Patents

Literature

59results about How to "Increase the amount of glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

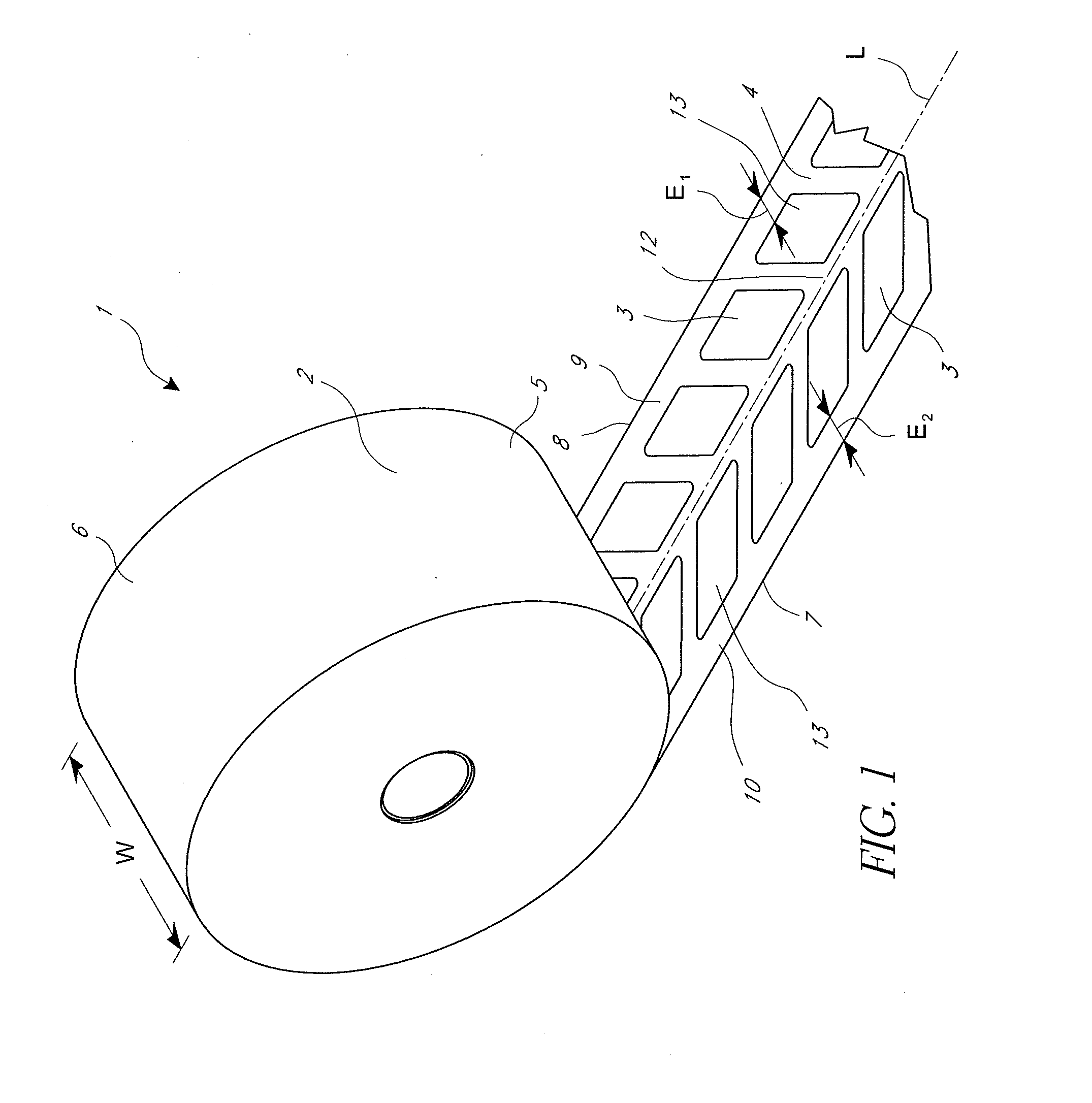

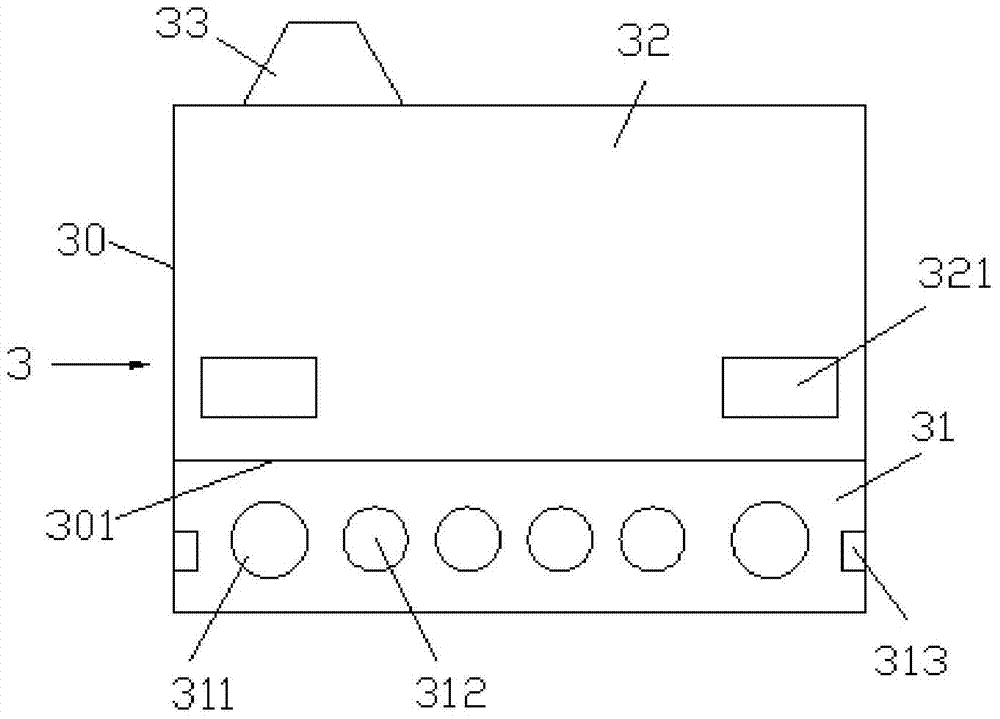

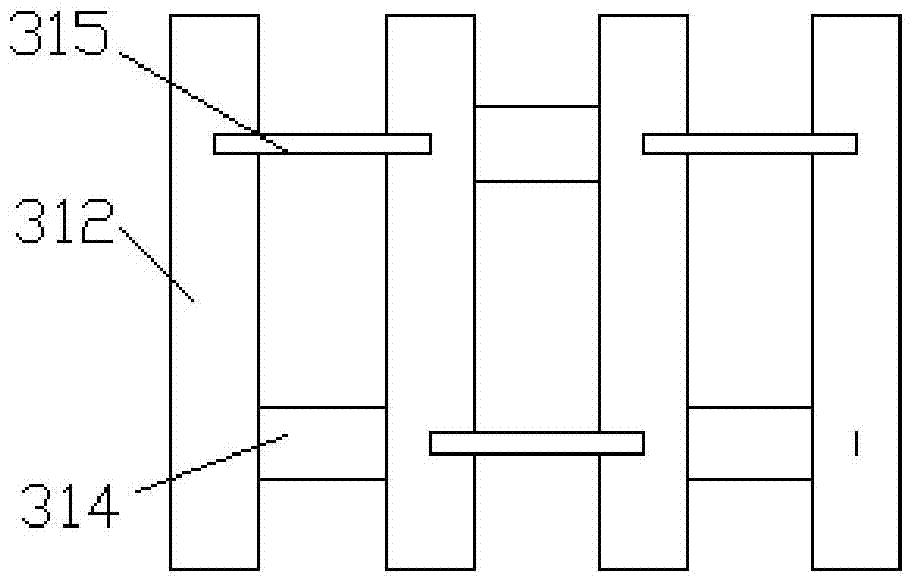

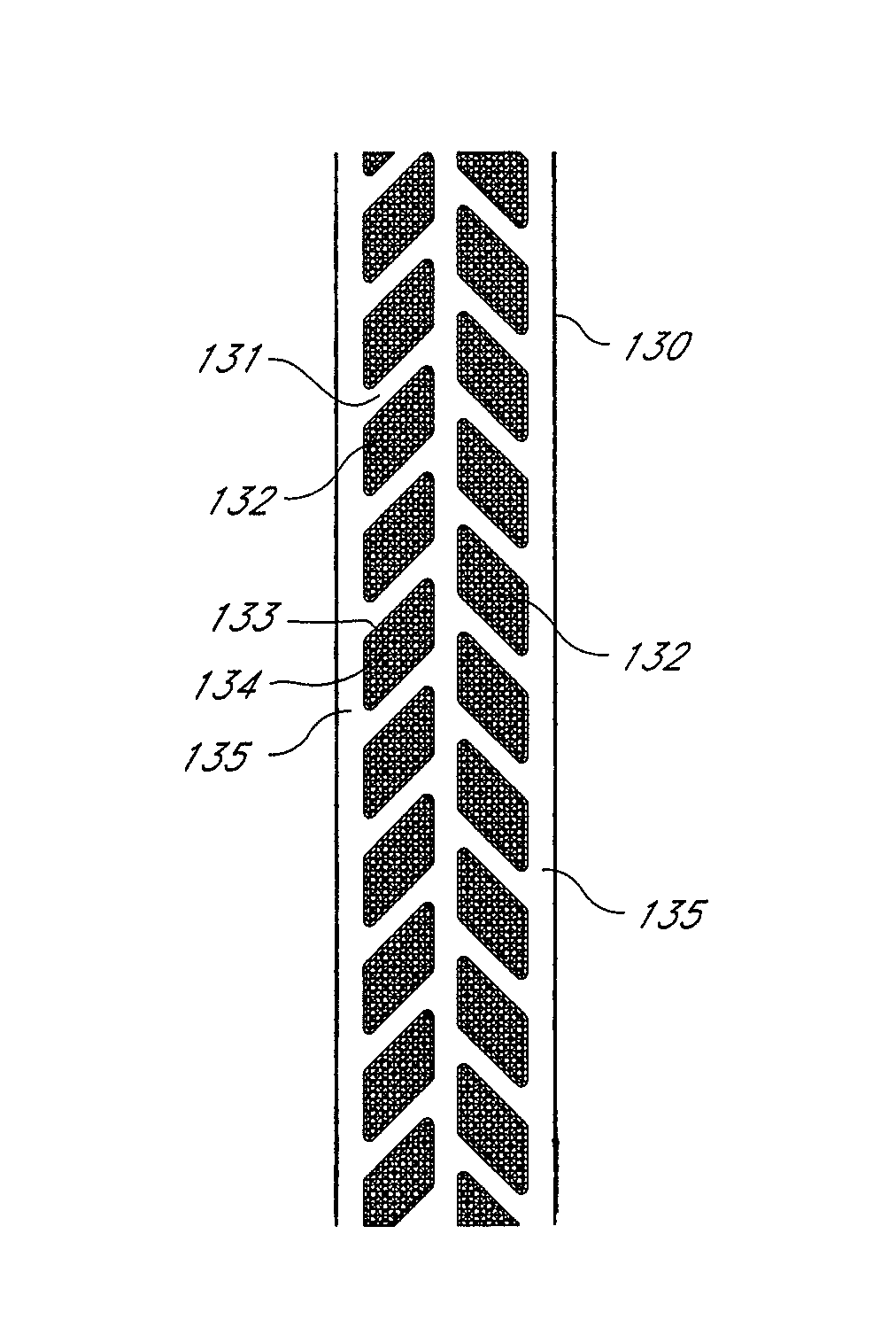

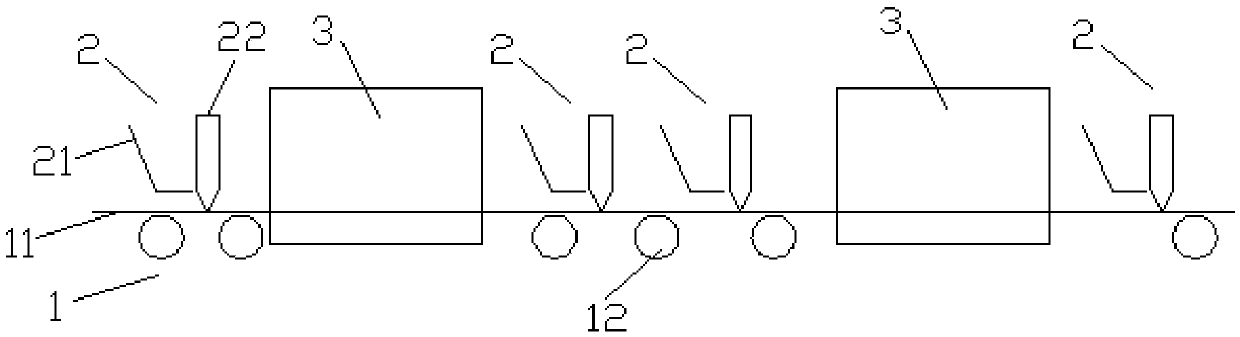

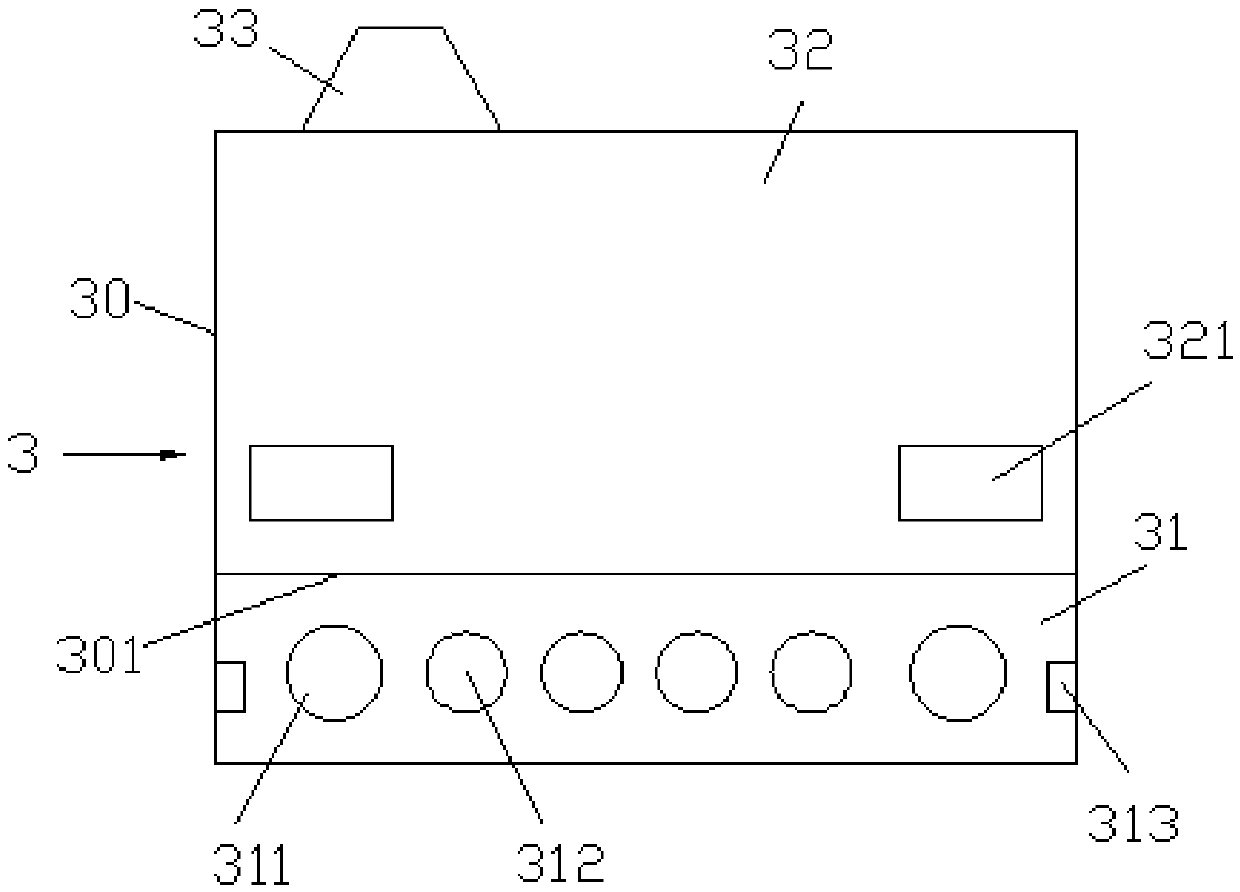

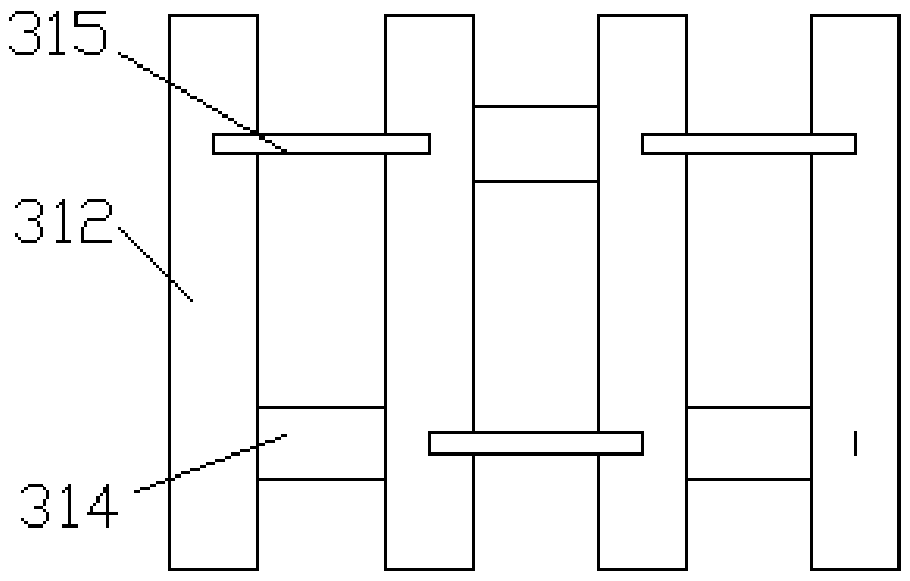

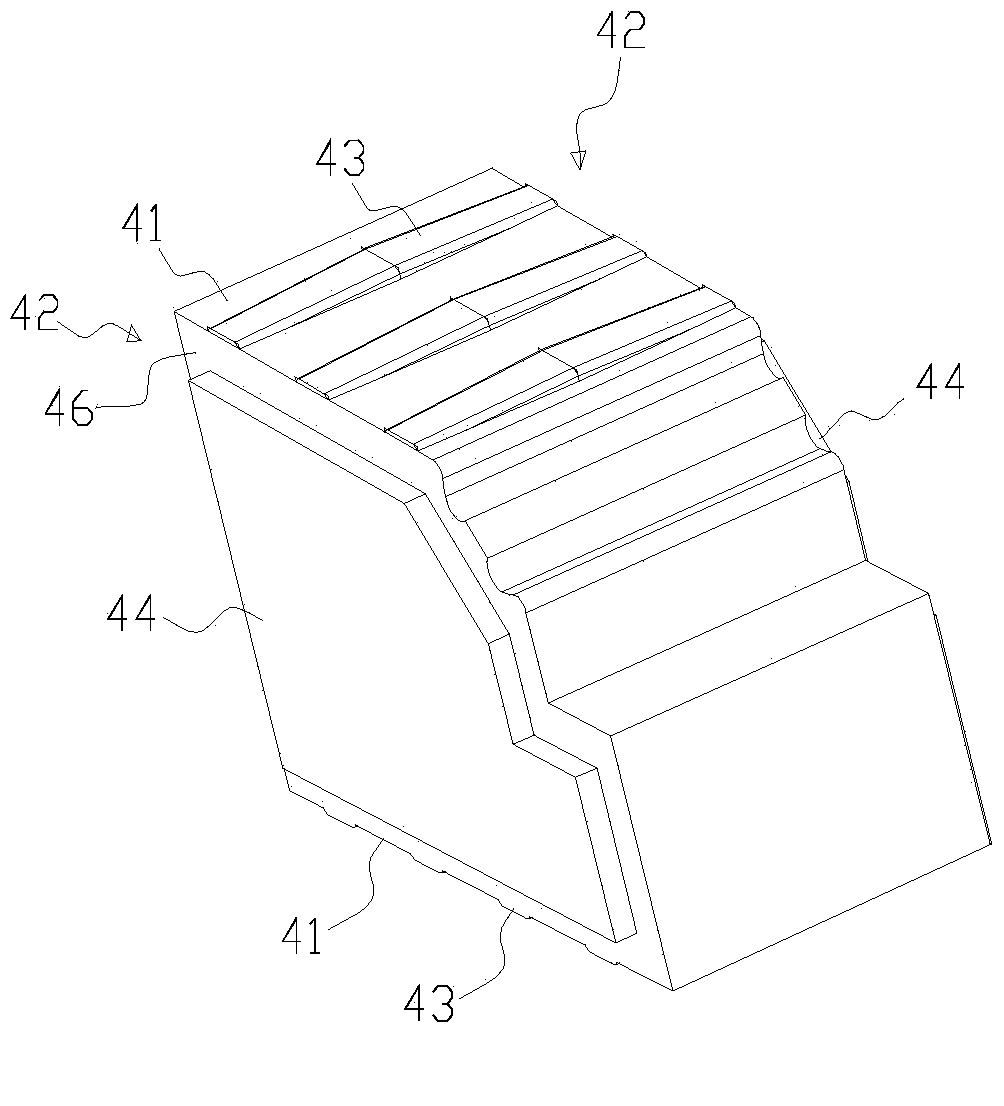

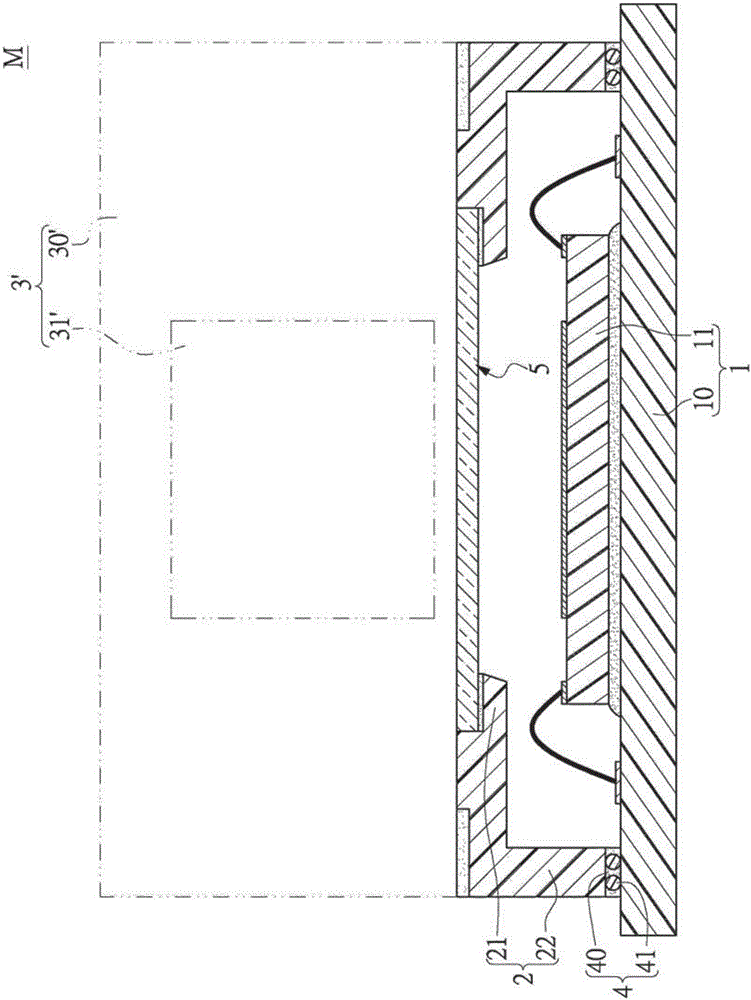

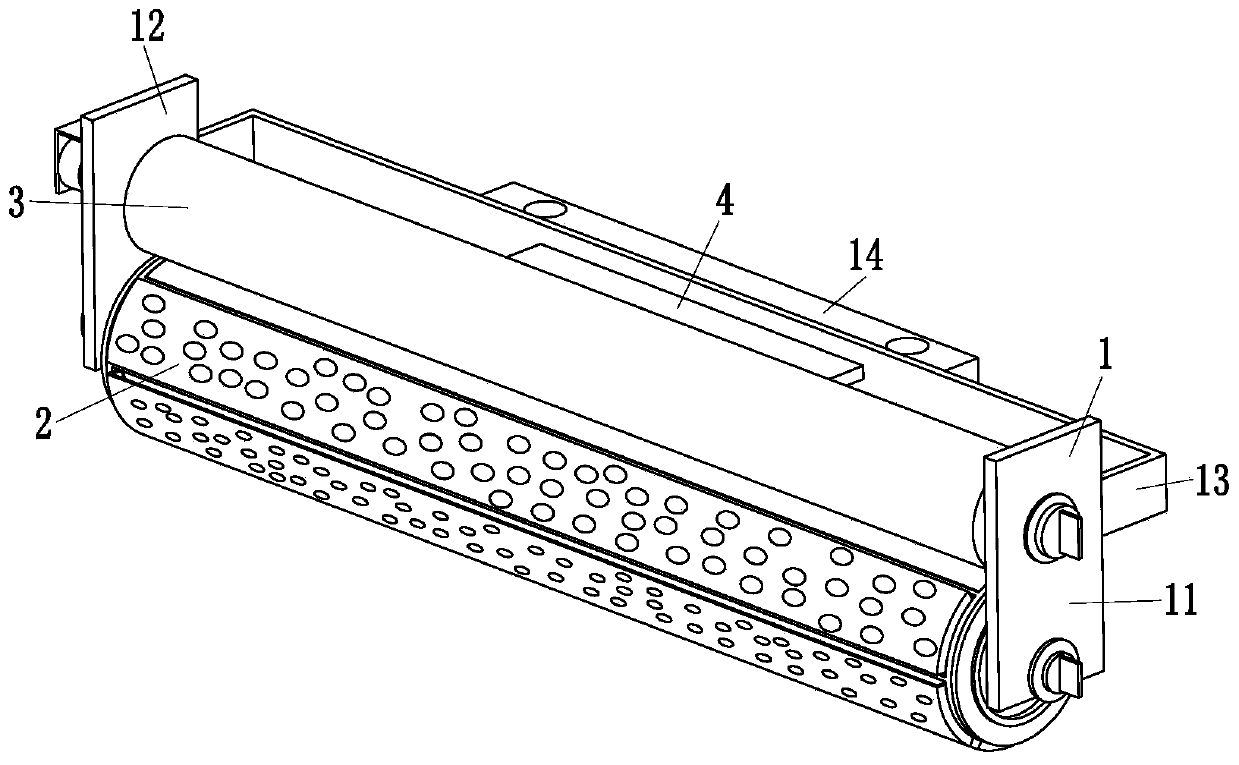

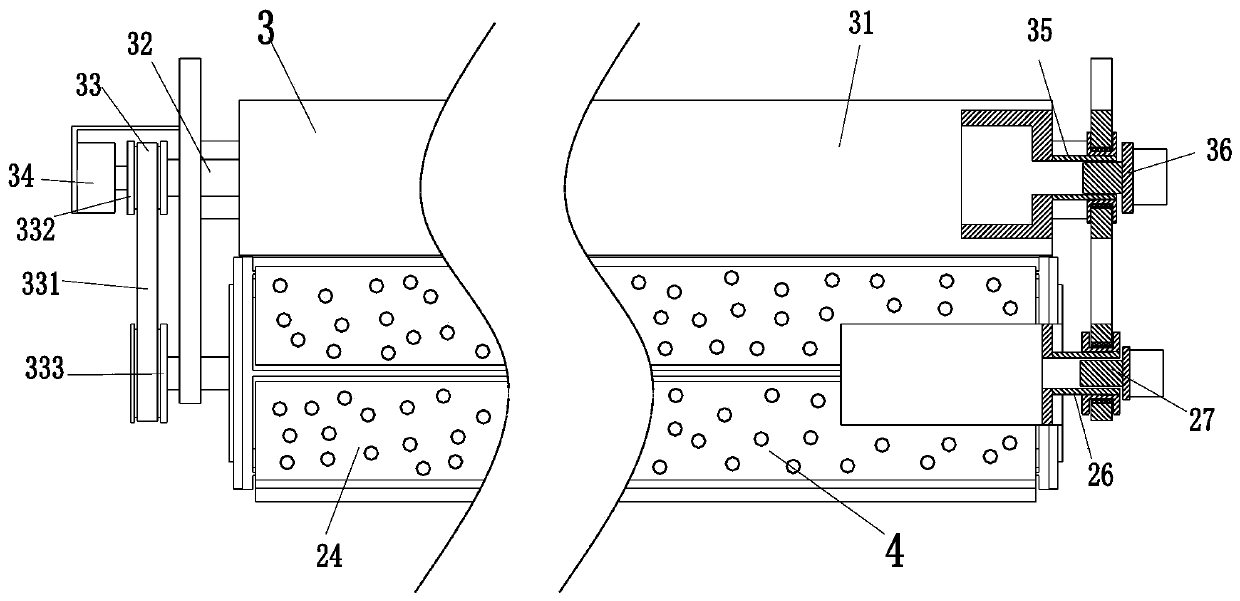

Coating equipment for fabric flame retardant coating layer

ActiveCN104117465AIncrease expansionSolve the problem of the upper limit of flame retardant and waterproof performanceLiquid surface applicatorsCoatingsEngineeringCoating

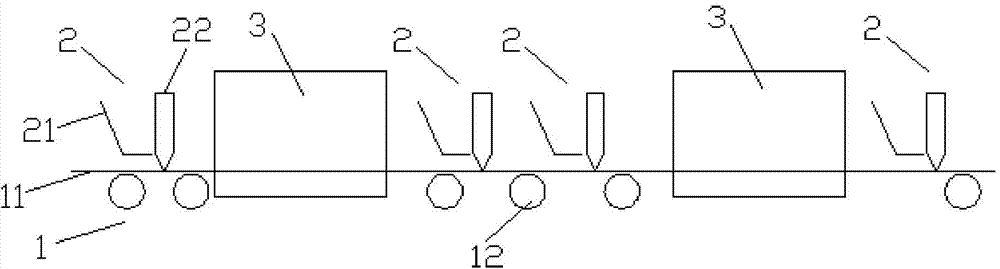

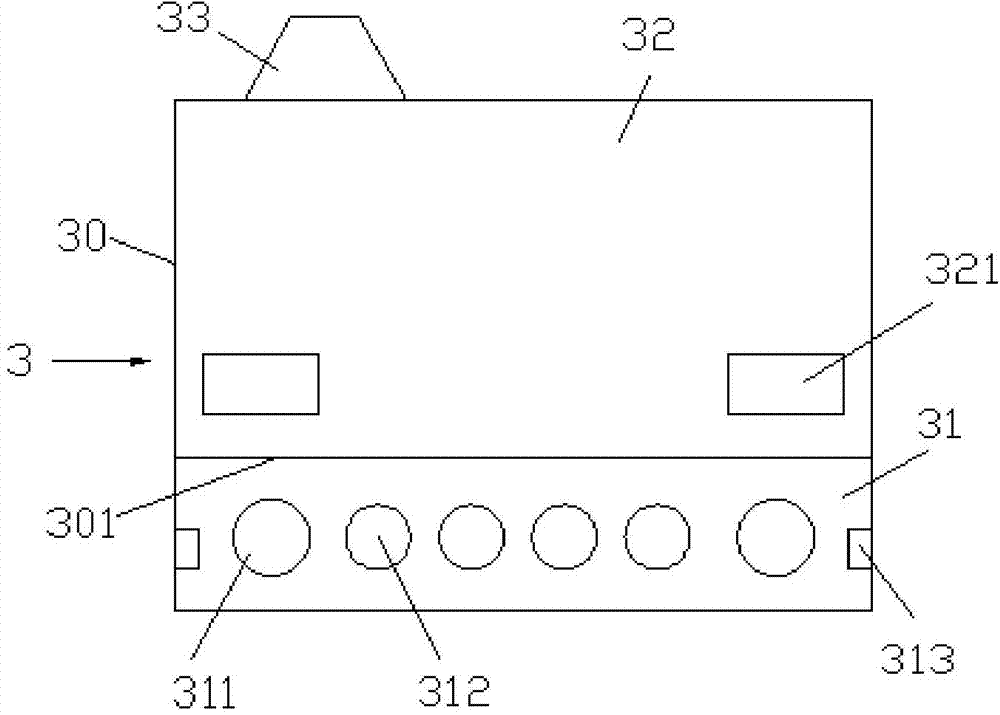

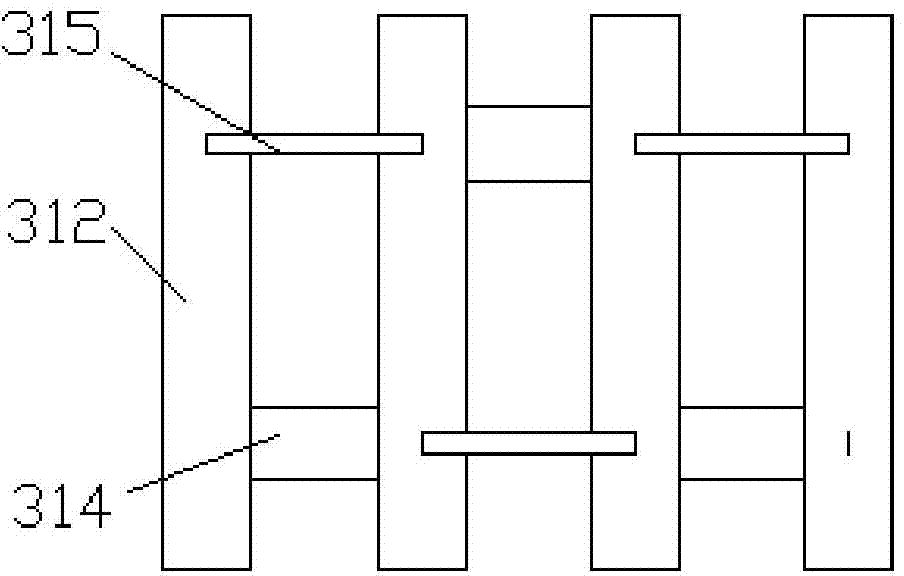

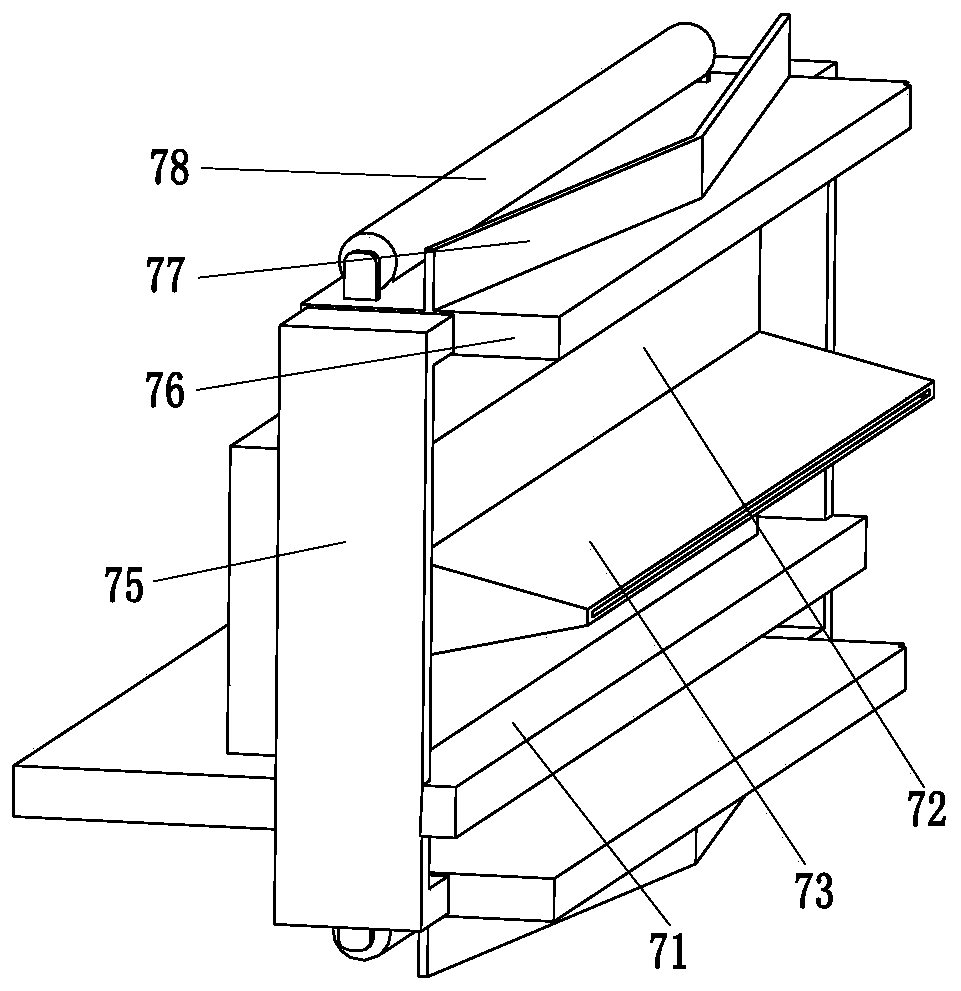

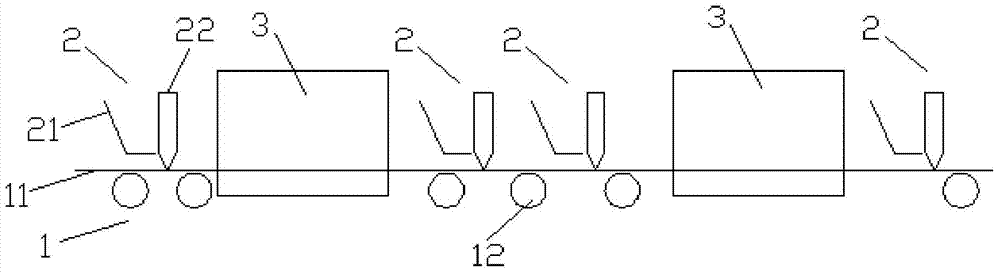

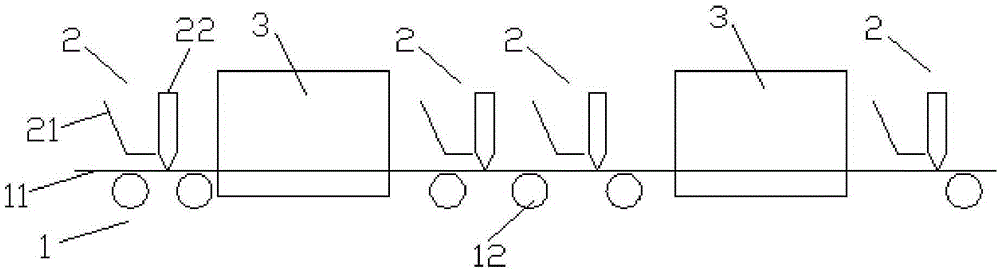

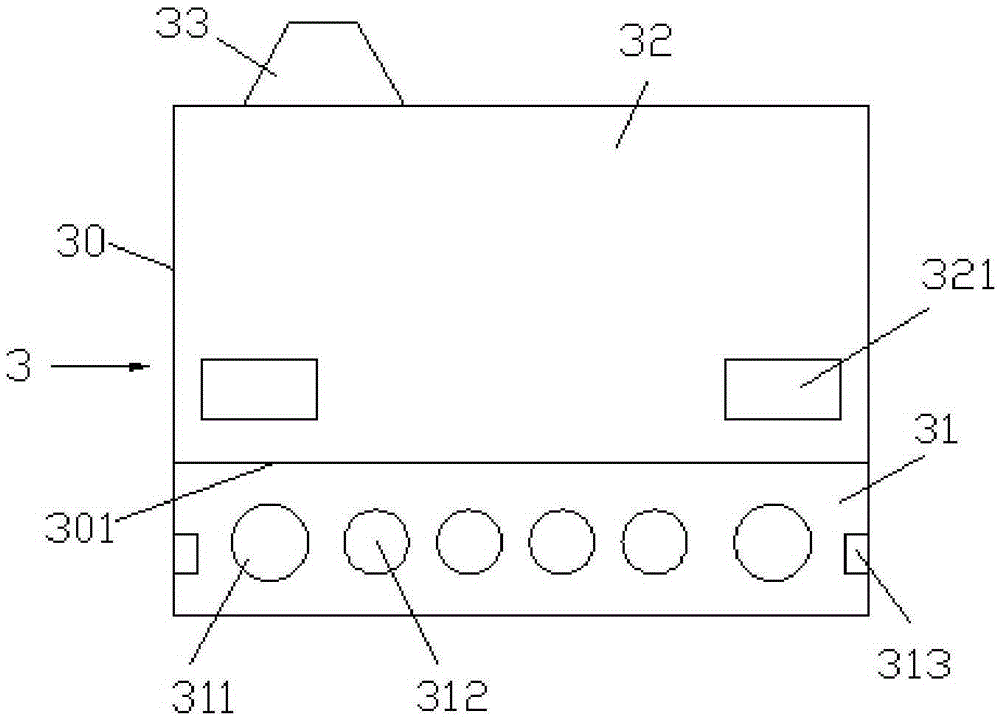

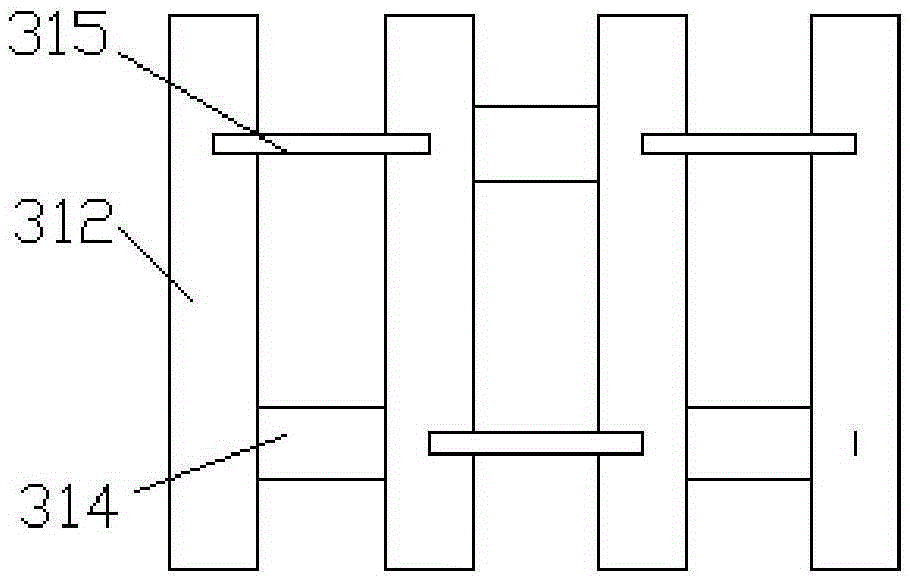

The invention discloses coating equipment for a fabric flame retardant coating layer. A base gel coating device, a middle gel coating device and a surface gel coating device are sequentially arranged in the conveying direction of fabric, drying devices are arranged between the base gel coating device and the middle gel coating device and between the middle gel coating device and the surface gel coating device, the base gel coating device, the middle gel coating device and the surface gel coating device are respectively composed of coating layer coating units composed of gel feeding grooves and scrapers, and the base gel coating device and the surface gel coating device are respectively provided with one set of coating layer coating units. The middle gel coating device is provided with two sets of coating layer coating units in sequence in the conveying direction. The two sets of coating layer coating units are arranged on the middle gel coating device, the coating layer coating units of the middle gel coating device are respectively more than the coating layer coating units of the base gel coating device and the coating layer coating units of the surface gel coating device by one set, and therefore the total amount of middle gel is divided into two parts for coating. The aim of increasing the total amount of the base gel, the total amount of the middle gel and the total amount of surface gel in the flame retardant coating is achieved, and the upper limit problem of the flame retardant waterproof performance is effectively solved.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

