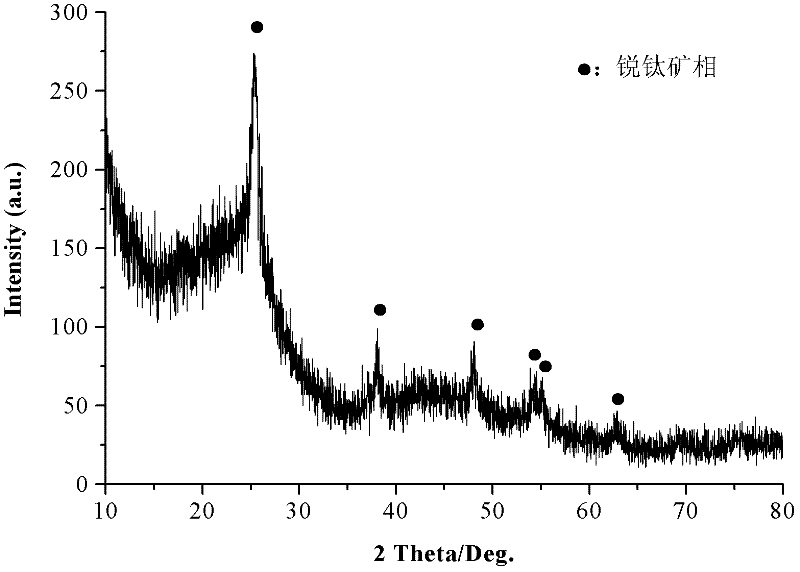

Formula and preparation method of activated carbon adsorbent for formaldehyde and methane adsorption

InactiveCN109277077AIncrease the number ofRaise the ratioGas treatmentPhysical/chemical process catalystsSorbentFiltration

The invention provides a formula and preparation method of an activated carbon adsorbent for formaldehyde and methane adsorption. The formula comprises modified activated carbon, a TiCl3 solution anda hydrochloric acid solution, and the preparation method comprises the following specific steps: performing pretreatment with ultrasonic wave activated carbon, and performing water washing and drying;performing pulverizing and calcining on bentonite; grinding the bentonite and activated carbon, and performing drying; performing hydrothermal treatment in a mixed solution of the TiCl3 solution withthe hydrochloric acid solution, and performing washing, suction filtration and drying; and performing calcination, and reducing the temperature to room temperature so as to obtain the activated carbon adsorbent for formaldehyde and methane adsorption. Through the activated carbon adsorbent produced by using the method, the number and proportion of mesopores of activated carbon are increased, thepenetration time of the adsorbent is improved, high catalytic oxidation ability and faster decomposition speed of formaldehyde and methane are achieved, and no by-products with pollution to the environment are produced in the preparation process; and in addition, the adsorbent also has a certain adsorption-decomposing effect on multiple small-molecule organic substances.

Owner:TIANJIN PURUITE PURIFICATION TECH

High-content hybrid fiber concrete bulletproof and explosionproof brick and preparation method thereof

The invention discloses a high-content hybrid fiber concrete bulletproof and explosionproof brick. The brick is prepared from, by mass, 14.21% of steel fibers, 0.04% of polypropylene fiber, 19.00%-19.80% of cement, 5.40%-5.80% of water, 17.00%-18.00% of sand, 37.50%-38.50% of crushed stone, 2.60%-3.00% of silica fume, 2.00% of fly ash and 0.45% of efficient water reducing agent. The high-content hybrid fiber concrete bulletproof and explosionproof brick has the advantages that the brick body has excellent dynamic and static mechanical properties of compression resistance, tensile resistance, bending resistance, shock resisting penetration, shock resisting toughness and the like, and the purpose of resisting bullets and preventing an explosion are achieved.

Owner:HUANGHE S & T COLLEGE

Silane paste protection agent

The invention discloses a silane paste protection agent. The silane paste protection agent is prepared from, by weight, 90-110 parts of silane monomers, 3-5 parts of an effective emulsifier, 10-30 parts of deionized water, 0.5-1.5 parts of a thickener, 0.5-1 part of an antioxidant and 0.2-0.4 part of a buffer solution. A preparing technology of the silane paste protection agent includes the first step of mixing and the second step of mixing. The silane paste protection agent overcomes the defects that a traditional concrete anti-corrosion coating is airtight, moisture in concrete can not volatilize easily, the coating structure is damaged, and the anti-corrosion performance is poor. Besides, compared with a liquid silane impregnation agent, the silane paste protection agent has the advantages that the silane paste protection agent has thixotropy and non-flowability, so that the number of painting times is reduced, the penetration time is prolonged, and the penetration depth is increased; a self-crosslinking reaction can happen, silane or siloxane in the product can be self-crosslinked with water under paste demulsification, and it is not required that concrete provides extra moisture for the reaction.

