Sealing method of display screen frame

A display screen and glue sealing technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor sealing effect of the terminal part, and achieve the effects of improving the sealing effect, improving the uniformity, and increasing the amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

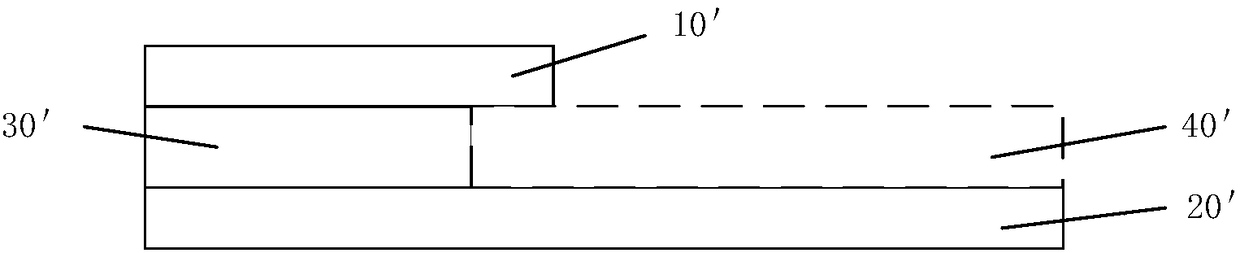

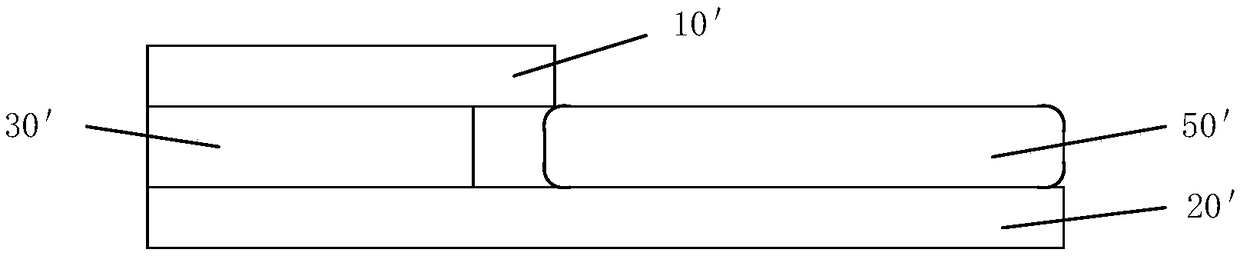

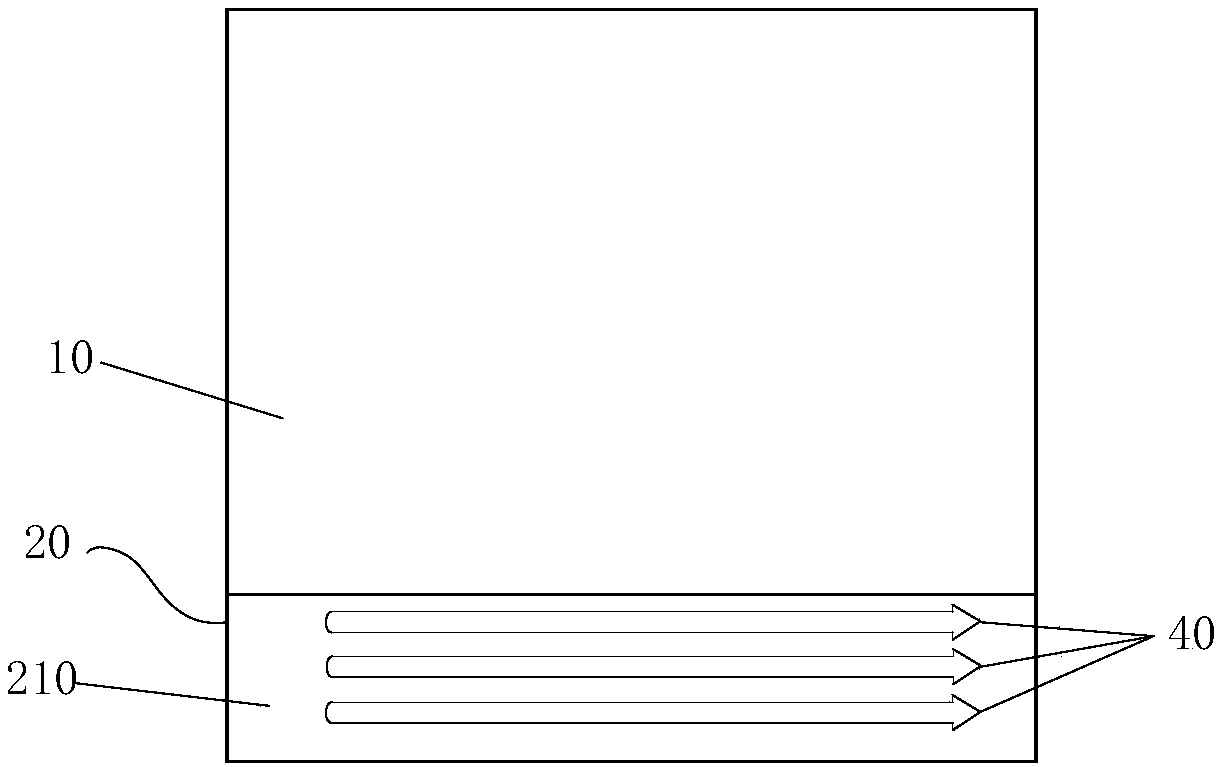

[0046] The display panel used in this embodiment is as Figure 6 As shown, the display screen includes an upper substrate 10 and a lower substrate 20 arranged in parallel. The surface of the lower substrate 20 near the upper substrate 10 has a region to be coated protruding from the upper substrate 10, and the upper substrate 10 has a region to be coated that is close to the region to be coated. 210 of the first edge, and the above-mentioned display screen also includes a sealing member 30 arranged between the upper substrate 10 and the lower substrate 20, the upper substrate 10 has one end of the first edge, and an accommodation space is formed between the sealing member 30 and the lower substrate 20 , the sealing method provided in this embodiment includes the following steps:

[0047] Use TUFFY glue to carry out six coating processes on the region 210 to be coated along the direction parallel to the first edge, so that each coating process forms a plurality of glue-coated r...

Embodiment 2

[0049] The difference between this embodiment and embodiment 1 is:

[0050] Odd-numbered coating processes have opposite coating directions to even-numbered coating processes.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is:

[0053] A group of adjacent glue-coated regions 40 near the first edge of the glue-coated regions 40 are adjacent, the width of the glue-coated regions 40 is 0.5 mm, and the interval between the start times of each coating process is 1 s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com