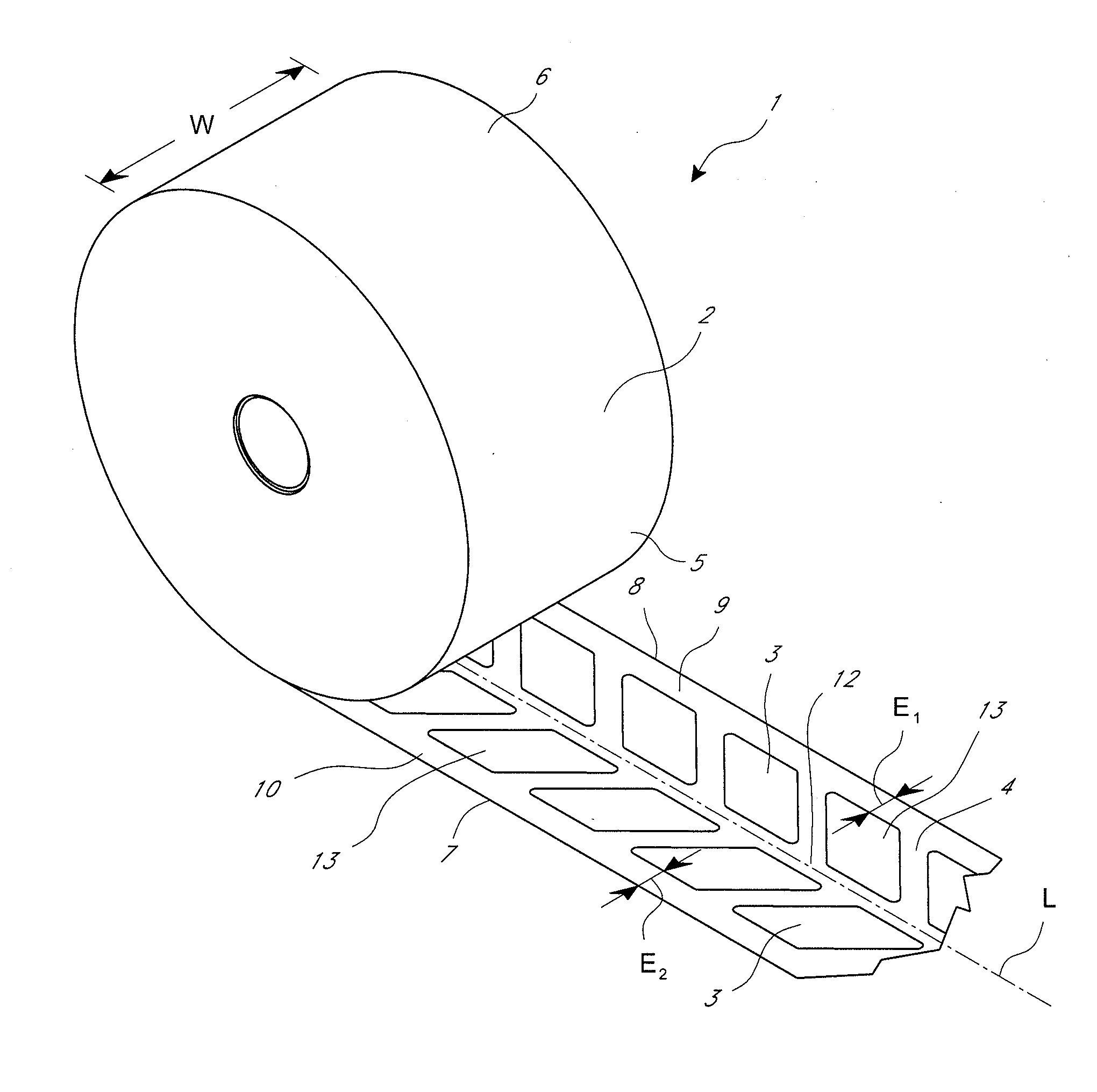

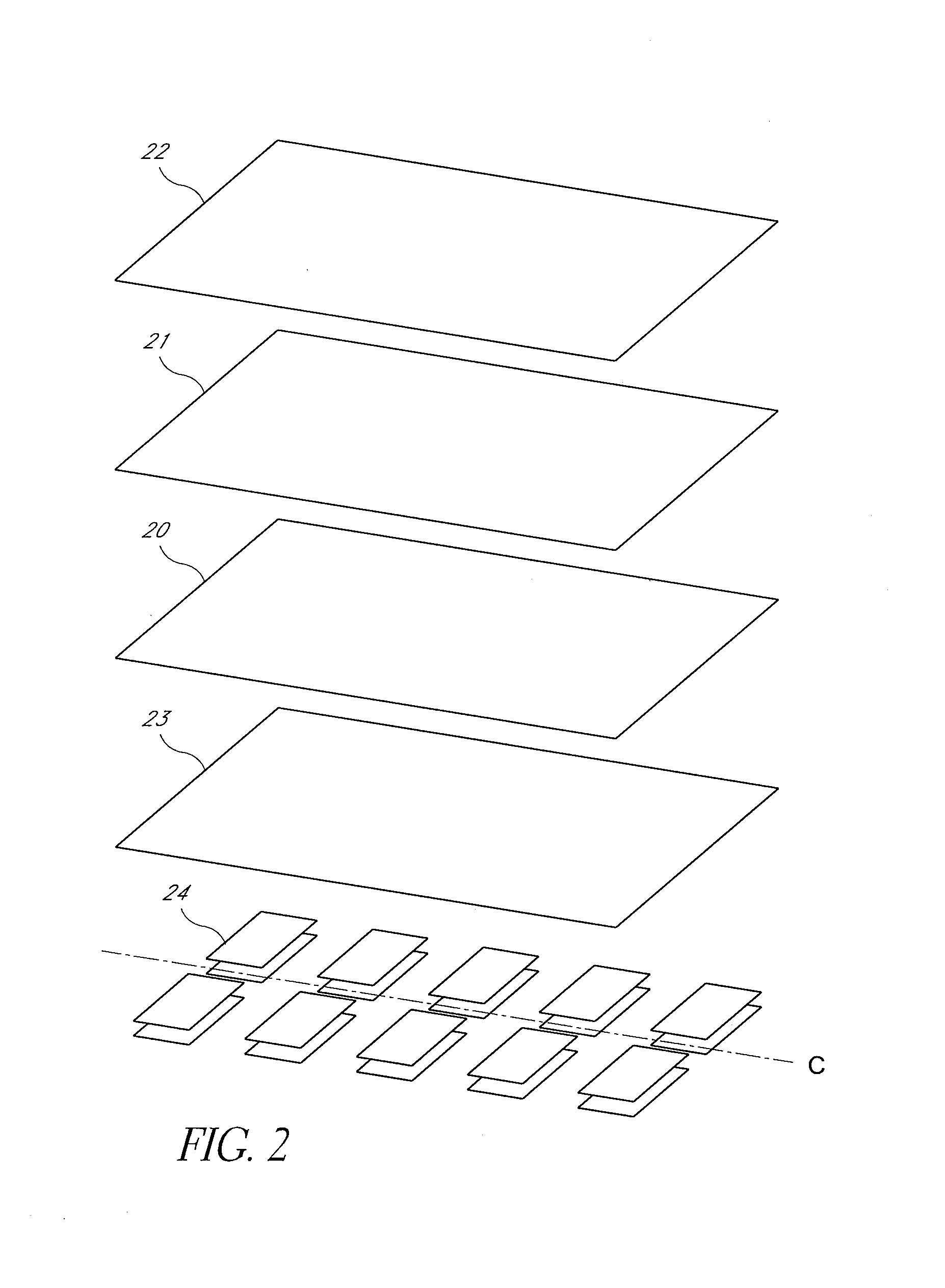

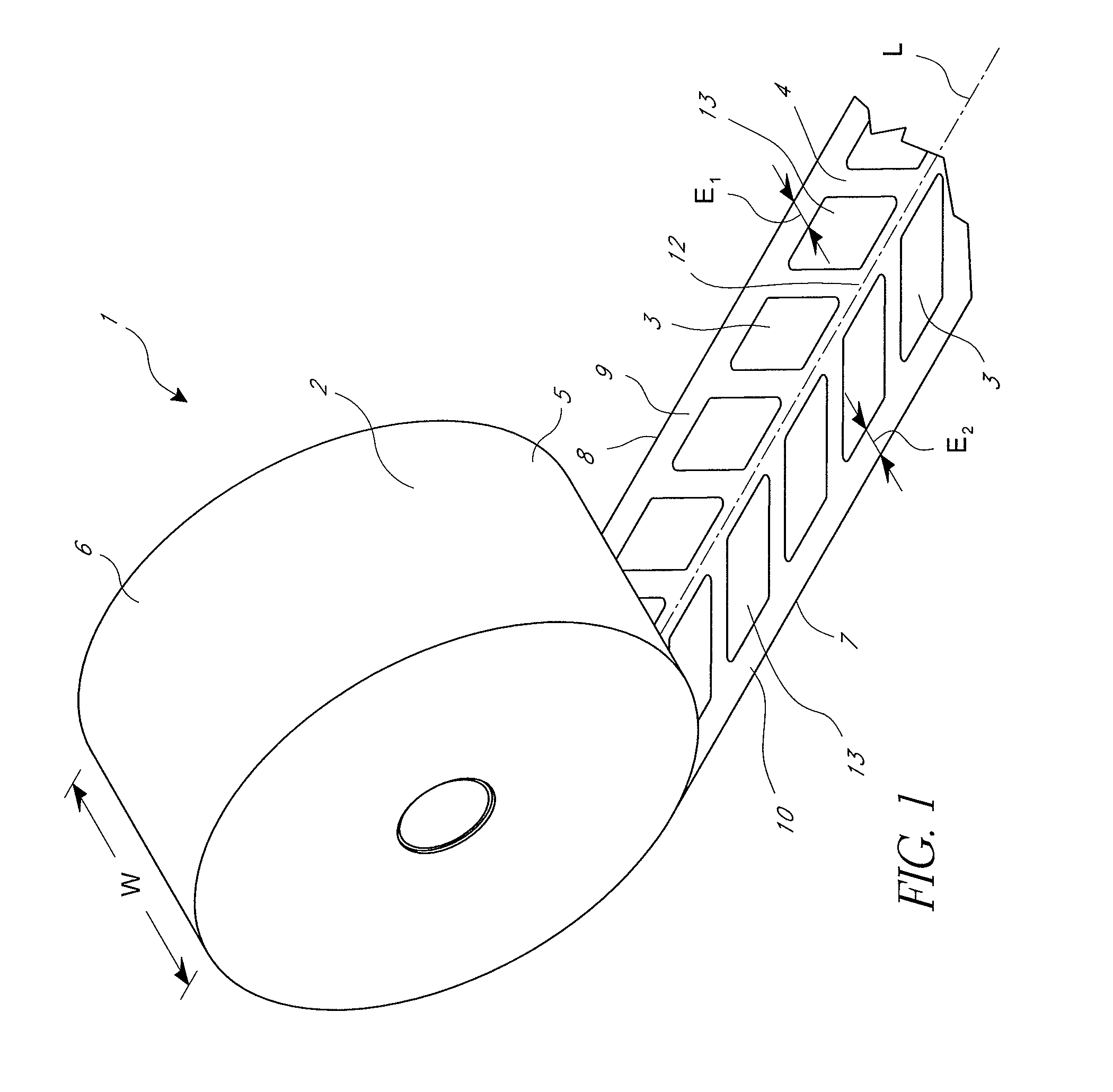

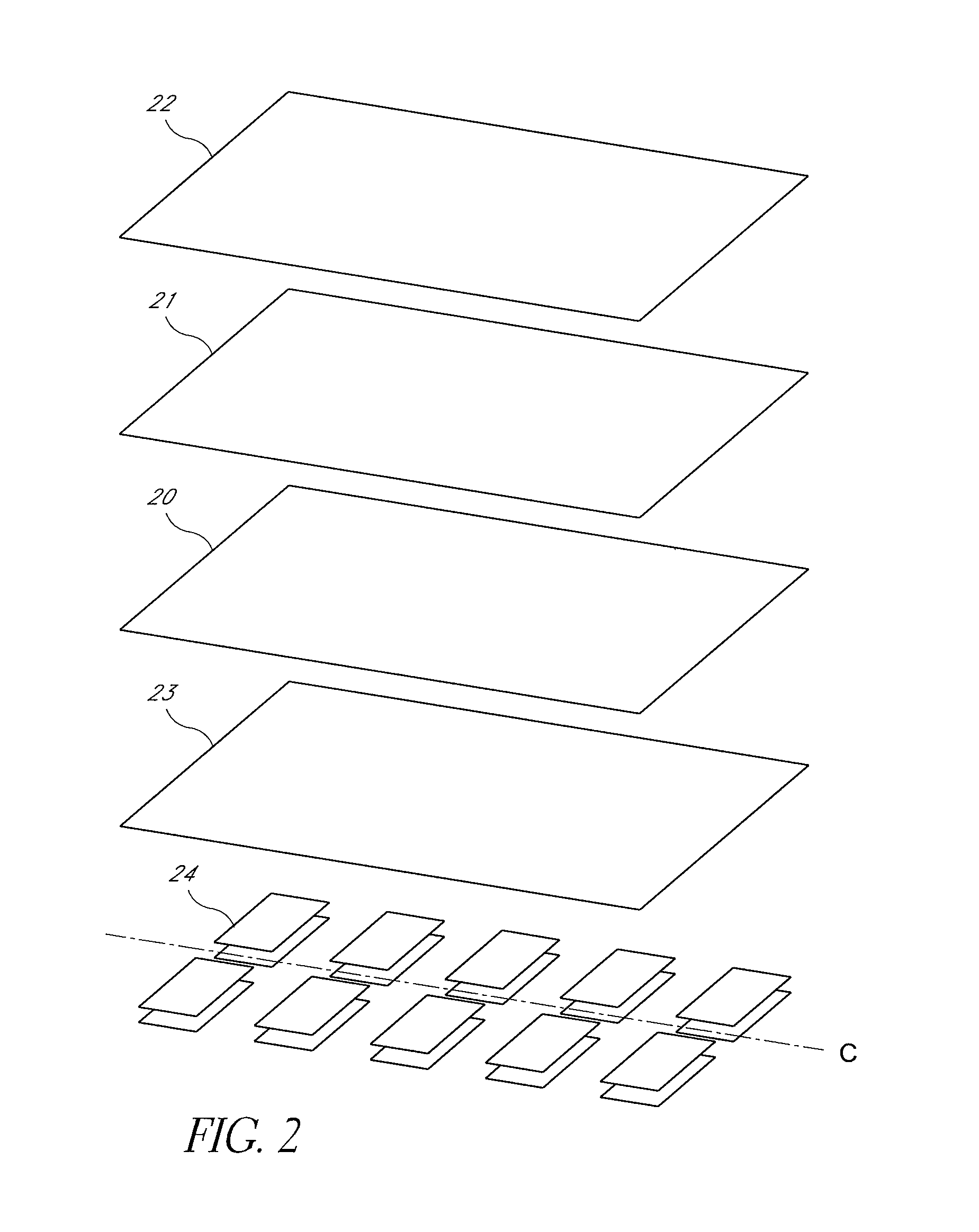

Paper, labels made therefrom and methods of making paper and labels

ActiveUS20130260991A1Clean enoughIncrease the amount of glueStampsPaper/cardboard articlesAdhesivePulp and paper industry

Paper is disclosed for use in making repositionable or removable adhesive labels. The adhesive can be applied in patches or discrete areas to the paper or to a layer of material that cleans rollers in the manufacturing line and / or in printers. The adhesive can be applied in single or multiple layers. The paper is light weight paper and preferably thermal paper for use in POS printers.

Owner:DOCUMOTION RES

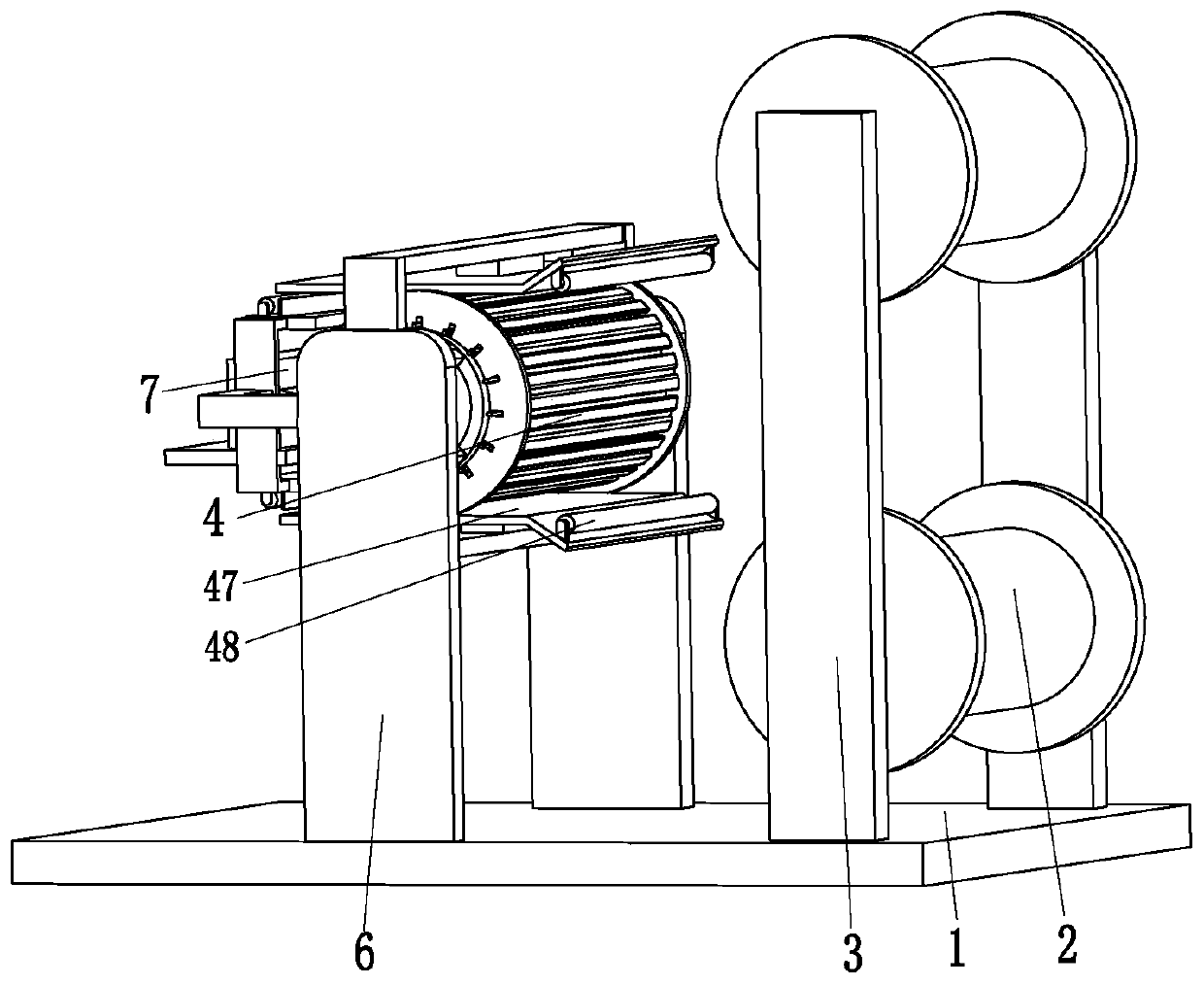

Gluing device for plastic lined woven bag

ActiveCN110918368AImprove continuityIncrease the uniformity of brushingLiquid surface applicatorsSpray nozzlesPlastic film

The invention relates to a gluing device for a plastic lined woven bag. The gluing device comprises a bottom plate, unwinding rollers, unwinding supporting plates, a gluing roller, a rotating motor, gluing supporting plates and a gluing mechanism, wherein two unwinding rollers are uniformly distributed vertically above the right end of the bottom plate, and the front and rear ends of the unwindingrollers are both installed on the top of the right end of the bottom plate by the unwinding supporting plates respectively; the gluing roller is positioned on the left side between the two unwindingrollers, and the gluing supporting plates are distributed on the front and rear sides of the gluing roller respectively; the gluing mechanism comprises a gluing cross plate, a glue tank, a nozzle, a pressurizing pump, connecting brackets, scraping supporting plates, a scraping frame and guide rollers. The problems that when woven films or plastic films are glued in the prior art, the woven films or plastic films can only be glued on one side and cannot be glued tightly at the later stage, and thickness of the woven films or plastic films is uncontrollable caused by the fact that the woven films or plastic films are glued unevenly by the rollers, and the like can be solved.

Owner:安徽省临泉县万隆塑料包装有限公司

A method of preparing a high-fastness elastic jean adhered fabric

ActiveCN107283996AImprove crispnessIncrease the amount of glueLamination ancillary operationsSynthetic resin layered productsShrinkage rateEvaporation

A method of preparing a high-fastness elastic jean adhered fabric is provided. The method includes surface fabric treating steps including beaming, dyeing, weaving, singeing, long-vehicle desizing, mercerizing and finishing; base fabric treating steps including preparing a grey fabric, desizing, dyeing and sizing with clear water; a surface fabric preshrinking step adopting a loose dryer, with water treating and drying being performed under a condition of no weft tension to reduce a weft shrinkage rate; a step of tightly pressing and adhering the surface fabric and a TPE film; a step of subjecting the adhered surface fabric and the TPE film to evaporation curing; a step of adhering the adhered surface fabric and the base fabric; a step of subjecting the surface fabric and the TPE film which are adhered to evaporation curing; and a water pouring step, namely a step of performing water pouring surface fabric treatment by adopting a waterproofing agent the liquid rate of which is 30-50%, and performing first-stage drying and second-stage drying. The method improves fabric fitting fastness, and increases water pressure resisting and water pouring resisting functions, and the like.

Owner:CONCORDIA ADVANCED FABRICS SUZHOU

Production process of digital photo paper synthesized by multiple fibers

InactiveCN102220724AImprove stiffnessGood surface absorptionVegetable material additionPaper/cardboardFiberUltrafiltration

The invention discloses a production process of digital photo paper synthesized by multiple fibers. The production process comprises the following procedures: internal sizing liquid preparing, surface sizing liquid preparing, pulp breaking, pulp mixing, net forming, surface sizing, drying and reeling, blending, prime coating and cast coating, wherein in the pulp breaking procedure, bamboo pulp and reed pulp are added to the original wood pulp and sodium silicate is added to the breaking solution; in the surface sizing procedure, the surface sizing liquid is prepared by decocting modified starch and cassava starch and a rheology modifier is added; in the blending procedure, the membrane ultrafiltration deionized water is used; and in the prime coating procedure, a soft calender and four dryers are added. The produced high gloss photo paper has a fine and smooth surface and the characteristics of high gloss and density, wide color gamut, high ink absorbency and water resistance, good stiffness and the like.

Owner:HUANGSHAN HUABANG DIGITAL TECH

Dual-electrode plates of fuel cell

InactiveCN1805190AGuaranteed tightness and reliabilityImprove pass rateCell electrodesCollectors/separatorsEngineeringExtrusion

The invention relates to a fuel battery dual electrode plate, which comprises the upper and lower adhered electrode plates, whose surfaces have guide grooves and the guide holes through said two electrode plates. The guide groove is connected to the guide hole; the adhesive surface on the electrode plate along the edge of guide groove and hole has the groove to avoid overflow of pastern and jamming the guide groove and the guide hole. After setting the grooves at the edge of guide hole and guide groove, when sticking the electrode plates, the left pastern can flow into the groove by the extrusion to avoid it flowing into guide hole or guide groove in present technique, which will affect the normal operation. The plated pastern can be increased to improve the adhesive reliability and sealing property, improve the pass percent of product, reduce the demand to operator and simplify the operation.