Owner:CARBON COMPOSITESTIANJIN CO LTD

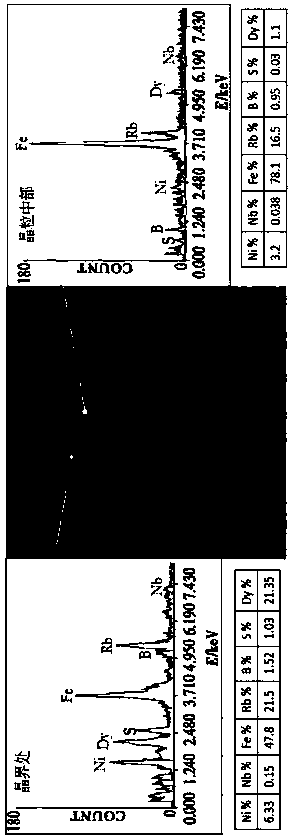

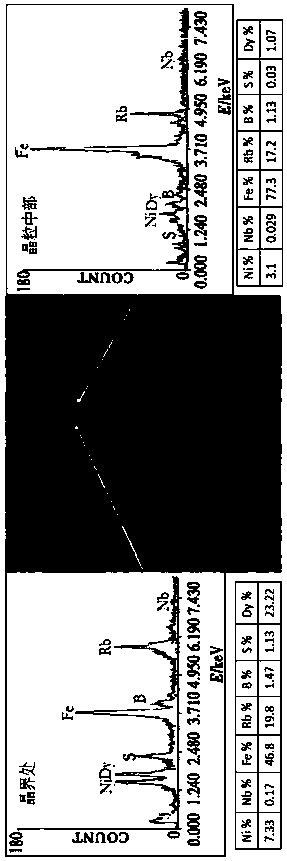

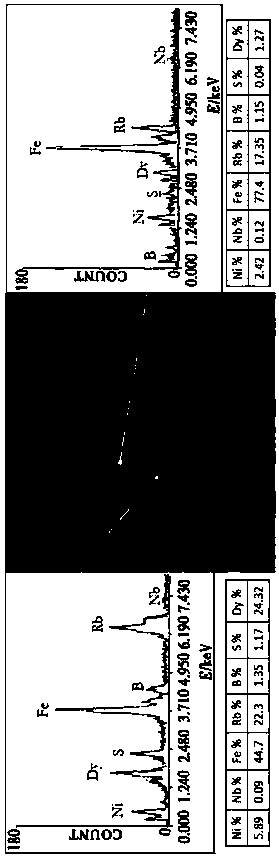

Inclusion precipitation control technology for silicon steel for motor

InactiveCN108766702AImprove coercive forceLow efficiencyInductances/transformers/magnets manufactureMagnetic materialsRubidiumNiobium

The invention relates to a permanent magnet material, in particular to a permanent magnet material for a motor and a processing technology for the permanent magnet material. The permanent magnet material comprises the following elements in percentages by mass: 16-17.8% of Rb (rubidium), 75.7-76.6% of Fe (ferrum), 1.1-1.3% of B (boron), 2-3.5% of Dy (dysprosium), 2.4-3.3% of Ni (nickel), 0.07-0.09%of S (sulfur) and 0.025-0.04% of Nb (niobium). All alloys and pure iron are put into a smelting furnace to be smelted according to a smelting principle, spinning, crushing and molding in a magnetic field are carried out, and sintering is finally carried out to obtain a finished product. According to the permanent magnet material, the limitations that a relatively thick product cannot be processedand the penetration time is long, of the conditions, such as the diffusion rate on a traditional penetration method are broken through. Precipitation of the Dy element at a grain boundary is achievedin solidification and subsequent secondary phase transition processes of molten steel through directly adding the Dy element in the smelting process. The target of improving the coercivity of the permanent magnet material is finally achieved. According to the permanent magnet material, the influence of the thickness of the material is avoided, the high-coercivity permanent magnet material with any thickness can be produced and the processing efficiency is high.

Owner:LUAN MICRO & SPECIAL MOTOR

A kind of 3D technology paper and its production method and production equipment

ActiveCN104562848BHigh hardnessImprove wear resistanceNon-fibrous pulp additionPaper/cardboardCross-linkAcrylic resin

The invention provides 3D science paper as well as a production method and production equipment thereof. The 3D science paper is prepared by soaking printing decorative paper serving as a raw material into glue with high transparency, wherein the glue comprises the following components in percentage by weight: 20-30% of polyurethane, 30-50% of acrylic resin, 1-3% of a cross-linking agent, 1-3% of a curing agent, 3-5% of a permeating agent, 1% of a flatting agent and the balance of water. The 3D science paper has an extremely good homochromatic effect, does not have chromatic aberration, is high in hardness, scratch-resistant, wear-proof and good in toughness, can be bent for 180 degrees without cracking, and is favorable for packaging. Moreover, the raw materials, aids, resin and the like in the production process of the product are water-soluble, so the 3D science paper is nontoxic and environmentally friendly.

