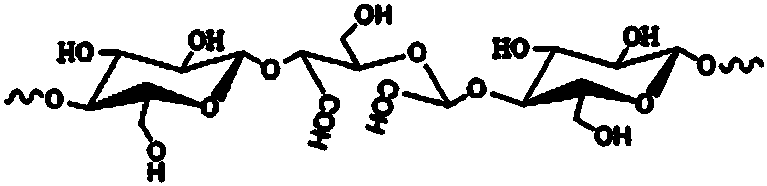

Surface decorated wood-based panel with paper impregnated thermosetting resin and preparation method thereof

A technology of impregnating film paper and wood-based panels, applied to paper, papermaking, adhesives, etc., to achieve the effect of small molecular weight, moderate viscosity, and solve the problem of paper damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Polyethylene glycol (molecular weight 200) and isophorone diisocyanate are added in the reactor with stirring and reflux device according to mol ratio 0.8, under the protection of high-purity nitrogen, carry out prepolymerization reaction, the reaction temperature The temperature is 40 °C, the reaction time is 1 h, and the polyurethane prepolymer is obtained.

[0031] 2) The prepolymer was heated to 65°C, and 1,4-butanediol was added dropwise to the prepolymer for 20 min, the chain extension reaction time was 1.5 h, and the stirring speed was 50 r / min. Then, the temperature was lowered to 40°C, and the hydrophilic agent was added, and the addition was completed within 30 minutes. The reaction time of this step was 0.5h.

[0032] 3) Cool to room temperature, add glacial acetic acid for neutralization, and use appropriate amount of acetone to reduce viscosity at the same time, add water and shear at high speed after the viscosity is appropriate, the shear rate is 2000r...

Embodiment 2

[0041] 1) Polyester diol CMA-1024 and isophorone diisocyanate are added to the reactor with stirring and reflux device according to mol ratio 2, under the protection of high-purity nitrogen, carry out prepolymerization reaction, reaction temperature The temperature is 60°C and the reaction time is 0.5h to obtain the polyurethane prepolymer.

[0042] 2) The prepolymer was heated to 80°C, and ethylene glycol was added dropwise to the prepolymer for 10 min, the chain extension reaction time was 0.5 h, and the stirring speed was 100 r / min. Then, the temperature was lowered to 60° C., and the hydrophilic agent was added, and the addition was completed within 30 min. The reaction time of this step was 1.5 h.

[0043] 3) Cool to room temperature, add glacial acetic acid for neutralization, and use appropriate amount of acetone to reduce viscosity at the same time, add water and shear at high speed after the viscosity is appropriate, the shear rate is 4000r / min, and the water-based po...

Embodiment 3

[0052] 1) Polyester glycol CMA-1024, polyethylene glycol (the two mol ratio 1: 1) and hexamethylene diisocyanate are added in the reactor with stirring and reflux device according to mol ratio 1.3, in Under the protection of high-purity nitrogen, a prepolymerization reaction was carried out, the reaction temperature was 50 °C, and the reaction time was 0.7 h to obtain a polyurethane prepolymer.

[0053] 2) The prepolymer was heated to 75°C, propylene glycol was added dropwise to the prepolymer, the dropwise addition time was 15 min, the chain extension reaction time was 0.8 h, and the stirring speed was 80 r / min. Then, the temperature was lowered to 50° C., and the hydrophilic agent was added, and the addition was completed within 30 min. The reaction time of this step was 1 h.

[0054] 3) Cool to room temperature, add glacial acetic acid for neutralization, and use appropriate amount of acetone to reduce viscosity at the same time, add water and shear at high speed after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com