Owner:南京博能燃料电池有限责任公司

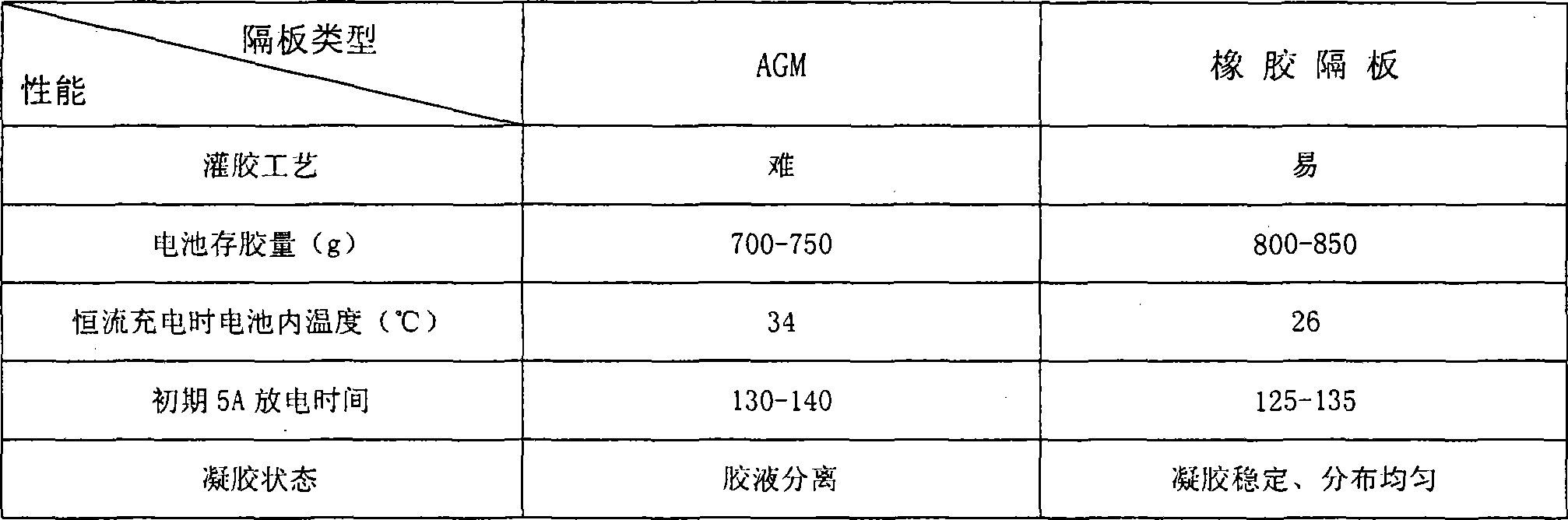

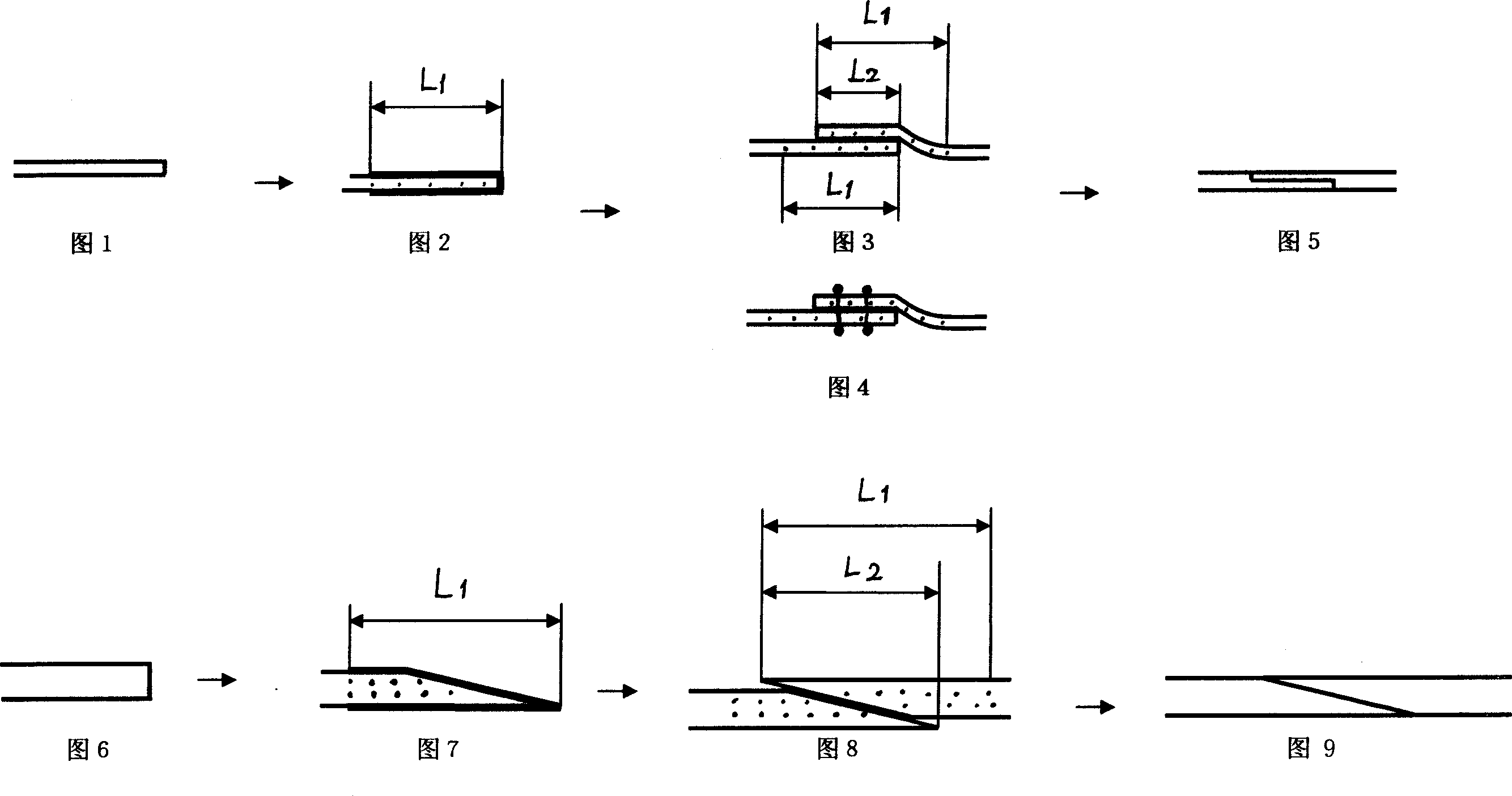

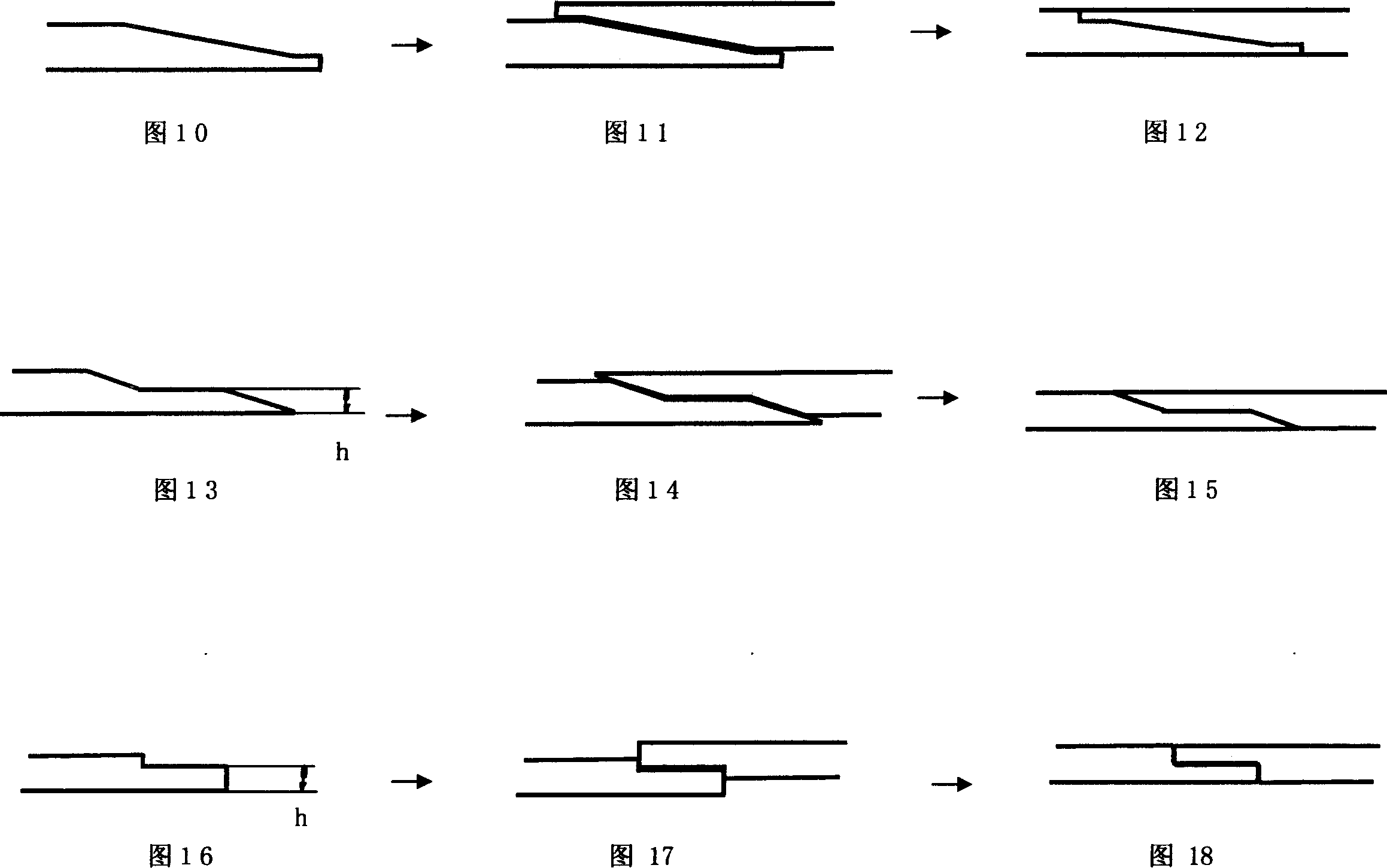

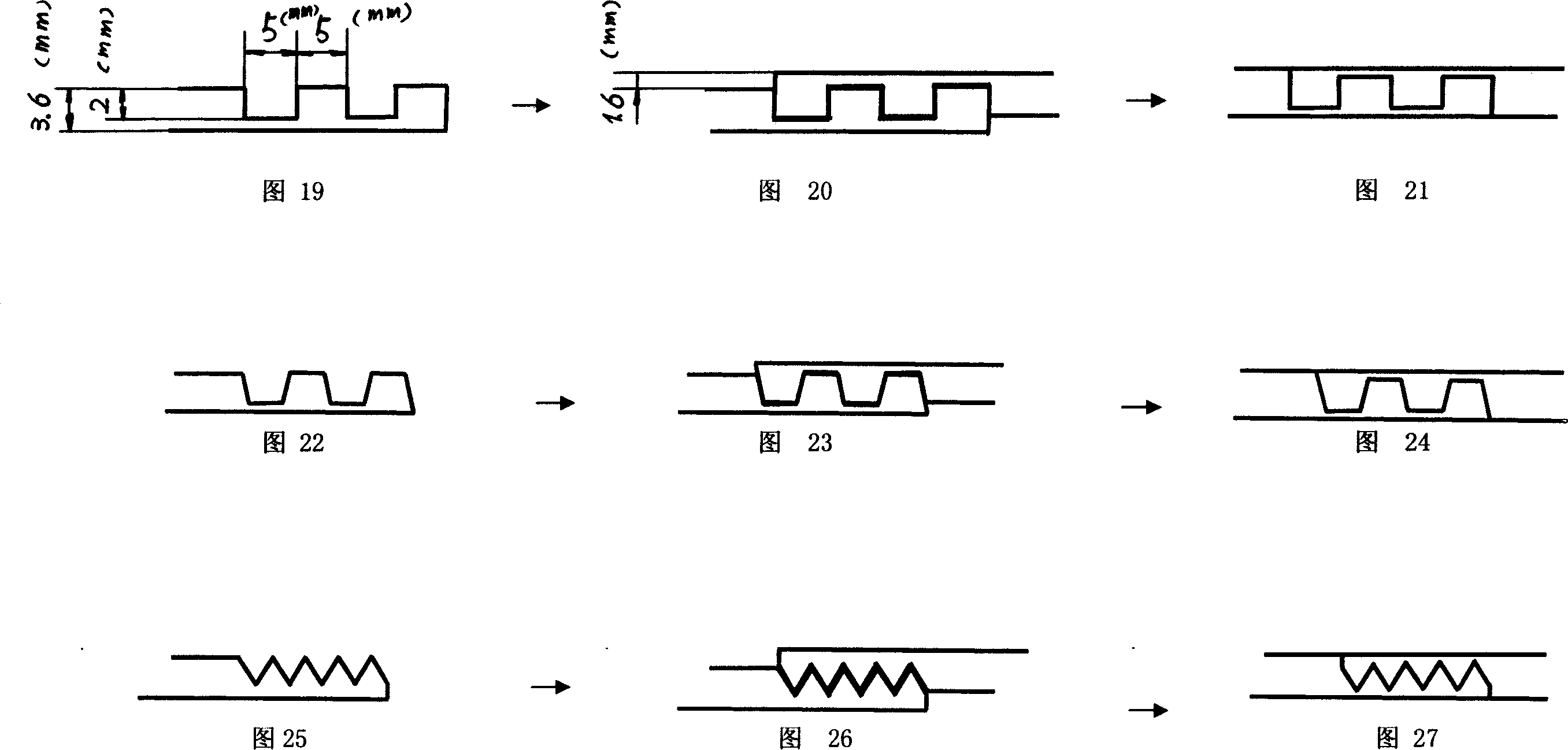

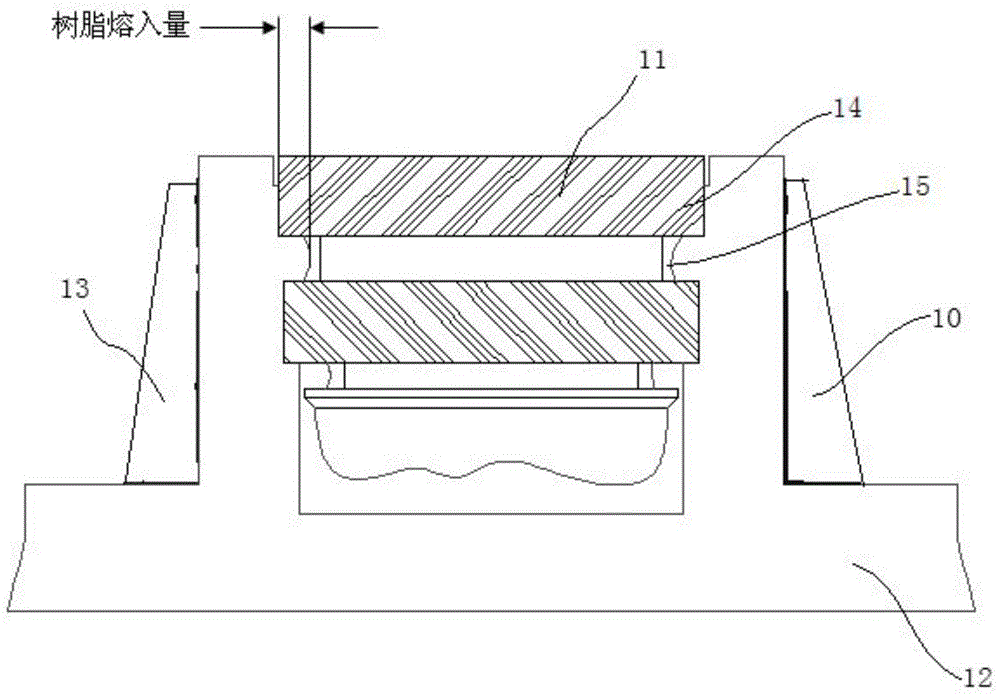

Coating process of fabric flame-retardant coating layer

ActiveCN104120571ASolve the upper limit of flame retardant and waterproof performanceImprove fire and water resistanceLiquid surface applicatorsCoatingsDry glueChemistry

The invention discloses a coating process of a fabric flame-retardant coating layer. A flame-retardant coating layer is coated on one or all of the upper surface and the lower surface of a fabric, primer coating, middle glue coating and surface glue coating are sequentially performed on a coating layer coating device, and total middle glue is coated in a twice mode. During coating, the middle glue accounting for 2 / 3 of total dried glue is added during the first-time coating, and the middle glue accounting for 1 / 3 of total dried glue is added during the second-time coating. The total middle glue is coated in a twice mode, so that the glue quantity of adhesive tapes in the fabric can be effectively increased, the upper limit problem of the flame-retardant water-proof performance is effectively solved, and the flame-retardant water-proof performance can be improved by a high level.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

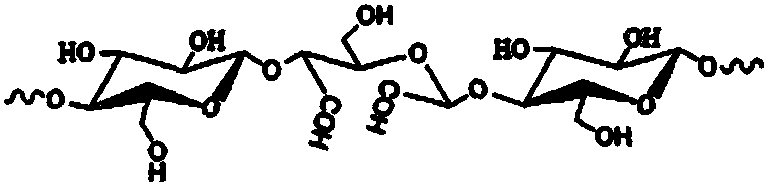

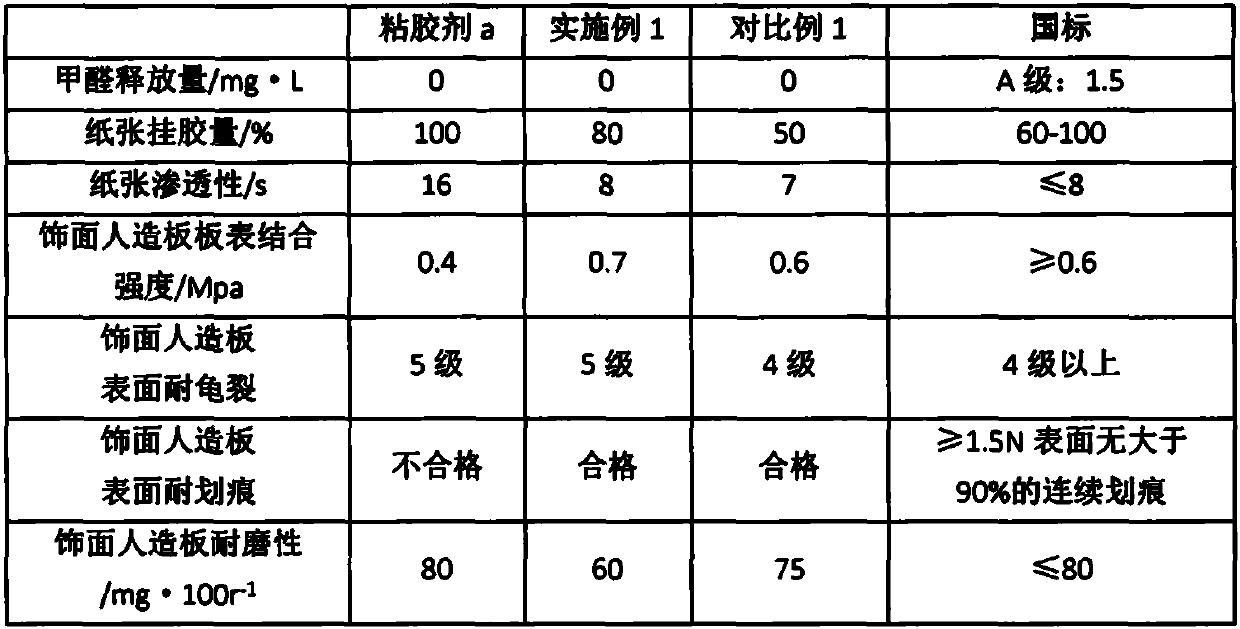

Formaldehyde-free adhesive for paper impregnated thermosetting resin and preparation method of adhesive

ActiveCN111411543AAchieve no formaldehydeSmall molecular weightPaper/cardboardInorganic compound additionPolymer scienceResin adhesive

The invention discloses a formaldehyde-free adhesive for paper impregnated thermosetting resin with physical strength meeting national standard requirements and a preparation method of the adhesive. The formaldehyde-free adhesive is prepared from the following components in parts by weight: 30 to 50 parts of waterborne polyurethane emulsion, 1 to 5 parts of nano cellulose, 5 to 10 parts of fillerand 200 to 300 parts of water. The preparation method comprises the following steps: according to a formula ratio, putting nano cellulose into water and waterborne polyurethane emulsion at room temperature, and stirring for 5-10min at 500-800r / min; and then adjusting the stirring speed to 1000-3000 r / min, meanwhile, adding the filler, continuing to stir for 10-20 min, and standing to obtain the product. The formaldehyde-free adhesive prepared by the preparation method disclosed by the invention is free from formaldehyde release, safe and environment-friendly, and the polyurethane emulsion is relatively small in particle size, relatively small in molecular weight and moderate in viscosity, so that the impregnating adhesive can better permeate into paper, the problem of inter-paper damage ofthe paper impregnated by a common resin adhesive is solved, meanwhile, the glue hanging amount of the impregnated film adhesive is increased, and the scratch resistance of the film adhesive can be improved to a certain extent.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