Owner:HANGZHOU TALENT DECORATION PAPER

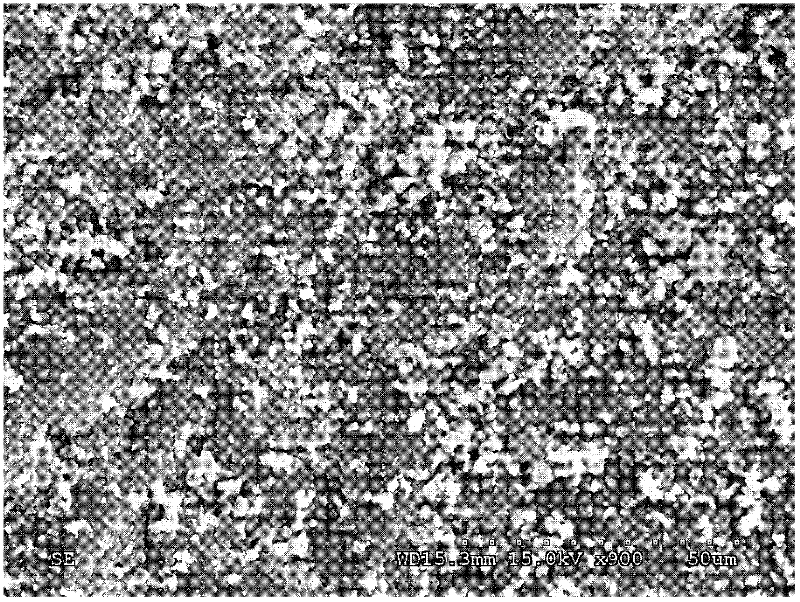

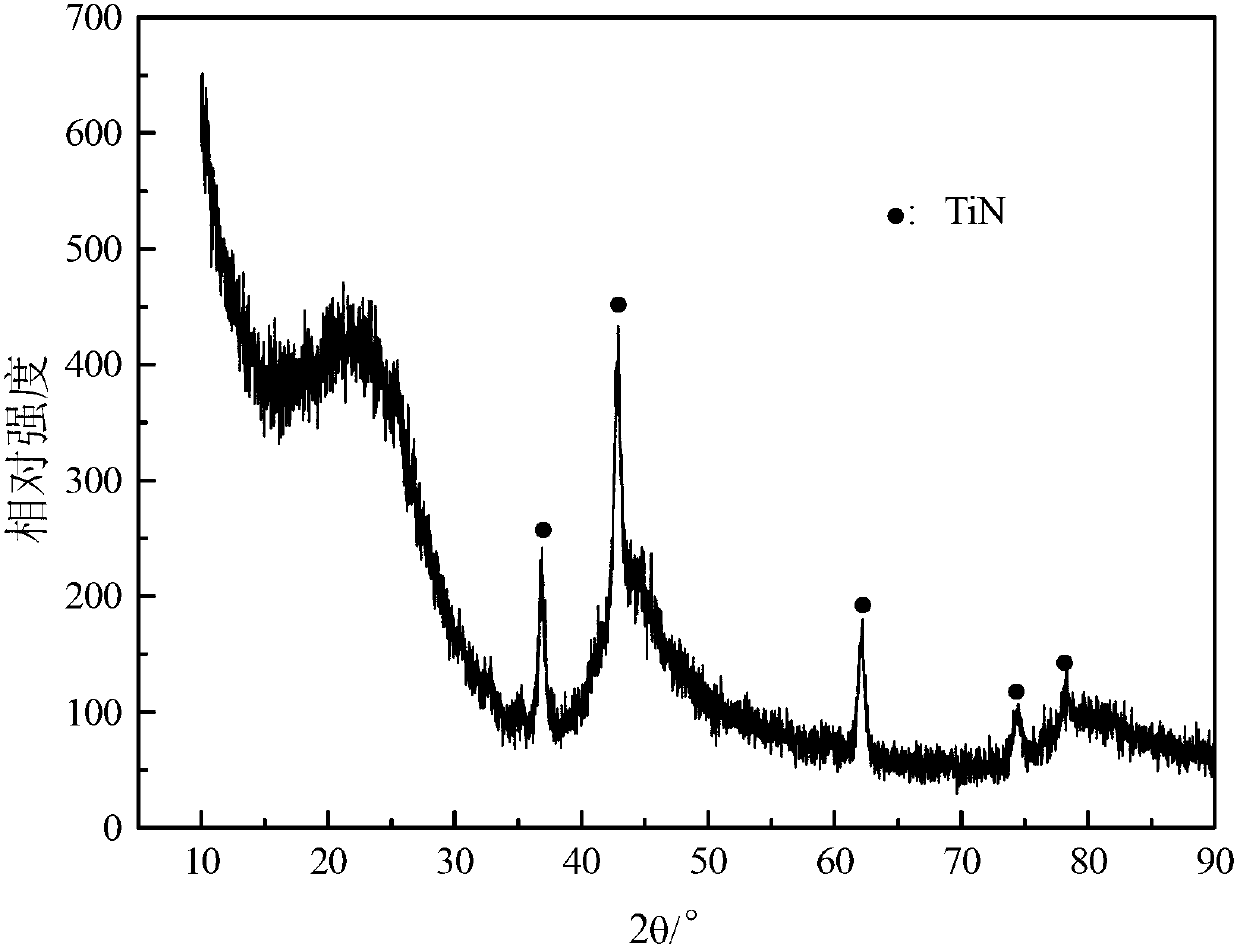

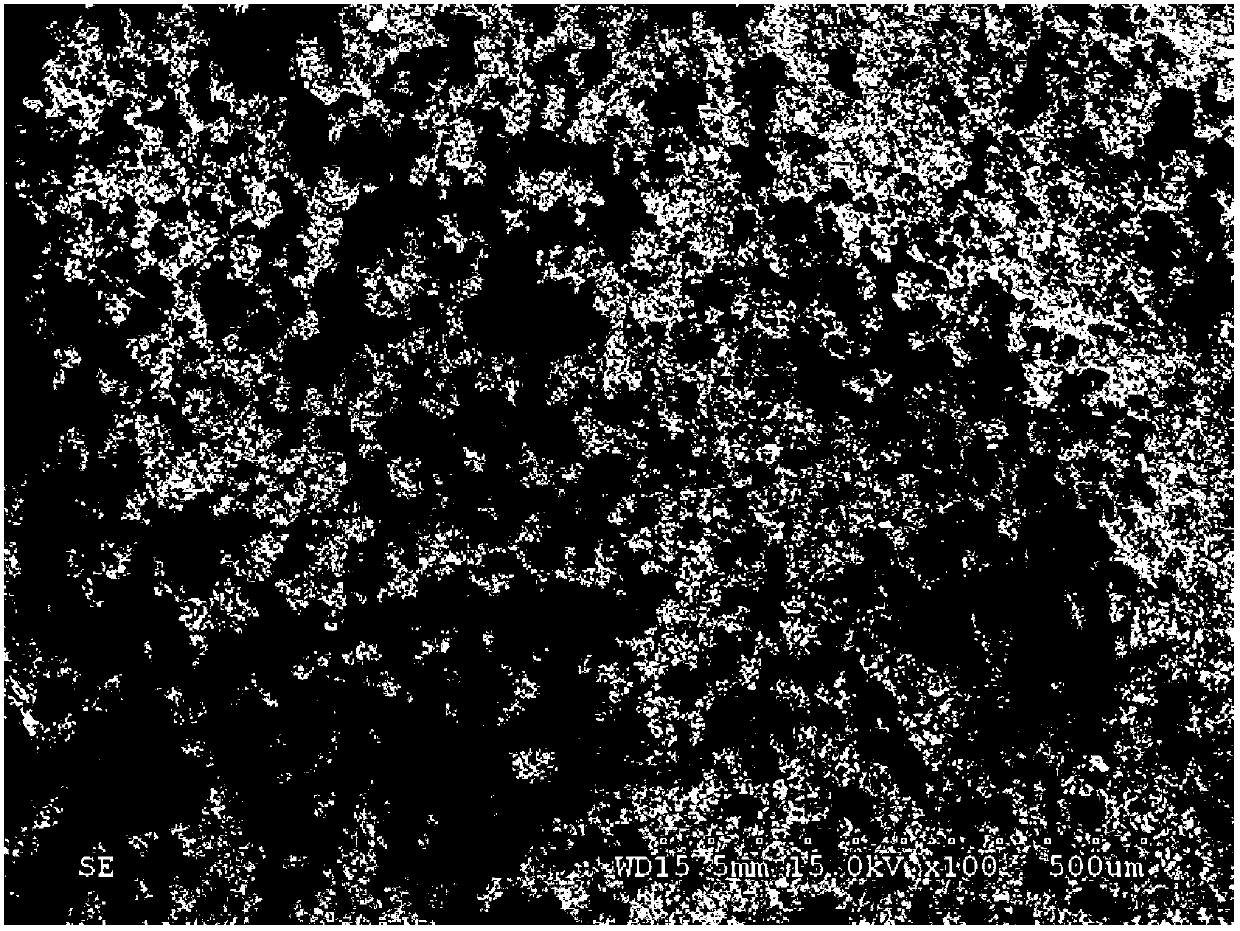

Titanium nitride-loaded active carbon adsorbent and preparation method thereof

Owner:BEIJING UNIV OF TECH

Anti-wrinkle tidying method for pure cotton fabric

InactiveCN101942750BImprove wrinkle resistanceImprove flatnessSucessive textile treatmentsFibre treatmentOrganic acidBrute force

