Device and method for modifying activated carbon adsorbent by using rotating low-temperature plasma

A low-temperature plasma and activated carbon adsorption technology, which is applied in the field of plasma modified activated carbon adsorbents, can solve problems such as destruction and atmospheric environmental pollution, and achieve the effects of simple process, improved breakthrough time, and mature preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

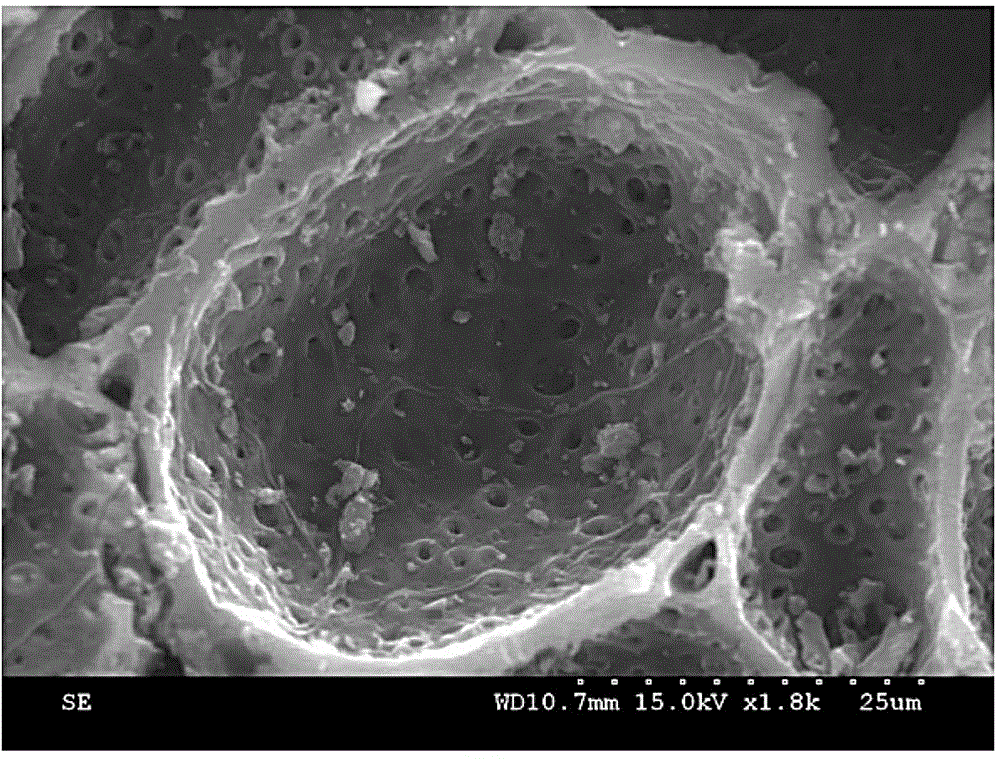

[0039] (1) figure 2 It is the scanning electron microscope picture of coconut shell activated carbon AC as it is. The coconut shell activated carbon AC is screened before use, sieved with 10-16 meshes, and the obtained activated carbon is placed in a beaker filled with deionized water that is about twice the volume of activated carbon. Place it in a digitally controlled ultrasonic cleaner filled with an aqueous solution, ultrasonicate at room temperature for 20 minutes, remove powder and oily substances in the activated carbon, wash with deionized water, filter with suction, and dry at 105°C;