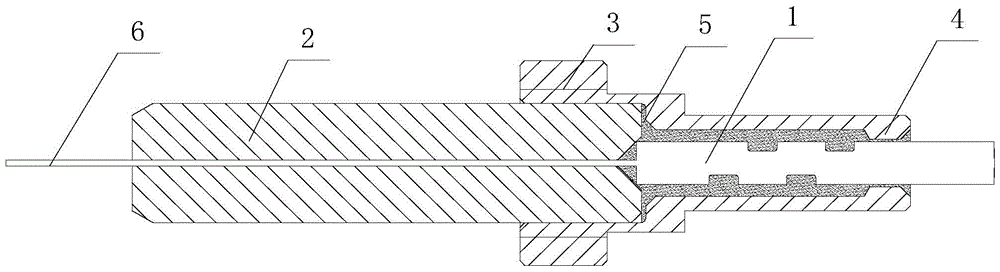

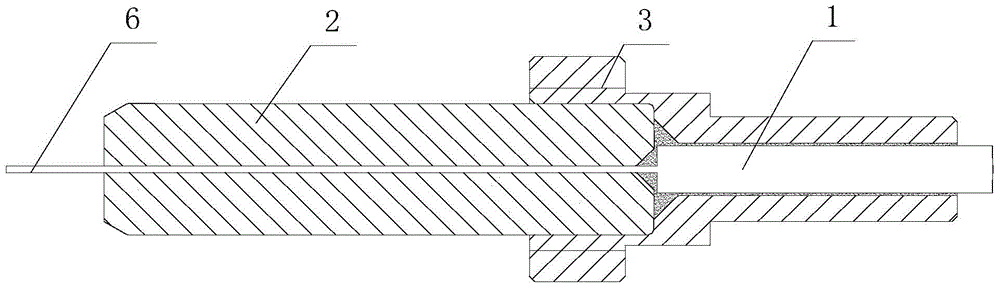

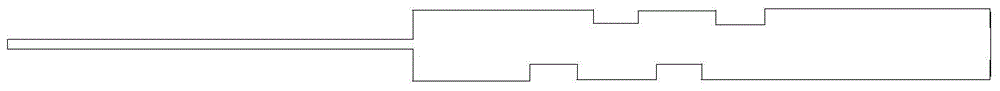

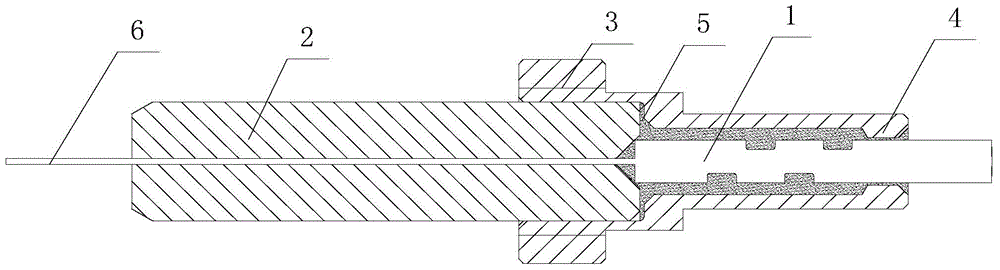

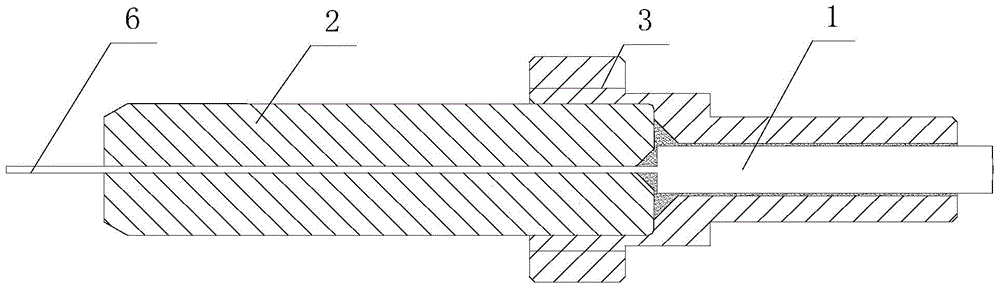

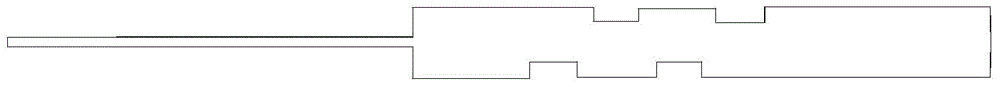

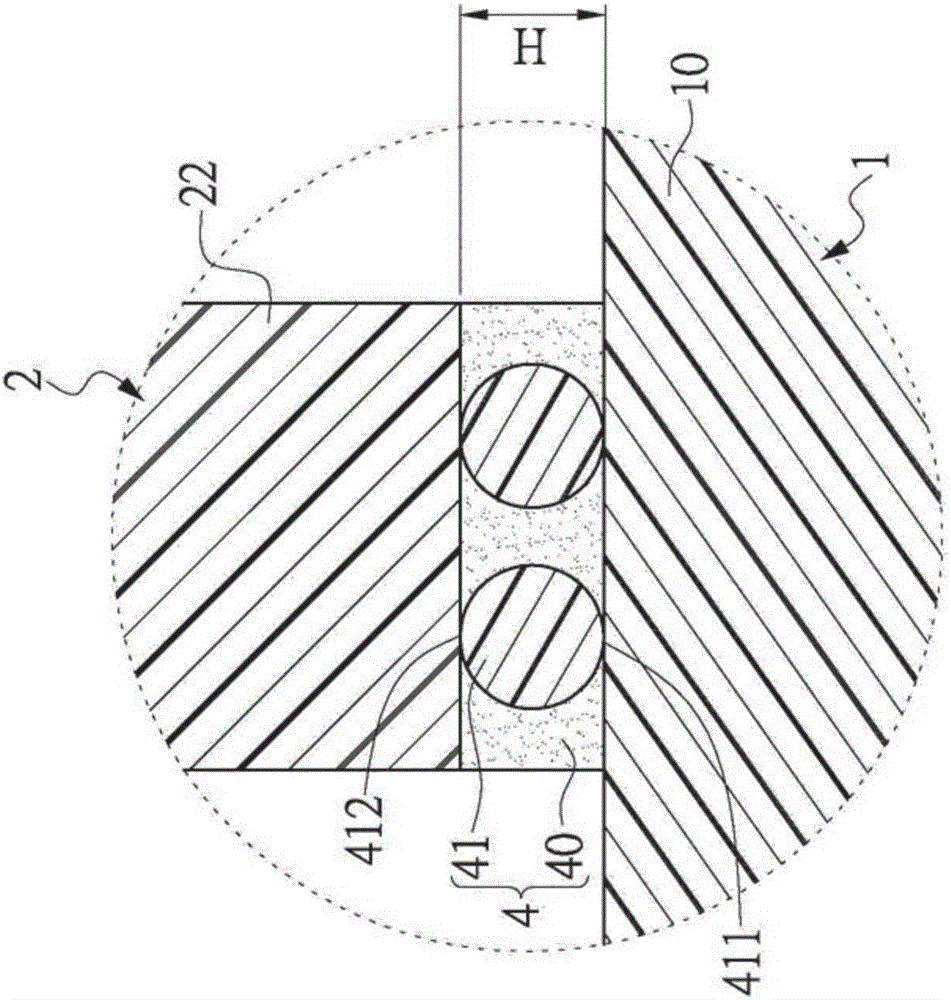

Optical Fiber Ceramic Ferrule Tail

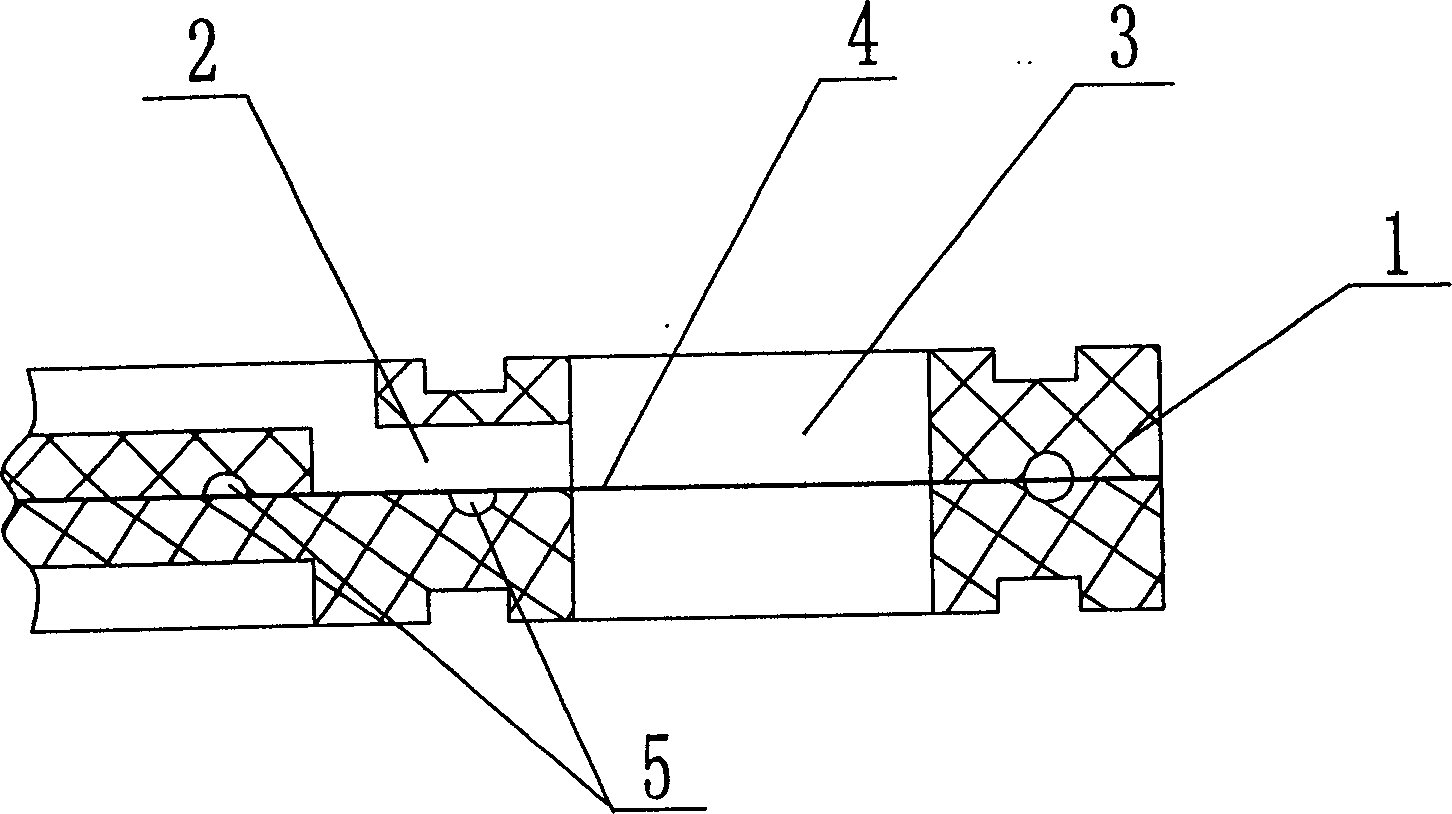

ActiveCN104317010BInhibit sheddingImprove reliability indexCoupling light guidesInterference fitFiber

The invention relates to the field of fiber processing, and provides a fiber ceramic insertion core tail handle for the purpose of effectively preventing fibers from falling off. The fiber ceramic insertion core tail handle disclosed by the invention comprises an optical cable with the fibers being stripped, and a ceramic insertion core and a tail seat which are connected in a sleeved mode. The optical cable with the fibers being striped is inserted into a space reserved by the ceramic insertion core and a shaft in the fiber ceramic insertion core tail handle and is fixed through casting glue. The optical fiber with the fibers being stripped, which is fixed in the tail seat, is an optical cable whose optical cable fiber skin is provided with a recess. According to the invention, through arranging the recess in the optical cable, the fiber ceramic insertion core tail handle is provided with a convex ridge as a bayonet, the tail seat is crimped with and is in interference fit with the ceramic insertion core, based on this, through glue perfusion and high-temperature solidification, at the time when a glue amount is increased, the solidified glue can form an enclosed fixation sleeve among the optical cable, the tail seat and the ceramic insertion core, and the press mark of the optical cable is reversely hooked on the solidified 353ND glue in a step form, such that when reliability tests such as high temperature and high moisture, TC, tension tests and the like are carried out, the problem that the optical cable falls off is radically prevented, and the reliability index of the optical cable is improved.

Owner:HONGYA CHUANGJIE COMM

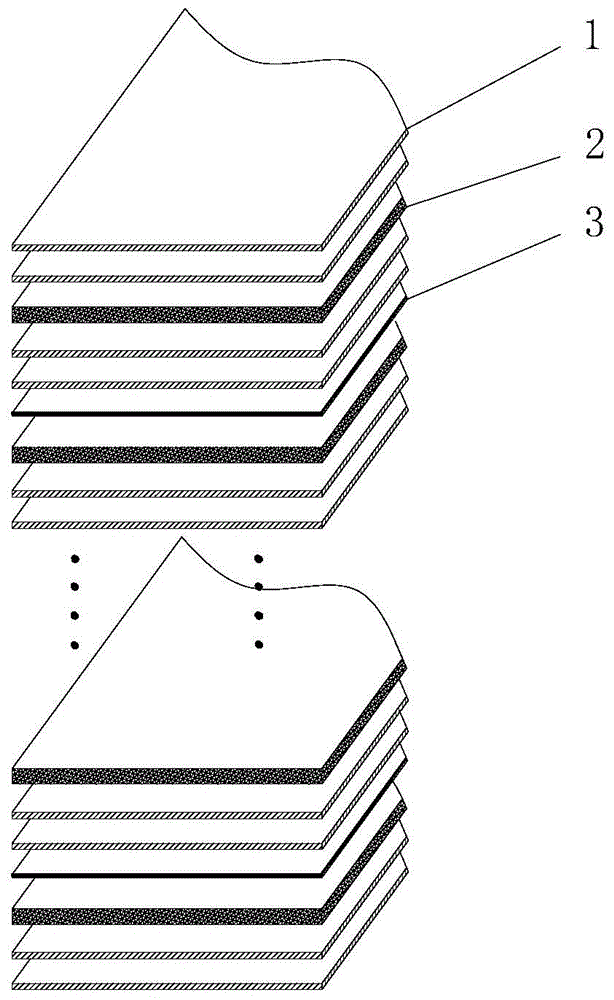

Surface decorated wood-based panel with paper impregnated thermosetting resin and preparation method thereof

ActiveCN111531658ASolve the problem of paper damageSmall particle sizeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention discloses a surface decorated wood-based panel with paper impregnated thermosetting resin and preparation method thereof. The method comprises the following steps that paper is completely impregnated in an formaldehyde-free impregnating adhesive for 20-40 seconds and dried at 75-105 DEG C until no excessive glue solution exists on the paper surface; after drying, the paper is completely impregnated in the adhesive for 10-30 seconds and completely dried at 85-105 DEG C; a formaldehyde-free wood-based panel is selected, and the paper impregnated thermosetting resin is subjected tohot pressing on the wood-based panel for 1-3 minutes at the pressure of 4-6 Mpa and the temperature of 150-210 DEG C to obtain the product; and the formaldehyde-free impregnating adhesive comprises 30-50 parts of waterborne polyurethane emulsion, 1-5 parts of nano cellulose, 5-10 parts of a filler and 200-300 parts of water. According to the wood-based panel prepared through the method, no free formaldehyde releases, and the no-formaldehyde effect is truly realized.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

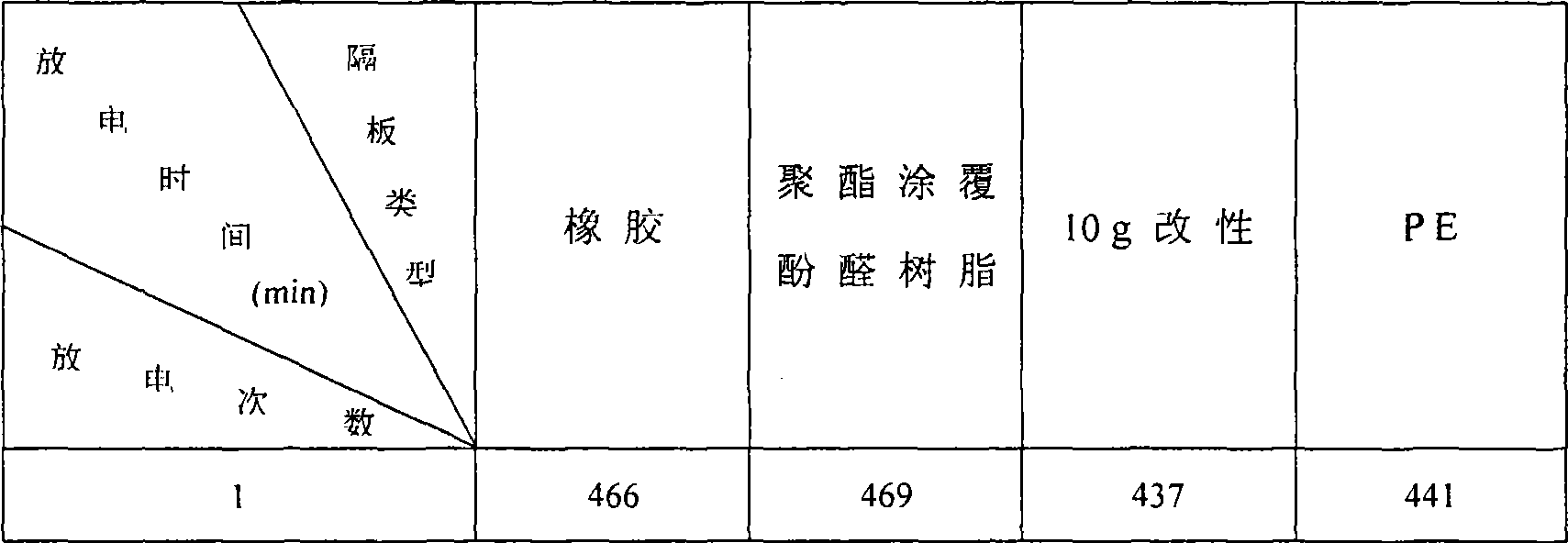

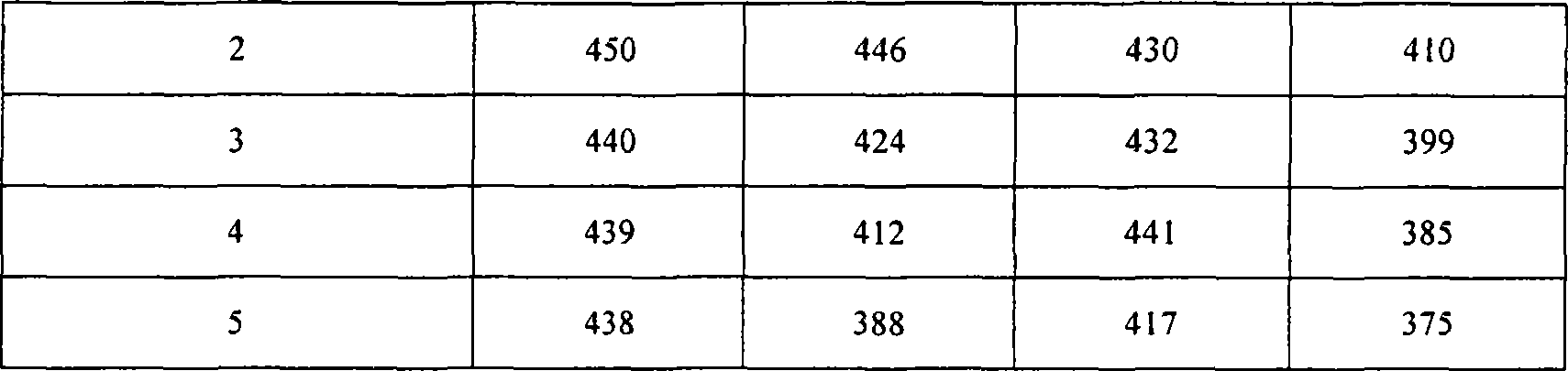

Production method for colloid accumulator

InactiveCN101459259ALow priceIncreased glue storageFinal product manufactureCell component detailsThermal runawayEngineering

The invention discloses a method of manufacturing a novel colloidal storage battery, which adopts a mircrporous hard rubber separator to substitute an absorptive glass mat separator (AGM), thereby overcoming the difficulty of filling colloid in the AGM-colloidal storage battery, and eliminating liquid leakage resulted from colloid-liquid separation caused by colloid leakage of AGM. The colloid storage amount of the obtained rubber separator colloidal battery is increased, colloid deposition is sufficient and uniform without acid and liquid separation, the battery does not leak liquid, and the battery has long circle life without thermal runaway.

Owner:江苏优德电源科技有限公司

Process of producing plate with small size timber

InactiveCN101088725AIncrease the amount of glueHigh strengthWood veneer joiningAdhesive application devicesEngineeringHot pressing

The process of producing plate with small size timber includes turning and shearing timber section, shaping sheet, gluing sheets, assembling sheets, forming large board, trimming, gluing, hot pressing, cutting edge and other steps. The present invention can produce plate with smooth flat surface and high strength.

Owner:贺微粒

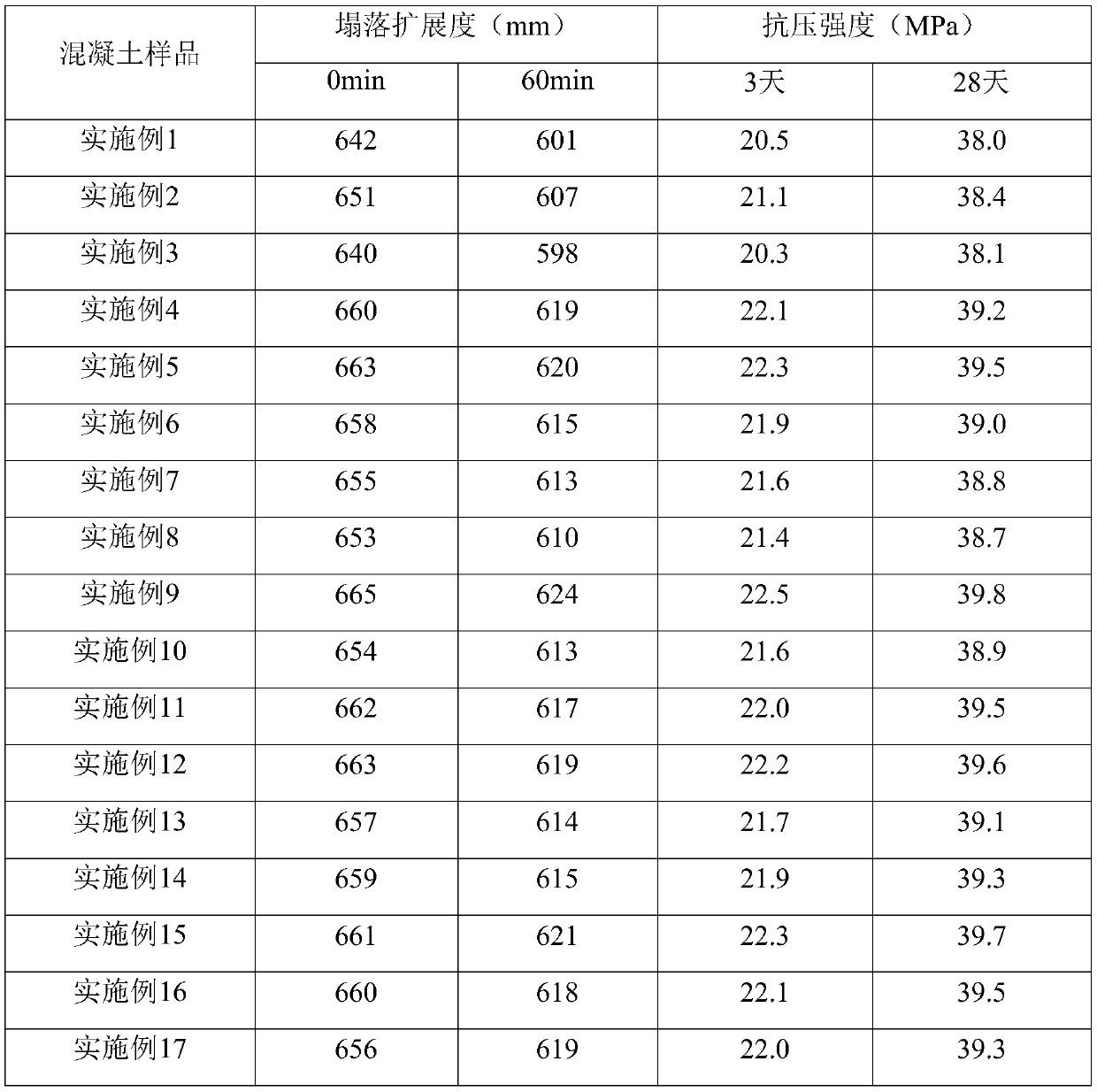

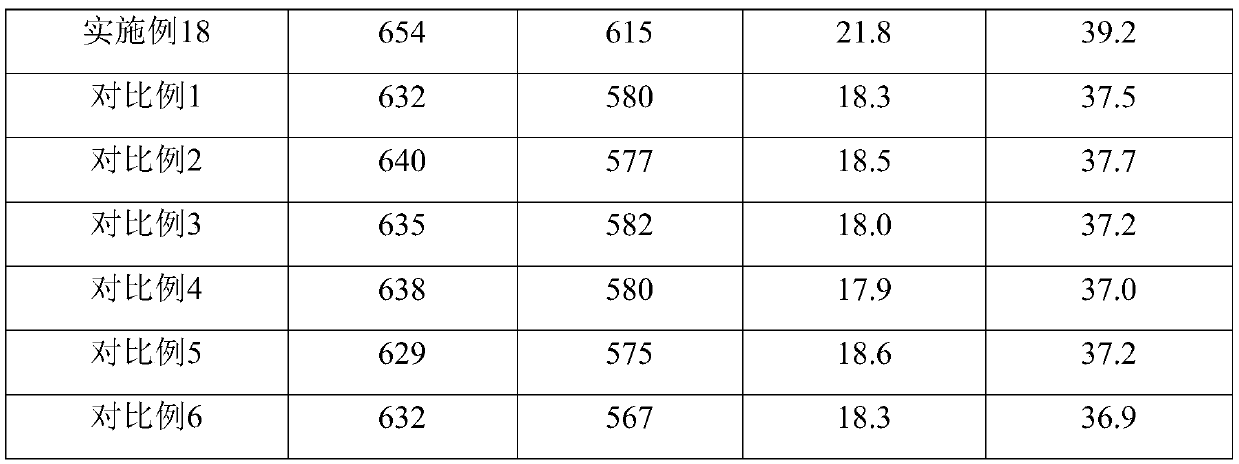

C35 self-compacting concrete adopting machine-made sand and preparation method thereof

The invention discloses C35 self-compacting concrete adopting machine-made sand and a preparation method thereof. The concrete is obtained by mixing the following raw materials: 250-320 parts of cement, 40-80 parts of fly ash, 80 to 120 parts of mineral powder; 580 to 680 parts of machine-made sand with the fineness of 3.1 to 3.5; 160 to 250 parts of natural fine sand with the fineness of 0.5 to 0.8, 150 to 350 parts of 5 to 16mm continuously graded natural broken stone, 500 to 750 parts of 5 to 20mm continuously graded natural broken stone, 180 to 210 parts of water, and 10.0 to 12.0 parts ofa polycarboxylate water reducer. The machine-made sand can also be subjected to a modification treatment: adding a filler composition containing diatomite and talcum powder according to a weight ratio of 1: (0.02-0.1) into a polyvinyl alcohol water solution according to 100-150g / L to obtain a modifying solution A; adding a fiber composition containing basalt fibers and brucite fibers according toa weight ratio of 1: (0.01-0.08) into the polyvinyl alcohol water solution according to 50-100g / L to obtain a modifying solution B; soaking and stirring the machine-made sand in the modifying liquidA for 1-2 hours, soaking and stirring the machine-made sand in the modifying liquid B for 1-2 hours, and drying. The concrete still has good fluidity and strength on the premise that a large amount ofmachine-made sand is adopted.