Owner:TIANJIN TIANGE TEXTILE

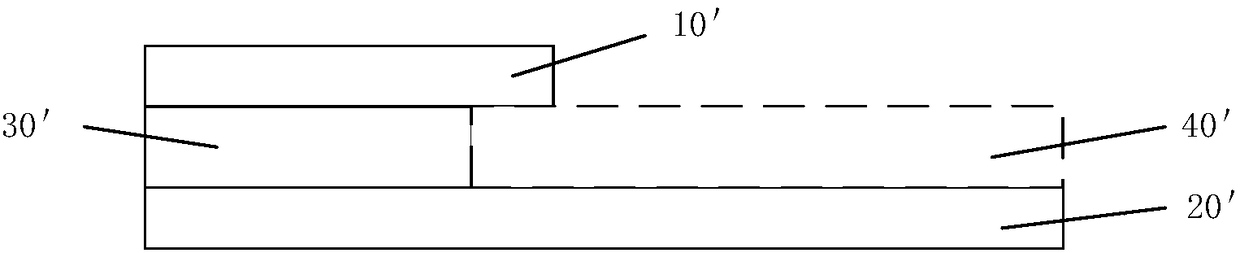

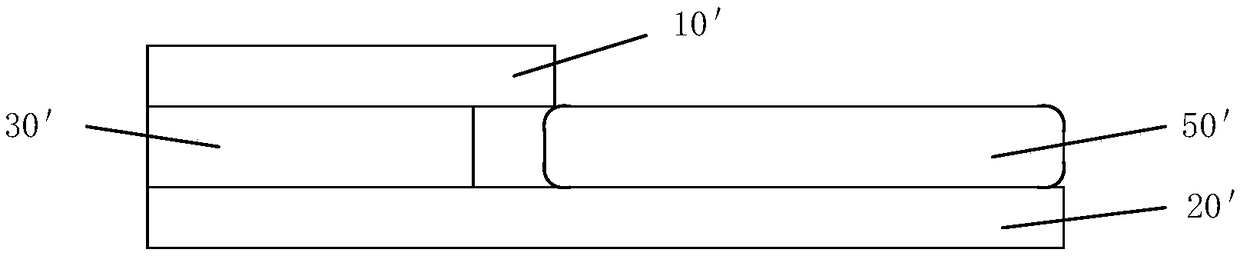

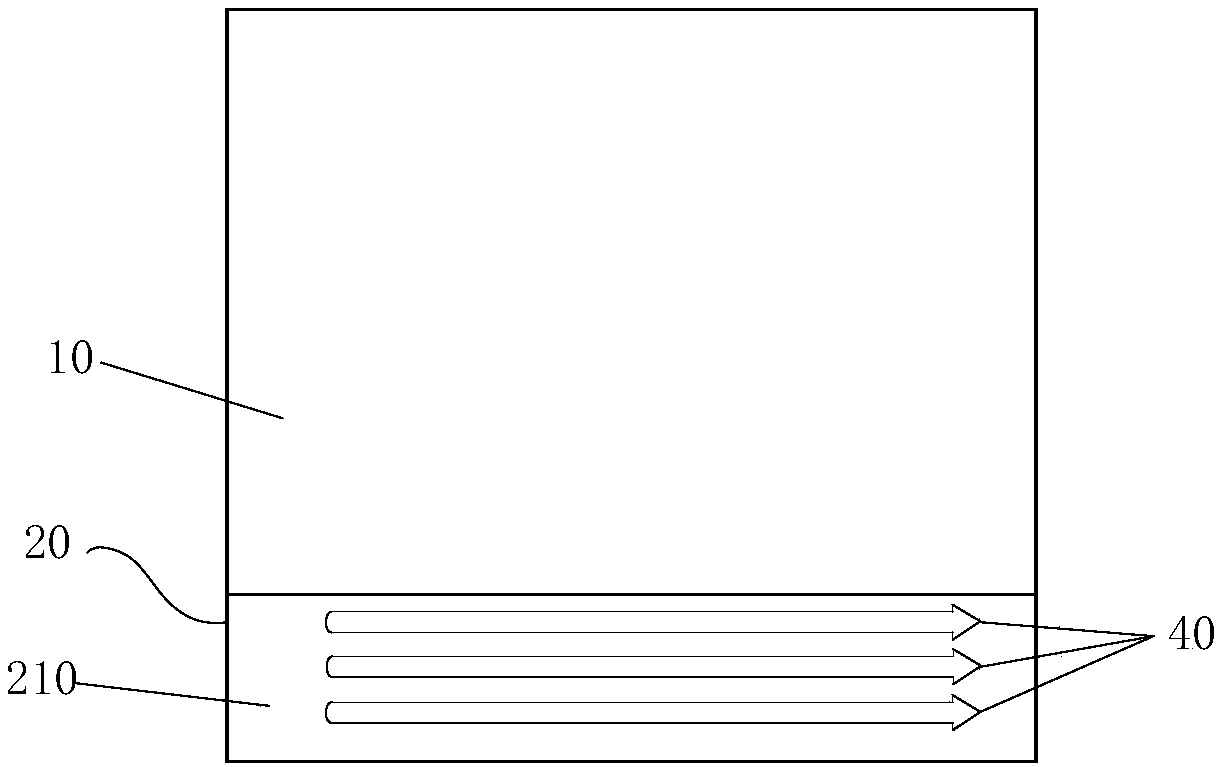

Sealing method of display screen frame

The invention provides a sealing method of a display screen frame. The sealing method of the display screen frame comprises the following step: coating a to-be-coated region in the direction of a first edge which is parallel to an upper substrate by using glue so that a plurality of gluing regions are formed on a lower substrate by various coating processes in a one-to-one correspondence manner, wherein the various gluing regions are successively formed along the direction which is away from the first edge. Therefore, the inner side of the first edge which is close to the to-be-coated region is coated with glue, then step-by-step outward coating is carried out, multiple gluing regions can be formed on the to-be-coated region, penetration time of the gluing region on the inner side is prolonged relatively, a seam can be filled with glue which is close to the gluing region of the first edge as much as possible, the amount of glue which permeates into the seam is increased, uniformity ofsolidified glue of the inside and the outside of the seam after the glue is solidified is improved effectively, and the sealing effect of the display screen frame is improved. In addition, the efficiency of the sealing process is improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