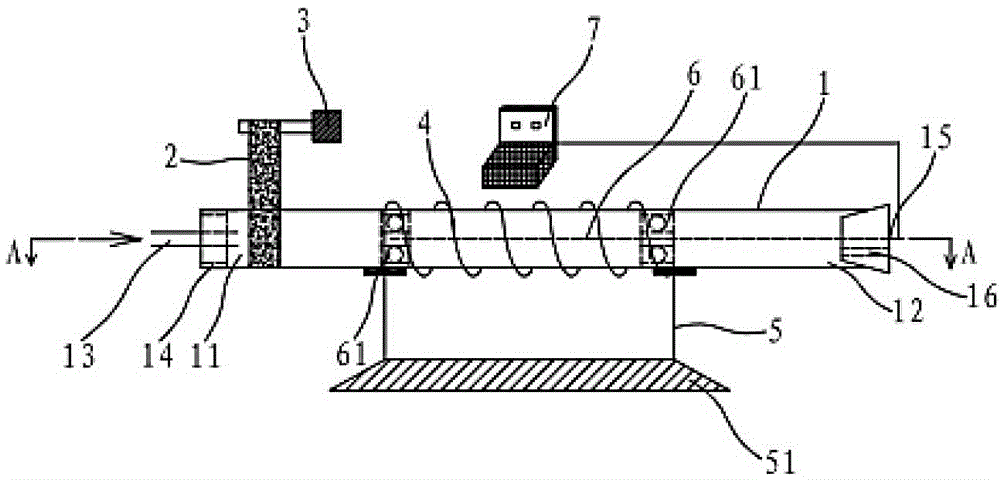

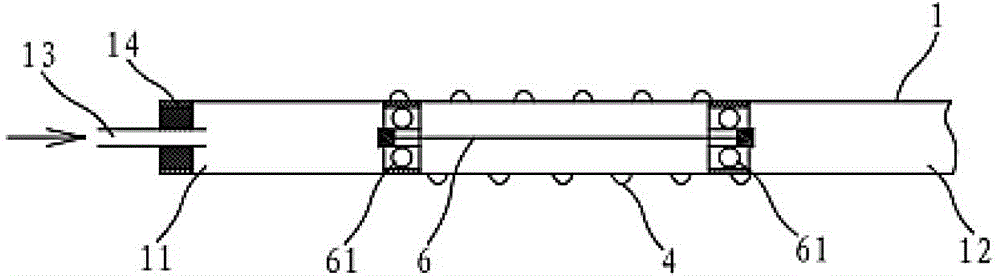

[0040] (2) Weigh 10g of activated carbon in (1) and spread it on the discharge area of the reactor, assemble it completely, and check the airtightness of the reactor inlet and outlet;

[0041] (3) Inject 50ml / min of N 2And start the motor to make it rotate for 4~5min, then adjust the frequency (100~300Hz), voltage (15~25KV) and response time (5~15min) of the AC power supply to get N...

Embodiment 2

[0043] (1) Screen coconut shell activated carbon AC before use, sieve through 10-16 meshes, place the obtained activated carbon in a beaker filled with deionized water twice the volume of activated carbon, and place it in a water solution In a digitally controlled ultrasonic cleaner, ultrasonicate at room temperature for 20 minutes to remove powder and oily substances in the activated carbon, wash with deionized water, filter with suction, dry at 105°C, soak in 1mol / L hydrochloric acid solution for 12 hours, wash with deionized water until neutral, Dry at 105°C;

[0044] (2) Weigh 10g of activated carbon in (1) and spread it on the discharge area of the reactor, assemble it completely, and check the airtightness of the reactor inlet and outlet;

[0045] (3) Pass in 50ml / min of air and start the motor to make it rotate for 4~5min, then adjust the frequency (100~300Hz), voltage (15~25KV) and response time (5~15min) of the AC power supply to get the air Activated carbon modifi...

Embodiment 3

[0047] (1) Screen coconut shell activated carbon AC before use, sieve through 10-16 meshes, place the obtained activated carbon in a beaker filled with deionized water twice the volume of activated carbon, and place it in a water solution In a digitally controlled ultrasonic cleaner, ultrasonicate at room temperature for 20 minutes to remove powder and oily substances in the activated carbon, wash with deionized water, filter with suction, and dry at 105°C;

[0048] (2) Weigh 10g of activated carbon in (1) and spread it on the discharge area of the reactor, assemble it completely, and check the airtightness of the reactor inlet and outlet;

[0049] (3) Inject 50ml / min of CO 2 And start the motor to make it rotate for 4~5min, then adjust the frequency (100~300Hz), voltage (15~25KV) and response time (5~15min) of the AC power supply to get the CO 2 Activated carbon modified under the best conditions in the atmosphere, the best conditions are 20KV / 100Hz / 10min / CO 2 .

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com