Owner:湖州三中混凝土有限公司

Paper, labels made therefrom and methods of making paper and labels

ActiveUS9058753B2Clean enoughIncrease the amount of glueStampsPaper/cardboard articlesAdhesivePulp and paper industry

Paper is disclosed for use in making repositionable or removable adhesive labels. The adhesive can be applied in patches or discrete areas to the paper or to a layer of material that cleans rollers in the manufacturing line and / or in printers. The adhesive can be applied in single or multiple layers. The paper is light weight paper and preferably thermal paper for use in POS printers.

Owner:DOCUMOTION RES

Impregnated adhesive film paper facing aldehyde-free artificial board and preparation method thereof

InactiveCN111496948AImprove permeabilitySmall particle sizeSpecial paperNon-macromolecular organic additionPolymer scienceEmulsion

The invention discloses an impregnated adhesive film paper facing aldehyde-free artificial board and a preparation method thereof. Paper is completely impregnated in an aldehyde-free impregnated adhesive for 30-60 s, and then dried at 80-110 DEG C, wherein the paper surface is free of redundant glue solution and does not stick to the hands; and after drying, the paper is completely impregnated into the adhesive for 20-40 s, and completely dried at 90-110 DEG C. An aldehyde-free artificial board is selected, and the impregnated adhesive film paper is pressed on the artificial board for 0.5-2 min under the pressure of 4-6 Mpa and the temperature of 140-220 DEG C. The aldehyde-free impregnated adhesive comprises: 40-60 parts of aqueous acrylic emulsion, 5-15 parts of organic amine, 1-5 partsof crosslinking agent, 1-5 parts of polyvinyl alcohol, 5-10 parts of filler, and 5-10 parts of water. The artificial board prepared by the invention does not release free formaldehyde, and really realizes no aldehyde.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

A fabric flame retardant coating coating equipment

ActiveCN104117465BIncrease tape glue volumeIncrease the amount of glueLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses coating equipment for a fabric flame retardant coating layer. A base gel coating device, a middle gel coating device and a surface gel coating device are sequentially arranged in the conveying direction of fabric, drying devices are arranged between the base gel coating device and the middle gel coating device and between the middle gel coating device and the surface gel coating device, the base gel coating device, the middle gel coating device and the surface gel coating device are respectively composed of coating layer coating units composed of gel feeding grooves and scrapers, and the base gel coating device and the surface gel coating device are respectively provided with one set of coating layer coating units. The middle gel coating device is provided with two sets of coating layer coating units in sequence in the conveying direction. The two sets of coating layer coating units are arranged on the middle gel coating device, the coating layer coating units of the middle gel coating device are respectively more than the coating layer coating units of the base gel coating device and the coating layer coating units of the surface gel coating device by one set, and therefore the total amount of middle gel is divided into two parts for coating. The aim of increasing the total amount of the base gel, the total amount of the middle gel and the total amount of surface gel in the flame retardant coating is achieved, and the upper limit problem of the flame retardant waterproof performance is effectively solved.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

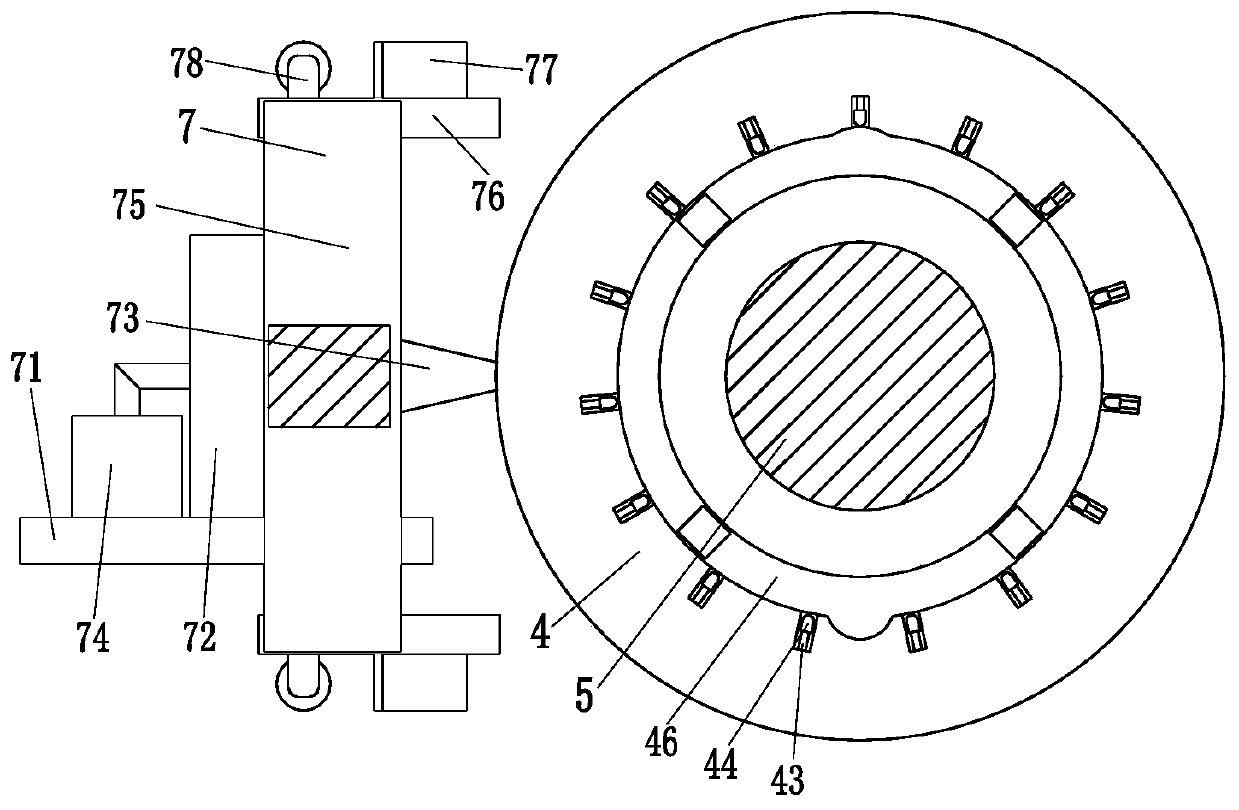

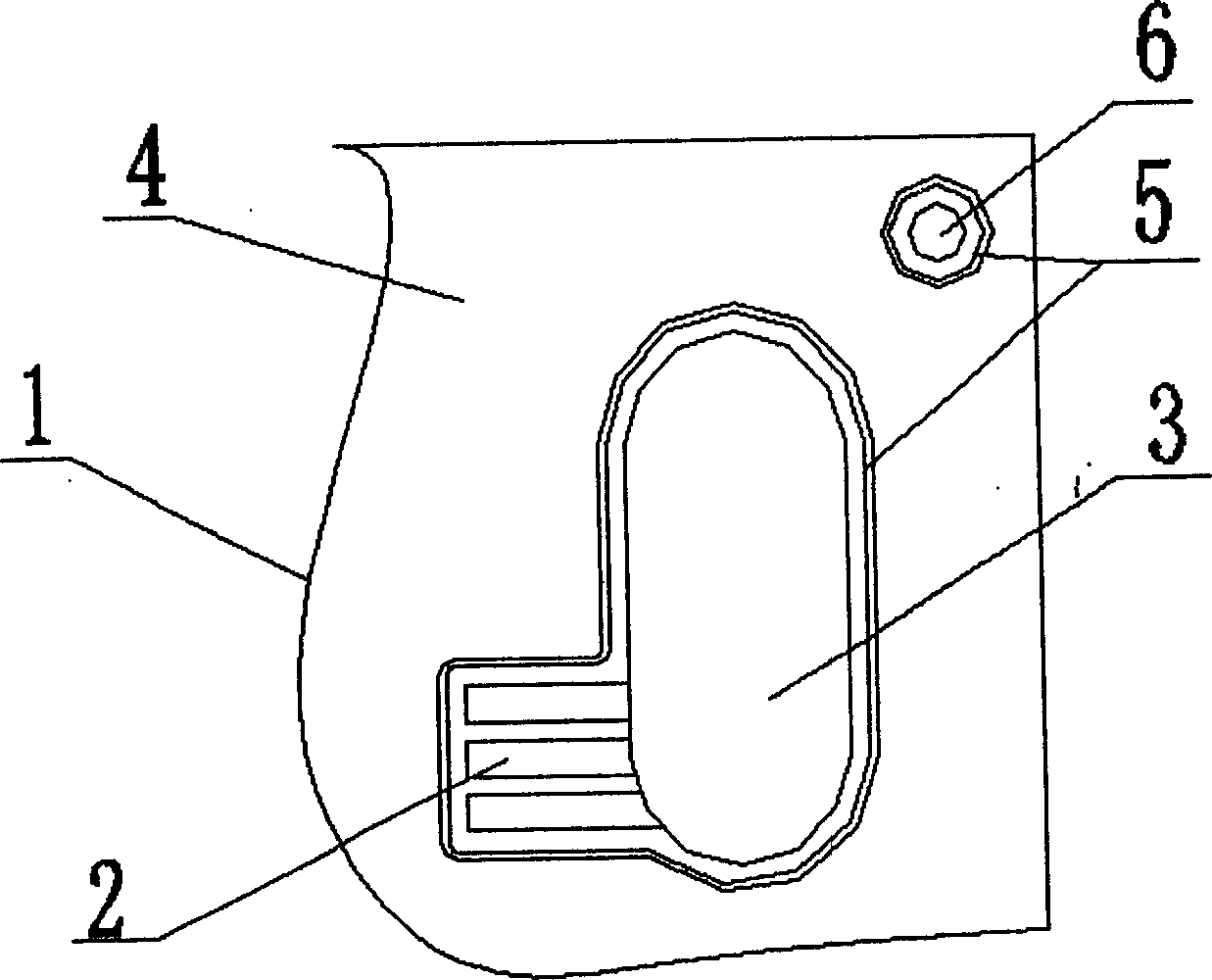

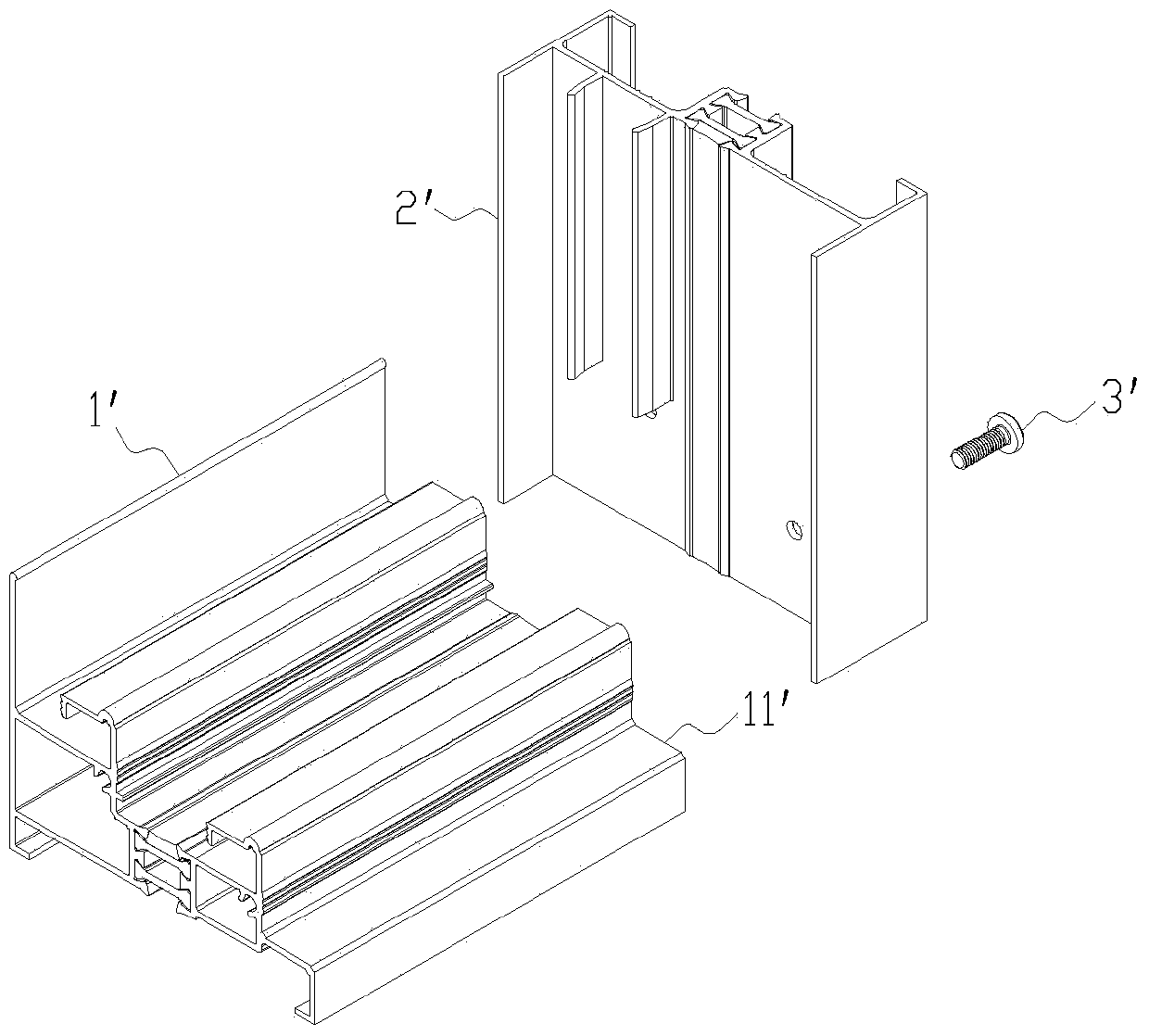

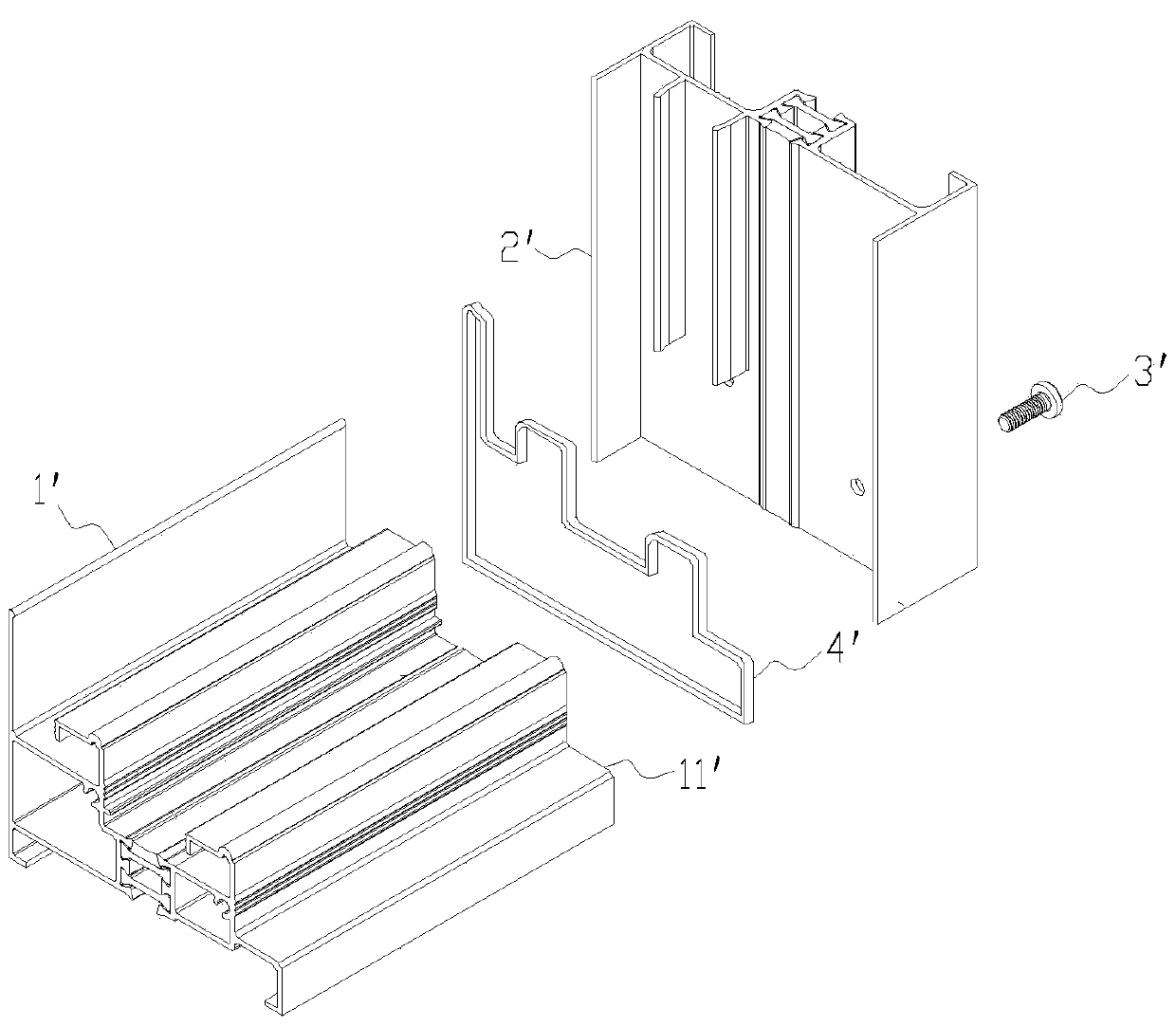

Connecting piece with cavity sectional material

ActiveCN103437666AIncrease profitOvercome water seepage gapsDoors/windowsUltimate tensile strengthMachining

The invention discloses a connecting piece with a cavity sectional material, and solves the defects that the connection of a connecting structure between the existing horizontal sectional material and the vertical sectional material is not firm and the water-proof property is poor. According to the technical scheme, the connecting piece provided by the invention is of a block shape, the outer shape of the connecting piece is matched with a cavity of the sectional material, so that the connecting piece is conveniently placed in the cavity, and the connecting piece comprises at least one inserting surface and a bonding surface which is perpendicular to the inserting surface. The connecting piece provided by the invention has the advantages that the block-shaped connecting piece arranged in the cavity of the horizontal sectional material is used for changing the line connection of a gluing position arranged among the sectional materials into surface connection, the connecting strength is effectively improved, a glue is subjected to extrusion so as to flow from inside to outside so as to rapidly and effectively fill a gap caused by the lower machining precision or sectional material specific structure requirement, the gap after solidifying is blocked, and the waterproof property is good.