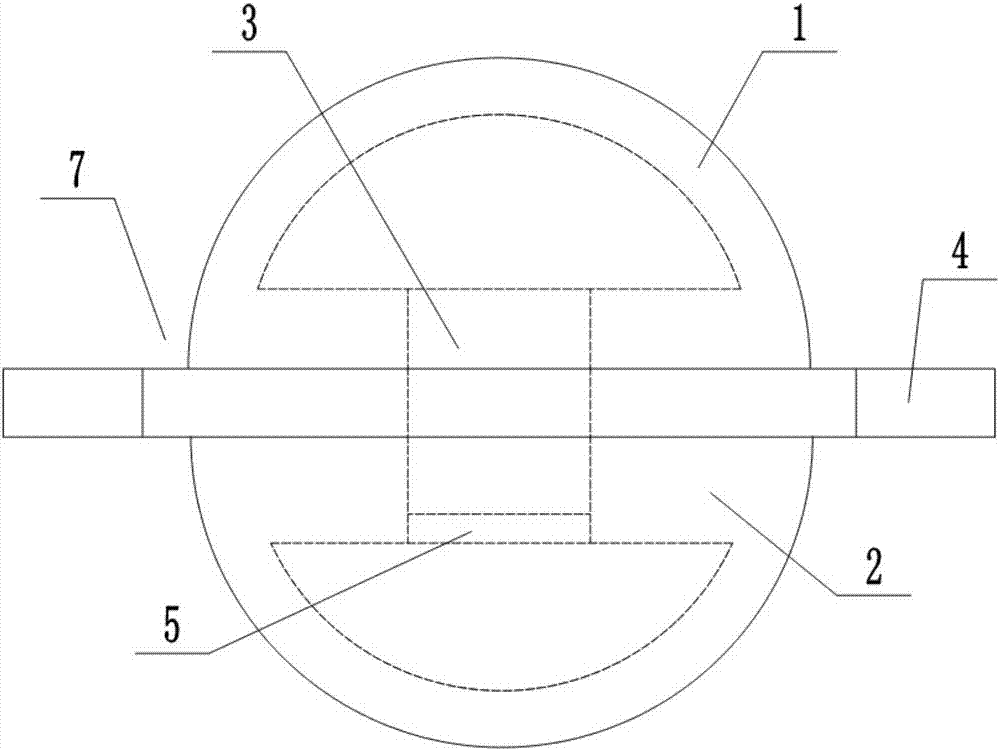

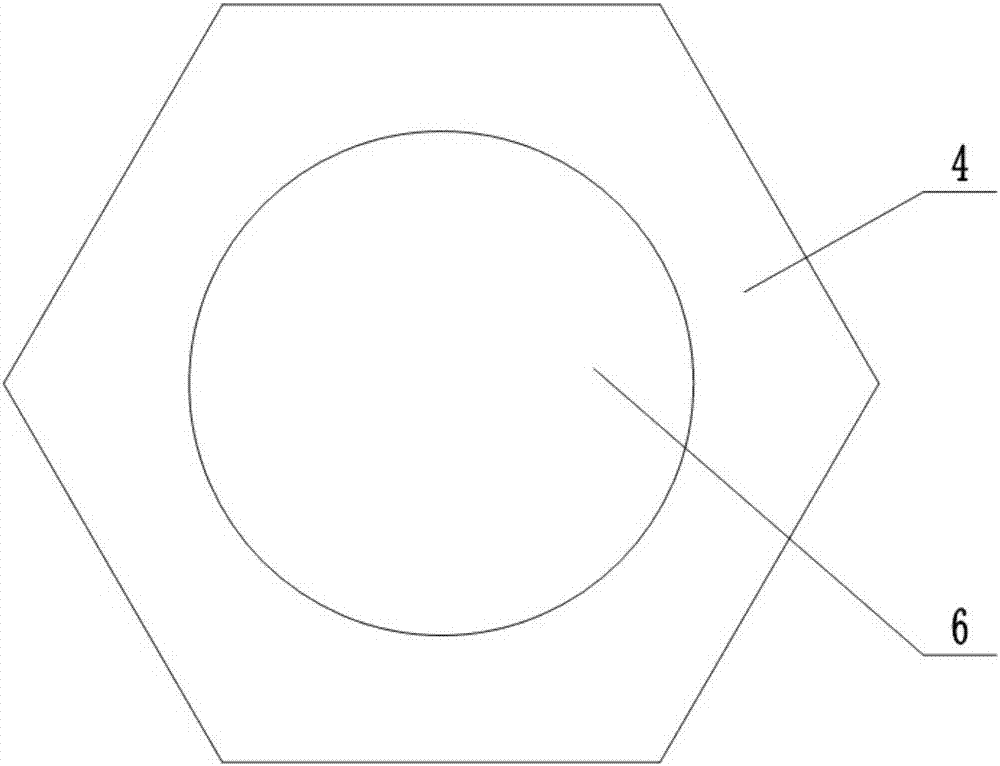

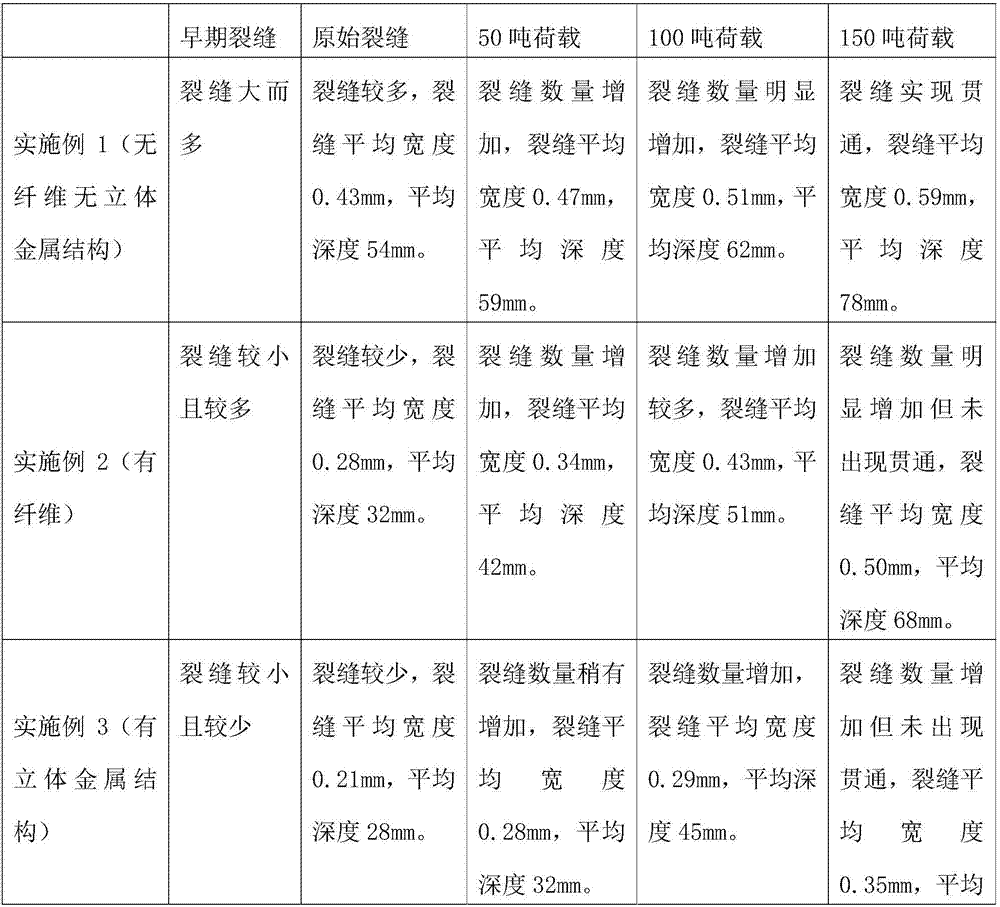

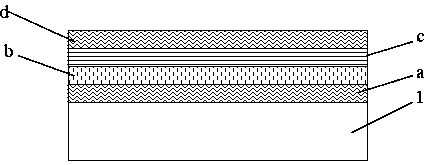

Crack-resistant reinforced concrete

The invention belongs to the field of building materials, and particularly discloses crack-resistant reinforced concrete. The crack-resistant reinforced concrete comprises the following components: athree-dimensional metal structure, an aggregate, low-alkali cement, fly ash, mineral powder, silica fume, a cement mortar defoaming agent and a coupling agent; the three-dimensional metal structure comprises a sphere and a ring plate; the sphere comprises an upper hemisphere and a lower hemisphere; a connecting rod is arranged on the upper hemisphere; the ring plate is arranged on the connecting rod; the lower hemisphere is provided with a connecting groove; and the connecting groove is connected with the connecting rod. The crack-resistant effect of the crack-resistant reinforced concrete inthe scheme is obvious, the tensile strength and anti-cracking strength are greatly improved, and the concrete can be used to prevent early cracks during a casting period; the tensile strength and theanti-cracking effect are improved during the solidification of the concrete, original cracks of the concrete interface are reduced and even eliminated, and the crack-resistant effect is achieved; after the solidification, further expansion of the cracks is prevented, the penetration time of the cracks is prolonged, and deformation of the three-dimensional metal structure can be utilized to preventfurther expansion of the cracks, so that the crack resistance effect is further enhanced.

Owner:CHONGQING VOCATIONAL INST OF ENG

A method for preparing recycled corrugated base paper using rosin-modified starch surface sizing

ActiveCN107354788BEasy to integrateFunction increaseMechanical working/deformationPaper recyclingFiberAdhesive

The invention discloses a method for preparing regenerated corrugated paper base paper through rosin modified starch surface sizing. The corrugated paper base paper produced through the preparation method can be prepared into various corrugated paperboards and corrugated cartons through an adhesive, has good moisture-proof and waterproof effects, is long in water flow permeation time, has certain compressive strength, and is good in quality and not easy to break; recycled waste paper, cottonseed hulls and other substances serve as raw materials, so that the cost is low, energy conservation and consumption reduction are achieved, waste is utilized, wood pulp fiber resources are saved, and the process is convenient to control.

