3D science paper as well as production method and production equipment thereof

A technology paper, 3D technology, applied in paper, paper, textile and paper making, etc., can solve the problems of different colors, wear resistance, poor hardness, etc., to achieve the effect of unchanged color, good wear resistance and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

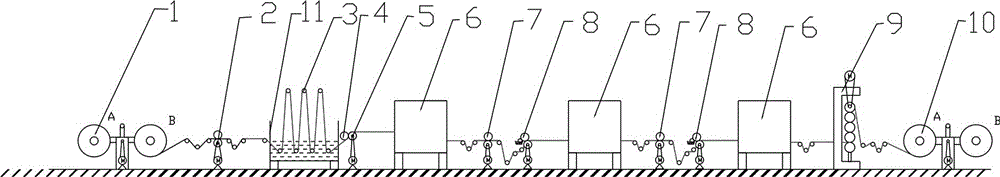

Image

Examples

Embodiment 1

[0030] The glue is formulated according to the following weight ratio: soft polyurethane 10%, hard polyurethane 10%, soft acrylic resin 15%, hard acrylic resin 15%, crosslinking agent 1%, curing agent 1%, penetrating agent 3%, leveling agent 1%, the balance is water.

Embodiment 2

[0032] The glue is formulated according to the following weight ratio: soft polyurethane 15%, hard polyurethane 15%, soft acrylic resin 25%, hard acrylic resin 25%, crosslinking agent 3%, curing agent 3%, penetrating agent 5%, leveling agent 1%, the balance is water.

Embodiment 3

[0034] The glue is formulated according to the following weight ratio: soft polyurethane 10%, hard polyurethane 5%, soft acrylic resin 20%, hard acrylic resin 10%, crosslinking agent 1%, curing agent 1%, penetrating agent 3%, leveling agent 1%, the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com