Owner:ZHEJIANG BOAO ALUMINUM

Manufacture method of fiber ceramic insertion core tail handle capable of preventing fibers from falling off

ActiveCN104317011AIncrease the amount of gluePrevent falling offCoupling light guidesFiberMaterials science

Owner:OPCONN COMM TECH

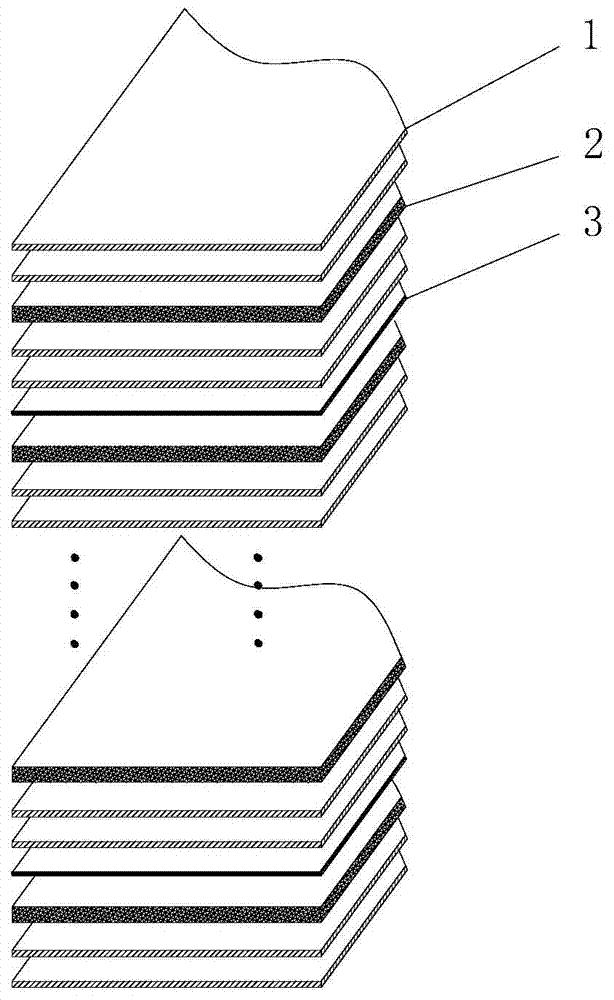

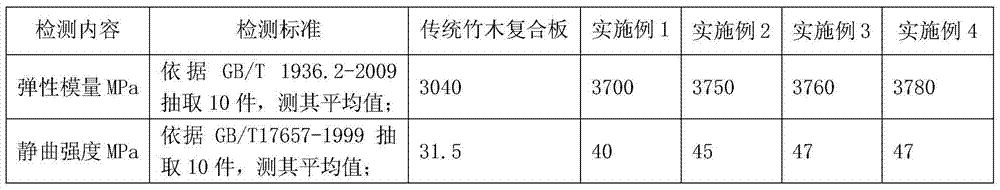

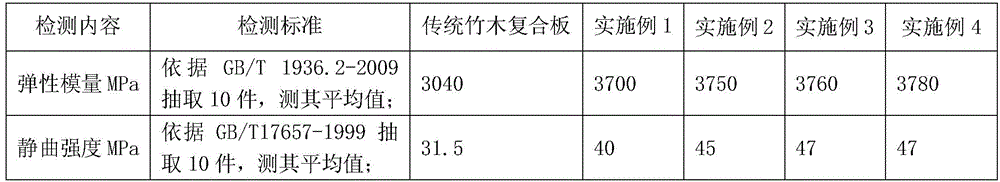

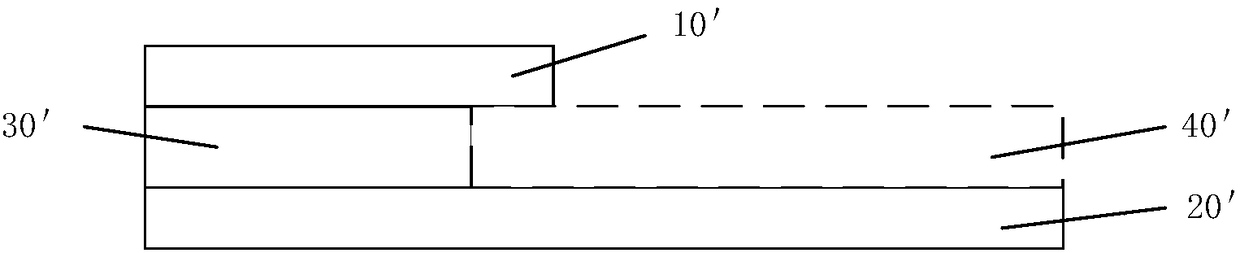

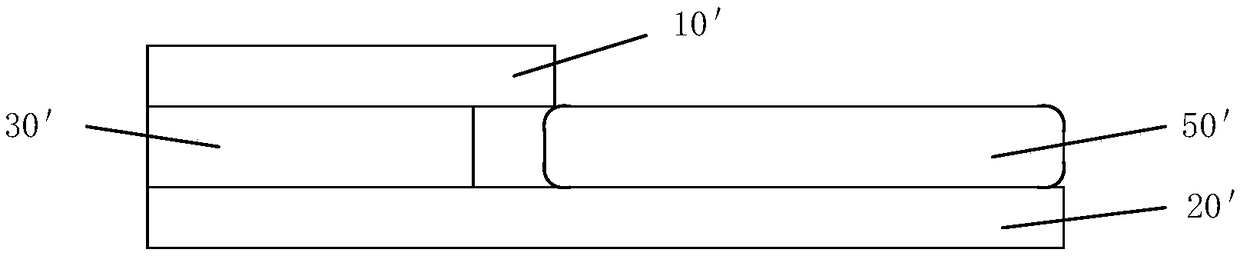

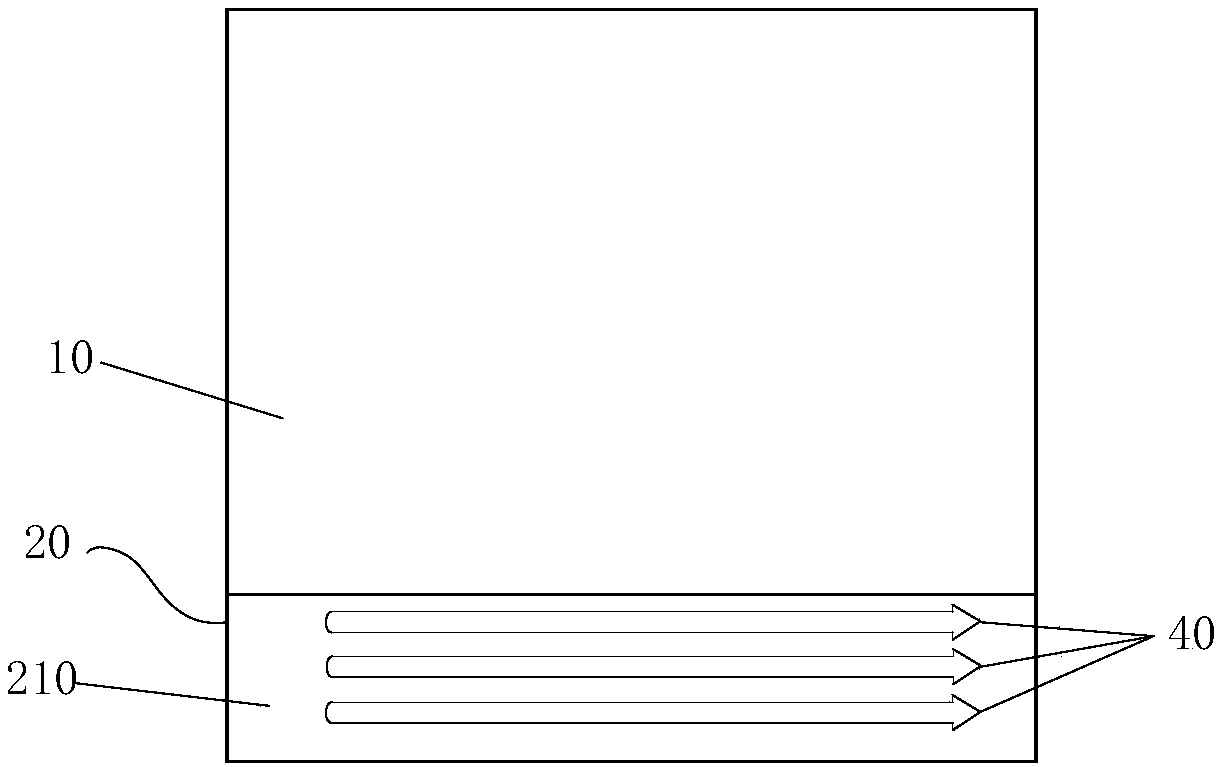

Bamboo and wood composite board and method for manufacturing same

ActiveCN104493916AImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

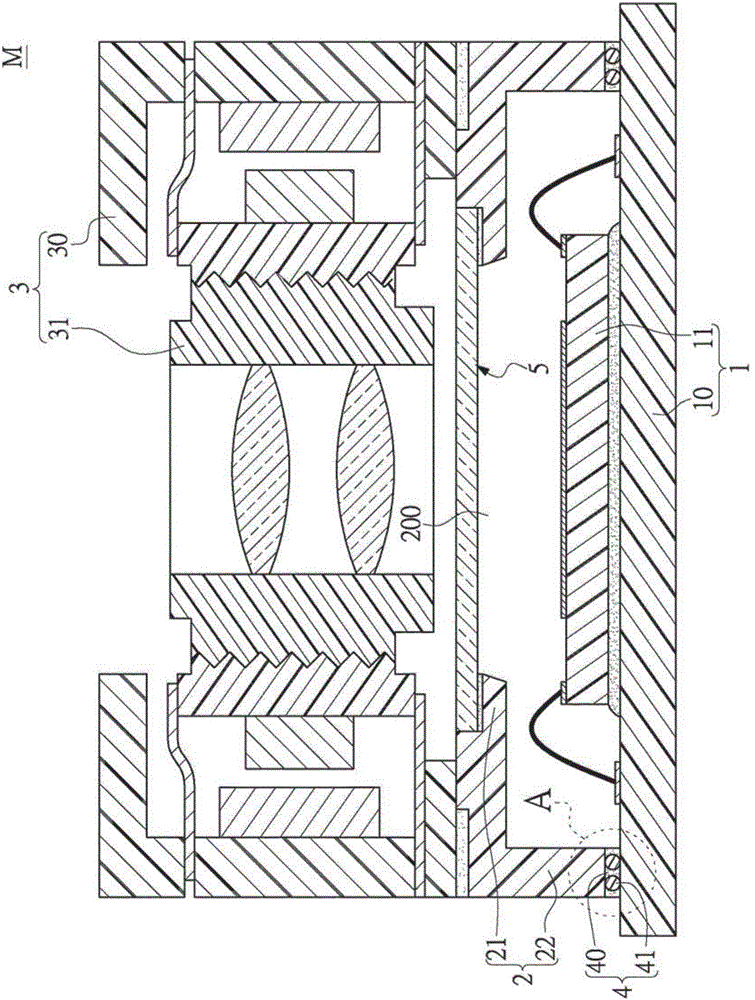

Image acquisition module

InactiveCN105025204AHigh bonding strengthReduce assembly inclinationTelevision system detailsColor television detailsEngineeringColloid

Provided is an image acquisition module, comprising an image sensing unit, a framework housing and an actuator structure. The image sensing unit comprises a bearing substrate, and an image sensing chip arranged on and electrically connected to the bearing substrate. The framework housing is arranged on the bearing substrate through a surrounding adhesive structure, and encircles the image sensing chip, wherein the surrounding adhesive structure comprises a surrounding adhesive colloid of uniform thickness, and a plurality of spheroidal particles of same dimension; the surrounding adhesive colloid is arranged between the bearing substrate and the framework housing, and each spheroidal particle is arranged between the bearing substrate and the framework housing, and is covered by the surrounding adhesive colloid. The actuator structure comprises a lens holder arranged on the framework housing, and a movable lens module capable of being movably arranged in the lens holder.

Owner:LITE ON TECH CORP

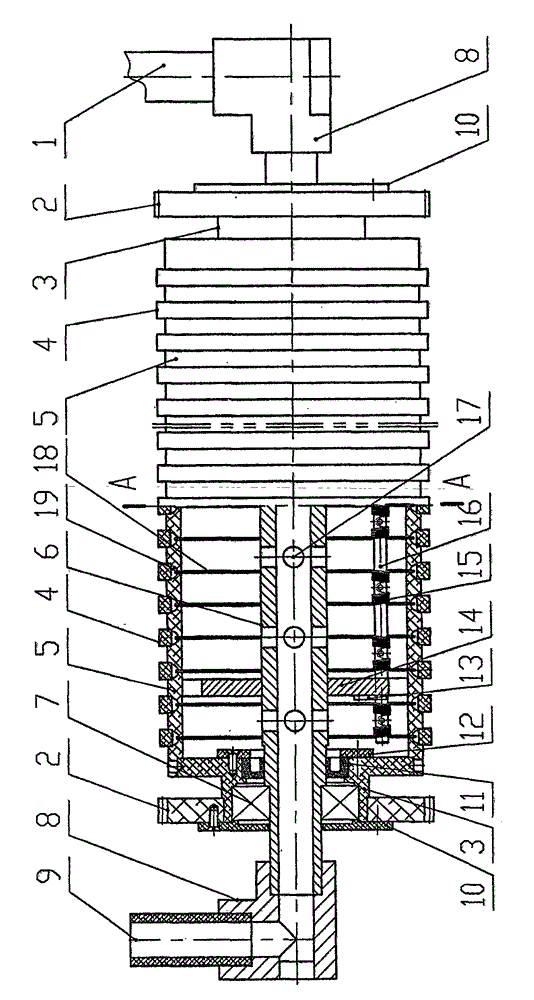

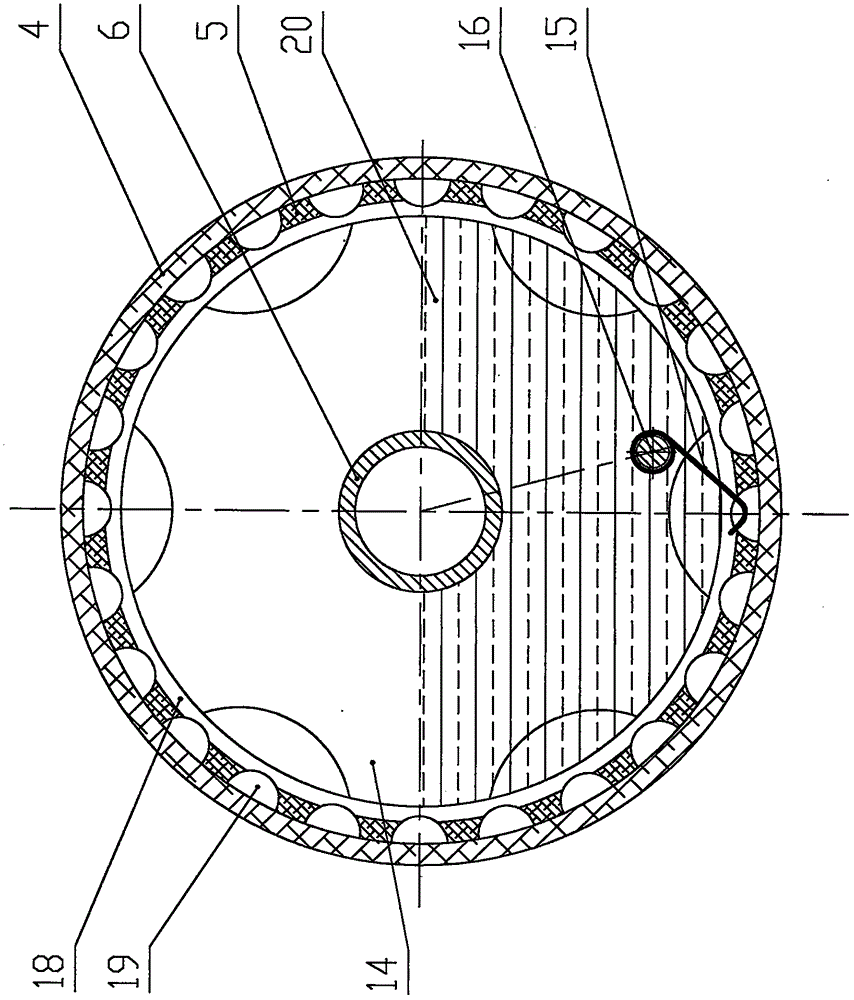

Strip-shaped glue coating device for paper seed tape

InactiveCN105075455AIncrease the amount of glueQuality improvementSeed arrangmentsVentilation tubeGear wheel

The invention discloses a strip-shaped glue coating device for paper seed tape and belongs to agricultural machinery. According to the device, two-way tube bases provided with a ventilation tube and a glue solution injection tube respectively are installed at the left end and the right end of a hollow shaft respectively, rollers provided with spherical holes and annular grooves are installed on the hollow shaft in a rotary mode through bearings and end covers on the left side and the right side of the hollow shaft, and the roller is sleeved with an annular sponge belt in a matched mode; driving gears are fixedly installed on the end covers on the left side and the right side of the hollow shaft respectively, a shaft base plate is fixedly installed on the hollow shaft, and an elastic claw shaft provided with elastic claws is fixedly installed on the shaft base plate through a fixed installation plate. By the adoption of the strip-shaped glue coating structure for the paper seed tape, glue coating amount is increased, and glue coating quality and effect are greatly improved. The device has the advantages of being simple and novel in structure, low in manufacturing cost, high in working quality, high in working efficiency, and reliable in use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

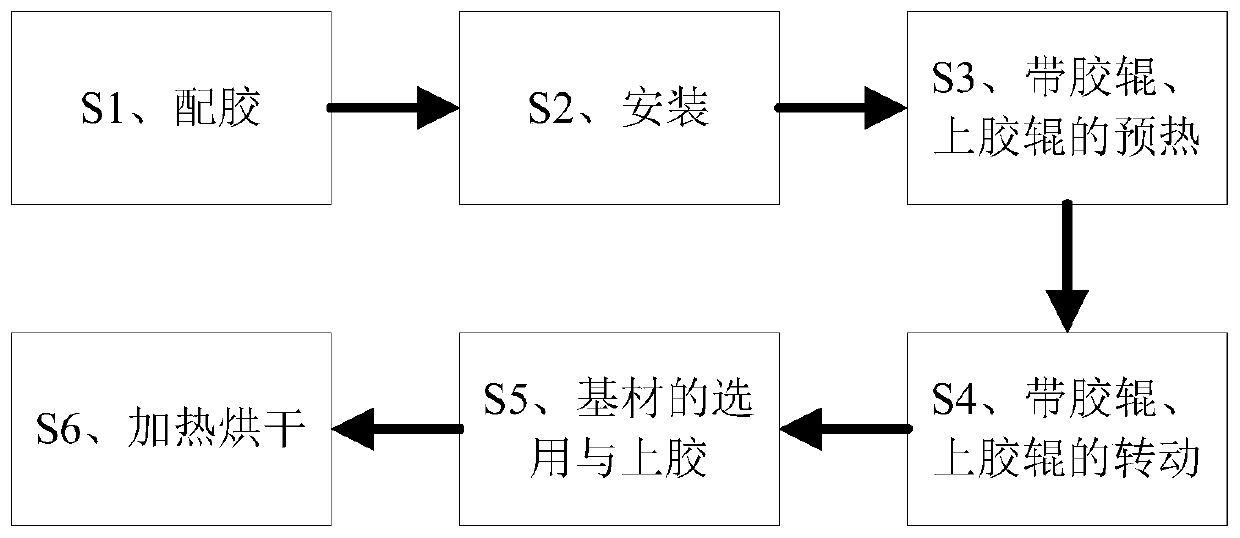

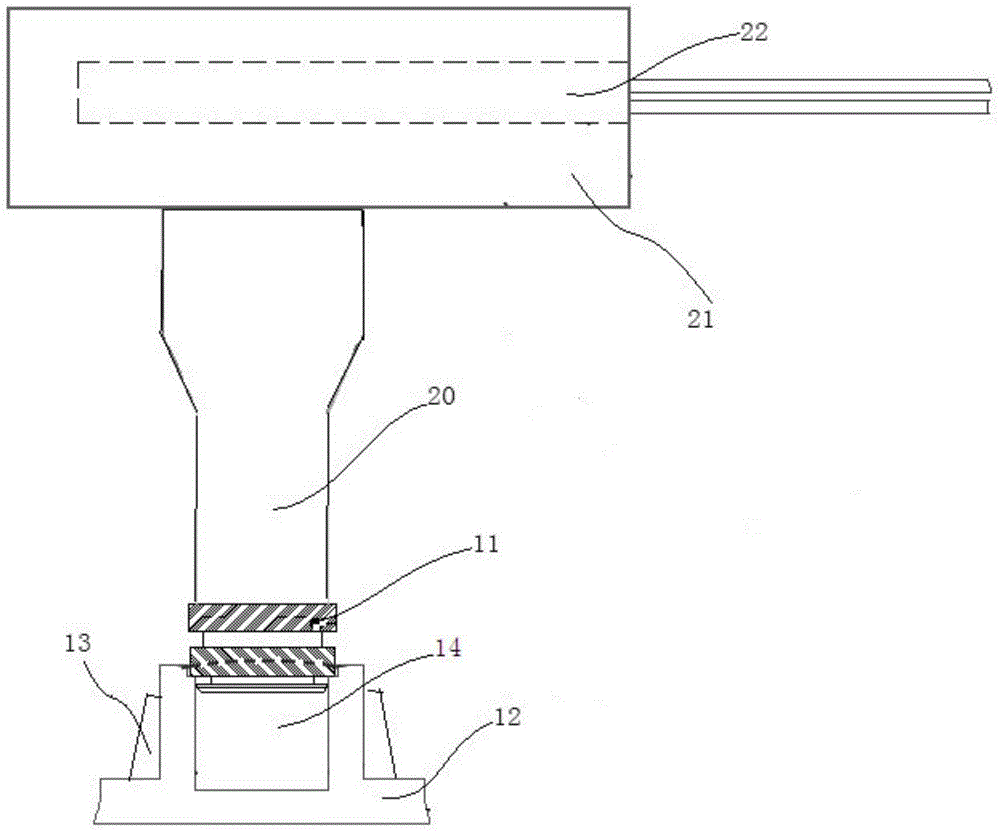

Gluing process for manufacturing copper-clad plate

ActiveCN110205872AAvoid Cured SituationsAvoid failure to adhere to gluePaper/cardboardPulp material addition processesFixed frameEngineering

The invention provides a gluing process for manufacturing a copper-clad plate. According to the gluing process, the work can be completed through the cooperation of a fixing frame, a rubber roller, agluing roller and a dispersing device. The gluing process can solve the problems that during gluing, the gluing amount of a base material is smaller, therefore a rotary transmission roller only needsto drive a small amount of glue liquid to the surface of the transmission roller, but resin glue liquid is in a fluid shape, so that the glue liquid is difficultly attached to the surface of the transmission roller, which may cause the situation that the distribution of the glue liquid is not uniform due to the fact that the resin glue liquid is not attached to the surface of the partial transmission roller, so that the partial base material is not subjected to gluing treatment, the resin glue liquid is in a fluid shape after being heated, since the temperature of the surface of the transmission roller is lower, the phenomenon may occur that the partial resin glue liquid is cured when the surface of the transmission roller is in contact with the resin glue liquid, thereby affecting the gluing efficiency of the base material.