Owner:义乌市申图包装有限公司

Method for carbonitriding on stainless steel surface

InactiveCN111500971AUniform steel structureFully release the stressSolid state diffusion coatingRare-earth elementTempering

The invention discloses a method for carbonitriding on a stainless steel surface. By quenching and tempering and ion implanting of rare earth elements on the stainless steel surface, the temperature,carbon potential and ammonia flow rate in a carbonitriding process can be fully controlled. A thickness and a microstructure of a carbonitriding layer on the stainless steel surface can be effectivelycontrolled, and stainless steel products with high strength, high hardness, good wear resistance and excellent fatigue resistance can be obtained. The method for carbonitriding on the stainless steelsurface has the good advantages of short production cycle, simple method and high production efficiency and can be applied to industrial production.

Owner:广州珈鹏科技有限公司

Combined cultivation method for water and soil conservation for sloping farmlands

InactiveCN102498779BReduce churnLoss avoidance or mitigationSoil-working methodsBiologyContour plowing

A combined cultivation method for water and soil conservation for sloping farmlands relates to cultivation methods for water and soil conservation and solves the problem that using the single cultivation technique for holding water is unsatisfactorily effective. The combined cultivation method includes: firstly, adjusting ridges of sloping farmlands on downward slopes and inclined slopes under ridge plowing adjusted into transverse slope ridges, and adopting contour farming and belt planting; secondly, building ridges, and planting protective plant belts on the ridges; thirdly, subsoiling forfarming; fourthly, performing furrow damming; and fifthly, performing no-tillage conservation tillage. Furrow subsoiling and furrow damming are technically combined and integrated according to soil and weather characteristics of a black soil area, so that water and soil loss is reduced or avoided for sloping farmlands to the greatest extent, water and soil are conserved, water utilization rate isincreased, and crop yield is increased evidently. By the method, soil saturation and infiltration speed ratio is increased by 24.1% in processing treatment, water utilization rate is increased by more than 15%, crop yield is 30kg per mu, and 100 Yuan per mu is increased..

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Bulletproof explosion-proof brick of high-content gradation fiber recycled aggregate concrete and preparation method thereof

InactiveCN106116343BPenetration preventionIncrease penetration timeCompressive resistanceWater reducer

Owner:HUANGHE S & T COLLEGE

Teflon paint coating method

InactiveCN103894326AReduce omission rateImprove flatnessLiquid surface applicatorsCoatingsMetallurgyCoating

Disclosed is a telfon paint coating method. The telfon paint coating method includes that: telfon paint made from a same material is coated in different coatings; the telfon paint made from different materials is coated in layers so as to enable a formed final coating to be provided with characteristics of teflon in multiple varieties, due to the fact that the teflon coatings made from different materials are different in permeability and permeability characteristics, permeating speeds and permeating directions of the coatings after coating in layers are further changed, and the final telfon coating comprising a plurality of materials is enabled to be longer in permeating time and service life. A plurality of coatings are coated on the surface of a workpiece, so that flatness of the surface of the workpiece after integral coating can be improved; due to the fact that paint contrasted in colors is adopted to adjacent coatings, a coating effect can be directly obtained by observing colors of the workpiece during coating, missed points of the coatings can be obviously displayed to be found and recognized, and missing rate for coating is lowered.

Owner:天津瑞唐科技有限公司

A method of soil preparation for sloping cultivated land with reverse slope and soil accumulation

InactiveCN104604385BReduce churnImproved utilization of in-situ storageSoil-working methodsSoil horizonPermeation

The invention discloses a method for counter-slope surface soil thickness increasing,permeation increasing and soil preparing of slope croplands, and relates to a method for permeation increasing and soil preparing of slope croplands. The method aims at solving the technical problems that at present, through a method for preventing and controlling water and soil loss of slope croplands, the height equality is hard to achieve, the occupied cultivation area is large, surface soil layers are disorganized, and the output reduction is caused. The method includes the steps of conducting shoveling in the direction opposite to the water running direction of a furrow and upwards pushing topsoil to form an inner channel, digging a groove in the pit bottom of the inner channel, filling the groove with a mixture of straw, fine sand and topsoil, placing deep soil dug out of a water storage permeation increasing groove on the lower portion in the water running direction of the furrow, and conducting backfill on the surface of the inner channel and the surface of a counter-slope surface soil ridge so that the bottom of the inner channel can be located on the same horizontal line. The method has the advantages that the rainfall water level can be reduced, the water and soil conservation effect is improved, the soil and nutrient loss of slope cropland surface layers is reduced, the ridge directions of the slope croplands are not changed, no land area is occupied, and the method is particularly suitable for slope croplands in black soil regions in the Northeast with vast territory, sparse population and shallow topsoil.

Owner:HEILONGJIANG PROVINCIAL HYDRAULIC RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com