Owner:安能电子有限公司

Polyamide fibre and aramid fibre gum dipping liquid and production process thereof

The invention discloses polyamide fibre and aramid fibre gum dipping liquid and a production process thereof. The formula of the gum dipping liquid comprises the following components: 142-146 parts of phenol, 42-46 parts of anacardol, 220-226 parts of formaldehyde solution, 23-26.5 parts of sodium hydroxide solution, 2.5-3.5 parts of hydrogen peroxide, 310-315 parts of resorcinol, and 245-250 parts of water. The process comprises the following steps of: adding and mixing phenol, anacardol and formaldehyde; adding sodium hydroxide at the temperature of 28-32 DEG C; heating when the vacuum degree value is 500mmHg, so as to enable the temperature to be 35 DEG C; stopping heating; performing self heat production for a period, so as to enable the temperature to rise to 75 DEG C, and keeping constant temperature of 75 DEG C; cooling to 40 DEG C; adding the water, hydrogen peroxide and resorcinol in sequence, rising the temperature to 95 DEGC and keeping the constant temperature of 95 DEG C, and measuring the viscosity; rapidly cooling after the viscosity is up to be at a certain degree, adding a small amount of the sodium hydroxide after the temperature is cooled to be at 40 DEG C so as to enable the water consistency and the pH value to be standard; and canning. According to the polyamide fibre and aramid fibre gum dipping liquid and the production process thereof, the anacardol is used for replacing part of the phenol, so that the harm on a body is reduced; and the gum attaching amount of an obtained product is increased, and the gum liquid intensity and the gum liquid viscosity are enhanced.

Owner:TAIZHOU HONGYUAN HANDICRAFT

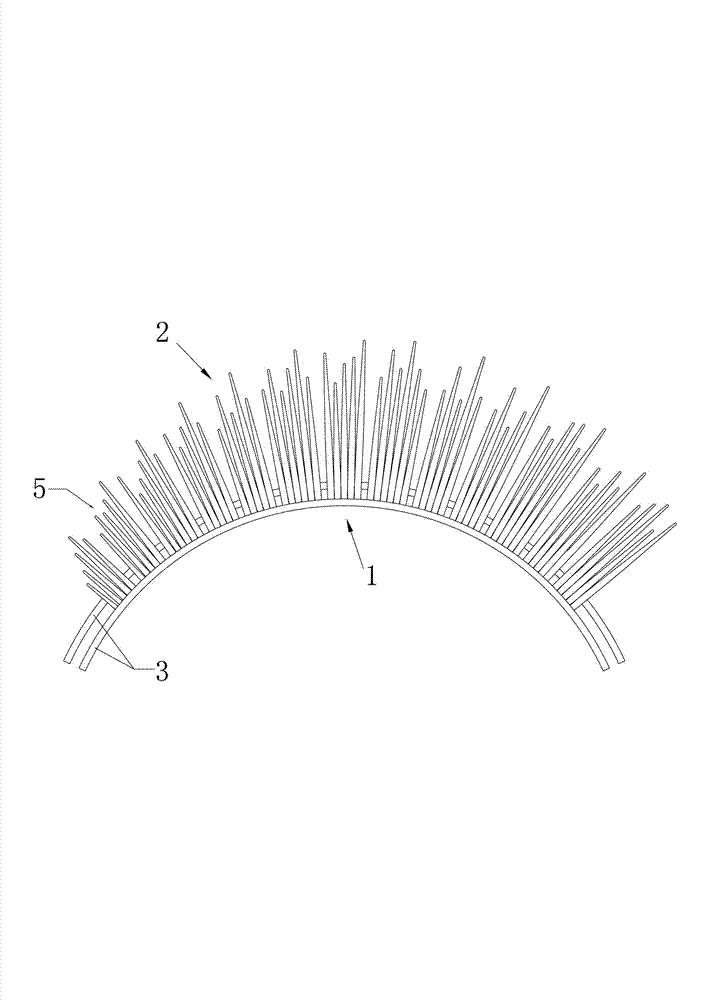

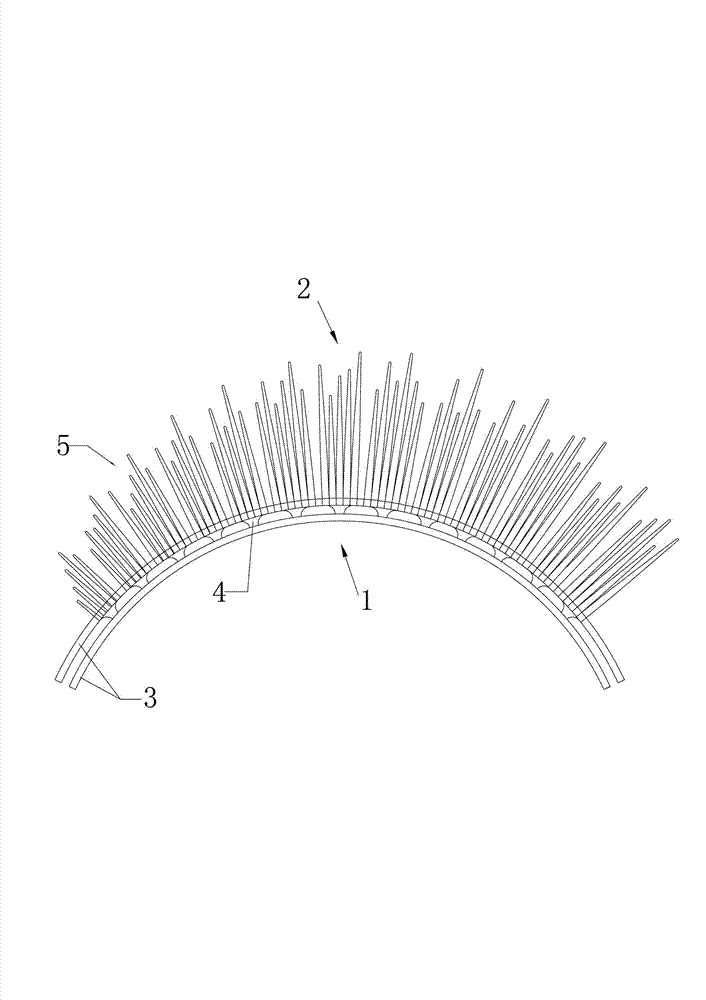

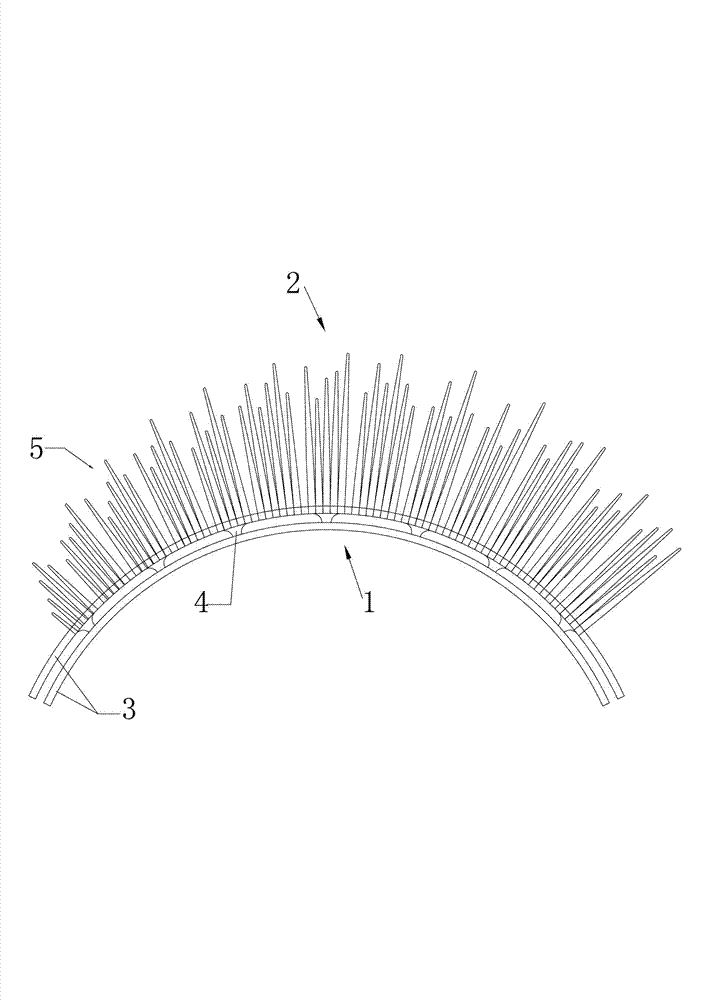

Multi-channel rubber feeding type artificial eyelashes with high flexibility

The invention provides multi-channel rubber feeding type artificial eyelashes with high flexibility. The artificial eyelashes comprise a sticking part for being stuck to the eyelid of a human body and an eyelash part extending outward from the outer side surface of the sticking part, wherein the sticking part is arc-shaped and is matched with the eyelid of the human body in appearance, the sticking part mainly comprises two or more channels of eyelash feeding roots longitudinally arranged side by side, every two eyelash feeding roots are connected by a plurality of elastic branches, and the plurality of elastic branches are spaced and are arranged in parallel along the bending direction of the sticking part; and the eyelash part is integrally molded on one of the eyelash feeding roots, the eyelash part mainly comprises a plurality of eyelash groups which are spaced and are arranged in parallel along the bending direction of the sticking part, and each eyelash group consists of multiple pieces of eyelashes which are arranged in parallel along the bending direction of the sticking part. The quantity of fed rubber can be increased during injection molding, the effective molding of the eyelash part is ensured, and the rate of finished products is increased. Meanwhile, the flexibility of artificial eyelashes is greatly improved due to the sticking part with the structure.

Owner:金文日

Method for fixing copper sleeve on notebook computer panel

InactiveCN104308501AImprove pull strengthImprove the problem of radial expansion deformationMetal working apparatusMaximum diameterEngineering

The invention provides a method for fixing a copper sleeve on a notebook computer panel. The method comprises the following steps: setting the diameter of a fixing hole which is correspondently and thermally sleeved by the copper sleeve to be 0.4cm smaller than the maximum diameter of the copper sleeve; arranging at least one pair of reinforcing ribs on the periphery of the fixing hole; thermally pressing the copper sleeve into the fixing hole to be fixed by adopting a high-temperature pressurizing manner. By adopting the method for fixing the copper sleeve on the notebook computer panel, adhesive amount entering a clearance can be increased by adjusting the inner diameter of the fixing hole, so that the binding force between the fixing hole and the copper sleeve can be increased.

Owner:SHANGHAI DIANJI UNIV

A kind of bamboo-wood composite board and preparation method thereof

ActiveCN104493916BImprove mechanical propertiesEasy to processWood veneer joiningWood veneerSurface layer

The invention relates to the technical field of composite boards, and discloses a bamboo and wood composite board and a method for manufacturing the same. The bamboo and wood composite board comprises bamboo layers, wood veneer layers, more than two non-woven fabric layers and adhesive. The corresponding wood veneer layer is arranged between each two bamboo layers, the total quantity of the bamboo layers and the wood veneer layers ranges from 14 to 35, the non-woven fabric layers are arranged between the bamboo layers and the wood veneer layers, the various layers are adhered with one another by the adhesive and are integrally laminated, a surface layer and a bottom layer of the bamboo and wood composite board are bamboo layers respectively, sealing wax layers with waterproof effects are arranged on the surfaces of the bamboo and wood composite board, the bamboo layers are bamboo chip layers or bamboo curtain layers, the thickness of each bamboo layer ranges from 0.5mm to 1.5mm, the thickness of each wood veneer layer ranges from 1.5mm to 2.0mm, the adhesive is made of phenolic resin adhesive with the solid content of 50%, impregnating compounds and more than one type of waterproof agents, mothproofing agents or inorganic flame retardants are added into the phenolic resin adhesive, and the adhesive is applied to double surfaces of each of the bamboo layers, the wood veneer layers and the non-woven fabric layers. The method for manufacturing the bamboo and wood composite board includes steps of manufacturing the adhesive; treating materials of the bamboo layers; treating wood veneers; arraying and assembling blanks; laminating and forming the blanks; treating the surfaces of the blanks and warehousing the finished product.

Owner:DEYI CULTURAL & CREATIVE GRP CO LTD

Sealing method of display screen frame

The invention provides a sealing method of a display screen frame. The sealing method of the display screen frame comprises the following step: coating a to-be-coated region in the direction of a first edge which is parallel to an upper substrate by using glue so that a plurality of gluing regions are formed on a lower substrate by various coating processes in a one-to-one correspondence manner, wherein the various gluing regions are successively formed along the direction which is away from the first edge. Therefore, the inner side of the first edge which is close to the to-be-coated region is coated with glue, then step-by-step outward coating is carried out, multiple gluing regions can be formed on the to-be-coated region, penetration time of the gluing region on the inner side is prolonged relatively, a seam can be filled with glue which is close to the gluing region of the first edge as much as possible, the amount of glue which permeates into the seam is increased, uniformity ofsolidified glue of the inside and the outside of the seam after the glue is solidified is improved effectively, and the sealing effect of the display screen frame is improved. In addition, the efficiency of the sealing process is improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Coating method of fabric flame-retardant coatings

ActiveCN105420965AImprove fire and water resistanceIncrease tape glue volumeLiquid surface applicatorsCoatingsAdhesiveChemistry

The invention discloses a coating method of fabric flame-retardant coatings. The upper surface and / or the lower surface of a fabric are / is coated with the fabric flame-retardant coatings. Primer coating, medium adhesive coating and surface adhesive coating are performed on the coating device of coatings in sequence. Medium adhesives are added for coating two times. During coating, according to the first-time coating, the medium adhesives with the amount being two thirds that of dried adhesives are added, and according to the second-time coating, the medium adhesives with the amount being one third that of the dried adhesives are added. Due to the fact that the medium adhesives are added for coating two times, the amount of the medium adhesives in the fabric can be effectively increased, the problem of the upper limit of the flame-retardant waterproof performance is effectively solved, and the flame-retardant performance can be improved by a level.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

High-permeability paper and preparation method thereof

ActiveCN106758535AGood permeabilityImprove breathabilitySpecial paperDryer sectionWear resistantRaw material

The invention belongs to the technical field of paper making, and particularly relates to high-permeability paper and a preparation method thereof. The high-permeability paper is prepared from the following raw materials in percentage by weight: 90 to 97 percent of wood pulp and 3 to 10 percent of auxiliary agents, wherein the wood pulp is metered by the dry weight. The high-permeability paper has the characteristics of high permeability, high ventilation performance, high uniformity, high gumming quantity and high softness; through lower steam customer gumming, wear-resistant materials are sprayed and coated onto the paper surface; after the high-temperature pressing and pasting, the high-permeability paper can be made into a reinforced wood floorboard; high glossiness and stable wear-resistant turn number are realized; the definition reaches the effect incomparable by the ordinary wear-resistant paper; the market prospects are very wide; the preparation method is scientific, reasonable and simple; the implementation is easy.

Owner:ZIBO OU MU SPECIAL PAPER

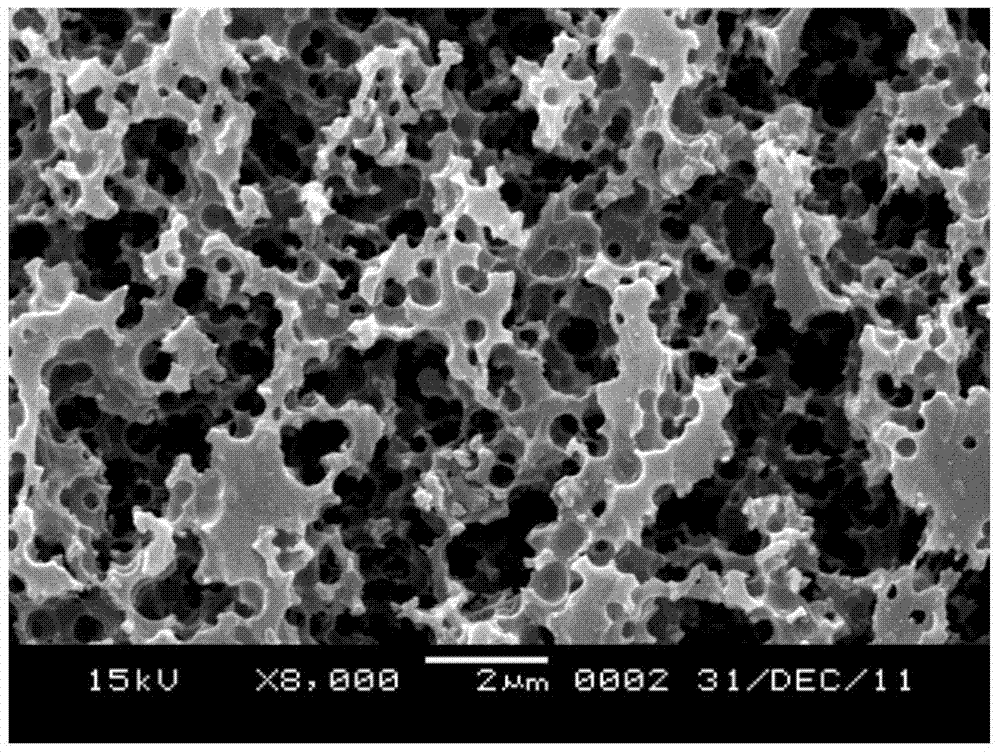

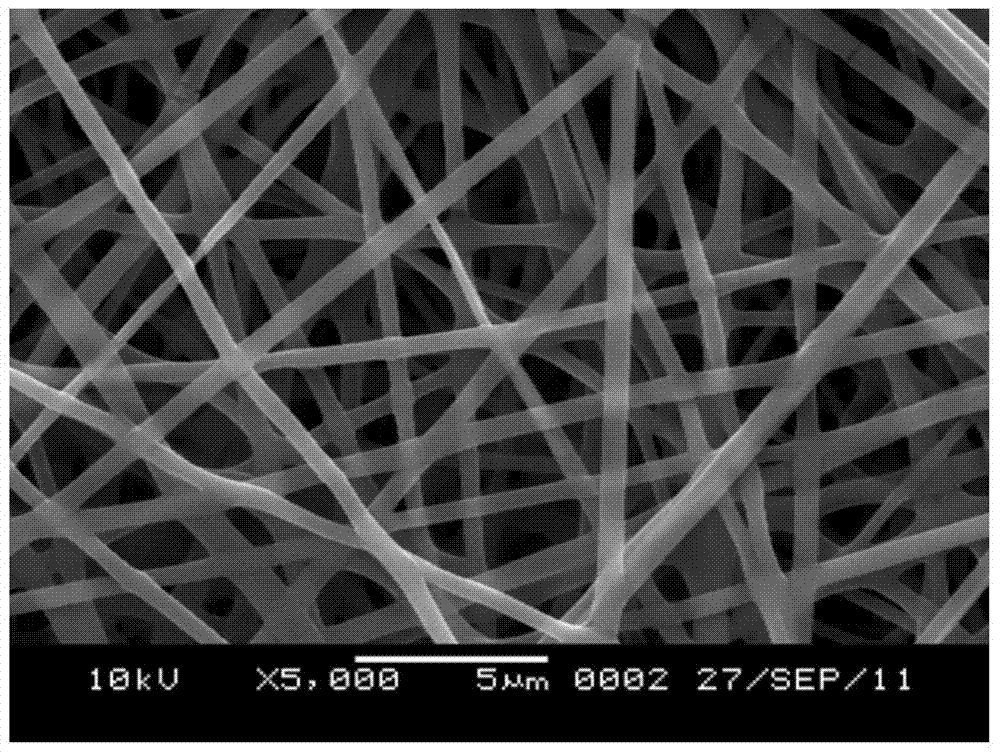

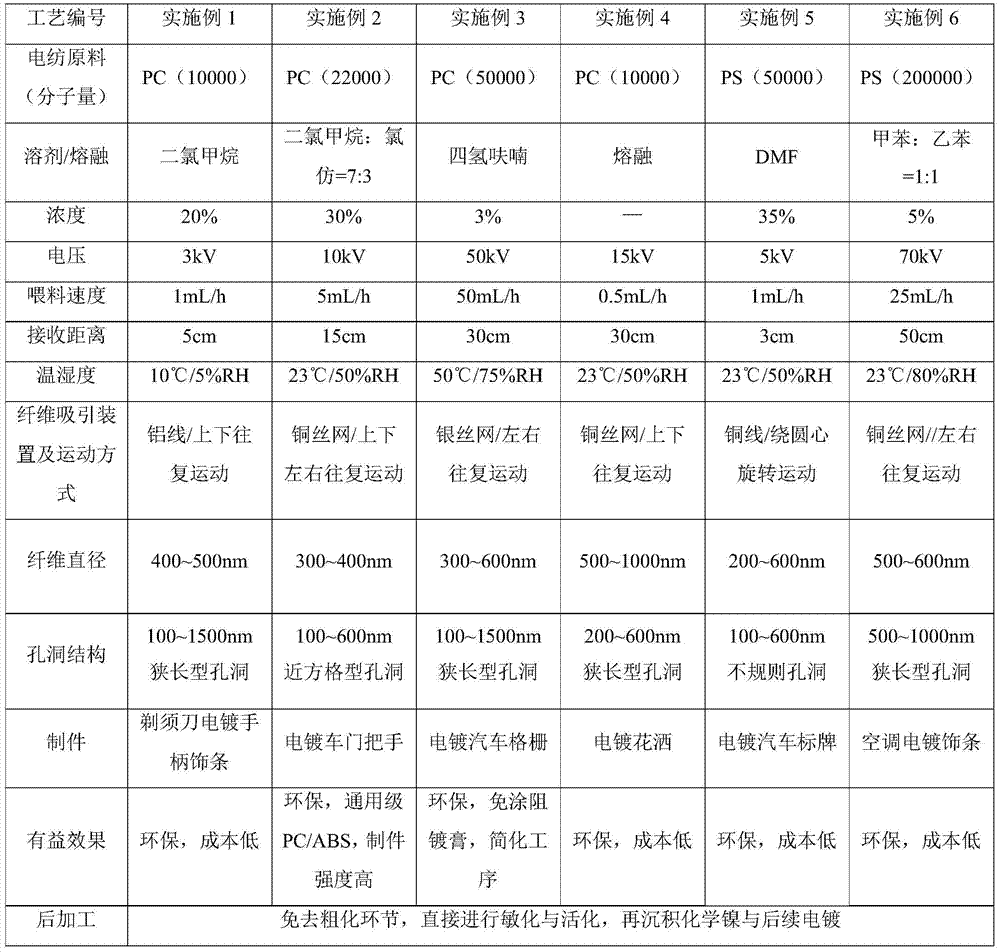

A kind of pre-plating treatment method of plastic parts for electroplating

ActiveCN105200669BReduce coarseningReduce usageFilament/thread formingNon-woven fabricsFiberPretreatment method

The invention relates to an electroplating pretreatment method for plastic parts for electroplating, and belongs to the technical field of plastic material treatment. The method comprises the steps that a plastic part for electroplating is fixed to a receiving pole of an electrostatic spinning device, and a polymer solution or melt forms nano-scale fiber through the electrostatic spinning device to be deposited on the surface of the plastic product, so that an electrospun film layer with a large number of submicron-order holes is formed on the surface of the plastic part. Compared with the prior art, the proper surface hole structure is given to the plastic part to be plated through the electrostatic spinning technology, so that the plastic part treated through the method can obtain the surface appearance where metal can be deposited without roughening, and can be put on a line for directly conducting sensitization, activation and electroplating.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com